Professional Documents

Culture Documents

Membrane Separation

Uploaded by

RahulrautOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Membrane Separation

Uploaded by

RahulrautCopyright:

Available Formats

ii. Separation by different in solubility and diffusive of materials.

The separation mechanism based on diffusion of the solute and solvent through the

membrane. These membranes are often in the form of composite of a homogenous film

on a microporous support as used in reverse osmosis pervaporation. Both of these

membranes has the smallest pores and allows only the solvent to pass through by

sorption-diffusion mechanism.

iii. Separation by charge.

An ion-exchange membrane separates compounds of different charges such as separation

of ions from water and non-ionic solutes. These membranes carry either fixed positive or

negative charges or separates by exclusion of ions of the same charge as carried in the

membrane phase. Ion-exchange membranes are generally used in operation like

electrodialysis and major application is as electrolytic cell separators in for example the

production of chlorine and caustic soda. Table 1 provides an overview of the various

types of membrane process.

Read more in Applied Science

« Nanotechnology

Biodiesel Recipe »

Basic Principle of Membrane Separation

The performance of a membrane can be distinct by two simple factors, flux (or product

rate) and selectivity through the membrane. Flux is defined as the permeation capacity

that refers to the quantity of fluid permeating per unit area of membrane per unit time.

Flux depends linearity on both the permeability and the driving force. The flux also

depends inversely upon the thickness of the membrane. Thinner membranes contributed

to the higher flux. Usually the water flux is measured in gallons per square foot per day

(galft-2day-1), kilogram per square meter per hour (kgm-2 hr-1) or meter cube per meter

square per day (m3m-2day-1). Membrane selectivity towards a mixture is generally

expressed by rejection. It is a measure of the relative permeation rates of different

components through the membrane. The simplest manner to express solute rejection

characteristics is defined as:

R =1 – Cp / Cf

where Cp and Cf denote concentration of permeate and concentration of feed/bulk

solution respectively, and both can be measured. Ideally a membrane with high

selectivity or rejection and with high flux is required, although it was observed that an

attempt to maximize one factor is compromised by a reduction in the other.

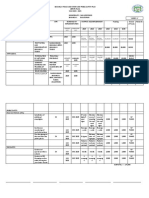

Table 1: Overview of membrane separation process, their operating principles and

applications

Membrane Method of

Driving force Application

Separati type separation

on process

Microfiltration Symmetric Hydrostatic pressure

difference, 10-500kPa

Pages: Previous page 1

2 3 Next page

You might be

interested in

Paid Distribution

Attention, Hollywood Actors:

What Your Voice-over

Commercials Say About Your

Acting Careers -- Vulture Vulture

Paid Distribution

7 Foods That Should Never

Cross Your Lips Prevention.com

Do Chicks Get Air While in

Egg? Scienceray

Dialysis: Hope for Chronic

Kidney Disease HealthMad

AGE of THE SUN Planetary

System Scienceray

How to Save Money on Tires for

Your Car A Thing for Cars

How to Save Money on Tires for

Your Car A Thing for Cars

AGE of THE SUN Planetary

System Scienceray

Dialysis: Hope for Chronic

Kidney Disease HealthMad

Do Chicks Get Air While in

Egg? Scienceray

7 Foods That Should Never

Cross Your Lips Prevention.com

Attention, Hollywood Actors:

What Your Voice-over

Commercials Say About Your

Acting Careers -- Vulture Vulture

[?]

1

Liked it

I Like It

Tags: filtration, membrane,

membrane separation,

reverse osmosis

One Response to

“Membrane Separation”

1.

essantise Says...

