Professional Documents

Culture Documents

SMOct 60 Bike Trailer

Uploaded by

JimOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SMOct 60 Bike Trailer

Uploaded by

JimCopyright:

Available Formats

Shopping Trailer for Bicycles

W HY not save

wear on the

car and have

number one son tone

up his muscles by do-

ing the shopping for

the family. He can,

with this roomy car-

rier you (or he) build

in an evening. No

welding is required.

The 16-in. O.D. semi-

pneumatic sidewalk

bike tires shown come

equipped with nylon

b e a r i n g s t h a t will

carry moderate loads

at up to 20 mph. In

fact, they will take

speeds of 25 to 30 mph

for a short distance,

but they are not in-

tended for towing be-

hind a car. Of course,

two matched wheels

from a discarded bike,

will also do the job.

Make the wheel

mounting b r a c k e t s

(Fig. 3) of 1-in. angle

iron. Drill the 3/8-in.

hole for the axle, and The trailer easily carries a load of five full grocery bags. A foam rubber floor

file or hacksaw out the liner absorbs road shock.

slot. Drill the ¼-in.

b r a c k e t mounting

holes and then mount By BILL MC HUGH

the wheels on the brackets.

You'll save time by asking

your lumber dealer to cut the

5/8 x 23½ x 29½-in. trailer

floorboard square and exactly

to size. Locate the wheel slots

slightly behind center so the

trailer rides tongue heavy.

The ¾ x ¾-in. framing strips

on the side panels give your

trailer a custom appearance.

Cut the bottom and top strips

¾-in. longer than the 12 x

28¾-in. side panels, since the

corner posts overlap the 3/8-in.

end panels. Use a dark oil stain

The swiveling tow bar fastens to the

seat with removable hitch, and clears

the rear fender by two inches so you

ride over curbs and ramps.

OCTOBER, 1960

145

to color the strips; it's easier to MATERIALS LIST—BIKE TRAILER

do this now, rather than after Amt. 2

Req. Size and Description

16-in. Semi-Pneumatic Sidewalk bike tires.

Use

wheels

c o n s t r u c t i o n is completed. Available complete with threaded axle, bearings,

When the stain is dry, use a nuts; from Schwinn Bike dealers for about

woodworker's glue such as 1 5/8 $4.25 each.

x 23½ x 2 9 ½ " plywood floor board

Elmer's Glue-All to coat the 2 3/8 x 12 x 2 8 ¾ " plywood side panels

2 3/8 x 12 x 22" plywood end panels

strips, and nail into place with 20 ft. ¾" square lumber panel trim

1-in. nails spaced every few 4 ft. ¾" quarter-round corner cleats

inches. Remove any surplus 1 2 1 x 12" angle iron wheel brackets

¾ x 3¾" x 6' fir wheel guards

glue exuding from the joints. 2 3/8 x 20½ x 8" plywood wheel guards

Side Panels. Glue and tack 1 ¾" (hardware x 10' galvanized electrical conduit

and electrical stores)

tow bar

the side panels to the bottom 6 ¼-20 x ¾" fh bolts with nuts wheel bracket mounting

board; then add 1-in. wood 21 14-20 x 1¾" bolts with nuts

1X 21¼ x 2 7 ¼ " foam rubber floor

tow bar mounting

cushion

screws for added strength. Cut (available upholstery shops)

the 3/8-in. thick front and back Misc. 1" nails, 1" fh wood screws, Elmer's Glue-All,

snap, plastic rain cover, bike reflectors

Rope

plywood panels to fit, and nail

diagonally through the corner posts as you you use a piece of scrap board as a support to

glue them in place. Make two cleats of the hold the cleats firmly in place while you nail.

%-in. strip lumber and fasten to the inside by For additional strength, cut four cleats of

nailing through from the outside. It's easier if ¾-in. quarter-round and nail and glue into

146 SCIENCE AND MECHANICS

the inside corners.

Make the wheel guards of ¾-in. lumber.

If you have no table saw, it may be difficult

to cut the bevel angles, so you can substitute

a square construction. Cover the wheel guard

with 3/8-in. plywood and nail and glue in

place.

The Trailer Bar is bent of a length of

¾-in. I.D. electrical tubing, as in Fig. 3A.

