Professional Documents

Culture Documents

PC Fapt Brochure

Uploaded by

babak6710 ratings0% found this document useful (0 votes)

266 views2 pagesFANUC PC Fapt CAD / CAM for CNC lathes is designed by the world's largest lathe control manufacturer. Supports multiple tool files - quickly create your own tool library for a particular machine or material. Full solid model animation of toolpath - lets you see exactly how the part will cut DXF in so you can import customers drawings.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFANUC PC Fapt CAD / CAM for CNC lathes is designed by the world's largest lathe control manufacturer. Supports multiple tool files - quickly create your own tool library for a particular machine or material. Full solid model animation of toolpath - lets you see exactly how the part will cut DXF in so you can import customers drawings.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

266 views2 pagesPC Fapt Brochure

Uploaded by

babak671FANUC PC Fapt CAD / CAM for CNC lathes is designed by the world's largest lathe control manufacturer. Supports multiple tool files - quickly create your own tool library for a particular machine or material. Full solid model animation of toolpath - lets you see exactly how the part will cut DXF in so you can import customers drawings.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

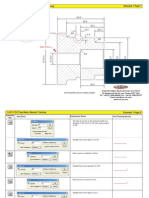

FANUC PC Fapt

CAD/CAM for CNC lathes

The versatility of FAPT now

available on your office PC.

The CAPT software is designed

by FANUC, the world's largest

lathe control manufacturer. Who

else is better qualified to

develop such a leading product?

Supports multiple tool files - quickly

create your own tool library for a

particular machine or material.

Automatic Toolpath creation mode greatly

Reduces the time spent in defining a components machining operations

Full solid model animation of toolpath - lets you see exactly how the part will cut

DXF in so you can import customers drawings avoiding have to draw the component

from scratch. DXF out so you can export your componet to your CAD system to

produce working drawings from your part.

During roughing operations CAPT shows exactly what metal the current tool can

remove safely whilst avoiding any gouging of components.

The user can print out a operation list which contains the tool information and

estimated machining time.

Optional C/Y axis for driven tooling

Associated toolpaths - If you change the component shape the toolpath will be

automatically updated.

If you prefer you can draw using the program's own CAD functions.

Cambridge Numerical Control

29 Stephenson Rd St. Ives Cambs PE27 3WJ

Tel : +44 (0) 1480-468639 Fax : +44 (0) 1480-301577

Email sales@cnc.uk.com

www.pcfapt.com

Solid Model Simulation Tool Libraries

Machining simulation using solid models to give a re- Tools can be quickly and easy defined and stored in a

alistic impression of the machining process. Graphic library. When a machining process is defined a suitable

display of tool tip and tool holder with checks for tool is automatically selected from the tool library,

interference between tool and chuck. however the user can still browse the library to change to

a different tool if required.

Automatic Toolpath Creation Cutting Condition Files

The user can either let the system determine its own Material files contain predefined information for depth of

optimal toolpath creation automatically or specify each cut, cutting speed, finishing allowances etc for a type of

cutting operation individually. Feeds and speeds are operation and type of tool. When an operation is selected

calculated automatically based on cutting conditions and the tool and cutting conditions are automatically selected.

surface finish requirements.

Symbolic Keys

C/Y Axis Module Option

Component profiles can be created using the well proven

FAPT method. If you don’t know a tangency point on the Driven tooling is fully supported by the C/Y axis module.

profile leave it blank and CAPT will calculate it Features such as keyways, hexagons, flats, face or side

automatically. Special buttons are available for operations drilling can be easily programmed.

such as grooving, necking and threading.

PC Fapt also has its own built in CAD functions and can

read and write DXF file formats.

