Professional Documents

Culture Documents

Astm A350 LF2

Uploaded by

anjangandak2932100%(1)100% found this document useful (1 vote)

4K views1 pageThe sum of copper (Cu), chromium (Cr) and molybdenum (Mo) shall not exceed 1,00%. The sum of chromium (Mo), shall not exceed 0,32% Carbon Equivalent CE = C + Mn / 6 + (Cr + Mo + V) / 5 + (Ni + cu) / 15 max 0,47 temperature degC Hot forming 1150-850 Soft annealing 700 air cooling Normalizing 880

Original Description:

Original Title

ASTM A350 LF2

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe sum of copper (Cu), chromium (Cr) and molybdenum (Mo) shall not exceed 1,00%. The sum of chromium (Mo), shall not exceed 0,32% Carbon Equivalent CE = C + Mn / 6 + (Cr + Mo + V) / 5 + (Ni + cu) / 15 max 0,47 temperature degC Hot forming 1150-850 Soft annealing 700 air cooling Normalizing 880

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

4K views1 pageAstm A350 LF2

Uploaded by

anjangandak2932The sum of copper (Cu), chromium (Cr) and molybdenum (Mo) shall not exceed 1,00%. The sum of chromium (Mo), shall not exceed 0,32% Carbon Equivalent CE = C + Mn / 6 + (Cr + Mo + V) / 5 + (Ni + cu) / 15 max 0,47 temperature degC Hot forming 1150-850 Soft annealing 700 air cooling Normalizing 880

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

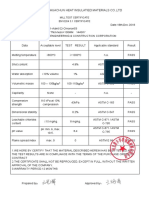

Quality ASTM A 350 LF2

According to standards ASTM A 350M – 07 Lucefin Group

Number --

Chemical composition

C% Si% Mn% P% S% Cu% Ni% Cr% Mo% V% Nb%

max max max max max max max max max

0,30 0,15-0,30 0,60-1,35 0,035 0,040 0,40 0,40 0,30 0,12 0,08 0,02

The sum of copper (Cu), chromium (Cr) and molybdenum (Mo) shall not exceed 1,00%

The sum of chromium (Cr) and molybdenum (Mo) shall not exceed 0,32%

Carbon Equivalent CE = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/ 15 max 0,47

Temperature °C

Hot forming Normalizing Quenching Tempering Stress relieving

1150-850 880-930 880-930 590 50 under the temperature of

air cooling oil / polymer water air cooling tempering

Soft Normalizing Isothermal Preheating Stress relieving

annealing and Tempering annealing welding after welding (PWHT)

700 900 air 860 furnace 200 590 furnace cooling

air cooling 600 air cooling to AC1 AC3 MS Mf

660 after, air -- -- -- --

Mechanical properties Steel Forgings

make reference the values of Forgeds Heat treatments must grant below mentioned values ASTM A 350M - 07

all dimension Testing at room temperature (longitudinal)

mm R Rp 0.2 A% C% - Z% Kv –46 °C cl. 1 Kv –18 °C cl. 2 HB

N/mm2 N/mm2 min. min. min. J average / minimum max

-- T 485-655 250 22 30 20 / 16 27 / 20 197

T= is the maximum heat-treated thickness

test specimen shall correspond to the ¼ T

Testing ( longitudinal ) LUCEFIN esperience

Heat treatments Ø product R Rp 0.2 A C-Z Kv - 46 °C Kv - 18 °C product

mm N/mm2 N/mm2 % % J J

Quenching 880 °C water 95 600 480 24.6 58.0 68-66-64 112–114-110 Hot-rolled

Tempering 640 °C air

Normalizing 900 °C air 210 580 400 32.6 64.4 22–24-18 70–74-70 Hot-rolled

Natural -- 95 526 302 28.6 62.0 6-6-4 16-10-8 Hot-rolled

EUROPE EN ITALY UNI CHINA GERMANY DIN FRANCE AFNOR U.K. B.S. RUSSIA USA AISI/SAE

S355J2G3 appr. Fe510 appr. 16Mn St52.3 N -- 50D 20G A350 LF2 cl. 1 – cl. 2

You might also like

- Astm A350 LF2 PDFDocument1 pageAstm A350 LF2 PDFAna Raquel SantosNo ratings yet

- Alloy Steel p22 PlatesDocument3 pagesAlloy Steel p22 PlatesMiguel PulidoNo ratings yet

- Asme Section Ii A-2 Sa-815 Sa-815mDocument10 pagesAsme Section Ii A-2 Sa-815 Sa-815mdavid perezNo ratings yet