You may need to alter its shape slightly to

fit your bike. If you can, borrow an elec-

trician's conduit bender (Fig. 3B). Otherwise

have the bends made at your local electric

shop. The ¾-in. tubing comes in 10-ft. lengths,

so have the bends made first, and then cut

the extra length down for a close fit to the

bike wheel. Flatten the trailer end of the bar

slightly with a vise or hammer, and drill ¼-

in. holes for bolting to the bottom.

The trailer hitch is made of a rope snap.

Used to fasten dog leashes to posts, this hard-

ware store item enables you to quickly attach In heavy traffic, remember that you need more road

the trailer to the bike saddle bar, or to a ring room. Be sure to warn drivers with the proper turn

that you can fasten to the seat post. Drill a and stop signals.

hole through the conduit and use a ¼-in. bolt

to fasten the hitch. cushion will work as well) will absorb egg-

As suggested earlier, the side framing breaking shocks when the trailer rides over

strips were stained a dark color before as- bumps. You'll find well packed grocery bags

sembly. Now stain the rest of the wood a will survive the roughest kind of street. A

contrasting lighter tone, such as light oak. few screw eyes with cord stretched across

When the stain is dry, apply several coats of the trailer will keep packages in place, and

varnish. Bolt the wheel assemblies and the you may want to add a plastic rain cover.

tow bar to the trailer, and varnish the ex- In traffic, remember that your bike and

posed axle and screw threads to keep the trailer combination is now less maneuver-

nuts from loosening. able, so allow for this in following bike safety

The optional foam rubber liner (a boat rules.

You might also like

- SMFeb 56 Roamabout Part 1Document17 pagesSMFeb 56 Roamabout Part 1Jim86% (7)

- River Boat Built For White WaterDocument5 pagesRiver Boat Built For White WaterJim100% (2)

- Super ScooterDocument6 pagesSuper ScooterzebrazeroNo ratings yet

- Super Scooter by Mechanix IllustratedDocument12 pagesSuper Scooter by Mechanix IllustratedJim100% (3)

- Instruction 6x16 Float DockmakerDocument1 pageInstruction 6x16 Float DockmakerJose MelloNo ratings yet

- Whelping Box DesignDocument12 pagesWhelping Box DesignLutafullahSaeedNo ratings yet

- 3 Wheel Go KartDocument5 pages3 Wheel Go KartLucas BrasilNo ratings yet

- Half Lite Stunter Building InstructionsDocument37 pagesHalf Lite Stunter Building InstructionsCarlos Manuel GonzálezNo ratings yet

- Coping Sled 003Document1 pageCoping Sled 003asep ridwanNo ratings yet

- Tracto Camion y AeroplanoDocument16 pagesTracto Camion y AeroplanoZosmo Simiao CostaNo ratings yet

- Dingbat WaterscooterDocument8 pagesDingbat WaterscooterJim100% (2)

- Breeze Baby Sailboat PlansDocument5 pagesBreeze Baby Sailboat PlansJim100% (5)

- Mini BikeDocument6 pagesMini BikeraadianNo ratings yet

- An Illustrated Guide to Making Mobile Toys - Scooter, Tricycle, Two Utility Carts and Wooden Land RoverFrom EverandAn Illustrated Guide to Making Mobile Toys - Scooter, Tricycle, Two Utility Carts and Wooden Land RoverNo ratings yet

- Star Lite SailboatDocument13 pagesStar Lite SailboatJim100% (8)

- GoCat: Build Your Own HovercraftDocument4 pagesGoCat: Build Your Own HovercraftJimNo ratings yet

- Workbed PlansDocument6 pagesWorkbed PlansThe WorldNo ratings yet

- 26 B Mount Blocks 04222020Document15 pages26 B Mount Blocks 04222020CarlosAgustoPinedaSanchezNo ratings yet

- Curtiss R-6 RacerDocument9 pagesCurtiss R-6 RacerAviation/Space History LibraryNo ratings yet

- Entry Bench PlanDocument8 pagesEntry Bench PlancajemarNo ratings yet

- A Classic CaseDocument6 pagesA Classic Casediegocearram100% (4)

