Professional Documents

Culture Documents

Supplier Quality System Audit Checklist

Uploaded by

rickymmarief100%(1)100% found this document useful (1 vote)

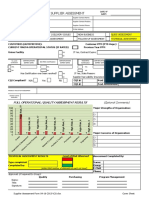

2K views5 pagesElbit Systems of America Fort Worth Operations 4700 Marine Creek Pkwy. PO Box 136969 Ft. Worth, TX 76136 Supplier Quality Engineering Fax: 817-306-6822 Email: SUPPLIER quality system AUDIT CHECKLIST General Information Vendor Name: Vendor Address: Completed by: Signature: Date: Phone Fax: products / Services Quality Key Personnel Name Title Education / Experience Previous Surveys / Approvals Company date level

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentElbit Systems of America Fort Worth Operations 4700 Marine Creek Pkwy. PO Box 136969 Ft. Worth, TX 76136 Supplier Quality Engineering Fax: 817-306-6822 Email: SUPPLIER quality system AUDIT CHECKLIST General Information Vendor Name: Vendor Address: Completed by: Signature: Date: Phone Fax: products / Services Quality Key Personnel Name Title Education / Experience Previous Surveys / Approvals Company date level

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

2K views5 pagesSupplier Quality System Audit Checklist

Uploaded by

rickymmariefElbit Systems of America Fort Worth Operations 4700 Marine Creek Pkwy. PO Box 136969 Ft. Worth, TX 76136 Supplier Quality Engineering Fax: 817-306-6822 Email: SUPPLIER quality system AUDIT CHECKLIST General Information Vendor Name: Vendor Address: Completed by: Signature: Date: Phone Fax: products / Services Quality Key Personnel Name Title Education / Experience Previous Surveys / Approvals Company date level

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

Elbit Systems of America

Fort Worth Operations Supplier Quality Engineering

4700 Marine Creek Pkwy. Fax: 817-306-6822

PO Box 136969

Ft. Worth, TX 76136 Email: SQE@elbitsystems-us.com

SUPPLIER QUALITY SYSTEM AUDIT CHECKLIST

General Information

Vendor Code: Phone Fax:

Vendor Name:

Vendor Address:

Completed by: Title: Signature: Date:

Management

Name: Title:

Products/Services

Description Description

Quality System Compliance To

ISO9001:2000 Appendix QG

AS9100 Other:

Main Customer

Customer Product/Service

Quality Key Personnel

Name Title Education/Experience

Previous Surveys/Approvals

Company Date Level Comments

CC-09-03, REV. NEW 1

Elbit Systems of America

Fort Worth Operations Supplier Quality Engineering

4700 Marine Creek Pkwy. Fax: 817-306-6822

PO Box 136969

Ft. Worth, TX 76136 Email: SQE@elbitsystems-us.com

Question Yes No NA Comments

1. Is there an up-to-date Quality Manual?

2. Are there Quality Procedures/Work Instructions?

3. Is there quality planning/program for each product/order?

4. Is there a process to assure all personnel are aware of the

procedures?

5. Do customers have access to quality management system

documentation?

6. Are the documents required by the quality management system

controlled?

7. Are documents changes coordinated with the customer?

8. Is there a procedure to define the method for controlling records?

9. Are records available for review by customers?

10. Is there a configuration management process in place? (see

ISO10007 for guidance)

11. Is there a documented quality policy?

12. Is the responsibility and authority of the quality parties defined?

13. Are there quality reviews at management level?

14. Does the management representative have the

freedom/responsibility to resolve matters pertaining to quality?

15. Is there a plan for training/certification of employees and is it

implemented?

16. Are the actual training/certifications made documented?

17. Is each new order reviewed?

18. Is each change to an order reviewed?

19. Are there development and testing procedures?

20. Are there up-to-date development planning documents?

21. Is there a requirements specification for each order?

22. Do the development documents undergo a process of review and

approval prior to their release?

23. Are Design Reviews conducted and documented?

24. Are the development products undergoing test and validation?

25. Are changes documented and approved?

26. Are key characteristics identified per design or contract

requirements?

