Professional Documents

Culture Documents

Orifice Discharge Lab Report

Uploaded by

JohnConorCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Orifice Discharge Lab Report

Uploaded by

JohnConorCopyright:

Available Formats

Orifice Discharge

1. Abstract

The objective of this experiment was to determine the contraction and velocity coefficients.

Calculation on the discharge coefficient will also be done.

2. Introduction

For mechanics of fluid, a fluid passing through an orifice constriction will experience a drop

in pressure across the orifice. With the time recorded for the required for the level in the

volumetric tank to rise from 10 to 20 litres and the diameter measured, the pressure drop can

then be used to calculate the flow rate of the fluid. This experiment allows us to detect the

effect of friction on water flow. In determining the performance of water through a jet and the

effect of friction on performance, the coefficient of discharge (Cd), coefficient of velocity (Cv)

and coefficient of contracta (Cc) are needed. These three coefficients allow us to understand

the effect of the friction on water flow more clearly. Each of these coefficients is a ratio of

the actual performance to ideal performance as related to discharge, velocity and contraction.

All of the three coefficients are also a measure of pressure loss. From this experiment, it is

evident that the energy loss in the system can be directly related to the difference in head

levels between ideal and actual conditions.

3. Experiment Methods and Materials

The apparatus used in the experiment include flow through orifice unit, manometers, pressure

transmitter, adjustable feet, control panel, water tank, pump, hydraulic bench, stop watch and

water.

The experiment procedures include:

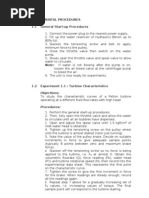

General Start-up Procedures

First, the flow through orifice unit was ensured to be placed on top of the hydraulic bench and

the equipment was ensured to be set up properly. The unit was levelled using adjustable feet.

Water was then filled into the sump tank of the hydraulic bench until approximately 90% full.

The water supply form hydraulic bench was connected to the water inlet using a flexible

hose. A flexible hose was also connected to the overflow outlet and it was made sure to be

directed into the sump tank. After that, an orifice provided was installed at the discharge

opening of the cylindrical tank which is located at the bottom of the tank. Then, the bench

flow control valve was then fully closed. The main power supply was connected and the

pump was switched on. Lastly, the flow control valve was gradually opened for inlet flow

and allows the piping and the cylindrical tank to fill with water until all air has been expelled

from the system.

Flow Through Orifice Procedures

First, the hydraulic bench was turned on and water was allowed to enter the cylindrical tank.

The flow was adjusted until the water level in the tank was just above the overflow. By using

the adjustable inlet pipe, the level of diffuser was raised until it was just below water level.

The level of diffuser was made sure to be always adjusted to meet this condition for best

results. Then, the water level (H o) in the tube connected to the bottom of the cylindrical tank

was recorded. Before that, the tube was made sure to have no bubbles. The Pitot tube was

then moved onto position directly underneath the existing water jet. The water level (Hc) in

the tube connected to the Pitot tube was recorded once equilibrium was reached. Before that,

the tube was also made sure to have no bubbles. After that, the diameter of the existing water

jet was measured using the wire by moving the wire through the water jet until it passes

completely through the water jet and is barely touching the water jet. The diameter of the

vena contracta was measured using the distance traversed by the wire. Time taken for the

water level in the tank to rise from 10L to 20L was also recorded. All the results were

recorded and tabulated.

4. Data Analysis

The specific results from the experiment allow us to determine the flow rate (Q), coefficient

of discharge (Cd), coefficient of velocity (Cv) and coefficient of contracta (Cc).

Hc Ho Time,t Vc Vo Dc Do

(m) (m) (s) (m/s) (m/s) (m) (m)

0.3479 0.3549 36.93 2.6126 2.6387 0.01128 0.012

0.3469 0.3589 30.85 2.6088 2.6535 0.01179 0.012

0.3519 0.3564 34.50 2.6275 2.6443 0.01145 0.012

Ac Ao Qc Qo Cd Cv Cc1 Cc2

(m/s) (m/s) (m3/s) (m3/s)

9.9933x10-5 1.131x10-4 2.7078x10-4 2.9844 x10-4 0.9073 0.9901 0.9164 0.8836

1.0917x10-5 1.131x10-4 3.2415x10-4 3.0011x10-4 1.0801 0.9832 1.0986 0.9653

1.0297x10-4 1.131x10-4 2.8986x10-4 2.9907 x10-4 0.9692 0.9936 0.9754 0.9104

5. Discussion

Calculations are done based on the formulas below:

V 2 gH

Qo = Vo x Orifice Area

V

QC

1000 t

QC

CD

QO

V

CV C

VO

C

CC1 D

CV

AC DC2

CC 2

AO DO2

You might also like

- Lab Report Flow Through Venturi Tube and Orifice PlateDocument17 pagesLab Report Flow Through Venturi Tube and Orifice PlateAnis ThuraiyaNo ratings yet