- C43Document1 pageC43rudramansingh123No ratings yet

- IS 10748_2004 Compliant HR Steel Coils CertificateDocument1 pageIS 10748_2004 Compliant HR Steel Coils CertificateravigurajapuNo ratings yet

- MTC Sample Dia 36 Inch Heat 639914 4130Document2 pagesMTC Sample Dia 36 Inch Heat 639914 4130emadabdelsattarNo ratings yet

- MTC-SML (1) - 4500528257 I - Ii - Tubos GB - SCH 6MT - 210251 - 210291 - 210377Document3 pagesMTC-SML (1) - 4500528257 I - Ii - Tubos GB - SCH 6MT - 210251 - 210291 - 210377Saul Omar Fernandez RojasNo ratings yet

- Sample MTC: Material Test CertificateDocument2 pagesSample MTC: Material Test CertificateSameer KmNo ratings yet

- 1.20mm T.C - Mehta SteelsDocument1 page1.20mm T.C - Mehta SteelsRonak FireNo ratings yet

- Flange 24 InchDocument2 pagesFlange 24 InchreniNo ratings yet

- 20-2572-MTC - 2 PDFDocument1 page20-2572-MTC - 2 PDFQualityNo ratings yet

- Sau - MTC 0001-002163 - Acc.aºcºDocument24 pagesSau - MTC 0001-002163 - Acc.aºcºrosa aurora montesano somarribaNo ratings yet

- ASTM Specs FittingsDocument10 pagesASTM Specs FittingskhaireddinNo ratings yet

- 30 MM Round Bar - EN8 - MTCDocument1 page30 MM Round Bar - EN8 - MTCMohammad Adil0% (1)

- Sample MTCDocument1 pageSample MTCheavens indiaNo ratings yet

- TubacexDocument1 pageTubacexMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- 90mm 316l Peeled and PolishedDocument1 page90mm 316l Peeled and PolishedB.M Industrial WorksNo ratings yet

- WN RF Flanges SCH 40 CL 150 19Document1 pageWN RF Flanges SCH 40 CL 150 19Mohamed RaafatNo ratings yet

- 300 C SailDocument2 pages300 C Sailchandrabhushan kushwahaNo ratings yet

- 19013 MTC【CY】 PDFDocument1 page19013 MTC【CY】 PDFConstruction ProjectsNo ratings yet

- Chemical DetailsDocument3 pagesChemical Detailsemmas18No ratings yet

- How To Read STD IS 2062 (2011)Document17 pagesHow To Read STD IS 2062 (2011)AkshayNo ratings yet

- Certified Material Test Report for EN 19-T Steel ForgingsDocument4 pagesCertified Material Test Report for EN 19-T Steel ForgingsashokNo ratings yet

- 4140 Material For TubeDocument2 pages4140 Material For Tubesharafudheen_sNo ratings yet

- MTC 4500528257 Iii - 210209Document3 pagesMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNo ratings yet

- JIS Standard ValveDocument8 pagesJIS Standard ValveJong JavaNo ratings yet

- MTC 17 4PH Al20201127a174Document1 pageMTC 17 4PH Al20201127a174Ajeng PratiwiNo ratings yet

- UGINEDocument1 pageUGINEjesusNo ratings yet

- 1 7335Document5 pages1 7335stamatsNo ratings yet

- 1jsl Ltd. TPI 3 (31803) MMDocument2 pages1jsl Ltd. TPI 3 (31803) MMPratik KarekarNo ratings yet

- Hastelloy B2 Alloy B2 UNS N10665 DIN 2.4617Document3 pagesHastelloy B2 Alloy B2 UNS N10665 DIN 2.4617SamkitNo ratings yet

- Material Test Certificate: For: Priminox OverseasDocument2 pagesMaterial Test Certificate: For: Priminox OverseasDSAFNo ratings yet

- Supercito (E 42 5 B 32 h5)Document1 pageSupercito (E 42 5 B 32 h5)brunizzaNo ratings yet

- PSP TCDocument7 pagesPSP TCPSP kanpurdehatNo ratings yet

- Asme Section II A Sa-234 Sa-234mDocument10 pagesAsme Section II A Sa-234 Sa-234mAnonymous GhPzn1xNo ratings yet

- Essar MTCDocument1 pageEssar MTCGowtham Vishvakarma33% (3)

- Welding Rod For c5 & f5 - Er 80s-b6Document1 pageWelding Rod For c5 & f5 - Er 80s-b6SatyamEngNo ratings yet