You might also like

- CNC Stands For Computer Numerical Control, And: G-Code. CNC Was Developed inDocument4 pagesCNC Stands For Computer Numerical Control, And: G-Code. CNC Was Developed inKhateeb Ul Islam QadriNo ratings yet

- Ncguide CNC Simulator: Ncguide (E) - 01,2016.4, Printed in JapanDocument4 pagesNcguide CNC Simulator: Ncguide (E) - 01,2016.4, Printed in JapanIvo DimitrovNo ratings yet

- Lazyturn Manual Rev 5Document49 pagesLazyturn Manual Rev 5s45rebatbnNo ratings yet

- Manual GuideDocument6 pagesManual GuideDeysi CardenasNo ratings yet

- 721p201 Concise Programming Manual For MillingDocument66 pages721p201 Concise Programming Manual For MillingAlejandroMaravillaVadillo100% (1)

- HaasLiveToolOpProgram - W - DS Manual PDFDocument70 pagesHaasLiveToolOpProgram - W - DS Manual PDFGuillermo RamirezNo ratings yet

- MTB Tech BlogDocument41 pagesMTB Tech Blog이종훈No ratings yet

- 1 IntroductionDocument33 pages1 IntroductionNebojsa NunicNo ratings yet

- The Use of Variables, Macros and Subroutines and Compatibility With FANUC Parametric Programming ......................... 3Document10 pagesThe Use of Variables, Macros and Subroutines and Compatibility With FANUC Parametric Programming ......................... 3Jérôme GRANGENo ratings yet

- FeatureCAM Fundamentals - Turning PDFDocument11 pagesFeatureCAM Fundamentals - Turning PDFBita MohajerniaNo ratings yet

- NCT 201MDocument232 pagesNCT 201Mineu2279No ratings yet

- Invo MillingDocument8 pagesInvo MillingOvidiu StoianNo ratings yet

- Fanuc Lathe Programming GuideDocument93 pagesFanuc Lathe Programming GuidenguyenanhsoNo ratings yet

- Hyundai L2000sy L3000sy TurningcenterDocument40 pagesHyundai L2000sy L3000sy TurningcenterAndreas AnugerahNo ratings yet

- TNC 426 TNC 430: User's Manual Conversational ProgrammingDocument374 pagesTNC 426 TNC 430: User's Manual Conversational ProgrammingСлоба ЈовановићNo ratings yet

- Milling PDFDocument282 pagesMilling PDFDulis DulisNo ratings yet

- PowerMILL 2016 - Getting Started enDocument87 pagesPowerMILL 2016 - Getting Started enRaulEstalNo ratings yet

- vERICUT Pro ENGINEERDocument119 pagesvERICUT Pro ENGINEERSérgio BassiNo ratings yet

- Turn Mate I Operator's ManualDocument322 pagesTurn Mate I Operator's ManualAnirban PalNo ratings yet

- Machining Simulation Software User ManualDocument89 pagesMachining Simulation Software User ManualJesus Alberto RIVERA /CALVEK AUTOMATIONNo ratings yet

- iTNC 530 Versatile Contouring ControlDocument60 pagesiTNC 530 Versatile Contouring ControlelumbNo ratings yet

- Autodesk Fusion 360: 2D Milling GuideDocument39 pagesAutodesk Fusion 360: 2D Milling GuideSapril ArikanoshikiNo ratings yet

- Comparative Study of CNC Controllers Used in CNC Milling MachineDocument9 pagesComparative Study of CNC Controllers Used in CNC Milling MachineAJER JOURNALNo ratings yet

- Probes HeidenhainDocument64 pagesProbes HeidenhainfbalestrinNo ratings yet

- 20 PDFDocument583 pages20 PDFAn FiggNo ratings yet

- 5 Axis Lesson 2 SampleDocument20 pages5 Axis Lesson 2 SampledizorientedNo ratings yet

- CNC Mill ProgrammingDocument24 pagesCNC Mill ProgrammingZahidah AmaninaNo ratings yet

- Tool Load For MC-APP2008-003Document16 pagesTool Load For MC-APP2008-003jon doughNo ratings yet

- 2008xmachining Compressed 161102023930Document104 pages2008xmachining Compressed 161102023930Iwan GantengNo ratings yet

- Ch4capp AptDocument28 pagesCh4capp AptRajesh VermaNo ratings yet

- Manual Guide +Document428 pagesManual Guide +Aloisio GonzagaNo ratings yet

- Get Started With Ultimax4Document189 pagesGet Started With Ultimax4Slobodan DimitrijevićNo ratings yet

- CNC TurningDocument13 pagesCNC TurningJAMES JUDYNo ratings yet

- User's Manual OverviewDocument789 pagesUser's Manual OverviewMACKAY9999No ratings yet

