Professional Documents

Culture Documents

Crotch-Grained Chess Table: Walnut, Poplar

Uploaded by

khunchaiyai100%(2)100% found this document useful (2 votes)

539 views5 pages3 CROTCH-GRAINED CHESS table is designed around a set of angles taken from the playing pieces. The creation of these joints is complicated by the compound angles at which the legs meet the tabletop. The tenon shoulders on the apron parts are cut at angles which are 83deg from the top edges.

Original Description:

Original Title

Chess Table

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document3 CROTCH-GRAINED CHESS table is designed around a set of angles taken from the playing pieces. The creation of these joints is complicated by the compound angles at which the legs meet the tabletop. The tenon shoulders on the apron parts are cut at angles which are 83deg from the top edges.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

100%(2)100% found this document useful (2 votes)

539 views5 pagesCrotch-Grained Chess Table: Walnut, Poplar

Uploaded by

khunchaiyai3 CROTCH-GRAINED CHESS table is designed around a set of angles taken from the playing pieces. The creation of these joints is complicated by the compound angles at which the legs meet the tabletop. The tenon shoulders on the apron parts are cut at angles which are 83deg from the top edges.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

3

CROTCH-GRAINED

CHESS TABLE

Walnut, Poplar

Copyright 2004 Martian Auctions 11

MAKING THE CHESS TABLE

This piece is designed around a set of angles taken from

the playing pieces, angles echoed in the fat dovetails holding

the stretchers to the legs and to each other, in the big

triangles cut from the apron parts, and in the compound

angles used to bring the legs into the tabletop. The repeti-

tion of these angles—in addition to the consistent color

of the walnut—unifies this piece.

Construction begins with the two sides (the faces of the

table showing the wide sides of the legs). Fasten the apron

parts to the legs with wide tenons glued only halfway across

their widths in order to minimize the potential for cracking

as these cross-grained constructions expand and contract

in response to seasonal changes in humidity.

The creation of these joints is complicated by the com-

pound angles at which the legs meet the tabletop. The

tenon shoulders on the apron parts, for example, are cut

at angles which are 83° from the top edges of these apron

parts. The dovetailed ends of the stretcher are simpler to

lay out, as these can be marked once the apron tenons have

been dry-fit into their leg mortises.

Once dry-fit, glue and clamp these sub-assemblies—

each of which consists of two legs, apron part, and stretcher.

On the table saw, give the center stretcher a dovetailed

bottom that extends from end to end. Then fit this into

dovetail mortises cut into the side stretchers. Surplus length

is necessary on this stretcher so that the end grain can be

pared back to the 83° angle at which the sides are canted.

Then fasten the apron part opposite the drawer front to

the legs on the back end of the table with a pair of

1/2"-long tenons. Again, in order to avoid cracking as a

result of this cross-grained construction, glue the tenon

only across half its width. Screw glue blocks into place

behind this joint to reinforce these stubby tenons.

Resaw the drawer guide stock so that one face is canted

at an 83° angle. Then, using a set of dado cutters on the

table saw, plough a 1/2" X 5/8" groove down the center of

the uncanted face of this stock. Cut the two drawer-guide

pieces to length and install them on the inside faces of the

apron sides. and he selected four of these for the top of this table because

The top is the next concern. the swirling grain in the walnut echoed the swirling figure

If woodworkers stay in the discipline long enough, they in the onyx frame of the chessboard.

inevitably become wood collectors. My dad is no exception. Once you have chosen the stock for the chessboard

Over the years he's put together a hoard of native hard- frame, give it a shaped outside edge, and rabbet the bottom

woods with an emphasis on black walnut, his personal inside edge to receive the base on which the chessboard

favorite among American species. At the time this table will set. Cut the slots for the splines. You can cut these by

was built, he had in his collection a number of short lengths hand with a tenon saw, but I find it much easier to perform

of crotch-grained walnut he'd harvested several years before, this operation on the table saw with a Universal Jig. (See

Copyright 2004 Martian Auctions 12

Copyright 2004 Martian Auctions 13

Copyright 2004 Martian Auctions 14

chapter six for a photo of this jig in operation. Please note, both the apron and the moulding appear to run continu-

however, that in order to cut the slots for the splines on ously around the table. Place a wedge of wood the full

the frame of the chess table, the work would be aligned length of the drawer front, tapered from a bottom thickness

so that the mitered end of the frame stock sets flat on the of 5/16" to a top thickness of 0 between the drawer front

saw table). Thickness and cut splines, and assemble the and the apron that covers the drawer front. This shim

frame. causes the apron to be canted at the same 83° angle as the

Next, install the 1/4" chessboard base in its 1/4" X 1/2" other sections of the apron. Slide the runners screwed to

rabbet with a number of small wood screws. the outside faces of the drawer sides into the grooves

