Professional Documents

Culture Documents

Top Drive Post Jarring Checks Bulletin

Uploaded by

ahmedsaid85Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Top Drive Post Jarring Checks Bulletin

Uploaded by

ahmedsaid85Copyright:

Available Formats

Product Bulletin No.

: 93-1

Rev A

Release Top Drive Drilling System

Date: May 14, 2003

Subject: Post Jarring Inspection of Top Drives

Product: Top Drive Drilling System

Affected

Assemblies: All TDS Models

Objective: To Update the Post Jarring Checklist

Problem: Jarring is a procedure that occurs on all drilling rigs. While it is not practical

to recommend that the Top Drive be removed from the string during jarring

operations, it is imperative that Top Drive users exercise care and caution

when using a Top Drive after a jarring operation.

Solution: Safe operation of the Top Drive is clearly the responsibility of the user and

the rig crew. In an effort to assist the user, we have prepared a “Post Jarring

Checklist” which was originally issued in 1993.

This checklist was prepared after considerable consultation with users, our

field service personnel and our engineering design staff. While the checklist

is our recommendation, your inspection should not be limited to this

checklist. With the advent of many new Varco Top Drive products since the

original release, it has become imperative that we update this checklist.

Our design, manufacturing and quality control procedures are designed to

provide the drilling industry with safe and reliable tools. We aggressively

pursue improvements in the design and manufacture of our equipment and

continually seek input from Top Drive users as a crucial component of that

process.

2003 Varco LP All Rights Reserved TDS-93-1

Rev A

Page 1 of 5

While we believe this Post Jarring Checklist is a useful tool, we welcome

your comments so that we may improve it over time. We have organized

this checklist by major sub-assembly. The checklist draws the inspector’s

attention to specific parts. The inspection process should be rigorous,

looking for any damage or wear that may pose a safety or operational risk.

The possibility of damage to a Top Drive during a jarring operation is

considerable. If prolonged jarring that may affect Top Drive components is

anticipated, the user should consider removing the Top Drive from the drill

string.

Please contact your local Varco Service Center or if you have any questions regarding this

product bulletin.

2003 Varco LP All Rights Reserved TDS-93-1

Rev A

Page 2 of 5

POST JARRING CHECKLIST

DESIGNATION / ITEM OK or NA COMMENTS

Elevators

Link Block Bolt Assemblies Secured _____

Hinge Pin retainer in Place _____

Latch Pin Retainer in Place _____

Pipe Handler

Guard Pin Secured _____

Bell Guide Bolts Secured (same as stabbing guide) _____

Hinge pin Retainer Bolts Inspect _____

Die Retainer Bolts Secured _____

Jaw Retaining Bolts Tight _____

Torque Wrench Mounting Bolts Secured _____

Bolts On Die Spring Covers Secured _____

Pins for Die Springs Secured _____

Lift Cylinder Pins Secured _____

Torque Cylinders/Torque Tube Secured _____

Hanger Nuts for IBOP Cylinders Secured _____

Hanger Pin for Pipe Handler/Rotating Head Secured _____

Fasteners for Stabbing Guide (PH-50/75/100) _____

Pins/Cotter Pins for Lift Cylinder Stop Tubes _____

Bolts on Torque Backup Clamp Assemblies _____

Fasteners- Clamp Clevis to Clamp Cylinder Piston

(PH-85) _____

Torque Cylinder Rod Gland Retaining Screws

(PH-85) _____

Hinge Pins/Fasteners on PH-50 Clamp Cylinder Assy _____

Clevis/Cotter Pins on Elevator Link Clamps

(PH-60/85) _____

Locking Rod on Rotating Head Locking Handle

(PH-60/85/100) _____

Outer Collar/Fasteners on PH-60 _____

Crank Pin (PH-50/75 Pipe Handlers only) _____

IBOP Actuator

Bolts for Crank Assembly Secured _____

Roller Assembly Bolts Secured _____

Actuator Arm Pins Secured _____

2003 Varco LP All Rights Reserved TDS-93-1

Rev A

Page 3 of 5

DESIGNATION / ITEM OK or NA COMMENTS

Dolly/Carriage Assembly

Bolts for Dolly Roller Brackets Secured _____

Bolts for Service Loop Clamp Bars Secured _____

Bolts for S/Pipe Clamp Secured _____

Bolts for Swivel Link Retainer Plates Secured _____

Quill Housing Trunion Cap Bolts Secured _____

Swing Bolt Pins/Nuts _____

Side Pads Secured _____

Cam Follower End Cap Fasteners (where applicable) _____

TDS-10/11HP Wear Pads _____

Cylinder Attachment Points _____

Cracks on Welded Stop Plates/Stop Brackets _____

(Retract Dollies)