- Puma Work Ejector Tip ReplacementDocument3 pagesPuma Work Ejector Tip ReplacementpaulNo ratings yet

- SAMPLE MastercamX9 Beginner TrainingTutorialDocument56 pagesSAMPLE MastercamX9 Beginner TrainingTutorialCristian FuentesNo ratings yet

- HEIDENHAIN Absolute Encoder CNC ApplicationsDocument4 pagesHEIDENHAIN Absolute Encoder CNC ApplicationsocchityaNo ratings yet

- Series8000LatheOperation PDFDocument324 pagesSeries8000LatheOperation PDFSnaldo EstradaNo ratings yet

- Swan SoftDocument90 pagesSwan Softandreeaoana45No ratings yet

- Inspection Software For LathesDocument90 pagesInspection Software For Latheselumb100% (1)

- Surface Toolpath OverviewDocument12 pagesSurface Toolpath OverviewSugumarKmNo ratings yet

- Gv-2500 (Vtl-3200) Operation Manual 01verDocument195 pagesGv-2500 (Vtl-3200) Operation Manual 01versunhuynhNo ratings yet

- Pickoff Pull Cutoff Application Guide in MasterCamDocument20 pagesPickoff Pull Cutoff Application Guide in MasterCameltklasNo ratings yet

- NC, CNC & Robotics: An IntroductionDocument143 pagesNC, CNC & Robotics: An IntroductionshafiqNo ratings yet

- CNC Programmer Job Description PostingDocument2 pagesCNC Programmer Job Description Postingsmith9krNo ratings yet

- Metrology & Workshop Practice ComponentsDocument48 pagesMetrology & Workshop Practice ComponentsAliah IzzahNo ratings yet

- 3-Axis Flowline FinishingDocument4 pages3-Axis Flowline FinishingCristian MartinezNo ratings yet

- Machine Tool Touch Probes GuideDocument44 pagesMachine Tool Touch Probes GuideMonteagudoNo ratings yet

- WinMax Mill NC Programming Englisch r0116-310Document265 pagesWinMax Mill NC Programming Englisch r0116-310ArjanDijkNo ratings yet

- CAD/CAM Laboratory Process PlanningDocument14 pagesCAD/CAM Laboratory Process Planningschriener50% (2)

- Emco Winnc Heidenhain TNC 426 Conversational The Emco Winnc Heidenhain TNC 426Document282 pagesEmco Winnc Heidenhain TNC 426 Conversational The Emco Winnc Heidenhain TNC 426AyoubNo ratings yet

- The Complete Cam Solution, With Revolutionary Imachining, Fully Integrated in SolidworksDocument28 pagesThe Complete Cam Solution, With Revolutionary Imachining, Fully Integrated in SolidworkssumejaNo ratings yet

- Doosan G76Document17 pagesDoosan G76Pham LongNo ratings yet

- Vericut 6Document1,012 pagesVericut 6Eric Liard100% (1)

- Sinumerik 840D SL Operate OPC UA 4 5Document9 pagesSinumerik 840D SL Operate OPC UA 4 5Sam eagle goodNo ratings yet

- Sodick Technology SelectorDocument14 pagesSodick Technology SelectorTrần Văn TrườngNo ratings yet

- Machine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryFrom EverandMachine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryNo ratings yet

- Symbolic Keys For Example1Document5 pagesSymbolic Keys For Example1babak671No ratings yet

- Symbolic Keys For Example1Document5 pagesSymbolic Keys For Example1babak671No ratings yet

- B 66102e - 10 - FanucDocument236 pagesB 66102e - 10 - Fanucbabak67167% (3)

- Steeves & Company Machinery For Sale by Private TreatyDocument17 pagesSteeves & Company Machinery For Sale by Private Treatybabak671No ratings yet

- Ug Nx3 TutorialDocument235 pagesUg Nx3 TutorialAJAYKRISHNAA92% (13)

- 4525 Fanuc PSDocument1 page4525 Fanuc PSbabak671No ratings yet

- Hul RuralDocument21 pagesHul Ruralchirag_nrmba15100% (1)

- Mcdonalds in India and Promotion Strategy of Mcdonalds in IndiaDocument7 pagesMcdonalds in India and Promotion Strategy of Mcdonalds in IndiaKrishna JhaNo ratings yet

