Professional Documents

Culture Documents

O&G Response To DOT, Oct. 22, 2010

Uploaded by

estannard0 ratings0% found this document useful (0 votes)

965 views25 pagesO&G Industries' response to the DOT's request for information concerning its bid for the New Haven highway interchange project.

Original Title

O&G response to DOT, Oct. 22, 2010

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentO&G Industries' response to the DOT's request for information concerning its bid for the New Haven highway interchange project.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

965 views25 pagesO&G Response To DOT, Oct. 22, 2010

Uploaded by

estannardO&G Industries' response to the DOT's request for information concerning its bid for the New Haven highway interchange project.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 25

BRACEWELL owt fina OO

&GIULIANI Comores” wazeeatoz once

‘Seato 60.286.610 Fax

Dobal

Kacakhsten evn ocomor@ngp.com

London’

Bracewell & Gin LLP

‘Goodin Square

226 Asyan Skt

Seta 2600

Hatiord, Connection

5103,

October 22, 2010

Via Hand Delivery

Jeffrey A. Parker

Commissioner

State of Connecticut

Department of Transportation

2800 Berlin Turnpike

Newington, CT 06111

Re: Project No. 92-531/622/627; New Haven Reconstruction of 1-95/1-91/Route

34 Interchange

‘Dear Commissioner Parker:

As you are aware, our client, O&G Industries, Inc. ("0&G"), was informed on

October 14, 2010 by the State of Connecticut Department of Transportation ("DOT") that the

bid it submitted with its joint venture partner, Tutor Perini, was the low bid, by more than

$22 million, on the above-referenced project (the "Project" or "Contract", Shortly thereafter,

O&G was asked by DOT to attend a responsibility meeting on October 25, 2010 to discuss

DOT's concers about O&G's role in the Project. Just yesterday O&G was also asked to

produce a significant amount of information to DOT, As part of its response to those

requests for production, O&G respectfully submits this letter and attachmenls to address

some of DOT's concems, in particular, to set forth O&G's position regarding Conn. Gen,

Stat. § 31-57b.

Of particular noic, O&G recognizes and appreciates DOT's safety concems,

particularly after the recent explosion at the Kleen Energy Project in Middletown,

Connecticut and the resulting citations issued against O&G by the Occupational Safety and

Health Administration ("OSHA"), While O&G, as is its right, is contesting the alleged

conditions cited by OSHA, it has, consistent with its long-standing commitment to workplace

safety, fully addressed and abated the alleged conditions and, therefore, addressed any safety

concerns even though it is not yet obligated to have done so, Accordingly, as demonstrated

below, DOT cannot, pursuant to Conn, Gen, Stat. § 31-57b, preclude O&G, as low bidder,

from being awarded the Contract,

Jeffrey A. Parker

October 22, 2010

Page 2

L A CKGROUN!

A. O&G's Successful History of Working with DOT

(O8G is a local, family-owned construction firm founded in Torrington, Connecticut

in 1923. Over its 87 years of operation, it has grown fo currently employ approximately 900

people and has become a leader in its industyy, It has enjoyed a long and productive

relationship with DOT. Its work has always been of the highest quality and it has partnered

with DOT over many years to successfully complete numerous large and complex projects.

As the attached letter from retired DOT Deputy Commissioner Jim Rice demonstrates, in

many cases, O&G has stepped in to help DOT complete projects when other contractors have

defaulted. See Exhibit 1. Moreover, and perhaps most importantly, O&G has consistently

dolivered its high quality work at a price much lower than its competitors, the above-

referenced project being the latest example, which has led to millions of dollars in savings for

DOF and Connecticut taxpayers,

B, O&G's Long and Distinguished History of Promoting Workplace Safety

O&G has a long-sianding and impressive track record of dedication and commitment

to workplace safety. This is not a self-serving statement, As the attached Memorandum

signed by the leaders of 17 local unions makes abundantly clear, O&G is "a quality

contractor who shares our concer for the well-being of the union women and men the

company employs." See Exhibit 2. Indeed, it is the unanimous opinion of these union

leaders ~ all of whom have many members with extensive experience working on O&G job

sites ~ that "O&G operates a quality safety program and has worked continuously to improve

‘workplace safety at its many construction sites, plants and locations.” Id.