The moulding under the tabletop is not merely decora- ploughed in the drawer guides. Construct a drawer stop

tive—it's also functional, serving to fasten the top to the by screwing a strip of wood across the bottom of the drawer

base via a number of wood screws passing up through the guides. When the drawer is opened to its greatest extension,

moulding into the top and passing through the apron into a pair of screws turned slightly into the bottom edge of

the moulding. the drawer sides strike this strip, preventing the drawer

The drawer is a simple open-topped, butt-jointed box, from coming out too far and spilling its contents.

to the front end of which a section of the apron and the After finishing the table, set the chessboard into place

moulding are affixed so that when the drawer is closed, on a felt pad.

1 Fasten the

stretcher to the leg

with a hand-cut

dovetail

2passing

Screws passing up through this moulding into the top and

through the apron into the moulding hold the top

to the base.

3 Fasten the drawer runner, which slides in the groove

ploughed in the drawer guides, to the drawer via several wood

screws passing through the drawer side into the slide. Note the

shim between the drawer front and the apron. This causes the

apron to be canted at the same angle as the table's legs. Note

also the spline set into the end grain of the apron. This prevents

the corners of the apron from breaking off because of the grain

4 The drawer can be seen sliding in the groove ploughed in

the drawer guide. When the screw turned into the bottom

of the drawer side strikes the stop strip, the drawer is prevented

runout on the apron's triangular tips. from being pulled completely from the table.

Copyright 2004 Martian Auctions 15

You might also like

- Ultimate Small Shop BookDocument245 pagesUltimate Small Shop BookDenise York100% (8)

- 6000+ Woodworking Projects PagesDocument1,079 pages6000+ Woodworking Projects Pagesmnboks100% (6)

- Barrister BookcaseDocument6 pagesBarrister Bookcasekhunchaiyai100% (3)

- Make A Wheel Marking GaugeDocument6 pagesMake A Wheel Marking Gaugeserkan ünlü100% (1)

- Writing Desk: Project 13586EZDocument7 pagesWriting Desk: Project 13586EZBSulliNo ratings yet

- How To: Build A Raised-Bed Garden: 2. Attach The EndsDocument20 pagesHow To: Build A Raised-Bed Garden: 2. Attach The EndsAndre Duvaux100% (1)

- Panel JigDocument16 pagesPanel JigfasdfNo ratings yet

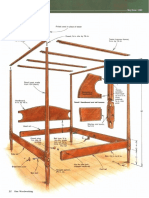

- The Pencil Post BedDocument6 pagesThe Pencil Post BedAnonymous QJ5j94luLmNo ratings yet

- Step-Back Cupboard: Build This Elegant 18th-Century Cupboard, and Hone Your Hand-Tool Skills at The Same TimeDocument8 pagesStep-Back Cupboard: Build This Elegant 18th-Century Cupboard, and Hone Your Hand-Tool Skills at The Same TimehelenmckaneNo ratings yet

- A Classic CaseDocument6 pagesA Classic Casediegocearram100% (4)

- Arbor - Lath Arch Rose ArborDocument6 pagesArbor - Lath Arch Rose ArborDaniel LourençoNo ratings yet

- Build BookcaseDocument7 pagesBuild Bookcasesaric_terrill4785100% (1)

- Stanley Tools Catalog (1941) (34th Edition)Document236 pagesStanley Tools Catalog (1941) (34th Edition)ArronNo ratings yet

- Ten Tips For Great StuccoDocument6 pagesTen Tips For Great StuccoAdityaNo ratings yet

- Artists EaselDocument13 pagesArtists Easelkhunchaiyai100% (3)

- Bed and Storage BoxesDocument9 pagesBed and Storage Boxespoimandres100% (1)

- Your First ToolkitDocument5 pagesYour First Toolkitmecrishatt100% (2)

- Barn Door Baby GateDocument17 pagesBarn Door Baby GateNovitates1No ratings yet

- Armario de ParedeDocument4 pagesArmario de ParedetovenoNo ratings yet

- How To Make A Cornhole BoardDocument4 pagesHow To Make A Cornhole BoardAndré VeigaNo ratings yet