- The Recumbent Bicycle and Human Powered Vehicle Information Center15Document1 pageThe Recumbent Bicycle and Human Powered Vehicle Information Center15Marcel PiersonNo ratings yet

- VDG Instruction PagesDocument12 pagesVDG Instruction PagesMarty cNo ratings yet

- 12thpak InstrutionsDocument5 pages12thpak InstrutionsJavier Rodriguez PaezNo ratings yet

- Disc Plow Operator'S Manual: Adjustment, Operation & MaintenanceDocument8 pagesDisc Plow Operator'S Manual: Adjustment, Operation & MaintenanceHTNNo ratings yet

- Vintage Playground Plans 1950s PDFDocument39 pagesVintage Playground Plans 1950s PDFAlexandre Mello100% (1)

- CaballeteDocument6 pagesCaballetermorenod77No ratings yet

- disc-plow-manual_1581001597Document8 pagesdisc-plow-manual_1581001597Alliah MendozaNo ratings yet

- Roller Descrip MeccanoDocument3 pagesRoller Descrip MeccanoRocalinaudNo ratings yet

- Camp TrailerDocument6 pagesCamp TrailerGreg Phillpotts100% (3)

- 1901 PackardDocument8 pages1901 PackardZosmo Simiao CostaNo ratings yet

- ScooterDocument7 pagesScooterBuyuangKota100% (1)

- Brando Plans-Instr DigitalDocument21 pagesBrando Plans-Instr Digital劉書良100% (1)

- Douglas DB-7 BomberDocument8 pagesDouglas DB-7 BomberAviation/Space History Library50% (2)

- Ultimate Router Table PlansDocument59 pagesUltimate Router Table Plansiacob_gilberto6473100% (6)

- Manual Construcion Lijadora de Banda (Edge Sander)Document17 pagesManual Construcion Lijadora de Banda (Edge Sander)Richard PeraltaNo ratings yet

- Motor Canoe Boat PlansDocument4 pagesMotor Canoe Boat PlansJim100% (6)

- How To Build The Little Zinger 1/2A Control Line Model AirplaneDocument15 pagesHow To Build The Little Zinger 1/2A Control Line Model AirplaneHeman Lee100% (2)

- METÁLICODocument6 pagesMETÁLICOjorge andres hereira cabanaNo ratings yet

- Rondack Lodge Heirloom CamperDocument63 pagesRondack Lodge Heirloom CamperNickiedeposieNo ratings yet

- Ottoman Diy PlanDocument4 pagesOttoman Diy PlanDGNo ratings yet

- Junior Backhoe: Half-Pint Sidewalk Superintendents Will Go Ape For This Boy-Size, Rugged, Easy-To-Build DiggerDocument5 pagesJunior Backhoe: Half-Pint Sidewalk Superintendents Will Go Ape For This Boy-Size, Rugged, Easy-To-Build Diggermagatsu2099No ratings yet

- Build This Brewster F2A-1 Flying Scale ModelDocument10 pagesBuild This Brewster F2A-1 Flying Scale ModelJose Antonio Lobo Gerardino100% (1)

- Aquarail JetskiDocument6 pagesAquarail Jetskitony_williams_4No ratings yet

- Drill Press TableDocument11 pagesDrill Press TableWil NelsonNo ratings yet

- 1 Making FrameDocument2 pages1 Making FrameRavi VenkatasubramanianNo ratings yet

- PLANS Folding KayakDocument15 pagesPLANS Folding KayakecalzoNo ratings yet

- F-15 Park Jet Plans (Assembly Drawing) Rev CDocument2 pagesF-15 Park Jet Plans (Assembly Drawing) Rev CMAIG ElectricosNo ratings yet

- Analog Circuit Design Discrete and Integrated 1St Edition Franco Solutions Manual Full Chapter PDFDocument36 pagesAnalog Circuit Design Discrete and Integrated 1St Edition Franco Solutions Manual Full Chapter PDFlanora.graham908100% (15)

- Final DocumentDocument21 pagesFinal Documentapi-353729726No ratings yet

- Mustang Rocking Horse: John W. Designs and Builds TheDocument11 pagesMustang Rocking Horse: John W. Designs and Builds ThemazarocomazarocoNo ratings yet

- Griffon2000TDX Manual rel-01OLDocument17 pagesGriffon2000TDX Manual rel-01OLHassan MohmedNo ratings yet