Loose Fasteners on Bolted Plates/Stop Brackets _____

(Retract Dollies)

Motor Housing/Quill Assembly

Junction Box Mounting Bolts Secured _____

Inspect Junction Box Feet _____

Blower Motor Mounting Feet Bolts Secured _____

Blower Motor Fan Shroud and Rain Shield

Bolts Secured with Lockwire _____

Instrument Covers and Mounting Feet Secured

and Lock-wired _____

Accumulator Retaining Clamp Bolts Secured and

Lockwired _____

Heat Exchanger Mounting Bolts Secured _____

Counterbalance Cylinder Pins Secured _____

Counterbalance Shackles Secured _____

Motor Armature Position (TDS-3/4/5/6/8) _____

TDS Lower Gear case to Main Body _____

TDS Pressure Filter Bowl _____

Retighten Washpipe Packing Box and Holding Nut _____

Verify Shaft Liner Assembly is seated (IDS only) _____

AC Auxiliary Motor Mounting Feet/Bolts are

Secured/Not Damaged _____

Torque Arrestors

All Bolts for Solid Body Elevator Plate Secured _____

Torque Arrestors/Mounting Pins at Rotating Head

Secured _____

Bolts for Solid Body Elevator Wear Guide Secured

and Lock-wired _____

2003 Varco LP All Rights Reserved TDS-93-1

Rev A

Page 4 of 5

DESIGNATION / ITEM OK or NA COMMENTS

Link Tilt

Shackle Secured _____

Mounting Bolts Secured to Solid Body Elevator _____

Check Mounting Feet on Link Tilt Frame _____

Stop Adjustment Pins or Lock Nuts Secured _____

Pivot Pin and Cotter Pins Secured _____

Cable Assembly for Intermediate Stop _____

Link Tilt Pin (PH-50) _____

Upper/Lower Retaining Bolts (PH-85 with

Hydraulic Link Tilt) _____

Link Tilt Linkage Pins secured w/cotter pins a nd

slotted nuts(PH-50, 55, 75 & 100) _____

Link Tilt Cylinder Rod and Clevis Pins secured with

cotter pins and slotted nuts (PH-50, 55,75 & 100) _____

Link Tilt Stop Adjustment Bolt secured with

lockwire (PH-50, 55, 75 & 100) _____

Elevator Link Attachment Clamp U-Bolt Nuts Secured _____

Gear Box

Alignment Cylinder Pins Secured _____

Auto Return Cylinder Pins Secured _____

Powered Rotating Link Adapter Motor/

Shot Pin Assy Bolts Secured and Lockwired

(TDS-8/9/10/11 and PH-85 w/Hyd Rot Head) _____

Cooling System

Extended Intake Inlet Mounting Bolts _____

Remote Blower Snorkel Tube Saddle Bolts _____

Main Shaft

Check Exposed Shaft Area for Damage _____

Shaft End Play _____

Landing Collar Retainer Tabs/Bolts _____

Service Loops

Service Loop Attachment Points _____

Service Loop Supports/D-Rings _____

Service Loop Connecting Links _____

Manifold Assemblies

Solenoid Valves and Wiring Intact _____

Guide Beam Assemblies (IDS, TDS-9/10/11)

Hinge Pins Secured _____

Lower Tie Back Attachment Hardware Secured _____

2003 Varco LP All Rights Reserved TDS-93-1

Rev A

Page 5 of 5

You might also like

- FS231 Top-Drive Install&removal PDFDocument108 pagesFS231 Top-Drive Install&removal PDFJesus Oliveros50% (2)

- 3092834-Varco Bulletin On TDSDocument9 pages3092834-Varco Bulletin On TDSSushil GuptaNo ratings yet

- 7838 Brake Care and OperationDocument54 pages7838 Brake Care and OperationMarutpal Mukherjee100% (1)

- TDS-Maintenance ManualDocument51 pagesTDS-Maintenance ManualAlejandro Hernadez100% (2)

- Traveling Equipment Anti-Collision System Tac-Ii ManualDocument66 pagesTraveling Equipment Anti-Collision System Tac-Ii ManualAlex RamirezNo ratings yet

- DP TD-500-HT DR523 0051 EN Rev00 PDFDocument99 pagesDP TD-500-HT DR523 0051 EN Rev00 PDFAbderrahmane Abdo100% (1)