27. Is all pertinent data that is required to allow the product to be

identified, manufactured, inspected, used and maintained defined?

(ie, drawings, part lists, specs, etc.)

28. Are docs/drawings reviewed and approved by authorized parties

prior their release?

29. Is there an up-to-date list of docs/drawings revision?

30. Are obsolete docs/drawings removed?

31. Are docs/drawings changes reviewed and approved by the same

parties who approved the original ones?

32. Is there a process of assessment/certification of new suppliers?

33. Does the process define actions to take when dealing with

suppliers that do not meet the requirements?

34. Is there a method to assure that the suppliers and their sub-tire

suppliers are using approved special process sources?

35. Is there a process of suppliers’ performance assessment?

36. Are records of the performance assessments available for review?

CC-09-03, REV. NEW 2

Elbit Systems of America

Fort Worth Operations Supplier Quality Engineering

4700 Marine Creek Pkwy. Fax: 817-306-6822

PO Box 136969

Ft. Worth, TX 76136 Email: SQE@elbitsystems-us.com

Question Yes No NA Comments

37. Is there an up-to-date list of certified suppliers (ASL)?

38. Does the function that has the responsibility for approving supplier

quality systems also have the authority to disapprove those

suppliers?

39. Are docs/drawings (specs and quality requirements) attached to

each order?

40. May the customer/representative of the customer perform

inspection at the suppliers (and sub-tiers) premises

41. Do purchase orders to your subcontractors define all processing

and testing requirements?

42. Are suppliers required to submit objective evidence of the quality

of the product (e.g., COC, test reports, etc)

43. Is there an incoming inspection activity to review the required

documentation or inspect the product upon receipt?

44. Is there a program whereby verification of the product is delegated

to the supplier?

45. Is there a mechanism for service to delivered products

46. Are process controls and control plans in place where key

characteristics have been identified?

47. Are the latest possible in-process verification points been

identified?

48. Are variable measurements taken, particularly for key

characteristics?

49. Are production and service provisions carried out under controlled

conditions? And do the controlled conditions include:

A. Accountability for all products during manufacture?

B. Evidence that all manufacturing and inspection operations

have been completed?

C. FOD prevention, detection and removed?

D. Monitoring and control of utilities and supplier such as water,

compressed air electricity and chemical product to the extent

that they affect product quality?

E. Are there clear and concise work instructions?

50. Does production documentation contain the following:

A. drawings, parts list, process flow charts, etc.

B. A list of specific or non-specific tools and numerical control

machines programs and instructions?

51. Are the persons authorized to approve changes to production

processes identified?

52. Does the supplier identify and obtain acceptance of changes that

require customer approval?

53. Are changes that affect processes, production equipment, tools

and programs documented?

54. Are the changes to production processes assessed to confirm that

the desired effect has been achieved without adversely effecting

product quality?

55. Are production equipment, tools and programs validated prior to

use?

56. Are there procedures requiring the production equipment, tools

and programs to be inspected periodically?

CC-09-03, REV. NEW 3

Elbit Systems of America

Fort Worth Operations Supplier Quality Engineering

4700 Marine Creek Pkwy. Fax: 817-306-6822

PO Box 136969

Ft. Worth, TX 76136 Email: SQE@elbitsystems-us.com

Question Yes No NA Comments

57. Are First Article inspections completed prior to production to

validate the design data/specification?

58. Where servicing is a specified requirement, does the services

operation provide for:

A. method of collecting and analyzing in-service date

B. a process for handling problems identified after delivery,

(investigating, reporting, service information.

C. control and updating technical documents

D. approval, control and use of repair schemes

E. process for off-site work, (at customer’s facility).

59. Is there a configuration management system to identify any

differences between the actual configuration and the agreed

configuration?

60. Is there a process for controlling acceptance authority media, e.g.,

stamps, electronic signatures, etc.

