Professional Documents

Culture Documents

Detail Castor Derivatives 05

Uploaded by

mailtobhavenOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Detail Castor Derivatives 05

Uploaded by

mailtobhavenCopyright:

Available Formats

Project Profile on Castor Oil Derivatives Perfumery Raw Materials

Mott MacDonald iNDEXTb

Sector Sub - sector Project No. Project Title

Agro and Food Processing Agro Processing AF-05 Castor Oil Derivatives Perfumery Raw materials

Project Description

The proposed project envisages setting up of a Castor oil derivatives unit to manufacture perfumery raw materials viz Undecylenic acid and Heptaldehyde by Pyrolytic decomposition of Castor oil. Product Applications The basic derivatives, Heptaldehyde and Undecylenic acid are used to manufacture various perfumery compounds, which in turn are used to manufacture perfumes and synthetic flavors.

Sr. No. 1

Perfumery Chemical Heptaldehyde

Perfumery Compounds prepared Alpha-amyl Cinnamic aldehydes Nonylenic acid esters to make 8-n-amylbutyrolactone Heptanoic acid Methyl-n-heptyl ketone and ester of 3-noninic acid Heptaldehyde

End use of Perfumery compound In soap perfumery Coconut aldehyde for flavor of coconut milk Verts de Violette Oil of Rue used in violet perfume Jasmine Flavor Peach odor Rose and Orange oil constituents Floral odor with fatty note Spicy Orange like odor Odor of quinches and as modifier

Undecylenic acid

Gamma Undecalactone also known as Aldehyde- C-14 Nonylic acid , Nonylic alcohol and nonylic aldehydes Undecylenic alcohol n-decylaldehyde Allyl esters of Undecylenic acid

Market and Growth Drivers

Market India is one of the leading manufacturers of Flavors and fragrances in the world. These all are natural products, but in developing synthetic flavors and fragrances from castor oil derivatives, India is lagging behind. India, being a world leader in Castor seeds and Castor oil production and processing has edge over other countries like Japan, France and Germany who are importing castor oil and manufacturing these perfumery chemicals for further processing into perfumes and Synthetic flavors.

Internationally, Germany, France, Switzerland and Japan are the leading producers of synthetic flavors and fragrances from many natural ingredients, including castor oil derivatives like Undecylenic

AF-05

Project Profile on Castor Oil Derivatives Perfumery Raw Materials

Mott MacDonald iNDEXTb

acid and Heptaldehyde. Though, there is large international market for perfumery chemicals, estimated market in India is approx. 5000 MT. The Global Demand of Flavors and Fragrances is set to increase. The following figure gives the region wise Demand Break up of Flavors and Fragrance market, estimated for the year 2008.

Global Demand of Flavors and Fragrances in 2008

Other Regions 16% Western Europe 29%

Asia/Pacific 27%

North America 28%

Source: FAO statistics

Growth Drivers

The Global Demand of flavors and fragrance is estimated to increase at a growth rate of around 4% per annum. Moreover, the demand for flavors and fragrances in the Asia/Pacific region is estimated to be growing at a rate of about 7% per annum through 2008. Growth in the worlds most developed markets will continue to be moderate, restrained by market maturity, consolidation in flavors and fragrances using industries and strong downward pressure on prices.

Flavor and fragrance is looking for products from natural sources and prefer to use rawmaterials which are harmless and bio-degradable. In the light of this fact, there is good scope for castor oil derivatives in the global market.

Demand for fragrance blends and essential oils will benefit from increased interest in natural and exotic aromas, which are more expensive than their synthetic counterparts. Trade statistics

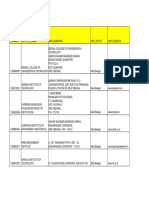

Sr. No 1

Product Heptaldehyde

Years 2002-03 2003-04 2004-05 2005-06

Export Quantity (MT) 112 130.01 210.57 183.74 372.66 385.02 257.96 365.91

Import Quantity (MT) N.A 0.68 10.44 N.A 768.18 1042.98 695.72 N.A

Undecylenic acid 2002-03 2003-04 2004-05 2005-06

Source: Department of Commerce, GOI

AF-05

Project Profile on Castor Oil Derivatives Perfumery Raw Materials

Mott MacDonald iNDEXTb

Why Gujarat?