- Experiment 3Document3 pagesExperiment 3MaisarahNo ratings yet

- Calculating water pressure and turbine selectionDocument7 pagesCalculating water pressure and turbine selectionMaulidNo ratings yet

- Flow Demonstration ExperimentDocument5 pagesFlow Demonstration ExperimentVictoria SooknananNo ratings yet

- Venturimeter and Orifice MeterDocument5 pagesVenturimeter and Orifice MeterVrushiket Patil100% (1)

- Flow Through an Orifice - Calculating Discharge, Velocity & Contraction CoefficientsDocument6 pagesFlow Through an Orifice - Calculating Discharge, Velocity & Contraction Coefficientshozipek559950% (2)

- ME 315 - Heat Transfer Laboratory Experiment No. 5 Pool Boiling in A Saturated LiquidDocument10 pagesME 315 - Heat Transfer Laboratory Experiment No. 5 Pool Boiling in A Saturated LiquidAswith R ShenoyNo ratings yet

- Hydrostatic forces on immersed plane surfacesDocument9 pagesHydrostatic forces on immersed plane surfacesEssam Ahmed Abd MeguidNo ratings yet

- L 31Document12 pagesL 31RadhaAnanthalekshmiNo ratings yet

- Orifice and Free Jet Flow I. Objective: Experiment No. 6Document12 pagesOrifice and Free Jet Flow I. Objective: Experiment No. 6hgfhfghfghgNo ratings yet

- Experiment 4 Head Losses in PipesDocument5 pagesExperiment 4 Head Losses in PipesChristine Anne LatayanNo ratings yet

- 5 Calibration of Triangular NotchDocument8 pages5 Calibration of Triangular Notchkanavan monNo ratings yet

- CH 3510: Mechanical Operations Lab: B Narasimhan: CH11B043 Naveenraaj K.P: CH11B044 Raghuveer P: CH11B045Document7 pagesCH 3510: Mechanical Operations Lab: B Narasimhan: CH11B043 Naveenraaj K.P: CH11B044 Raghuveer P: CH11B045aravind1997muraliNo ratings yet

- Fluid Mechanics Lab ReportDocument14 pagesFluid Mechanics Lab ReportEdwin Jesu DassNo ratings yet

- Fluid Mechanics Lab Experiment 2Document8 pagesFluid Mechanics Lab Experiment 2SSShakeelNo ratings yet

- Impact of JetDocument5 pagesImpact of Jetميسرة33% (3)

- Energy Losses in Pipes: Experiment # 4Document4 pagesEnergy Losses in Pipes: Experiment # 4محمد جوادNo ratings yet

- Dimensional Analysis Guide for Fluid MechanicsDocument19 pagesDimensional Analysis Guide for Fluid MechanicsnethmiNo ratings yet

- Lab Report 2Document16 pagesLab Report 2Limmy Yingran0% (1)

- Calibration of VenturimeterDocument2 pagesCalibration of VenturimeterAhmedElsayedNo ratings yet

- Fluid Mechanic Lab ManualDocument15 pagesFluid Mechanic Lab ManualAltamash NadimallaNo ratings yet

- LabDocument6 pagesLabamyNo ratings yet

- Orifice and Free Jet Flow: University of NebraskaDocument8 pagesOrifice and Free Jet Flow: University of NebraskaJemuel Flores100% (1)

- CE 2020 - Fluid Mechanics LaboratoryDocument67 pagesCE 2020 - Fluid Mechanics LaboratoryMd.Tarequl IslamNo ratings yet

- Experiment No.10: Introduction of Kneader MixerDocument4 pagesExperiment No.10: Introduction of Kneader MixerUsama0% (1)

- Calibrating a Venturi MeterDocument10 pagesCalibrating a Venturi MeterAgyeman EmmanuelNo ratings yet

- CE142P Exercise No. 02Document2 pagesCE142P Exercise No. 02streetranpuNo ratings yet

- H1 Report - Flow Through OrificeDocument11 pagesH1 Report - Flow Through OrificeNasrulNo ratings yet

- Appreciation: Fluid Friction TestDocument10 pagesAppreciation: Fluid Friction TestLuqman Yusof100% (1)

- Theory VenturiDocument7 pagesTheory VenturiMahendranath RamakrishnanNo ratings yet

- Calibration of VenturimeterDocument5 pagesCalibration of VenturimeterRahul KumarNo ratings yet

- Lab 7Document18 pagesLab 7coopere23100% (1)

- Impact of A Water JetDocument5 pagesImpact of A Water JetAnirban SardarNo ratings yet

- Level HE6: RAS AL Khaimah CampusDocument6 pagesLevel HE6: RAS AL Khaimah CampusUmer RaufNo ratings yet