61. Is there a unique identification for each product unit (catalog

number/serial number)

62. Is there a Traceability report for the items in each product unit

(As Planned/As Build)

63. Are there procedure for handling customer property

64. Is there an up-to-date list of customer property

65. Is the entrance/exit from storage areas controlled

66. Is the packaging done in accordance to defined

requirements/packaging specs

67. Are delivered products accompanied by the docs required by

customer

68. Is the calibration method compliant with ISO-10012?

69. Are there instructions for calibration/maintenance for each type of

M&TE tool?

70. Is there an up-to-date list of M & TE tools and their calibration

history?

71. Is there a periodical calibration plan and is it implemented (recall)

72. Is an up-to-date calibration tag attached to each M&TE tool?

73. Is there a plan for conducting internal quality audits and is it

implemented?

74. Is an audit report submitted for each audit, including required

corrective actions?

75. Is there follow-up on open corrective actions?

76. Is there a process for monitoring and controlling identified key

characteristics?

77. Is there a process for documenting the measurement requirements

for product or service acceptance?

78. Are there sampling inspections made and according to which

standard?

79. Is there an SPC plan for processes and is it implemented

80. Is there a positive recall system for product that is released prior to

completion of all required measurement and monitoring activities?

CC-09-03, REV. NEW 4

Elbit Systems of America

Fort Worth Operations Supplier Quality Engineering

4700 Marine Creek Pkwy. Fax: 817-306-6822

PO Box 136969

Ft. Worth, TX 76136 Email: SQE@elbitsystems-us.com

Question Yes No NA Comments

81. Is measurement requirements for product/service acceptance

documented and does it include:

A. Criteria for acceptance/rejection

B. Where in the sequence measurement and test operations are

performed?

C. a record of the measurement results

D. type of measurement instruments required and use instructions

82. Do records provide evidence that the product meets the defined

requirements?

83. Does the supplier perform First Article Inspections to include the

inspection, verification and documentation of a representative item

from the first production run of a new part?

84. Does the documented procedure define the responsibility for

review and the authority for dispositioning nonconforming

product?

85. Is there a process for approving the personnel to make decisions

regarding disposition of nonconforming product?

86. Is there a process of disposition of nonconforming material, with

the participation of all involved parties (MRB board)

87. Is the customer approving nonconforming material dispositions (if

contractually required)

88. Is nonconforming material identified by "Nonconforming

Material" tag

89. Is nonconforming material passed to segregated storage (MRB)

90. Is there an up-to-date list of nonconforming material in the MRB

segregation area

91. Is there a mechanism for handling customer complaints

92. Is there a mechanism for handling nonconforming product

93. Is analysis Performed to identify root causes of problems/failures

94. Is there action initiated to prevent recurrence of problems/failures

95. Are problems/failures brought to management attention

96. Is there a process for flowing down the corrective action

requirement to a supplier when it is determined that the supplier is

responsible?

97. Is there a process for actions to be taken when timely or effective

corrective actions are not achieved?

CC-09-03, REV. NEW 5

You might also like

- Quality Audit Checklist On FabricatorDocument9 pagesQuality Audit Checklist On Fabricatorarinmerliana100% (1)

- Supplier Quality QuestionnaireDocument4 pagesSupplier Quality QuestionnairesutharitesshNo ratings yet

- Supplier Audit Checklist: Nisan Scientific Process Equipments PVT - LTDDocument6 pagesSupplier Audit Checklist: Nisan Scientific Process Equipments PVT - LTDPratik KarekarNo ratings yet

- Supplier AuditDocument14 pagesSupplier AuditJayant Kumar JhaNo ratings yet

- Supplier Audit Checklist NewDocument7 pagesSupplier Audit Checklist NewsigmasundarNo ratings yet

- Supplier Audit Check SheetDocument33 pagesSupplier Audit Check SheetMotive PostNo ratings yet

- Supplier QMS Survey and Audit ExampleDocument7 pagesSupplier QMS Survey and Audit ExampleHaleem Ur Rashid BangashNo ratings yet

- Warehouse Audit Checklist for Supplier InputsDocument2 pagesWarehouse Audit Checklist for Supplier InputsGreat TR100% (1)