Gujarat is the largest producer of Castor seed and estimated production is 5.71 Lac tons in the year 2005-06. These Castor seeds are processed in Gujarat itself to produce approx 2.57 Lac MT of castor oil of various grades. Thus, Gujarat is also largest processor and exporter of Castor oil from India. Gujarat has a well developed chemical industry base, which can offer ready availability of technical and commercial manpower.

Technology / Process

Castor oil, when subjected to pyrolysis or destructive distillation at temperature of over 450 C under vacuum, under goes decomposition to yield mainly Undecylenic acid and Heptaldehyde, in roughly equal quantities ( 28% approx). The presence of water vapor has been found to enhance the yields of both acid and aldehyde. The spongy mass left behind, consisting principally of polymerized Undecylenic acid, which can be used in recovering of some quantity of Undecylenic acid. Esters of Undecylenic acid are used as input for perfumery chemicals. Heptaldehyde is having characteristic Jasmine flavor in it and typically it is also known as Jasmine aldehyde, and it can be converted to Heptanoic acid and Heptanol which are used in manufacture of many perfumery compounds. Specifications for Proposed Perfumery Chemicals Sr.No. 1 2 3 4 5 6 7 8 9 Specification Details Appearance Description Color Acid content Max % Aldehyde content. Min % Refractive index at 25 C Freezing point, C Acid value Specific gravity Boiling point, C

o o

Heptaldehyde Pungent smelling Oily liquid Colorless to pale yellow 5 90-95 1.415 N.A. N.A. 0.815 152-154

Undecylenic Acid Oily liquid Water white to pale yellow 90-95 % minimum 3 to 5 % maximum 1.4880 21-24 295-304 0.92 N.A

AF-05

Project Profile on Castor Oil Derivatives Perfumery Raw Materials Heptaldehyde and Undecylenic acid Process flow sheet

Mott MacDonald iNDEXTb

Commercial oil storage Tank

Cracking Vessels

84% Crude Residue

16% Heptaldehyde (97% Purity)

Saponification Vessels Acidification Reactor-R2 Re-distillation

Driers Storage Tanks of Crude Fatty acid Heptaldehyde (99 %+)

Technology sources: 1. Indian Institute of Chemical Technology- Hyderabad 2. Jepro Engineering- Mumbai

Raw material requirement

Castor oil 5000 MT/annum (first special grade). Gujarat has assured and continuous supply of castor seeds. The production trend for the same is as follows: Area, Production and Yield Castor seeds in Gujarat Sr. 1 2 3 4 5 Year 2000-01 2001-02 2002-03 2003-04 2004-05 Area (00 Hectares) 4586 3047 2422 2903 3305 Production (00 MT) 6388 4651 2831 5411 5648 Yield, Kg. / Hectare 1393 1527 1168 1864 1709

Source: Department of Agriculture Statistics, Gandhinagar, Government of Gujarat

AF-05

Project Profile on Castor Oil Derivatives Perfumery Raw Materials

Mott MacDonald iNDEXTb

Suggested Plant Capacity and Project Cost

Looking to the market size and financial out go, a medium size project with 1500 MT per annum finished product capacity is suggested to start with. Once the process and quality parameters are set, the capacity can be expanded further looking to the demand of end use segments. The estimated project cost of the proposed project is INR 30 million (US $ 0.67 million) Cost of Project and Means of Finance Sr. No. 1 2 3 4 5 6 7 Particulars Land and Land development Building & Civil works Plant & Machinery 10 MT/day Misc./ Other Fixed Assets Preliminary & Pre-operative Provision for contingencies Total Fixed Assets Margin Money for working capital Estimated Block Capital Cost of Project Means of Finance 8 9 Promoters contribution Term loan Total Means of Finance 11.57 23.43 35.00 INR in million 3.50 6.00 10.00 2.00 1.50 1.50 24.50 10.50 35.00

As indicated above, the proposed project will require an approx 5000 sq. mt of land with an proposed built up area of 2000 sq. mt. Considering 150 working days in a year the unit is proposed to have an installed capacity of 1500 TPA. The total fixed cost of the project is estimated at INR 24.50 million and INR 10.50 million is the working capital margin which adds up to a capital cost of INR 35 million. The unit is being proposed to cater to domestic as well as International demand and is suggested to have a Debt equity ratio of 2:1. Thus, the estimated term loan amounts to INR 23.43 million and Equity at INR 11.57 million.