On August 23, 2009

at 9:29 pm

nice article! very

useful especially for

me who has a

research about

membran

emulsification with

porous and

symmetric

membrane. thanks

Post Comment

Subscribe

Search

powered

by

Custom Search Control

Web

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Extraction and Isolation of Saponins PDFDocument2 pagesExtraction and Isolation of Saponins PDFMikeNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Ted TalkDocument4 pagesTed Talkapi-550727300No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- IEC60947 3 Approved PDFDocument3 pagesIEC60947 3 Approved PDFosmpotNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- PRC 2017 Annual Report ENDocument88 pagesPRC 2017 Annual Report ENmuhammad suryadiNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- DaloDocument2 pagesDalojosua tuisawauNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Greenhouse Effect: Greenhouse Gases and Their Impact On Global WarmingDocument9 pagesGreenhouse Effect: Greenhouse Gases and Their Impact On Global WarmingrabiulNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Moot CourtDocument7 pagesMoot CourtsushmaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Two-day workshop budgetDocument2 pagesTwo-day workshop budgetVishwanath BaliNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- JDP Rainbox Attenuation CratesDocument6 pagesJDP Rainbox Attenuation CratesBerat DalyabrakNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Atlas Tool Specs SummaryDocument3 pagesAtlas Tool Specs SummaryWaleed Barakat MariaNo ratings yet

- Fetal Products AllDocument1 pageFetal Products AllIon pasterfNo ratings yet

- Lit Crit TextDocument8 pagesLit Crit TextFhe CidroNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Cholinergic DrugsDocument29 pagesCholinergic DrugsKiranNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- JP - Health and Wholeness Through The Holy CommunionDocument62 pagesJP - Health and Wholeness Through The Holy Communionjevontan90% (10)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Installation TubeeeDocument7 pagesInstallation TubeeeDini NovitrianingsihNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- ISO 9001 2008-List of Sample Audit QuestionsDocument5 pagesISO 9001 2008-List of Sample Audit QuestionsSaut Maruli Tua SamosirNo ratings yet

- Venkateshwara Institute of MedicalDocument10 pagesVenkateshwara Institute of Medicalbolhari070No ratings yet

- Q 400 SYSTEM BestDocument9 pagesQ 400 SYSTEM BestTeddy EshteNo ratings yet

- Weekly Home Learning Plan: Grade 8 - Quarter 2. Week 7Document3 pagesWeekly Home Learning Plan: Grade 8 - Quarter 2. Week 7Danmer Jude TorresNo ratings yet

- TLC Analysis of Siling Labuyo Extract ComponentsDocument3 pagesTLC Analysis of Siling Labuyo Extract ComponentsJan Eric Balete0% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Persuasive Speech On Behalf of Inspector GooleDocument4 pagesPersuasive Speech On Behalf of Inspector GooleSahanaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Fundamentals of Plant BreedingDocument190 pagesFundamentals of Plant BreedingDave SubiyantoNo ratings yet

- Barangay Peace and Order and Public Safety Plan Bpops Annex ADocument3 pagesBarangay Peace and Order and Public Safety Plan Bpops Annex AImee CorreaNo ratings yet

- Read The Following Text. A Day in The Life of Paula Radcliffe - Marathon RunnerDocument2 pagesRead The Following Text. A Day in The Life of Paula Radcliffe - Marathon RunnerAldo JimenezNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Soni Clinic & Pathology Center Chanda: Address:-Front of TVS AgencyDocument1 pageSoni Clinic & Pathology Center Chanda: Address:-Front of TVS AgencyVishalNo ratings yet

- 2016 Ruptured Pseudoaneurysm of The Middle Meningeal ArteryDocument5 pages2016 Ruptured Pseudoaneurysm of The Middle Meningeal ArteryJulio Cesar Velasco CastroNo ratings yet

- Insulation MBMA-NAIMA Acousticical Performance Guide Noise SoundDocument26 pagesInsulation MBMA-NAIMA Acousticical Performance Guide Noise SoundDianna LambertNo ratings yet

- Oxyprobe PDFDocument16 pagesOxyprobe PDFSrinivasa RNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Fuel Cell HandbookDocument352 pagesFuel Cell HandbookHamza SuljicNo ratings yet

- UK & India Health Insurance Actuarial ExamDocument4 pagesUK & India Health Insurance Actuarial ExamVignesh SrinivasanNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)