O&G's exemplary safety record has not only been recognized by those who work on

its projects, but by the industry ~ repeatedly — as well, Indeed, O&G has received annual

Safety Awards from the Associated General Contractors of Connecticut for 12 of the past 16

years. Moreover, O&G has, for every year since 1998, received recognition from the

Connecticut Construction Industries Association for achieving Excellence in Construction

Safety and Health,

(0&G maintains a policy of continuous improvement in its safety practices. Through

regular review of its programs, routine and frequent inspection of its worksites and perpetual

improvement of its practices in line with best practices and emerging trends, O8&G strives to

be at the foreftont of construction safety,

O&G's most senior executives communicate directly with employees about the

company's dedication to safety and the importance that the company places on the health and

Jefftey A. Parker

October 22, 2010

Page 3

‘well-being of every employee. O&G's Safety Department provides ongoing safety training

‘and instruction to all employees, including training on any changes in practices or programs

resulting from its frequent safety audits. O&G regularly gives recognition to employees and

projects that exemplify the company's commitment to safety. And, as part of its continuous

safety improvement program, O&G has regular safety mechanisms that it employs on a daily,

weekly, monthly, quarterly and annual basis, including job hazard analysis, training, site

review, safety meetings and safety plan reviews,

Every month, Safety and Human Resources personnel meet with senior executives in

each division to review any safety-related incidents, to ensure that appropriate and adequate

responses were made to each event, and to discuss and implement any program changes

necessary to enhance safety and advance the company’s focus on safety. O&G also conducts

an annual review and evaluation of its safety programs. This review culminates in an annual

safety mecting for employees with safety responsibilities, filling a hall with foremen,

superintendents, project engineers, project managers, safety professionals, support staff, and

senior management, This event reinforces O&G's philosophy of a keen focus on safety at all

of its project sites.

O&G continues to increase the tools, resources and staffing level of its Safety

Department. Outside safety consultants are being utilized to conduct additional onsite audits,

including a review of safety documentation and procedures. O&G has taken the further step

of increasing its safety capacity by cross training existing field staff. O&G utilizes an

Environmental Department for compliance purposes, and these experienced individuals

travel throughout O8&G's worksites inspecting for environmental concerns and

improvements, 4G cross trains these individuals to serve as another resource to spot safety

issues and report their findings to the Safely Department for follow up,

C, The February 7, 2010 Kleen Bnergy Explosion and O&G's Response

On February 7, 2010, an explosion occurred at the Kleen Energy Project Site in

Middletown, Connecticut, The explosion, which tragically killed six workers and injured

others, occured when vented natural gas used by a subcontractor to clean pipes was released

into an open air courtyard and ignited by an unknown souree. O&G, the general contractor,

had hired a specialized subcontractor to plan, execute and oversee the pipe cleaning process,

The subcontractor’s duties included ensuring the safety and propriety of the pipe cleaning

process, No federal workplace safety standard prohibits the use of natural gas blows to clean

pipes. Moreover, according to a June 2010 study conducted by the Chemical Safety and

Hazard investigation Board, as many as 63% of respondents from the Combined Cycle

Users' Group, a power plant industry group, utilized gas blows to clean pipes,

Jefltey A. Parker

October 22, 2010

Page 4

‘The tmgic accident of Febraery 7, 2010 represented a ue avomaly in terms of the

Kleen Energy Project Site's safety performance.’ The site safety performance prior to

February 7, 2010 was approximately 2.5 million man hours worked (total site hours) with 12

lost time injuries; this represents a lost time incident rate of .96, significantly below the

national average for the construction industry.” Since the accident, more than 761,220 man

hhours have becn logged at the site without a lost time incident,

Consistent with its track recard of dedication to workplace safety and while, as is its

right, contesting the allegations in the OSHA citations and civil suits filed against it, O&G

has nevertheless taken definitive steps to ensure that this type of event eannot occur again. Tt

cooperated fully with the investigations conducted in the Wake of the explosion by OSHA,

the Chemical Safety Board, the Workforce Protections Subcommittee of the Education and

Labor Committee of the U.S House of Representatives and the Nevas and Thomas

Commissions appointed by the Governor of Connecticut. O8&G also voluntatily prohibited

the use of natural gas blows to clean pipes at the Kleen Energy Project Site as well as at its

other worksites Jong before the Governor issued an Executive Order banning the procedure.