Plant and machinery

The list of main plant and machineries required for Castor oil derivatives proposed in this project is summarized in following table: List of Plant and Machinery Sr. No 1

Particular Cracking unit with column (MS), condenser (MS), receiver (MS) with electrical heating

Quantity

Supplier

Troika Process Pvt Ltd. Mumbai / Jepro Engineering Pvt. Ltd, Mumbai

AF-05

Project Profile on Castor Oil Derivatives Perfumery Raw Materials Sr. No 2 3 4 5 6 7 8

Mott MacDonald iNDEXTb

Particular Castor oil (raw material) tanks Acidification tank (SS) Saponification tank (SS) Caustic tank (MS) H2SO4 tank (SS) Dryer (PVC) Storage tanks of crude fatty acid (PVC)

Quantity 4 2 2 1 1 1 1

Supplier Sterling Equipments Pvt. Ltd.- Pune Sterling Equipments Pvt. Ltd.- Pune Mag-Tech Engineers - Ghaziabad Mag-Tech Engineers - Ghaziabad Sterling Equipments Pvt. Ltd.- Pune Proton Engineering Works- Mumbai Elixir Engineering Private Limited Mumbai

Utilities required

The proposed unit will necessitate 90 KVA LT power. A man power of 10 will be required for the proposed project.

Suggested Location

Suggested location for the proposed project is Kutchh, and districts of North and Central Gujarat.

Project Time Line

The proposed project will have project timeline of 6 to 8 months in obtaining necessary clearances from concerned authorities and a project implementation period of 10 to 12 months.

Financial Indicators

Based on the profitability projections worked out for the proposed project, key financial indicators are as summarized below: Key Financial Indicators Sr. No. A B C D E Financial Ratios Break-Even Point in % capacity Debt-service Coverage Ratio Average DSCR Return on Investment (ROI) IRR 21.76 1 year 33.56 1.71

st

nd

year 31.75 2.14 2.17 26.66 40%

3 year 30.00 2.66

rd

31.58

The proposed project will have an indicative IRR of approx 40% considering initial 10 years operation. Proposed Debt equity ratio is 2:1.

AF-05

Project Profile on Castor Oil Derivatives Perfumery Raw Materials

Mott MacDonald iNDEXTb

Clearances Required

The proposed unit will have to register itself with Secretariat of Industrial Approvals (SIA), Ministry of Industries and Government of India, by filing Industrial Entrepreneurs Memorandum (IEM), as it will have plant and machinery investment of more than INR 10 million. The major perfumery chemical market is in advanced countries like USA, Canada, Europe, Japan and CIS countries. The unit will be required to get its product registered with Food and Drugs Administration (FDA) in these countries, apart from registration with Indian and state Drugs control authorities as cosmetics ingredient. The unit will get EOU registration from RBI, DGFT and with CHEMEXCIL as registered manufacturer exporter to avail export incentives.

Agencies to be contacted

Industrial Extension Bureau Gujarat Agro Industries Corporation Mott MacDonald India

AF-05

You might also like

- Vegetable Oil Refinary Project ReportDocument9 pagesVegetable Oil Refinary Project ReportAkhilesh KumarNo ratings yet

- Castor Oil Report Preview EbookDocument31 pagesCastor Oil Report Preview EbookMega BuanaNo ratings yet

- Animal FeedstockDocument21 pagesAnimal Feedstockaimi wahabNo ratings yet

- Declaration: Liquid Detergent Production From Castor SeedDocument117 pagesDeclaration: Liquid Detergent Production From Castor SeedZemariyam BizuayehuNo ratings yet

- Analysis of Humic Acid (Final Version)Document13 pagesAnalysis of Humic Acid (Final Version)rafiqqaisNo ratings yet

