Professional Documents

Culture Documents

Computer Controlled Direct Gasoline Fuel Injection

Uploaded by

a256850Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Computer Controlled Direct Gasoline Fuel Injection

Uploaded by

a256850Copyright:

Available Formats

International Journal of Mechanical & Mechatronics Engineering IJMME-IJENS Vol: 10 No: 04

Modeling and Programming for a Computer Controlled Direct Gasoline Fuel Injection System of SI Engine Md. Nizam Uddin and M. M. Syed Ali Department of Mechanical Engineering Khulna University of Engineering & Technology (KUET) Khulna-9203, Bangladesh E-mail: engrnizam02@gmail.com ABSTRACT A computer controlled direct gasoline fuel injection (DGI) system has been modeled, programmed and constructed for a four-stroke SI engine. Locally available materials have been used for this experimental model. All the old model vehicle were equipped with carburetor for air fuel mixing and later on electronic fuel injection system has been introduced for maintaining better air fuel ratio and mixing in many late model vehicles. Later on Japan introduced direct gasoline fuel injection system in their SI engine but it is not yet commercialized in many under developed countries. Direct gasoline fuel injection (DGI) system has the advantage of fulfilling proper air fuel ratio in various operating conditions and loads providing minimum air pollution. In four stroke engine, fuel needs to be supplied once in every two revolution. A logic control and program is necessary to control and supply fuel supply once in the cylinder at every two revolution. A program has been made to control the system. Fuel injection period was maintained by opto-isolator sensor in this model. But fuel injection period need to be varied depending on operating condition and loads. Further research is necessary to develop this model and program depending upon engine loads. The designed DGI system is found to work properly with the designed constant speed of 3000 rpm. The development of this model with variable speed and load is necessary for improvement of vehicle performances and emission control. 1. INTRODUCTION Nearly thirty percent of the population in USA is involved with automotive business. Internal combustion engines are widely used in the field of transportation, irrigation, power generation etc. Cylinder is the heart of energy generation of IC engine where energy is generated from combustion of air-fuel mixture. The fuel system mixes gasoline or similar fuel with air to make a mixture which is burned in the engine cylinder. Early model automobiles used carburetor for supplying the airfuel mixture. The construction of the carburetor is relatively simple and it has been used almost exclusively on gasoline engines in the past. However, the recent demands for cleaner exhaust emissions, more economical fuel consumption and improved drivability etc, the carburetor now must be equipped with various compensating devices, making it a more complex system. In place of carburetor, therefore, EFI system was used, assuring the proper air-fuel ratio by injecting fuel in the intake manifold depending upon various driving conditions. EFI (Electronic Fuel Injection) system was comparatively successful to maintain correct ratio fuel air mixture to the cylinders in various speed and loads. In EFI system air- fuel mixing is done in the intake manifold or intake port outside cylinder. An electronic control unit or computer controls one or more injectors. When the engine

International Journal of Mechanical & Mechatronics Engineering IJMME-IJENS Vol: 10 No: 04

needs fuel, a signal from ECU opens the injector. After getting signal from ECU, the fuel is injected in the intake manifold of the engine. But it got some disadvantages and inaccuracy in providing measured fuel quantity in each cylinder which can be meet up by direct gasoline fuel injection system. In a direct gasolinefuel injection engine, the injectors are mounted in the cylinder head and they spray fuel directly into the combustion chamber. Compared with port fuel injection, GDI is more difficult and expensive. But the payback for the added complexity is higher torque, dramatically reduced emissions and increased engine efficiency. This is because fuel can be injected in the measured and exact quantity with injection time and location that its needed. The high injection pressure and air temperature help to atomize and vaporize the fuel in the combustion chamber. But more importantly the chamber shape, injector location and injection timing and duration, all work together to create what is called a stratified charge. The air -fuel mixture is richer close to the spark plug and leaner out towards the edges of the chamber. Engines generate their worst emissions just after cold start. During worm-up of a DGI engine, a small shot of fuel is injected just before the exhaust valve opens. Theres still enough heat and oxygen in the chamber for this charge to ignite and the heat from that after burn gets the catalyst up to operating temperature just seconds after cold start. The injectors are either open or closed, not pulsed as in a port injection system. Since the fuel flows directly into the combustion chamber instead of impinging on the intake valve, the nozzle can be designed to form a cloud of fuel with a specific size and shape. Sawada et. al. [1] investigated and confirmed the possibility of using stratified scavenging and lean combustion as alternative technologies for reducing THC and CO emissions, in a two-stroke cycle engine. Two different types of engines were used. One is a prototype two-stroke cycle engine with leaner combustion technology and air-head stratified scavenging, the other one is current twostroke cycle engine with Schnurle scavenging. THC