- Hebei Jufeng Huachun Heat Insulatied Materials Co.,Ltd: Mill Test Certificate EN10204 3.1 CERTIFICATEDocument1 pageHebei Jufeng Huachun Heat Insulatied Materials Co.,Ltd: Mill Test Certificate EN10204 3.1 CERTIFICATEAnonymous TPoO5u8MeNo ratings yet

- TC-ST52 MSLDocument1 pageTC-ST52 MSLVijay BhureNo ratings yet

- Heat C090 SK3RQ1.5X1Document1 pageHeat C090 SK3RQ1.5X1Keshia Murillo PinnockNo ratings yet

- MTC Review ChecklistDocument5 pagesMTC Review ChecklistShaheen Andre ChikkuNo ratings yet

- A299 A299m (2001) Standard Specification For Pressure Vessel Plates, Carbon Steel, Manganese-Si PDFDocument2 pagesA299 A299m (2001) Standard Specification For Pressure Vessel Plates, Carbon Steel, Manganese-Si PDFGagan SinghNo ratings yet

- MTC Item # 02Document26 pagesMTC Item # 02ClarkFedele27No ratings yet

- M12X50 HDG GR 8.8 ISO 4017 Hex Bolt 2019HD-261Document1 pageM12X50 HDG GR 8.8 ISO 4017 Hex Bolt 2019HD-261Athul T.NNo ratings yet

- Codes RTDocument1 pageCodes RTJayeshNo ratings yet

- Astm A788Document10 pagesAstm A788Lucas Prezotto Puertas ErnandesNo ratings yet

- Perno A325 HDG 5-8 X 1 1-4 (TKR+D7042279)Document1 pagePerno A325 HDG 5-8 X 1 1-4 (TKR+D7042279)Alexander Ortiz CarrionNo ratings yet

- 622888Document1 page622888DeepakNo ratings yet

- QM-System: Certification As Per ISO 9001: (WWW - Dillinger.de/certificate)Document20 pagesQM-System: Certification As Per ISO 9001: (WWW - Dillinger.de/certificate)hemantmech099200No ratings yet

- Hollow Bar 304L Φ80ΧΦ50Document6 pagesHollow Bar 304L Φ80ΧΦ50Agoritsa100% (1)

- ISO 9001-2015 Certified Co. supplies ASME certified pipe fittingsDocument1 pageISO 9001-2015 Certified Co. supplies ASME certified pipe fittingsSACHIN PATELNo ratings yet

- ASME SA-516 Pressure Vessel Plate SpecificationDocument7 pagesASME SA-516 Pressure Vessel Plate SpecificationSTRUCPIPE CALIDAD100% (1)

- BS Uni En10204Document10 pagesBS Uni En10204Hazwan AizatNo ratings yet

- Mittal Corp Limited Test Certificate FinalDocument1 pageMittal Corp Limited Test Certificate FinalMehmet SoysalNo ratings yet

- Flange 10 & 12 InchDocument2 pagesFlange 10 & 12 InchreniNo ratings yet

- IS 4923 Chemical CompositionDocument1 pageIS 4923 Chemical CompositionTulasidas MalajiNo ratings yet

- E985F8E88F069BF1BB6F005056AC67B7Document1 pageE985F8E88F069BF1BB6F005056AC67B7Jose ReynosoNo ratings yet

- Page 1 of 1: Test Certificate No. 0000141878Document1 pagePage 1 of 1: Test Certificate No. 0000141878Vishwanathan NagarajanNo ratings yet

- Quality: Astm A 105Document1 pageQuality: Astm A 105Venkat NarasimmanNo ratings yet

- 41 CR 4Document2 pages41 CR 4Jhon ChitNo ratings yet

- Valve Glossary - Tom KirkmanDocument323 pagesValve Glossary - Tom KirkmanBogdan StanciuNo ratings yet

- RPT Pidf 30042014Document29 pagesRPT Pidf 30042014anjangandak2932No ratings yet

- Pei201509 DLDocument46 pagesPei201509 DLanjangandak2932No ratings yet

- D12 - Workpack Challenge Rev.1Document179 pagesD12 - Workpack Challenge Rev.1anjangandak2932100% (4)

- Surah Al-Kahf Arabic Text - Translation and Modern Commentary by Imran N HoseinDocument87 pagesSurah Al-Kahf Arabic Text - Translation and Modern Commentary by Imran N HoseinscparcoNo ratings yet