- eXPERIMENT NO 06 FMDocument9 pageseXPERIMENT NO 06 FMAsim Bajwa100% (1)

- Bernoulli's TheoremDocument5 pagesBernoulli's TheoremVrushiket PatilNo ratings yet

- Guided Lab MPE Laboratory Sheet For Fluid Mechanics: 1.0 TitleDocument7 pagesGuided Lab MPE Laboratory Sheet For Fluid Mechanics: 1.0 TitleCharles BongNo ratings yet

- Flow Through A Pipe Orifice Meter LabDocument8 pagesFlow Through A Pipe Orifice Meter LabHenDricky MagosiNo ratings yet

- Calibrate V-Notch Weir for Fluid Mechanics LabDocument2 pagesCalibrate V-Notch Weir for Fluid Mechanics LabRahul Kumar0% (1)

- Pelton Turbine CharacteristicsDocument10 pagesPelton Turbine CharacteristicsViknesh MjNo ratings yet

- Flow Over A Broad-Crested Weir in Subcritical Flow Conditions, Physical StudyDocument6 pagesFlow Over A Broad-Crested Weir in Subcritical Flow Conditions, Physical Studyho_afsharNo ratings yet

- Lab7-Phelton Turbine Experiment-UpdatedDocument7 pagesLab7-Phelton Turbine Experiment-Updatedtomtoms92No ratings yet

- Shell and Tube Heat Exchanger PerformanceDocument28 pagesShell and Tube Heat Exchanger PerformanceAmoluck BhatiaNo ratings yet

- Hydraulic Laboratory Civil Engineering Department Sultan Azlan Shah Polytechnic Experiment: 2 Title: Impact of Jet TestDocument8 pagesHydraulic Laboratory Civil Engineering Department Sultan Azlan Shah Polytechnic Experiment: 2 Title: Impact of Jet TestAzrol Azmir Long100% (3)

- Impact of JetDocument7 pagesImpact of JetHeng Xiu KohNo ratings yet

- SEO Flow Weirs Lab ReportDocument20 pagesSEO Flow Weirs Lab ReportGua HantuNo ratings yet

- LAB REPORT - Discharge Over WeirsDocument9 pagesLAB REPORT - Discharge Over WeirsLuli LolNo ratings yet

- Tutorial PE104Document7 pagesTutorial PE104aquabeefmanNo ratings yet

- Venturi MeterDocument15 pagesVenturi MeterFatimah BadruddinNo ratings yet

- PPSDocument94 pagesPPSaamirNo ratings yet

- Bernoullis Equation Lab ReportDocument12 pagesBernoullis Equation Lab ReportgeduyoxNo ratings yet

- Pitot Tube Lab ManualDocument7 pagesPitot Tube Lab ManualUmAr Malick50% (2)

- OrificeDocument7 pagesOrificePrasillaPrisiNo ratings yet

- Performance Test of A Hydraulic Turbine Mid Term 2Document8 pagesPerformance Test of A Hydraulic Turbine Mid Term 2jethro ganeloNo ratings yet

- Flow of Water by Notch and WeirsDocument17 pagesFlow of Water by Notch and WeirsMuhammad Zulhusni Che RazaliNo ratings yet

- Gas Diffusion ExperimentDocument18 pagesGas Diffusion ExperimentMuhammad NasrulNo ratings yet

- Flow Over WeirsDocument22 pagesFlow Over WeirsNurfayyadhahtul Syafawani100% (1)

- Orifice DischargeDocument12 pagesOrifice Dischargehammada1001100% (3)

- Masinde Muliro University of Science and TechnologyDocument51 pagesMasinde Muliro University of Science and TechnologyKelvho GitongaNo ratings yet

- Flow of Water by Notch and WeirsDocument15 pagesFlow of Water by Notch and WeirsCik Tiem Ngagiman93% (29)

- Extraction of Benzoic Acid Lab ReportDocument5 pagesExtraction of Benzoic Acid Lab ReportJohnConor80% (5)

- Bernoilli's Principle Lab ReoprtDocument2 pagesBernoilli's Principle Lab ReoprtJohnConor100% (2)

- Phase Diagram of A Ternary System Lab ReportDocument3 pagesPhase Diagram of A Ternary System Lab ReportJohnConor89% (9)

- Impact of A Jet Lab ReportDocument3 pagesImpact of A Jet Lab ReportJohnConor86% (83)

- Heat Exchanger Lab ReportDocument5 pagesHeat Exchanger Lab ReportJohnConor92% (72)

- Marcet Boiler Lab ReportDocument4 pagesMarcet Boiler Lab ReportJohnConor98% (40)

- Heat Conduction Lab ReportDocument3 pagesHeat Conduction Lab ReportJohnConor96% (23)