- Varco Tds 11sa顶驱新图2014年Document261 pagesVarco Tds 11sa顶驱新图2014年Baber824No ratings yet

- 1000012667-PIB Shot PinDocument3 pages1000012667-PIB Shot PinAdrian CantaragiuNo ratings yet

- Top Drive Course Level IDocument31 pagesTop Drive Course Level IGiezy Daniela Velasquez Hernandez100% (2)

- Lewco Direct Drive BrochureDocument4 pagesLewco Direct Drive Brochurenepotu25100% (3)

- TDS11 Training Manual PDFDocument264 pagesTDS11 Training Manual PDFNelson AlvarezNo ratings yet

- 1625 de Das 001Document7 pages1625 de Das 001Leonardo Alvarez100% (1)

- National Oilwell: Installation, Operation and Maintenance Instructions For Baylor Eddy Current Brake, Model 7838Document51 pagesNational Oilwell: Installation, Operation and Maintenance Instructions For Baylor Eddy Current Brake, Model 7838sorangel_123100% (1)

- Saturn Amphion User Manual D811001294 MAN 001Document208 pagesSaturn Amphion User Manual D811001294 MAN 001Oprea Ionut100% (2)

- Canrig TD 4 Inch Actuator ManualDocument42 pagesCanrig TD 4 Inch Actuator ManualAshrafNo ratings yet

- Maintenance Manual Varco ST 80 Roughneck 2 PDFDocument42 pagesMaintenance Manual Varco ST 80 Roughneck 2 PDFNAMRAJ SHARMANo ratings yet

- 12T1600 Mud Pump Clearance Check FormDocument1 page12T1600 Mud Pump Clearance Check FormMoataz Nazeem100% (1)

- Rotary Table ZP-375 Ó ÷Document13 pagesRotary Table ZP-375 Ó ÷Gabriel IbarraNo ratings yet

- 2 - Canrig Top Drive Rig Crew TrainingDocument104 pages2 - Canrig Top Drive Rig Crew TrainingDiego Fabian Ruiz Vacaflor89% (9)

- 7838 Manual165-31591 ManualDocument52 pages7838 Manual165-31591 ManualDaniel TostaNo ratings yet

- Cyber BaseDocument39 pagesCyber BaseayhamNo ratings yet

- Tds-11sa - Top DriveDocument64 pagesTds-11sa - Top DriveRuben Dario Conde Leon100% (1)

- 500 650 ECI 900 Top Drive PDFDocument2 pages500 650 ECI 900 Top Drive PDFHamada Shehata100% (2)

- Um199021 eDocument104 pagesUm199021 eForos IscNo ratings yet

- Baylor Elmagco Composite PDFDocument12 pagesBaylor Elmagco Composite PDFWill BuickNo ratings yet

- Varco TDS 10Document254 pagesVarco TDS 10Florin Stoica100% (3)

- M14030 - R3 - MA-RG Series Manual PDFDocument80 pagesM14030 - R3 - MA-RG Series Manual PDFAdonay Jimenez Ruiz100% (2)

- Drawworks(绞车)Document10 pagesDrawworks(绞车)Omar Fathy100% (1)

- Training Manual PDFDocument400 pagesTraining Manual PDFcarlospais2100% (3)

- JC-70D Drawworks Instruction ManualDocument59 pagesJC-70D Drawworks Instruction Manualratiinspection100% (6)

- Ezy Torq Operating ManualDocument28 pagesEzy Torq Operating ManualSyed Zain Ahmad100% (2)

- Rotary Table D-375Document15 pagesRotary Table D-375adjoudj100% (2)

- Operation Manual: Softspeed Ii-AmphionDocument28 pagesOperation Manual: Softspeed Ii-AmphionTaymoor Malek100% (1)

- User'S Manual: Bpm-Downhole MotorDocument80 pagesUser'S Manual: Bpm-Downhole MotorXueying LiNo ratings yet

- Electric House Manual: Top Drive Drilling EquipmentDocument22 pagesElectric House Manual: Top Drive Drilling EquipmentAlejandro HernadezNo ratings yet

- Drawworks Operation Manual S0100707-OPM-200 - Rev. 0Document46 pagesDrawworks Operation Manual S0100707-OPM-200 - Rev. 0Mohammad Usman100% (2)

- DG450 HOOK 大钩: Parts List 5-B)Document8 pagesDG450 HOOK 大钩: Parts List 5-B)waleed100% (1)