- Castor Oil Report Preview EbookDocument30 pagesCastor Oil Report Preview EbookBolly Dou100% (1)

- Groundnutdpr 04.08.23Document17 pagesGroundnutdpr 04.08.23TNRTP SALEMNo ratings yet

- 2313 Castor Seed Outlook 2013 04 08Document15 pages2313 Castor Seed Outlook 2013 04 08Jose Jeronimo VelezNo ratings yet

- Edible Oil GheeDocument25 pagesEdible Oil GheeLTE00233% (3)

- Project Report On Natural Oil Based Soaps & Shampoos (Bars and Liquids) Made by Cold Process SaponificationDocument5 pagesProject Report On Natural Oil Based Soaps & Shampoos (Bars and Liquids) Made by Cold Process SaponificationEIRI Board of Consultants and PublishersNo ratings yet

- Cold Press Oil UploadDocument8 pagesCold Press Oil UploadVikrantNo ratings yet

- Present Scenario of Indian Soap IndustryDocument8 pagesPresent Scenario of Indian Soap IndustryBUILDUNGSROMAN75% (4)

- Soap NoodlesDocument3 pagesSoap Noodlessundhar100% (1)

- CastorOil Diverse Business PotentialDocument16 pagesCastorOil Diverse Business Potentialarunesh_clix100% (1)

- Activation of Spent Bleaching Earth For Dehumidification ApplicationDocument8 pagesActivation of Spent Bleaching Earth For Dehumidification ApplicationWorld-Academic JournalNo ratings yet

- Guideline For Establishment of Lube Plant and Application FormDocument11 pagesGuideline For Establishment of Lube Plant and Application FormEmmanuel OguaforNo ratings yet

- Edible Oil SourcesDocument22 pagesEdible Oil Sourcesshym hjrNo ratings yet

- Castor Oil Various GradesDocument2 pagesCastor Oil Various GradesTomas Morales Duran100% (1)

- Testing Procdure For OilDocument66 pagesTesting Procdure For Oilisaiah mathengeNo ratings yet

- Amee Castor & DerivativesDocument44 pagesAmee Castor & DerivativesJay TrivediNo ratings yet

- Sunflower: Prepared By: Mudita ShahDocument8 pagesSunflower: Prepared By: Mudita Shahmayank27933No ratings yet

- Project Report On Mint Oil Process and FormulaDocument6 pagesProject Report On Mint Oil Process and FormulaEIRI Board of Consultants and PublishersNo ratings yet

- Waxes Are A Diverse Class of Organic Compounds That Are Hydrophobic, MalleableDocument5 pagesWaxes Are A Diverse Class of Organic Compounds That Are Hydrophobic, MalleableAmmar SiddiquiNo ratings yet

- Processing of Vegitable OilDocument11 pagesProcessing of Vegitable OilAJAGUN JOHNSON100% (1)

- Alcohol From Yam CassavaDocument15 pagesAlcohol From Yam Cassavadinba123No ratings yet

- 09 Peanut Processing PDFDocument8 pages09 Peanut Processing PDFkalaamolNo ratings yet

- Smeda Oil Distillaiton UnitDocument21 pagesSmeda Oil Distillaiton UnitHaseeb A ChaudhryNo ratings yet

- Palm Stearin ExtractDocument4 pagesPalm Stearin ExtractShu ShuadaNo ratings yet

- Production & Export of Sesame Seed OilDocument5 pagesProduction & Export of Sesame Seed OilPatrick AbojeNo ratings yet

- Sesame SeedsDocument24 pagesSesame Seedsrainbowexports100% (2)

- Denim Jeans Stitching UnitDocument25 pagesDenim Jeans Stitching UnitSaad NaseemNo ratings yet

- Extraction of Oil From Seed PDFDocument6 pagesExtraction of Oil From Seed PDFNahid Akhter KathaNo ratings yet

- Properties of Palm Oil MargarineDocument7 pagesProperties of Palm Oil Margarinemcalidonio5656No ratings yet

- Vegetable Oil Extraction - Vegetable Refinery - Solvent Extraction Plant - MectechDocument9 pagesVegetable Oil Extraction - Vegetable Refinery - Solvent Extraction Plant - Mectechmectech50% (2)