was measured on a wet basis while CO and CO2 were measured on dry basis. The prototype engine with Air-head stratified scavenging and leaner combustion reduced specific THC output to 1/5 compared to current Schnurle scavenging engine. This suggests that the engine can conform to CARB 1999 or Tier 2 emission standards regarding THC, CO and NOx emission without sacrificing mechanical simplicity and light weight. Nuti, et al. [2] extended the research experiment on the 'phylogeny' of the Hi-Tech 2T SI engine in Piaggio started on the early 70s. Several solutions to this problem have been introduced for the past twenty years. An analysis has been conducted to determine the extent of research activities in this area,. Through this analysis, the ultimate possibilities of the 2T SI engine have been clarified. Fansler et al. [3] performed individual-cycle exhaust-hydrocarbon measurements on a directinjection two-stroke-cycle engine. Time-resolved hydrocarbon (HC) concentration data were obtained using a fast flame-ionization detector. The resulting data were converted to individual-cycle exhaust mass flow. Two types of air-assist fuel injectors were evaluated using simultaneously acquired individual-cycle heat-release data, exhaust-HC mass data, and in-cylinder spray/combustion visualization. Results of this study were used in conjunction with previous imaging and heat-release studies to clarify the principal mechanisms leading to unburned HCs from this two-stroke engine Johnson et al. [4] applied an electronic direct fuel injection (EDFI) system to a 1100cc two-stroke PWC engine. This effort proved to be very successful. In particular, it demonstrated the ability to meet the EPA regulated spark ignited marine engine HC + NOx emission standard for the model year 2006. The system showed a 76.3% reduction in weighted mass hydrocarbon emissions. Zhao F. et al. [5] designed to inject gasoline directly in to the combustion chamber of four stroke, spark ignition engines which is an important worldwide

International Journal of Mechanical & Mechatronics Engineering IJMME-IJENS Vol: 10 No: 04

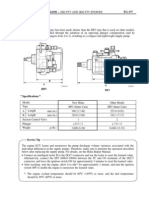

initiative of the automotive industry. The thermodynamic potential of such engines for significantly enhanced fuel economy, transient response and cold start hydrocarbon emission levels has led to a large number of research and development projects that have the goal of understanding, developing and optimizing gasoline direct injection (GDI) combustion systems. The process of fuel injection, spray atomization and vaporization, charge cooling, mixture preparation and the control of in-cylinder air motion are all being actively researched. The new technologies such as high-pressure, common-rail, gasoline injection systems, and swirl-atomizing gasoline fuel injectors, along with computer control capabilities, have enabled the current new examination of the direct injection, stratified-charge (DISC) gasoline engine. 2. DESIGN AND OPERATION PRINCIPLES OF DIRECT GASOLINE FUEL INJECTION (DGI) SYSTEM The design and fundamental operation principles of direct gasoline fuel injection system is done by thee vital units i.e. sensing units, controlling unit and actuating units. The sensing units provide signals to microprocessor or computers. Microprocessor or computer which processes the input signal and provide signal to actuators. Actuators receive senses from processor or computer and provide output signals to actuators or fuel injector in the cylinder. Fig 2: Circuit Diagram of Direct Gasoline Fuel Injection System The fuel injector is an electro-mechanical device which meters, atomizes and directly supplies fuel into the cylinder based on signals from the controller. All engines used one injector per cylinder. The injectors are installed with an insulator/seal on the cylinder wall to isolate the injector from heat and to prevent pressure leakage of the cylinder. The fuel delivery pipe serves to secure delivery of fuel to the injector. In a direct fuel injection engine, the fuel must be injected in a short period of time and at pressures at least 40 times higher than in port fuel injection. The electric fuel pump supplies the fuel to the injectors under pressure. As soon as the injector receive signals from the computer, its needle valve is opened by electrically operated solenoid valve and fuel injection start with desired spray pattern. An electric solenoid valve in the injector opens and closes the valve. The solenoid valve is magnetized to lift valve against spring force when a voltage is applied. Fuel sprays out as long as the valve raised. When the computer cut off signals the solenoid valve coil is demagnetized spring pushes the valve back down onto its seat. This stops the fuel spray.