- Maintenance Manual - Varco ST-80 RoughneckDocument42 pagesMaintenance Manual - Varco ST-80 RoughneckCarlos Alberto Perdomo100% (2)

- Product Bulletin No.: TDS-03-16 Release Top Drive Drilling SystemDocument8 pagesProduct Bulletin No.: TDS-03-16 Release Top Drive Drilling Systemahmedsaid85No ratings yet

- HHF-1600L Drilling Pump Set Parts ListDocument21 pagesHHF-1600L Drilling Pump Set Parts ListAhmed SaeedNo ratings yet

- TDS-Hydraulic ManualDocument59 pagesTDS-Hydraulic ManualAlejandro HernadezNo ratings yet

- Varco TDS-4S Pocket GuideDocument21 pagesVarco TDS-4S Pocket GuideAdrian Cantaragiu88% (8)

- 166-31590 Manual BaylorDocument54 pages166-31590 Manual BaylorJairo Peña100% (5)

- Manual de ServicioDocument102 pagesManual de ServiciowiloNo ratings yet

- SL 450 Swivel User's ManualDocument19 pagesSL 450 Swivel User's ManualHala DawodNo ratings yet

- BAYLOR 7040 166-54238 Rev FDocument68 pagesBAYLOR 7040 166-54238 Rev FPablo Galvez Rodriguez100% (3)

- Loadcraft CatalogueDocument33 pagesLoadcraft CatalogueJuanVela100% (1)

- Vol.10 SCR MCCDocument1,083 pagesVol.10 SCR MCCSaleh TaalabNo ratings yet

- Brandt NOV Serie M PDFDocument124 pagesBrandt NOV Serie M PDFArturo suzan arvizu0% (1)

- Washpipe WPT00070 (NOV Etc.7.50 Inch Thread X 4 Tapered To 3 Inch Bore)Document12 pagesWashpipe WPT00070 (NOV Etc.7.50 Inch Thread X 4 Tapered To 3 Inch Bore)osvaldoNo ratings yet

- Top Driver Commissioning ProcedureDocument26 pagesTop Driver Commissioning Procedurejinyuan74No ratings yet

- TDS 93 1 Pib PDFDocument6 pagesTDS 93 1 Pib PDFMohamed HashemNo ratings yet

- Product Bulletin No. - TDS Top Drive Drilling SystemDocument10 pagesProduct Bulletin No. - TDS Top Drive Drilling Systemali rezaNo ratings yet

- Caja Direcciones HFB64-Manual TallerDocument58 pagesCaja Direcciones HFB64-Manual TallerJose Armando Benavides Canchala100% (1)

- HFB64 IntroDocument25 pagesHFB64 IntroJefer MenaNo ratings yet

- Enviro Seal System Rotary ValavesDocument16 pagesEnviro Seal System Rotary ValavesJhne OkNo ratings yet

- TDS 04 04 PIB 背钳扶正环Document6 pagesTDS 04 04 PIB 背钳扶正环xlzyydf2015No ratings yet

- Diesel Customer Information No. 289: Check of Valve RotationDocument12 pagesDiesel Customer Information No. 289: Check of Valve RotationmariodalNo ratings yet

- Manual DA5Document71 pagesManual DA5Edgar CanelasNo ratings yet

- Technical Manual Rotary ValveDocument8 pagesTechnical Manual Rotary ValvexichengrenNo ratings yet

- TM 120 MaintenanceDocument24 pagesTM 120 Maintenanceahmedsaid85No ratings yet

- Generac Mobile Products Manual Parts Light Towers MLT4060 80Document64 pagesGenerac Mobile Products Manual Parts Light Towers MLT4060 80ahmedsaid85No ratings yet

- CAMERON DRLG and Production Sys Quote# 21254151Document3 pagesCAMERON DRLG and Production Sys Quote# 21254151ahmedsaid85No ratings yet

- Canrig Torque GuideDocument2 pagesCanrig Torque Guideahmedsaid85No ratings yet

- AD00877M BARTON Chart Recorders Models 202E 202N 242E J8A Data Sheet PDFDocument4 pagesAD00877M BARTON Chart Recorders Models 202E 202N 242E J8A Data Sheet PDFjmcarvajal77No ratings yet

- 166-31590 Manual BaylorDocument54 pages166-31590 Manual BaylorJairo Peña100% (5)

- Product Bulletin No.: TDS-03-16 Release Top Drive Drilling SystemDocument8 pagesProduct Bulletin No.: TDS-03-16 Release Top Drive Drilling Systemahmedsaid85No ratings yet