- PLX118FDocument4 pagesPLX118FSoPhiakNo ratings yet

- Assistive Technology For People With Disabilities 2nd EditionDocument52 pagesAssistive Technology For People With Disabilities 2nd Editionmatthew.grasso983100% (41)

- Cobit 5 ChecklistDocument21 pagesCobit 5 Checklist8octavociclo100% (1)

- RC Olivia Liem 2023Document74 pagesRC Olivia Liem 2023Mustika NSNo ratings yet

- PA10 0389 Technical Manual 911 GT3 Cup 991 MY 2019 V8 enDocument491 pagesPA10 0389 Technical Manual 911 GT3 Cup 991 MY 2019 V8 enjlee_296737No ratings yet

- Catalog Tecumseh CompresoresDocument10 pagesCatalog Tecumseh Compresorescesardsc1No ratings yet

- AU 9 Consideration of ICDocument11 pagesAU 9 Consideration of ICJb MejiaNo ratings yet

- 800-25992 HVMV Um PDFDocument70 pages800-25992 HVMV Um PDFHuanNo ratings yet

- YugaByte Fundamentals DBA Certification GuideDocument8 pagesYugaByte Fundamentals DBA Certification GuidemullerafNo ratings yet

- CAT - C7 (All Others) .Prefix LBM, NPH, WAX, or SAPDocument9 pagesCAT - C7 (All Others) .Prefix LBM, NPH, WAX, or SAPPhil B.No ratings yet

- Design and Fanrication of Tricycle For HandicappedDocument4 pagesDesign and Fanrication of Tricycle For HandicappedshilpaNo ratings yet

- Ws 604Document21 pagesWs 604Enoc Alexander Gelabert CornielleNo ratings yet

- Certification of teachers at A. Mabini Elementary SchoolDocument40 pagesCertification of teachers at A. Mabini Elementary SchoolTchr VhinzNo ratings yet

- LPP in 1 Shot PDFDocument36 pagesLPP in 1 Shot PDFSam RockxNo ratings yet

- Breslmairbrass 2018Document30 pagesBreslmairbrass 2018Alisson MedeirosNo ratings yet

- U-WAVEPAK User's Manual (English) PDFDocument144 pagesU-WAVEPAK User's Manual (English) PDFSeanRojasNo ratings yet

- 7th Sem Reports' FormatsDocument2 pages7th Sem Reports' FormatsAnimesh Kumar JhaNo ratings yet

- Mixing in The Oil and Gas Industry PDFDocument12 pagesMixing in The Oil and Gas Industry PDFGilles DakouriNo ratings yet

- Guideline 0.2 Commissioning Process For Existing Systems and Assemblies 2015Document80 pagesGuideline 0.2 Commissioning Process For Existing Systems and Assemblies 2015Abd Alhadi100% (2)

- Abacus Software CommandsDocument20 pagesAbacus Software CommandsMohammad Shipan SattarNo ratings yet

- Using Matlab Sisotool 2016 - Part 2Document12 pagesUsing Matlab Sisotool 2016 - Part 2kiko zotroNo ratings yet

- Flow Sharing Control Block in Mono Block / Sandwich Plate Design M6-22Document18 pagesFlow Sharing Control Block in Mono Block / Sandwich Plate Design M6-22andrerocha7No ratings yet

- Flock Color Scheme Worksheets - 1Document5 pagesFlock Color Scheme Worksheets - 1Olivia GogasNo ratings yet

- MIQ Typical Applications 09 2015Document40 pagesMIQ Typical Applications 09 2015Miguel CamargoNo ratings yet

- Synthesize of Design of Inertial Navigation System (INS) Using MEMS SensorDocument76 pagesSynthesize of Design of Inertial Navigation System (INS) Using MEMS SensorYosha AlassadNo ratings yet

- SOP For Talent AcquisitionDocument2 pagesSOP For Talent AcquisitionRamesh KumarNo ratings yet

- Manual de Instalare Sirena Incendiu de Exterior Autonoma Cu Lampa Signal PS 128F 118 DB IP34Document2 pagesManual de Instalare Sirena Incendiu de Exterior Autonoma Cu Lampa Signal PS 128F 118 DB IP34Luiza OcheanaNo ratings yet

- 1 s2.0 S1574013721000186 MainDocument13 pages1 s2.0 S1574013721000186 MainThanmai MuvvaNo ratings yet

- Sheet1: Username User Clatite Marte Numere Robo Mihai Rumbal Pepeni Premiu Oltenesc Caracatita Doubledrop Lanturi GlobalDocument9 pagesSheet1: Username User Clatite Marte Numere Robo Mihai Rumbal Pepeni Premiu Oltenesc Caracatita Doubledrop Lanturi GlobalMihaela MihaiNo ratings yet

- How To Get Free Scampage Letter For SpammingDocument63 pagesHow To Get Free Scampage Letter For SpammingMicheal Newton100% (1)