- Supplier Assessment Form NewDocument49 pagesSupplier Assessment Form NewChinh Lê ĐìnhNo ratings yet

- Supplier Quality System QuestionnaireDocument9 pagesSupplier Quality System QuestionnaireSami UllahNo ratings yet

- F4E-QA-102 Supplier Audit Implementation 296E7T v2 3Document18 pagesF4E-QA-102 Supplier Audit Implementation 296E7T v2 3Jai BhandariNo ratings yet

- Supplier AuditDocument37 pagesSupplier Auditjacksodb100% (1)

- Quality checklist ensures product standardsDocument8 pagesQuality checklist ensures product standardsSenthil_KNo ratings yet

- ISO 9001-2015 Supplier Audit Checklist SAMPLEDocument2 pagesISO 9001-2015 Supplier Audit Checklist SAMPLEFaisal0% (1)

- Supplier Audit Checklist - ZftvsDocument3 pagesSupplier Audit Checklist - Zftvsaboo2uNo ratings yet

- 4100F-QAS-151 (Supplier Quality Assurance Manual)Document35 pages4100F-QAS-151 (Supplier Quality Assurance Manual)Sanjay KumarNo ratings yet

- CQI19 FormsDocument7 pagesCQI19 FormsEmre TekinNo ratings yet

- Product & Manufacturing Process Audit Checklist: Part NumberDocument6 pagesProduct & Manufacturing Process Audit Checklist: Part NumberDuy Le100% (4)

- Supplier Evaluation and Approval - Disapproval PGP2001ADocument6 pagesSupplier Evaluation and Approval - Disapproval PGP2001ASayed AbbasNo ratings yet

- PPAP-APQP Guide B45157 - Rev-ADocument29 pagesPPAP-APQP Guide B45157 - Rev-AMoti Ben-ZurNo ratings yet

- Receiving, Inspection, Acceptance Testing and Acceptance or Rejection ProcessesDocument18 pagesReceiving, Inspection, Acceptance Testing and Acceptance or Rejection ProcessesjeswinNo ratings yet

- Capa FormDocument3 pagesCapa FormZahid Nazir100% (1)

- Scar 201164448Document4 pagesScar 201164448tonierlandaNo ratings yet

- MR Process ManualDocument20 pagesMR Process ManualaskannancvNo ratings yet

- Auditor Training Content Files CombinedDocument211 pagesAuditor Training Content Files CombinedSaemundrSigfussonNo ratings yet

- Counterfeit Parts Standards and Certifications GuideDocument38 pagesCounterfeit Parts Standards and Certifications GuideVenkateswararao GantaNo ratings yet

- IQA Audit PlanDocument1 pageIQA Audit PlanSachin RamdurgNo ratings yet

- APQP Internal Assessment Checklist: ManagementDocument3 pagesAPQP Internal Assessment Checklist: ManagementKapil HarchekarNo ratings yet

- Unlocked - Supplier Audit Checklist ExampleDocument68 pagesUnlocked - Supplier Audit Checklist ExampleVi KraNo ratings yet

- Verify online supplier scorecardDocument13 pagesVerify online supplier scorecardMani Rathinam RajamaniNo ratings yet

- Supplier Audit ProcedureDocument4 pagesSupplier Audit Proceduresakshi patil100% (2)

- FAI Report FormsDocument4 pagesFAI Report FormskmalysiakNo ratings yet

- Supplier Audit ChecklistDocument20 pagesSupplier Audit ChecklistSteven Singleton100% (1)

- Supplier Quality ManualDocument24 pagesSupplier Quality Manualshobhit2310100% (1)

- Effectiveness of The QMSDocument33 pagesEffectiveness of The QMSvavvavNo ratings yet

- Supplier Audit Checklist: Explanation of Audit Value Ratings PointsDocument17 pagesSupplier Audit Checklist: Explanation of Audit Value Ratings Pointsjaxf001No ratings yet