- TDS-02-11-PIB Rev D PDFDocument5 pagesTDS-02-11-PIB Rev D PDFahmedsaid85No ratings yet

- Lincolin Weldig Transf.Document4 pagesLincolin Weldig Transf.ahmedsaid85No ratings yet

- Case Study FormatDocument2 pagesCase Study FormatMarianel Antiqueña EspinosaNo ratings yet

- STR Mpa-MpmDocument8 pagesSTR Mpa-MpmBANGGANo ratings yet

- AlgorithmicTradingNew PDFDocument15 pagesAlgorithmicTradingNew PDFSriheri DeshpandeNo ratings yet

- Global Edge Interview ExperienceDocument2 pagesGlobal Edge Interview Experienceshafi hasmaniNo ratings yet

- Driving Goods VehiclesDocument336 pagesDriving Goods VehiclesAsmawi AkhirNo ratings yet

- Guidelines in Test ConstructionDocument8 pagesGuidelines in Test ConstructionSharlene Fae Fabicon86% (7)

- Manual qf1200Document24 pagesManual qf1200Guilherme MiyashiroNo ratings yet

- NR 10 Specification 75ADocument2 pagesNR 10 Specification 75AHsalmani1991No ratings yet

- Make A Project of Calculator in Visual BasicDocument9 pagesMake A Project of Calculator in Visual BasicCHITRA MINI96% (23)

- 381Document8 pages381Nidya Wardah JuhanaNo ratings yet

- GANTREX® MK6 Rail PadDocument4 pagesGANTREX® MK6 Rail PadwickremasingheNo ratings yet

- Starter MP EecDocument21 pagesStarter MP EecIshan 96No ratings yet

- Dodge Journey 2017 - Owner's ManualDocument510 pagesDodge Journey 2017 - Owner's Manualandres camachin100% (1)

- Current Volt Meter Ina219Document40 pagesCurrent Volt Meter Ina219sas999333No ratings yet

- Lista Preturi Linhai 300 2014 PDFDocument25 pagesLista Preturi Linhai 300 2014 PDFSimonaVătafuNo ratings yet

- Braemar ApplicationDocument2 pagesBraemar Applicationjoemedia0% (1)

- Resume For FaisalDocument3 pagesResume For FaisalFaisal Zeineddine100% (1)

- Ms 95-2018 Solved AssignmentDocument15 pagesMs 95-2018 Solved AssignmentPramod ShawNo ratings yet

- SystemVerilog DPI With SystemCDocument17 pagesSystemVerilog DPI With SystemCSWAPNIL DWIVEDINo ratings yet

- cHIPSET AND CONTROLLERDocument9 pagescHIPSET AND CONTROLLERMelody MwhengwereNo ratings yet

- Mobil Pyrotec™ HFD 46Document2 pagesMobil Pyrotec™ HFD 46ABDUL REHMAN PIPRANINo ratings yet

- Split Panasonic Cspc18dkqDocument16 pagesSplit Panasonic Cspc18dkqMaria de VillalobosNo ratings yet

- BX Tuner ManualDocument4 pagesBX Tuner ManualdanielthemanNo ratings yet

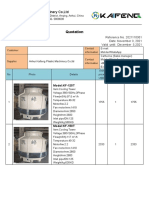

- KAIFENG Quotation For 150T Cooling TowerDocument13 pagesKAIFENG Quotation For 150T Cooling TowerEslam A. FahmyNo ratings yet

- Viola - David Tudor - The Delicate Art of FallingDocument9 pagesViola - David Tudor - The Delicate Art of FallingRobin ParmarNo ratings yet

- Physics 23 Fall 1993 Lab 2 - Adiabatic Processes: PV NRTDocument13 pagesPhysics 23 Fall 1993 Lab 2 - Adiabatic Processes: PV NRTvipul ch v v n s sNo ratings yet

- New Approach For The Measurement of Damping Properties of Materials Using The Oberst BeamDocument6 pagesNew Approach For The Measurement of Damping Properties of Materials Using The Oberst BeamMatnSambuNo ratings yet

- Xid-2025857 1Document6 pagesXid-2025857 1Thanh NguyenNo ratings yet

- Mobile Robots and Autonomous VehiclesDocument2 pagesMobile Robots and Autonomous VehiclesAbel Varghese DavidNo ratings yet

- Communication With Energy Meter and Field Devices Using PLCDocument3 pagesCommunication With Energy Meter and Field Devices Using PLCIJRASETPublicationsNo ratings yet