- of Modern Theories of ManagementDocument29 pagesof Modern Theories of ManagementShristi ShreeNo ratings yet

- Sieve Shaker Octagon 200Cl and Sieveware Evaluation SoftwareDocument2 pagesSieve Shaker Octagon 200Cl and Sieveware Evaluation SoftwareRamirez FrancisNo ratings yet

- 3 SPS Sop RCC FullDocument14 pages3 SPS Sop RCC FullDwitikrushna RoutNo ratings yet

- Funds Flow AnalysisDocument120 pagesFunds Flow Analysisamarnadh allaNo ratings yet

- Final - Mahlet, - June - 5 Edited As of 31.08.16Document58 pagesFinal - Mahlet, - June - 5 Edited As of 31.08.16yayehyiradNo ratings yet

- Bank of America Vs CADocument2 pagesBank of America Vs CAVebsie D. Molavin100% (1)

- Tax Invoice for Mobile Phone PurchaseDocument1 pageTax Invoice for Mobile Phone PurchaseSiddhartha MondalNo ratings yet

- P Task FinalsDocument2 pagesP Task FinalsLyka RamosNo ratings yet

- FAQ List For VOLKSWAGEN CATIA Additional ApplicationsDocument37 pagesFAQ List For VOLKSWAGEN CATIA Additional ApplicationszarasettNo ratings yet

- Sabri Suby ad #1 sales funnel offerDocument3 pagesSabri Suby ad #1 sales funnel offerHassan HameedNo ratings yet

- Various Types of Tax in IndiaDocument4 pagesVarious Types of Tax in IndiaUtkarsh LodhiNo ratings yet

- ScriptDocument2 pagesScriptBellapu Durga vara prasadNo ratings yet

- PDF DocumentDocument2 pagesPDF DocumentNavya RaiNo ratings yet

- The Sampoong Department Store CollapseDocument27 pagesThe Sampoong Department Store CollapseelleNo ratings yet

- PADS ES Suite Evaluation GuideDocument280 pagesPADS ES Suite Evaluation GuideAkhilesh AroraNo ratings yet

- Group Assignment Group 1 Report Bib 3084Document12 pagesGroup Assignment Group 1 Report Bib 3084SashivNo ratings yet

- Core Competency: Supply Chain Management Inventory Management Profit & Loss ManagementDocument3 pagesCore Competency: Supply Chain Management Inventory Management Profit & Loss ManagementsunilkumarchaudharyNo ratings yet

- Subscription Contract: Add-OnDocument2 pagesSubscription Contract: Add-OnAiona MendozaNo ratings yet

- CIR v. British Overseas AirwaysDocument21 pagesCIR v. British Overseas Airwaysevelyn b t.No ratings yet

- Process Reflections: Andon Signaling SystemsDocument2 pagesProcess Reflections: Andon Signaling SystemshametNo ratings yet

- Enforce PAymentDocument1 pageEnforce PAymentJebs KwanNo ratings yet

- PHD Dissertation in Agricultural EconomicsDocument8 pagesPHD Dissertation in Agricultural EconomicsPaySomeoneToWriteYourPaperSavannah100% (1)

- Solutions for math word problemsDocument54 pagesSolutions for math word problemsAshishAmitavNo ratings yet

- The Role of Internal Financial Audit in Detecting Irregularities in Private InstitutionsDocument10 pagesThe Role of Internal Financial Audit in Detecting Irregularities in Private InstitutionsIAEME PublicationNo ratings yet

- Request For Copy of Tax ReturnDocument2 pagesRequest For Copy of Tax ReturnAsjsjsjsNo ratings yet

- RL100 TA Maturity Model 1578448325Document1 pageRL100 TA Maturity Model 1578448325vvvasimmmNo ratings yet

- Intuit Case Study - Analyzing Opportunities for QuickBooks Platform ExpansionDocument6 pagesIntuit Case Study - Analyzing Opportunities for QuickBooks Platform ExpansionAndrés Pérez100% (1)

- International Economics 12th Edition Salvatore Test BankDocument10 pagesInternational Economics 12th Edition Salvatore Test Bankbewet.vesico1l16100% (21)