- 1912-Problems in Furniture MakingDocument82 pages1912-Problems in Furniture MakingMaton de GongoraNo ratings yet

- Mission Style Open Shelf Bathroom Vanity: AdvancedDocument22 pagesMission Style Open Shelf Bathroom Vanity: AdvancedMaricruz Valdivieso de PalaciosNo ratings yet

- David de Lossy/Photodisc/Getty ImagesDocument15 pagesDavid de Lossy/Photodisc/Getty ImagesasiasiNo ratings yet

- Lock Rabbet Drawer JointsDocument3 pagesLock Rabbet Drawer JointsSANTI90900% (1)

- Foldable Stool Reverse Engineering The Tallon StooDocument37 pagesFoldable Stool Reverse Engineering The Tallon StooEnrique CoronelNo ratings yet

- Arbor - Making An Easy ArborDocument5 pagesArbor - Making An Easy ArbordaniellourencoNo ratings yet

- PostarA Bench Built To LastDocument6 pagesPostarA Bench Built To Lastbonte01100% (2)

- BarPlans PDFDocument43 pagesBarPlans PDFconfused597No ratings yet

- Triple Tier Jewelry BoxDocument8 pagesTriple Tier Jewelry BoxRossNo ratings yet

- Anniversary Desk: Celebrate 100 Years of PM With The Fourth in Our Furniture SeriesDocument11 pagesAnniversary Desk: Celebrate 100 Years of PM With The Fourth in Our Furniture SeriesШиша ШишулінNo ratings yet

- Over Toilet Storage ShelvesDocument13 pagesOver Toilet Storage ShelvesSergio OrellanoNo ratings yet

- Çalışma Tezgahı PlanıDocument14 pagesÇalışma Tezgahı PlanıÖmür Eryüksel50% (2)

- Essential Cabinetmaking TechniquesDocument19 pagesEssential Cabinetmaking TechniquesJeroen Matthee Jay100% (1)

- Kitchen Knife BlockDocument3 pagesKitchen Knife Block- yAy3e -No ratings yet

- Bco Carp Robust BenchDocument6 pagesBco Carp Robust BenchFabio Fernando FigaroNo ratings yet

- Build Your Own French Doors - Popular Woodworking MagazineDocument34 pagesBuild Your Own French Doors - Popular Woodworking Magazinekostas1977No ratings yet

- Drywall Installation Guide Fall 2006Document9 pagesDrywall Installation Guide Fall 2006extrcrimeaNo ratings yet

- The Pochade and Wet Panel Carrier Do It Yourself PlanFrom EverandThe Pochade and Wet Panel Carrier Do It Yourself PlanRating: 4 out of 5 stars4/5 (1)

- Building a Blown Gas Forge from ScratchDocument3 pagesBuilding a Blown Gas Forge from ScratchRedirecting DecoyNo ratings yet

- Drop Leaf TableDocument3 pagesDrop Leaf Table- yAy3e -No ratings yet

- Tools & Techniques for Building a Classic Garden Table & BenchDocument2 pagesTools & Techniques for Building a Classic Garden Table & BenchmarianrkwNo ratings yet

- Woodworking Magazine, Issue 6 Autumn 2006Document36 pagesWoodworking Magazine, Issue 6 Autumn 2006crm102b100% (1)

- Valet StandDocument9 pagesValet StandflerziNo ratings yet

- Barnsley TableDocument6 pagesBarnsley Tableroose1100% (1)

- Bow SawDocument6 pagesBow Sawkhunchaiyai100% (2)

- The Return of Roubo: An 18th-Century French Workbench Is Quite Possibly The Most Perfect Design Ever Put To PaperDocument10 pagesThe Return of Roubo: An 18th-Century French Workbench Is Quite Possibly The Most Perfect Design Ever Put To PaperRodrigo Alonso Garrido StuardoNo ratings yet

- Lawn Swing: IMPORTANT: Read This Before You StartDocument6 pagesLawn Swing: IMPORTANT: Read This Before You StartBill RNo ratings yet

- Folding KayakDocument4 pagesFolding KayakCarlos MPNo ratings yet

- Microfiche Reference Library: A Project of Volunteers in AsiaDocument21 pagesMicrofiche Reference Library: A Project of Volunteers in AsialinteringNo ratings yet

