Professional Documents

Culture Documents

HZSD B0502

Uploaded by

r0 ratings0% found this document useful (0 votes)

22 views2 pagesOriginal Title

HZSD-B0502

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views2 pagesHZSD B0502

Uploaded by

rCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

HITACHI MAN-B&W No. :HZSD-B0S02

DIESEL ENGINE SERVICE DATA pats : 28-3-2005

i

|

Disc position of air piston at exhaust valve close timing

ENGINE TYPE: L/S60MC/MC-C

As for some ships equipped with the captioned engine, exhaust gas

temperature at cylinder outlet was found getting higher

After several inspections, exhaust gas leakage through the

incompletely closed exhaust valve was detected.

This has been caused due to the contact of bolt head on air

piston with the lower surface of oil cylinder, as shown in Fig.1.

As shown in Fig.2, the original clearance, between the bolt head

for disc holding and the lower surface of oil cylinder, is 4.6mm,

at delivery.

on the other hand, max. grinding limit for the seat surface of

valve spindle and valve-seat is about 2mm each (4mm in total),

as specified in the instruction book of VOLUME II 908-2.

Hereupon, after reconditioning of valve spindle and valve-seat, if

grinding amount of each seat surface has reached the max. grinding

limit 2mm (4mm in total, equivalent to 4.6mm in vertical

direction), this may cause contact of bolt head with lower

surface of oil cylinder, at valve closing, by adding effects

such as deformation by wear of exhaust valve components, and

thermal elongation, so on

Please check the bolt head on disc whether they are in contact

with the lower surface of oil cylinder, when each seat surface

is ground up to near max. permissible limit, as there is a

possibility of the above mentioned inconvenience.

Moreover, we recommend to machine the upper surface of the disc

3.5mm so as to decrease the thickness from 13.5mm to 10mm

(Please refer to Fig.3.)

REMARKS

AZ D&E ‘iiacxi zosen diese! & Engineering Co,, Lc.

B0S02-2/2

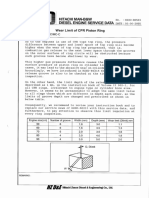

Fig. 2

= Original clearance :

Contact of bolt 3

headwith disc %

8

a:

} ae

LU &

ot 4.6mm Omm

} (In case that (at delivery)

You might also like

- HZSD B0507Document2 pagesHZSD B0507rNo ratings yet

- HZSD B0506Document1 pageHZSD B0506rNo ratings yet

- HZSD B0501Document2 pagesHZSD B0501rNo ratings yet

- HZSD B0503Document2 pagesHZSD B0503rNo ratings yet

- HZSD B0407Document1 pageHZSD B0407rNo ratings yet

- HZSD B0406Document1 pageHZSD B0406rNo ratings yet

- HZSD B0404Document2 pagesHZSD B0404rNo ratings yet