Fig.1: Schematic Diagram of Direct Gasoline Fuel Injection System for a Four Stroke SI Engine

International Journal of Mechanical & Mechatronics Engineering IJMME-IJENS Vol: 10 No: 04

Each opening and closing of the injector valve is an injector impulse. 2.1SENSORS AND ITS OPERATION PRINCIPLE In this research work, an opto-isolator has been used as a sensor. Opto-isolator:

Fig. 3: Circuit Diagram of an Opto-isolator An opto-isolator (or optical isolator, optocoupler or photocoupler) is a device that uses a short optical transmission path to transfer a signal between elements of a circuit, typically a transmitter and a receiver, while keeping them electrically isolated. A common implementation involves an LED and a light sensor, separated so that light may travel across a barrier but electrical current may not. When an electrical signal is applied to the input of the opto-isolator, its LED lights, its light sensor then activates, and a corresponding electrical signal is generated at the output. Unlike a transformer, the opto-isolator allows for DC coupling and generally provides significant protection from serious over voltage conditions in one circuit affecting the other. With a photodiode as a detector, the output current is proportional to the amount of incident light supplied by the emitter. The diode can be used in a photovoltaic mode or a photoconductive mode. In photovoltaic mode, the diode acts like a current

source in parallel with a forward-biased diode. The output current and voltage are dependent on the load impedance and light intensity. In photoconductive mode, the diode is connected to a supply voltage and the magnitude of the current conducted is directly proportional to the intensity of light. An opto-isolator can also be constructed using a small incandescent lamp in place of the LED; such a device, because the lamp has a much slower response time than an LED., will filter out noise or half- wave power in the input signal. In so doing, it will also filter out any audio or higher frequency signals in the input. It has the further disadvantage, of course, that incandescent lamps have finite life spans. Thus such an unconventional device is of extremely limited usefulness, suitable only for applications such as science projects. The optical path may be air or a dielectric waveguide. The transmitting and receiving elements of an optical isolator may be contained within a single compact module, for mounting, for example, on a circuit board; in this case, the module is often called an opto-isolator. Thr photo sensor may be a photocell, or an optically triggered SCR or Triac. Occasionally, this device will in turn operate a power relay or contractor. Several types of optocouplers. The figure indicate above, detect the presence of an object in between them. They are interruptible. The middle one detects reflections from objects in front of it

2.2 CONTROLLER Contrary to some "informed" opinions and numerous suggestions from movies, computers can not think for themselves; when properly programmed, however, they can carry out explicit instructions with blinding speed and almost flawless consistency.

International Journal of Mechanical & Mechatronics Engineering IJMME-IJENS Vol: 10 No: 04

10

2.2.1 COMPUTER PROGRAM AND FLOW CHART FOR CONTROLLING FUEL INJECTION SYSTEM The Program for the controlling of direct gasoline fuel injection system has been developed and its flow chart is described herewith.

an analog signal. Digital signals also vary but not continuously, and time is not needed for the change to occur. Turning a switch on and off creates a digital signal; voltage is either there or it is not. Digital signals are often referred to as square wave signal. 2.2.3 BINARY CODE A Computer converts a series of digital signals to a binary number made of 1s or Os; voltage above a given value converts to one and zero voltage. Each 1 or 0 represents a bit of information. 2.2.4 INTERFACE The microprocessor is the heart of a computer, but it needs several support functions, one of which is interface. A computer has an input and output interface circuit. The interface has two functions: it protects the delicate electronics of the microprocessor from the higher voltages of the circuits attached to the computer, and it translates input and output signals. The input interface translates all analog input data to binary code; most sensors produced an analog signal. It is sometimes referred to A/D, analog to digital. The output interface, D/A, translates digital signals to analog for any controlled functions that need an analog voltage.