- The DIY Smart Saw - Desktop Version - PlansDocument39 pagesThe DIY Smart Saw - Desktop Version - PlansEduardo Hassin RodriguesNo ratings yet

- How to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityFrom EverandHow to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityNo ratings yet

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- Tractor Ploughing Manual, The, 2nd Edition: The Society of Ploughman Official HandbookFrom EverandTractor Ploughing Manual, The, 2nd Edition: The Society of Ploughman Official HandbookRating: 5 out of 5 stars5/5 (2)

- Bull Frog Go KartDocument15 pagesBull Frog Go KartJim100% (3)

- Homemade ATVDocument67 pagesHomemade ATVJim100% (7)

- Polliwog Sailboat PlansDocument6 pagesPolliwog Sailboat PlansJim100% (4)

- Candle Powered EngineDocument2 pagesCandle Powered EngineJimNo ratings yet

- Mineral Vegetable and Animal LifeDocument4 pagesMineral Vegetable and Animal LifeJim86% (7)

- Breeze Baby Sailboat PlansDocument5 pagesBreeze Baby Sailboat PlansJim100% (5)

- Star Lite SailboatDocument13 pagesStar Lite SailboatJim100% (8)

- Model Hot Air EngineDocument4 pagesModel Hot Air EngineJim100% (4)

- Free Electric Power WindmillDocument3 pagesFree Electric Power WindmillJim100% (4)

- Dorothy 24 Foot Sailing CruiserDocument11 pagesDorothy 24 Foot Sailing CruiserJim92% (12)

- Electric Scooter PlansDocument6 pagesElectric Scooter PlansJim88% (8)

- Air Cooled Hot Air EngineDocument6 pagesAir Cooled Hot Air EngineJim50% (2)

- War Toys For BoysDocument48 pagesWar Toys For BoysJim100% (2)

- Listening LoopsDocument2 pagesListening LoopsJim75% (4)

- Magnetic Current PamphletDocument9 pagesMagnetic Current PamphletJim100% (2)

- O Livro de Ouro Dos Experimentos Químicos (RARIDADE)Document114 pagesO Livro de Ouro Dos Experimentos Químicos (RARIDADE)Davidson De Oliveira Lima100% (1)

- Magnetic BaseDocument3 pagesMagnetic BaseJim100% (2)

- Crystal Radio LampDocument4 pagesCrystal Radio LampJim100% (2)

- Foxhole RadioDocument2 pagesFoxhole RadioJim89% (9)

- Flashlight RadioDocument5 pagesFlashlight RadioJim67% (3)

- Radio SimplifiedDocument94 pagesRadio SimplifiedJim100% (3)

- Vintage Transistor RadioDocument4 pagesVintage Transistor RadioJim100% (1)

- A Crystal Set For The Boy BuilderDocument3 pagesA Crystal Set For The Boy BuilderJim100% (4)

- The Boy's Book of Crystal SetsDocument36 pagesThe Boy's Book of Crystal SetsJim100% (9)

- Build A Scintillometer Uranium Detector For ProspectingDocument11 pagesBuild A Scintillometer Uranium Detector For ProspectingJim80% (5)

- Space Age Crystal SetDocument3 pagesSpace Age Crystal SetJim100% (3)

- Receive Short W A V E Onyour HomeradioDocument5 pagesReceive Short W A V E Onyour HomeradioJim100% (9)

- Vintage Transistor RadioDocument4 pagesVintage Transistor RadioJim100% (1)

- Wren Minibike PlansDocument7 pagesWren Minibike PlansJim100% (5)

- Company Risk Assessment Version 1Document15 pagesCompany Risk Assessment Version 1Петр Шкиль100% (1)

- TV 22 2015 6 1447 1456 PDFDocument10 pagesTV 22 2015 6 1447 1456 PDFMuhammad Izzamir FirdausNo ratings yet

- LO1 HospitalityDocument41 pagesLO1 HospitalityDinesh NayakNo ratings yet

- JetBlue - Trip Review2Document3 pagesJetBlue - Trip Review2Daniel Concepcion RoigNo ratings yet

- Ingles Basico - 2023Document11 pagesIngles Basico - 2023mctsiamasNo ratings yet