- Industrial Project ReportDocument28 pagesIndustrial Project ReporteiribooksNo ratings yet

- Bio Diesel Business PlanDocument10 pagesBio Diesel Business PlanAnonymous KeraxgNo ratings yet

- Rice BranDocument10 pagesRice BranKarachibreezeNo ratings yet

- EssOilsLemongrass PDFDocument26 pagesEssOilsLemongrass PDFAdamMadaNo ratings yet

- Indian Edible Oil Industry: Types of Oils Commonly in Use in IndiaDocument11 pagesIndian Edible Oil Industry: Types of Oils Commonly in Use in IndiaMani BmvNo ratings yet

- Synthetic Detergent PowderMaking PlantDocument27 pagesSynthetic Detergent PowderMaking PlantFekadie TesfaNo ratings yet

- Project Profile On Groundnut Oil and Oil Cake ManuafcuringDocument2 pagesProject Profile On Groundnut Oil and Oil Cake ManuafcuringprtmNo ratings yet

- Dhara Soap and CosmeticsDocument10 pagesDhara Soap and CosmeticszalaksNo ratings yet

- Project Profile On Petroleum JellyDocument10 pagesProject Profile On Petroleum JellymahahajNo ratings yet

- Powder Detergent Ingredents (Pakistan)Document2 pagesPowder Detergent Ingredents (Pakistan)Kashif SaleemNo ratings yet

- Detergent Powder and CakeDocument8 pagesDetergent Powder and CakeSabhaya ChiragNo ratings yet

- Bio FertilizerDocument2 pagesBio FertilizerAnkit PandeyNo ratings yet

- Niger Seed OilDocument16 pagesNiger Seed Oilbig johnNo ratings yet

- Zeolite 4A White Powder For Detergent Det Build 150Document2 pagesZeolite 4A White Powder For Detergent Det Build 150kanu Patel100% (1)

- A Search For Alternative Solvent To Hexane During Neem Oil ExtractionDocument5 pagesA Search For Alternative Solvent To Hexane During Neem Oil ExtractiontramiNo ratings yet

- Project Report On Onion Dehydration-Powder, Flakes / Kibbled and Minced (Onion Products Garlic Powder)Document10 pagesProject Report On Onion Dehydration-Powder, Flakes / Kibbled and Minced (Onion Products Garlic Powder)Sachin SharmaNo ratings yet

- Oil Extraction ProcessDocument8 pagesOil Extraction ProcessMansoor Ali100% (1)

- Avocado Oil Refined Tx008222 PdsDocument3 pagesAvocado Oil Refined Tx008222 Pdskwamina20No ratings yet

- Calcium StearateDocument2 pagesCalcium StearateMulayam Singh YadavNo ratings yet

- Method For Manufacturing Rumen by Pass FatDocument6 pagesMethod For Manufacturing Rumen by Pass FatAnonymous 6HADGUEXDNo ratings yet

- Project Report On Ethanol Broken Rice (Miscellaneous Products)Document10 pagesProject Report On Ethanol Broken Rice (Miscellaneous Products)Sachin Sharma0% (1)

- Poster-Refining of Edible OilDocument1 pagePoster-Refining of Edible OilAman PaulNo ratings yet

- Technologies of Millet Value Added Products-1Document51 pagesTechnologies of Millet Value Added Products-1KeertNo ratings yet

- Iocl 1Document80 pagesIocl 1Rishi KumarNo ratings yet

- Sangat Mustard Oil Business PlanDocument15 pagesSangat Mustard Oil Business PlanSahil Singla100% (1)

- Project Report On Herbal OilDocument8 pagesProject Report On Herbal OilAnkur Sanghvi0% (2)

- Where We Are in Place and Time "We Are Part of The Universe and Feel Compelled To Explore It."Document1 pageWhere We Are in Place and Time "We Are Part of The Universe and Feel Compelled To Explore It."Safia-umm Suhaim- FareedNo ratings yet

- Lesson 3 - ReviewerDocument6 pagesLesson 3 - ReviewerAdrian MarananNo ratings yet