- Scrapwood Frame Saw: InstructablesDocument12 pagesScrapwood Frame Saw: InstructablesJasmine VaaltynNo ratings yet

- Fernando, John Paulo P. Bsce - 1 Assignment in Timber Design Wood Connections The Butt Wood JointDocument14 pagesFernando, John Paulo P. Bsce - 1 Assignment in Timber Design Wood Connections The Butt Wood JointtheDLordP15No ratings yet

- Bookcase End TableDocument3 pagesBookcase End Tablekhunchaiyai100% (1)

- Building A Hut - The Beginners' Guide PDFDocument19 pagesBuilding A Hut - The Beginners' Guide PDFNelio CostaNo ratings yet

- 2 Drawer Box: D.W. Collection 2/17/2011Document4 pages2 Drawer Box: D.W. Collection 2/17/2011Emilian Baluta100% (1)

- Digital Patterns: Designed by Steve GoodDocument14 pagesDigital Patterns: Designed by Steve GoodRichard PerezNo ratings yet

- Woodwork Joints PDFDocument173 pagesWoodwork Joints PDFAnestisNo ratings yet

- Peteward-Com MAKING A BOWDocument5 pagesPeteward-Com MAKING A BOWdescaraoNo ratings yet

- Basics of Mechanical Workshop Practice Lab ManualDocument92 pagesBasics of Mechanical Workshop Practice Lab ManualMOHAMMED MANSOORNo ratings yet

- Wood - May 2016Document92 pagesWood - May 2016Alexandra Ene100% (6)

- Power Sharpening System - Woodworking Techniques - American WoodworkerDocument8 pagesPower Sharpening System - Woodworking Techniques - American WoodworkerAnonymous xEKsRmtjONo ratings yet

- Precision Drill Frame ConstructionDocument7 pagesPrecision Drill Frame ConstructionMahesa SanggadipaNo ratings yet

- Bamboo Rodmaking Tips - Articles Area - Wood Planing FormsDocument7 pagesBamboo Rodmaking Tips - Articles Area - Wood Planing FormscannotdecideNo ratings yet

- Cópia de CR Fine Woodworking PlanemakingDocument8 pagesCópia de CR Fine Woodworking PlanemakingjrjuliaoNo ratings yet

- Chiefsshop Pirateschest PDFDocument12 pagesChiefsshop Pirateschest PDFdonguie100% (1)

- Small Colonial Bench: Project 10297EZDocument5 pagesSmall Colonial Bench: Project 10297EZmhein68No ratings yet

- Medieval Furniture: Rope BedDocument7 pagesMedieval Furniture: Rope BedCharmaineTanti100% (1)

- Build A Toy BoxDocument10 pagesBuild A Toy BoxkhunchaiyaiNo ratings yet

- F & C 269 (April 2018) - Pages-10-16Document7 pagesF & C 269 (April 2018) - Pages-10-16JuanRodriguez100% (5)

- Chess Salt and Pepper MillsDocument23 pagesChess Salt and Pepper MillsMaxmore KarumamupiyoNo ratings yet

- SpecificationsDocument41 pagesSpecificationsrohanNo ratings yet

- Kalinga HouseDocument21 pagesKalinga HouseAddie WagsNo ratings yet

- Book Case (Mission Style)Document8 pagesBook Case (Mission Style)khunchaiyai100% (3)

- CarpenterDocument59 pagesCarpenterRenu Saini100% (1)

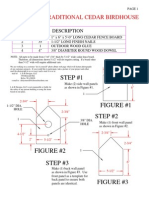

- Bird HouseDocument3 pagesBird Housekhunchaiyai100% (3)

- Showcase Cabinets: The Delicate Interplay of Glass and WoodDocument7 pagesShowcase Cabinets: The Delicate Interplay of Glass and WoodAdrian Cocis100% (1)

- Bookcase PlansDocument7 pagesBookcase PlansBrenda LeeNo ratings yet

- How To Make A Meat SafeDocument5 pagesHow To Make A Meat SafeChristian Theriault100% (1)

- Build a Post-and-Plank Retaining WallDocument13 pagesBuild a Post-and-Plank Retaining WallAnonymous 1TTYYaNo ratings yet

- WWMM Desk Organizer PDFDocument13 pagesWWMM Desk Organizer PDFjmontanerNo ratings yet

- Chest of Drawers 2Document6 pagesChest of Drawers 2khunchaiyai100% (3)