- ISO 9001 Clause 7.5.2 Validation of Special ProcessesDocument3 pagesISO 9001 Clause 7.5.2 Validation of Special Processeseconchan100% (1)

- QMS PROCEDURE IDENTIFICATION & TRACEABILITYDocument3 pagesQMS PROCEDURE IDENTIFICATION & TRACEABILITYRainer-SlawetzkiNo ratings yet

- QMS Audit Check SheetDocument7 pagesQMS Audit Check Sheetaboo2uNo ratings yet

- Supplier Audit Check ListDocument6 pagesSupplier Audit Check ListShalinMishraNo ratings yet

- Checklists For Vendors AuditDocument7 pagesChecklists For Vendors AuditDeepak GargNo ratings yet

- Audit Checklist Process ApproachDocument7 pagesAudit Checklist Process Approachsrinivas8587100% (3)

- ISO 13485 Lead Auditor Two Page BrochureDocument2 pagesISO 13485 Lead Auditor Two Page BrochurePECBCERTIFICATIONNo ratings yet

- ISO 9001 Checklist for Quality Management SystemsDocument38 pagesISO 9001 Checklist for Quality Management SystemsZia MalikNo ratings yet

- Product Realization (Quality Control)Document16 pagesProduct Realization (Quality Control)Khaled AbdelbakiNo ratings yet

- Supplier Quality Manual PDFDocument13 pagesSupplier Quality Manual PDFSAMPATHU100% (1)

- Supplier Assessment Audit ReportDocument16 pagesSupplier Assessment Audit ReportKovacs AndreeaNo ratings yet

- Engineering Change Request Template EmptyDocument9 pagesEngineering Change Request Template EmptyNigel Lim0% (1)

- Audit Checklist For ContractorDocument1 pageAudit Checklist For ContractorMadhawa Habarakada100% (1)

- Supplier Quality ManualDocument29 pagesSupplier Quality Manualppanambo100% (2)

- ISO 13485 PurchasingDocument5 pagesISO 13485 PurchasingSubhashNo ratings yet

- 4th Edition PPAPDocument83 pages4th Edition PPAPTerri Paleno Lebow100% (1)

- Software Verification And Validation A Complete Guide - 2020 EditionFrom EverandSoftware Verification And Validation A Complete Guide - 2020 EditionNo ratings yet

- Smart Inspection Systems: Techniques and Applications of Intelligent VisionFrom EverandSmart Inspection Systems: Techniques and Applications of Intelligent VisionNo ratings yet

- ISO 13485 Quality Management System A Complete Guide - 2020 EditionFrom EverandISO 13485 Quality Management System A Complete Guide - 2020 EditionNo ratings yet

- Supplier Quality System Audit Checklist - Elbit Systems of AmericaDocument8 pagesSupplier Quality System Audit Checklist - Elbit Systems of Americaamirkhakzad498No ratings yet

- SurveyDocument4 pagesSurveyInas BawareshNo ratings yet

- VVRTS Brochure March 2008Document2 pagesVVRTS Brochure March 2008AbdelBrahmNo ratings yet

- Supplier Evaluation Questionnaire: InstructionsDocument6 pagesSupplier Evaluation Questionnaire: Instructionsutpa8080No ratings yet

- Vendor Qualification Quality Audit ChecklistDocument6 pagesVendor Qualification Quality Audit ChecklistManu aravaNo ratings yet

- How Am I Doing - The HospitalistDocument9 pagesHow Am I Doing - The HospitalistJuan pablo Lopez MuñosNo ratings yet

- ING Info Sheet (2016 - 09) 2 Harvard Analytical Framework (Ludgate)Document3 pagesING Info Sheet (2016 - 09) 2 Harvard Analytical Framework (Ludgate)Ibra MalikiNo ratings yet

- 11 September 2001Document208 pages11 September 2001keramatboy88No ratings yet

- Leave Form Rev.1Document32 pagesLeave Form Rev.1lyn dela cruzNo ratings yet

- The Dairy Industry Act: RegulationDocument5 pagesThe Dairy Industry Act: RegulationelinzolaNo ratings yet