- KPP Book EngDocument160 pagesKPP Book EngSora Mayonaka100% (1)

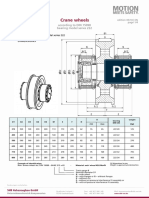

- Datasheet Crane Wheels DIN15090Document4 pagesDatasheet Crane Wheels DIN15090ayavuzbvsNo ratings yet

- Af521 (2012) - ManDocument22 pagesAf521 (2012) - ManNUCLEONIX SYSTEMS PVT LTDNo ratings yet

- Bradbury. Kpn-Boats, Punt Trade, and A Lost EmporiumDocument25 pagesBradbury. Kpn-Boats, Punt Trade, and A Lost EmporiumBelén CastroNo ratings yet

- Answer For Task 1-Unit 4 TransportDocument4 pagesAnswer For Task 1-Unit 4 TransportAung Kyaw Moe100% (1)

- Brand Audit of Singapore AirlinesDocument14 pagesBrand Audit of Singapore Airlinesmegan50% (2)

- Method Statement of Pipeline Pigging Services: Polmaz LimitedDocument10 pagesMethod Statement of Pipeline Pigging Services: Polmaz LimitedVineet Agrawal100% (1)

- Price List Part Yamaha Scorpio TH 2006Document12 pagesPrice List Part Yamaha Scorpio TH 2006gualagiNo ratings yet

- Static, Dynamic and Impact Stress Analysis of A Bus Body Structure Using Finite Element AnalysisDocument12 pagesStatic, Dynamic and Impact Stress Analysis of A Bus Body Structure Using Finite Element AnalysisTJPRC PublicationsNo ratings yet

- Operation and Maintenance ManualDocument488 pagesOperation and Maintenance ManualHéctorHernándezDíazNo ratings yet

- Compact Wheel Loader and Pivot Steer Teleloader Product Range 2014/IIDocument52 pagesCompact Wheel Loader and Pivot Steer Teleloader Product Range 2014/IIDragos Manole0% (1)

- CE 323-Highway Engineering I Editted 2011Document118 pagesCE 323-Highway Engineering I Editted 2011Athiyo Martin100% (1)

- Network MarketingDocument32 pagesNetwork MarketingAvinash Kumar Singh100% (2)

- Wolter Jetfan Broschuere English 2017 PDFDocument15 pagesWolter Jetfan Broschuere English 2017 PDFViệt Đặng XuânNo ratings yet

- Oarr 10000310 1 PDFDocument520 pagesOarr 10000310 1 PDFyoussefNo ratings yet

- Bibby TopazDocument4 pagesBibby TopazPraveen BalasubramanianNo ratings yet

- Automated storage and retrieval systems (AS/RS) for efficient warehouse managementDocument26 pagesAutomated storage and retrieval systems (AS/RS) for efficient warehouse managementEusebiu PetuNo ratings yet

- Protection of Old Shophouses Due To MRT Excavation & Tunnelling Works On Downtown Line Stage 3 Contract 933Document14 pagesProtection of Old Shophouses Due To MRT Excavation & Tunnelling Works On Downtown Line Stage 3 Contract 933freezefreezeNo ratings yet

- CES 6.0.0 Deck Management Chemical Tanke PDFDocument13 pagesCES 6.0.0 Deck Management Chemical Tanke PDFChristian Legaspi75% (12)

- SealandDocument3 pagesSealandLixmarys QuirozNo ratings yet

- Guidance On Conducting Bus Staff and IPT Operator Survey 210825Document36 pagesGuidance On Conducting Bus Staff and IPT Operator Survey 210825ITDP IndiaNo ratings yet

- Concrete Saw Core Drilling Swms 10067-8Document12 pagesConcrete Saw Core Drilling Swms 10067-8JamesNo ratings yet

- 15ES Electric Pallet Stacker Operation and Service ManualDocument53 pages15ES Electric Pallet Stacker Operation and Service ManualmehdiNo ratings yet

- In-Situ Burning of Oil in Ships or Other Vessels: Standard Guide ForDocument6 pagesIn-Situ Burning of Oil in Ships or Other Vessels: Standard Guide ForAhmad Zubair RasulyNo ratings yet