- Preservation NORSOK Std.Document20 pagesPreservation NORSOK Std.KARTHIGEYAN.RNo ratings yet

- Npi20160102 DLDocument20 pagesNpi20160102 DLanjangandak2932No ratings yet

- Norsok Material Data Sheet (M-630r2)Document77 pagesNorsok Material Data Sheet (M-630r2)karuna346No ratings yet

- Ogjournal20150511 DLDocument39 pagesOgjournal20150511 DLanjangandak2932No ratings yet

- Dinar & Dirham - Islam and The Future of Money - Shaikh Dr. Imran N. HoseinDocument49 pagesDinar & Dirham - Islam and The Future of Money - Shaikh Dr. Imran N. Hoseinm.suh100% (4)

- Data Sheet Width Flange BeamDocument32 pagesData Sheet Width Flange BeamIrvan IskandarNo ratings yet

- D Internet Myiemorgmy Iemms Assets Doc Alldoc Document 175 - CPD005 - Circular01 PDFDocument1 pageD Internet Myiemorgmy Iemms Assets Doc Alldoc Document 175 - CPD005 - Circular01 PDFanjangandak2932No ratings yet

- 4.2. Consumable Consumption and Welding Time 4.2.1 Calculation of Electrode ConsumptionDocument9 pages4.2. Consumable Consumption and Welding Time 4.2.1 Calculation of Electrode ConsumptionNejat Ababay50% (2)

- ARO ExPert PumpsDocument2 pagesARO ExPert Pumpsanjangandak2932No ratings yet

- OE - August 2016Document100 pagesOE - August 2016anjangandak2932No ratings yet

- Angle Bar Dimension & WeightDocument1 pageAngle Bar Dimension & Weightanjangandak2932No ratings yet

- Asian Oil and Gas-July-August 2015Document32 pagesAsian Oil and Gas-July-August 2015anjangandak2932No ratings yet

- Modern Pumping - 102015 PDFDocument62 pagesModern Pumping - 102015 PDFanjangandak2932No ratings yet

- Structures, Legalities and Perceptions of Colonial Powers and Kerajaan in Maritime Southeast AsiaDocument14 pagesStructures, Legalities and Perceptions of Colonial Powers and Kerajaan in Maritime Southeast Asiaanjangandak2932No ratings yet

- Champa MalayDocument12 pagesChampa MalaymalaystudiesNo ratings yet

- Federation in Practice PDFDocument7 pagesFederation in Practice PDFanjangandak2932No ratings yet

- Article Arch 0044-8613 1980 Num 19 1 1524Document19 pagesArticle Arch 0044-8613 1980 Num 19 1 1524anjangandak2932No ratings yet

- Amnesty International - IsraelDocument18 pagesAmnesty International - Israelsavoisien88No ratings yet

- Eunuchs and Concubines in The History of Islamic Southeast AsiaDocument12 pagesEunuchs and Concubines in The History of Islamic Southeast AsiaAmir MuhammadNo ratings yet

- Structures, Legalities and Perceptions of Colonial Powers and Kerajaan in Maritime Southeast AsiaDocument14 pagesStructures, Legalities and Perceptions of Colonial Powers and Kerajaan in Maritime Southeast Asiaanjangandak2932No ratings yet

- CR-Catalog2 FEB08 PDFDocument23 pagesCR-Catalog2 FEB08 PDFanjangandak2932No ratings yet

- Hydrotest Material f9Document4 pagesHydrotest Material f9anjangandak2932No ratings yet

- Ramadan Health GuideDocument30 pagesRamadan Health GuideISLAMICULTURE100% (2)

- Chevron, SWP Lifting Rigging GuidelinesDocument82 pagesChevron, SWP Lifting Rigging GuidelinesCarlos Alberto Zamorano PizarroNo ratings yet

- Basic Rigging Work BookDocument45 pagesBasic Rigging Work BookJohn Henry Sinurat100% (1)

- Materials SelectionDocument9 pagesMaterials SelectionZeeshan AnwarNo ratings yet

- SiteCollectionDocuments Outokumpu Stainless Steel Wall ChartDocument1 pageSiteCollectionDocuments Outokumpu Stainless Steel Wall ChartPedro PiniaNo ratings yet

- NDT of Precipitation Hardened SteelsDocument12 pagesNDT of Precipitation Hardened SteelsMahade Hasan DipuNo ratings yet

- Iron Ironcarbidediagram 161008052257Document41 pagesIron Ironcarbidediagram 161008052257Siddharth Sharma100% (1)