Notably, 026's prohibition on the use of natural ges to clean pipes also fully addresses over

three quarters ofthe alleged conditions cited by OSHA.

D. ‘The OSHA Investigation and Citations

On August 3, 2010, after a six-month investigation with which O&G fully

cooperated, OSHA issued citations in connection with inspection numbers 109179937 and

314295460 conducted at the Kleen Energy Project Site. Specifically, in connection with

inspection 314295460, OSHA issued two citations to O&G, the first of which consisted of

seven items characterized as "serious" and the second of which consisted of three items

characterized as "other." In connection with inspection 109179937, OSHA issued two

citations to O&G, the first of which consisted of fificen items characterized as "serious" and

the second of which consisted of 117 items characterized as “willful.” Of note, over three

quarters of the alleged OSHA violations arose from a subcontractor’s use of natural gas to

clean and vent pipes and their execution of that process, a process O&G has addressed by

prohibiting its future use ~ not just in Connecticut where it was subsequently prohibited by

Executive Order, but at all ofits job sites, including those outside of Connecticut,

Indeed, a week-long OSHA inspection of the Kleen Energy Project Site conducted

prior to the explosion on February 7, 2010 resulted in O&G being deemed in full compliance

‘with all safety standards and regulations.

* In 2008, the national average lost time incident rate was 1.7.

You might also like

- Lawsuit Brought by Maren Sanchez's MotherDocument17 pagesLawsuit Brought by Maren Sanchez's MotherestannardNo ratings yet

- Angela Skyers AffidavitDocument8 pagesAngela Skyers Affidavitestannard100% (1)

- White-Nose Syndrome in Bats by Chris WisniewskiDocument33 pagesWhite-Nose Syndrome in Bats by Chris WisniewskiestannardNo ratings yet

- Letter From Jack Montague's AttorneyDocument2 pagesLetter From Jack Montague's AttorneyestannardNo ratings yet

- Conley Monk v. Mabus LawsuitDocument37 pagesConley Monk v. Mabus LawsuitestannardNo ratings yet

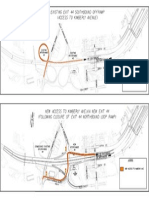

- Exit 44 NorthboundDocument1 pageExit 44 NorthboundestannardNo ratings yet

- Exit 44, SouthboundDocument1 pageExit 44, SouthboundestannardNo ratings yet

- 2014 Roadmap of State Highway Safety LawsDocument56 pages2014 Roadmap of State Highway Safety LawsestannardNo ratings yet

- Downtown Crossing Phase 2: Orange StreetDocument55 pagesDowntown Crossing Phase 2: Orange StreetestannardNo ratings yet

- Metro-North 2014 Customer Satisfaction SurveyDocument5 pagesMetro-North 2014 Customer Satisfaction SurveyestannardNo ratings yet

- Connecticut's Pearl Harbor CasualtiesDocument1 pageConnecticut's Pearl Harbor CasualtiesestannardNo ratings yet

- Sikhism in The United States ReportDocument24 pagesSikhism in The United States ReportestannardNo ratings yet

- Alternate Routes To Avoid Traffic Shift Area July 27-29Document7 pagesAlternate Routes To Avoid Traffic Shift Area July 27-29estannardNo ratings yet

- The Fix We're in For: The State of Our Nation's Bridges 2013Document8 pagesThe Fix We're in For: The State of Our Nation's Bridges 2013estannardNo ratings yet

- Detour To Sargent Drive From I-95 SouthboundDocument1 pageDetour To Sargent Drive From I-95 SouthboundestannardNo ratings yet

- Pearl Harbor Memorial Bridge LetteringDocument1 pagePearl Harbor Memorial Bridge LetteringestannardNo ratings yet

- Metro-North Accident Preliminary ReportDocument2 pagesMetro-North Accident Preliminary ReportNewsdayNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)