- Administrative Law ProjectDocument30 pagesAdministrative Law ProjectRashi BakshNo ratings yet

- L9 1 Lis Read Homework 20 9Document5 pagesL9 1 Lis Read Homework 20 9Rikki RoukiNo ratings yet

- The Role of Civil Society OrganizationsDocument113 pagesThe Role of Civil Society OrganizationsGracePolendeGuzmanNo ratings yet

- St. William's Academy Bulanao, Inc. Senior High School DepartmentDocument2 pagesSt. William's Academy Bulanao, Inc. Senior High School DepartmentLyka FrancessNo ratings yet

- CAPE Communication Studies 2011 P1B (Examiner)Document3 pagesCAPE Communication Studies 2011 P1B (Examiner)brit0% (1)

- Unit 2 Association and Community PDFDocument14 pagesUnit 2 Association and Community PDFobaidulNo ratings yet

- Survey On Energy Management System: InstructionDocument7 pagesSurvey On Energy Management System: InstructionFadzilah MohamadNo ratings yet

- AAU Prospective Graduates of 2020 PDFDocument343 pagesAAU Prospective Graduates of 2020 PDFyakadimaya4388% (17)

- Gender and Social Policy in A Global Context: Shahra Razavi and Shireen HassimDocument367 pagesGender and Social Policy in A Global Context: Shahra Razavi and Shireen HassimMauro KnovaNo ratings yet

- Architectural Conservation UNIT I & IIDocument21 pagesArchitectural Conservation UNIT I & IIAnishma AyyappanNo ratings yet

- Effectiveness of Geogebra in Learning Linear FunctionsDocument6 pagesEffectiveness of Geogebra in Learning Linear FunctionsChristian Elim SoliganNo ratings yet

- B.3.b VIU Forestry SWOT Analysis 2014Document5 pagesB.3.b VIU Forestry SWOT Analysis 2014Ankitha KavyaNo ratings yet

- Crime and LawDocument7 pagesCrime and LawhezielnuezNo ratings yet

- Calls Back. Indian RTR-Radio Telephoney Restricted (A), For Part-1 (Doc-B)Document137 pagesCalls Back. Indian RTR-Radio Telephoney Restricted (A), For Part-1 (Doc-B)Gaurav Sawaai100% (8)

- Everything Secret Degenerates 2004Document139 pagesEverything Secret Degenerates 2004ChadBerginNo ratings yet

- Computer Company MEMORANDUM OF ASSOCIATIONDocument8 pagesComputer Company MEMORANDUM OF ASSOCIATIONShuja Shabbir100% (1)

- AWMUN AcceptanceDocument4 pagesAWMUN AcceptanceHuda HashiramaNo ratings yet

- EXPRESSIONISM PowerpointDocument35 pagesEXPRESSIONISM PowerpointJayzeel Castor Casaria - FarillonNo ratings yet

- Tiny Hearts (Shaminy)Document13 pagesTiny Hearts (Shaminy)Shanthana LoshiniNo ratings yet

- Student Upload Sample 1yDocument65 pagesStudent Upload Sample 1yRushabh PatelNo ratings yet

- 1.1 The Important of Technology in Everyday LifeDocument15 pages1.1 The Important of Technology in Everyday Lifeaduka_wiranaNo ratings yet

- Teachers Manual in Araling Panlipunan Grade 6Document3 pagesTeachers Manual in Araling Panlipunan Grade 6Angelica Rumbaua Guillermo56% (34)

- Notice: Adjustment Assistance Applications, Determinations, Etc.: Sherwood Forest Family GolfDocument2 pagesNotice: Adjustment Assistance Applications, Determinations, Etc.: Sherwood Forest Family GolfJustia.comNo ratings yet

- Danger Signs: Pedestrians & MotoristsDocument1 pageDanger Signs: Pedestrians & MotoristsHonolulu Star-AdvertiserNo ratings yet

- En12lit Id 26Document5 pagesEn12lit Id 26Queenie Anne Soliano55% (11)