- Cherry End TableDocument5 pagesCherry End TablekhunchaiyaiNo ratings yet

- Candle BoxDocument4 pagesCandle Box- yAy3e -No ratings yet

- Carved Fruit BowlDocument5 pagesCarved Fruit Bowlkhunchaiyai100% (1)

- Brydcliffe CabinetDocument3 pagesBrydcliffe CabinetkhunchaiyaiNo ratings yet

- CandlelabraDocument3 pagesCandlelabrakhunchaiyai100% (1)

- Chairside BookcaseDocument3 pagesChairside Bookcasekhunchaiyai100% (2)

- Cappucino BarDocument3 pagesCappucino Bar- yAy3e -100% (1)

- Candle Stands PDFDocument2 pagesCandle Stands PDFBenivaldo Do Nascimento JuniorNo ratings yet

- Bungalow MailboxDocument3 pagesBungalow MailboxkhunchaiyaiNo ratings yet

- Bunk BedsDocument5 pagesBunk Bedskhunchaiyai100% (4)

- Book Case 2Document5 pagesBook Case 2khunchaiyai100% (1)

- Book Case 1Document6 pagesBook Case 1khunchaiyaiNo ratings yet

- Blanket ChestDocument3 pagesBlanket ChestkhunchaiyaiNo ratings yet

- Bird House2Document3 pagesBird House2khunchaiyai100% (1)

- Basic Board FenceDocument4 pagesBasic Board Fencekhunchaiyai100% (1)

- Baby Changing TableDocument6 pagesBaby Changing TablekhunchaiyaiNo ratings yet

- Bentwood Box With Snap-Fit Lid: Walnut, Hard MapleDocument4 pagesBentwood Box With Snap-Fit Lid: Walnut, Hard MaplekhunchaiyaiNo ratings yet

- ArmchairDocument3 pagesArmchairkhunchaiyaiNo ratings yet

- Bathroom Mirror PDFDocument3 pagesBathroom Mirror PDFBenivaldo Do Nascimento JuniorNo ratings yet

- Arts and Crafts ChairDocument9 pagesArts and Crafts ChairlaniNo ratings yet

- Wood Frame Construction GuideDocument144 pagesWood Frame Construction GuideRoland CepedaNo ratings yet

- En 131-2 (1993)Document14 pagesEn 131-2 (1993)Tiago FerreiraNo ratings yet

- Wood Fasteners Joinery AdhesivesDocument9 pagesWood Fasteners Joinery AdhesivesTudor CalomirNo ratings yet

- Building A Roubo Bench Will MyersDocument32 pagesBuilding A Roubo Bench Will MyersOpi DaculNo ratings yet

- Carpentry Joints (Woodwork)Document19 pagesCarpentry Joints (Woodwork)Umesh ChakravartiNo ratings yet

- Woodwork JointsHow They Are Set Out, How Made and Where Used. by Fairham, WilliamDocument156 pagesWoodwork JointsHow They Are Set Out, How Made and Where Used. by Fairham, WilliamGutenberg.org100% (6)

- Building Layout & Foundation EssentialsDocument60 pagesBuilding Layout & Foundation EssentialsROQUENo ratings yet

- Carpentry ToolsDocument19 pagesCarpentry ToolsRitsy Pantallano100% (1)

- WS - 133. - Heavy - Duty - Workbench - Plan - PDF Filename UTF-8''WS 133. Heavy Duty Workbench Plan PDFDocument16 pagesWS - 133. - Heavy - Duty - Workbench - Plan - PDF Filename UTF-8''WS 133. Heavy Duty Workbench Plan PDFAR RmsNo ratings yet

- MP Lab ManualDocument20 pagesMP Lab ManualramkishorNo ratings yet

- Finger-Joint Metric PDFDocument2 pagesFinger-Joint Metric PDFKawit DumyNo ratings yet

- Wooden Windows: Cape CultureDocument44 pagesWooden Windows: Cape CultureSerge SalnikoffNo ratings yet

- Reading Comprehension: Tugas TOEFLDocument11 pagesReading Comprehension: Tugas TOEFLveviola fitri100% (1)

- Sedgwick TE/TESH TenonerDocument5 pagesSedgwick TE/TESH TenonerbigbangNo ratings yet

- Lining Tools Used in CarpentryDocument3 pagesLining Tools Used in Carpentryrufaida haila managilNo ratings yet