- ISO 27001 Introduction Course (05 IT01)Document56 pagesISO 27001 Introduction Course (05 IT01)Sheik MohaideenNo ratings yet

- Lecture 2 Effects of Operating Conditions in VCCDocument9 pagesLecture 2 Effects of Operating Conditions in VCCDeniell Joyce MarquezNo ratings yet

- PDF Chapter 5 The Expenditure Cycle Part I Summary - CompressDocument5 pagesPDF Chapter 5 The Expenditure Cycle Part I Summary - CompressCassiopeia Cashmere GodheidNo ratings yet

- Speech On Viewing SkillsDocument1 pageSpeech On Viewing SkillsMera Largosa ManlaweNo ratings yet

- My Mother at 66Document6 pagesMy Mother at 66AnjanaNo ratings yet

- 50114a Isolemfi 50114a MonoDocument2 pages50114a Isolemfi 50114a MonoUsama AwadNo ratings yet

- Business Plan in BDDocument48 pagesBusiness Plan in BDNasir Hossen100% (1)

- Hướng Dẫn Chấm: Ngày thi: 27 tháng 7 năm 2019 Thời gian làm bài: 180 phút (không kể thời gian giao đề) HDC gồm có 4 trangDocument4 pagesHướng Dẫn Chấm: Ngày thi: 27 tháng 7 năm 2019 Thời gian làm bài: 180 phút (không kể thời gian giao đề) HDC gồm có 4 trangHưng Quân VõNo ratings yet

- Cable To Metal Surface, Cathodic - CAHAAW3Document2 pagesCable To Metal Surface, Cathodic - CAHAAW3lhanx2No ratings yet

- Government College of Nursing Jodhpur: Practice Teaching On-Probability Sampling TechniqueDocument11 pagesGovernment College of Nursing Jodhpur: Practice Teaching On-Probability Sampling TechniquepriyankaNo ratings yet

- WAQF Podium Design Presentation 16 April 2018Document23 pagesWAQF Podium Design Presentation 16 April 2018hoodqy99No ratings yet

- Enochian Dragon Ritual PDFDocument4 pagesEnochian Dragon Ritual PDFDenis NantelNo ratings yet

- DLP - Light Science 7Document6 pagesDLP - Light Science 7Samara M. SalacayanNo ratings yet

- QuexBook TutorialDocument14 pagesQuexBook TutorialJeffrey FarillasNo ratings yet

- Lesson 6 - Vibration ControlDocument62 pagesLesson 6 - Vibration ControlIzzat IkramNo ratings yet

- Activity Title: Learning Targets: Reference (S)Document5 pagesActivity Title: Learning Targets: Reference (S)Jhev LeopandoNo ratings yet

- Bachelor of Arts in Theology: Christian Apologetics/ Seventh-Day Adventist Contemporary IssuesDocument13 pagesBachelor of Arts in Theology: Christian Apologetics/ Seventh-Day Adventist Contemporary IssuesRamel LigueNo ratings yet

- Teaching Profession - Educational PhilosophyDocument23 pagesTeaching Profession - Educational PhilosophyRon louise PereyraNo ratings yet

- Chapter 23Document9 pagesChapter 23Javier Chuchullo TitoNo ratings yet

- Micro EvolutionDocument9 pagesMicro EvolutionBryan TanNo ratings yet

- Apple Change ManagementDocument31 pagesApple Change ManagementimuffysNo ratings yet

- An Annotated Bibliography of Timothy LearyDocument312 pagesAn Annotated Bibliography of Timothy LearyGeetika CnNo ratings yet

- Pg2022 ResultDocument86 pagesPg2022 ResultkapilNo ratings yet

- ASHRAE Journal - Absorption RefrigerationDocument11 pagesASHRAE Journal - Absorption Refrigerationhonisme0% (1)

- Economic Review English 17-18Document239 pagesEconomic Review English 17-18Shashank SinghNo ratings yet

- Biblical World ViewDocument15 pagesBiblical World ViewHARI KRISHAN PALNo ratings yet

- WBDocument59 pagesWBsahil.singhNo ratings yet

- Prevention of Waterborne DiseasesDocument2 pagesPrevention of Waterborne DiseasesRixin JamtshoNo ratings yet