- SchlageDocument11 pagesSchlageapi-262447022No ratings yet

- Modern Metallic MaterialsDocument6 pagesModern Metallic MaterialsRajaganapathy GanaNo ratings yet

- Structure and hardness changes reversed through heat treatment of welded Hardox steel jointsDocument13 pagesStructure and hardness changes reversed through heat treatment of welded Hardox steel jointsPankaj KumbhareNo ratings yet

- Localized CorrosionDocument11 pagesLocalized CorrosionJack AndreasNo ratings yet

- Kim2006 Article EffectsOfHeatTreatmentOnWearReDocument11 pagesKim2006 Article EffectsOfHeatTreatmentOnWearReRicardo Andrés García LeónNo ratings yet

- HEAT TREATMENT OF TOOL STEELDocument20 pagesHEAT TREATMENT OF TOOL STEELعزت عبد المنعمNo ratings yet

- 2004 - Herring - Gear Heat TreatmentDocument6 pages2004 - Herring - Gear Heat TreatmentGustavo FagundesNo ratings yet

- 2013 Mechanismofdebismuthizingwithcalciumandmagnesium PDFDocument5 pages2013 Mechanismofdebismuthizingwithcalciumandmagnesium PDFLayos Peru HdzNo ratings yet

- Influence of Austempering and Quenching and Partitioning (Q&P) Heat Treatment On The Mechanical Properties and Wear Behavior of Aisi 9255 SteelDocument142 pagesInfluence of Austempering and Quenching and Partitioning (Q&P) Heat Treatment On The Mechanical Properties and Wear Behavior of Aisi 9255 SteeljhonNo ratings yet

- Metallurgy SyllabusDocument1 pageMetallurgy SyllabusSathrudhan ChoudharyNo ratings yet

- Heat Treat Steel to Achieve Desired MicrostructuresDocument6 pagesHeat Treat Steel to Achieve Desired MicrostructuresMahmoud AlwasifNo ratings yet

- Lvsuysl Blikr DH Iysv) Píjsa RFKK Ifùk K¡ Fof'Kf"V: HKKJRH EkudDocument17 pagesLvsuysl Blikr DH Iysv) Píjsa RFKK Ifùk K¡ Fof'Kf"V: HKKJRH EkudshamrajjNo ratings yet

- 41Cr4 ExplanationDocument9 pages41Cr4 Explanationkumar QANo ratings yet

- CHALLANDocument307 pagesCHALLANUmesh SakhareliyaNo ratings yet

- Mandal Kumar SushilDocument14 pagesMandal Kumar SushilramajssNo ratings yet

- Revised Notice For MTech Admission Form Session 2021-23Document7 pagesRevised Notice For MTech Admission Form Session 2021-23Prashant Ranjan SinghNo ratings yet

- Influence of Heat Treatment On Microstructure and Properties of Gx12Crmovnbn9-1 Cast SteelDocument6 pagesInfluence of Heat Treatment On Microstructure and Properties of Gx12Crmovnbn9-1 Cast SteelSankar GaneshNo ratings yet

- Training Plans For Colleges of Technology - Bachelor Degree PDFDocument63 pagesTraining Plans For Colleges of Technology - Bachelor Degree PDFimo7a7No ratings yet

- Effect of Tungsten in Mechanical Properties of Resuced Activation Ferriitic Martensitic SteelDocument7 pagesEffect of Tungsten in Mechanical Properties of Resuced Activation Ferriitic Martensitic SteelshouldNo ratings yet

- Tin Smelting Slag CharacteristicsDocument5 pagesTin Smelting Slag CharacteristicsJoão CoelhoNo ratings yet

- Pernos UNF UNCDocument14 pagesPernos UNF UNCEvelin MamaniNo ratings yet

- Presentation Heat Treatment-Induction HardeningDocument37 pagesPresentation Heat Treatment-Induction HardeningRizwanNo ratings yet

- Mechanism of Improved Corrosion Resistance of Type 304L Stainless Steel, Nitric Acid Grade, in Nitric Acid EnvironmentsDocument7 pagesMechanism of Improved Corrosion Resistance of Type 304L Stainless Steel, Nitric Acid Grade, in Nitric Acid EnvironmentsNaveen KumarNo ratings yet

- WSS M1P87 BXDocument6 pagesWSS M1P87 BXShu Fu100% (1)

- CH 11Document55 pagesCH 11Anuj shuklaNo ratings yet

- Ferrous Metals Lecture OverviewDocument37 pagesFerrous Metals Lecture OverviewGidNo ratings yet