Fig.4: Flow Chart for Controlling Fuel Injection System

Interfacing to the PC Parallel Printer Port 8 output pins accessed via the DATA Port. 5 input pins (one inverted) accessed via the STATUS Port 4 output pins (three inverted) accessed via the CONTROL Port. The remaining 8 pins are grounded. Use of a PC Printer Port for Control and Data Acquisition A PC Printer port is an inexpensive and yet powerful platform for implementing projects dealer with the control of real world peripherals. The printer port provides eight TTL outputs, five

2.2.2 COMMUNICATIONS SIGNALS A computer uses voltage values as communication signals, thus voltage is often referred to as a signal or a voltage signal. There are two types of voltage signals: analog and digital. An analog signal's voltage is continuously variable within a given range and time is used for the voltage to change. An analog signal is generally used to convey information about a condition that changes gradually and continuously within an established range. Temperature-sensing devices usually give off

International Journal of Mechanical & Mechatronics Engineering IJMME-IJENS Vol: 10 No: 04

11

input and four bi-directional leads and it provides a very simple means to use the PC interrupt structure. This article discusses how to use program the printer port. A larger manual which deals with sue topics as driver circuits, optoisolators, control of DC and stepping motors, infrared and rad remote control, digital and analog multiplexing, D/A and A/D is available.

4. RESULTS & DISCUSSION During the experiment with the model, the fuel is found to inject in cylinder and the program controlled the fuel injection at every alternative cycle. The performance of the test was found satisfactory. Taking consideration of all parameters of SI engine, this model may be improved to use in DGI system engine.

2.3. OUTPUTS AND ACTUATORS All outputs on the Data port are true logic. That is, writing a logic one to a bit cause the corresponding output to go high. That is, outputting a logic one to a bit cause a logic zero on the corresponding output. This adds some complexity in using the printer port, but the fix is to simply invert those bits using the exclusive OR functions prior to outputting. 2.3.1 ELECTRIC FUEL PUMP Fuel is delivered from the tank by an electric fuel pump. Fuel flows through the fuel filter to the fuel rail (fuel delivery pipe) and up to the pressure regulator where it is held under pressure. The pressure regulator maintains fuel pressure in the rail at a specified value above cylinder pressure. This maintains a constant pressure drop across the fuel role, which brings a number of important performance benefits compared to the compromise solution offered by carburetors. 3. EXPERIMENTAL PROCEDURE After design, construction of the model of the experimental setup, the injection timing for a constant speed (3000) rpm has been calculated. The calculated injection time is 1.38 milliseconds or 250 rotation of the flywheel. And the amount of fuel injected per cycle is 0.27 X 10 -3 milliliters. The cross sectional area of the injector nozzle is 0.00052 mm2 for suction pressure 2 bar. The flywheel was rotated at a designed speed of 3000 rpm by a model engine or motor.

5. CONCLUSIONS The following conclusions are made from this research work. (i) The present model has been designed with a constant speed (3000 rpm) and it is found to work properly. Future development of this model and program with variable engine operating conditions i.e. variable speeds and loads may be useful in the real design fields of direct gasoline fuel injection system of a SI engine.

(ii)

NOTATIONS

CARB Emission standard (California air research bureau) Tier Emission standard CO Carbon monoxide CO2 Carbon dioxide Oxides of nitrogen NOx THC/HCs Total hydro carbon/ hydro carbons

International Journal of Mechanical & Mechatronics Engineering IJMME-IJENS Vol: 10 No: 04

12

REFERENCES

[1] Sawada, Toshiharu; Wada, Minoru; Noguchi, Masanori; Kobayashi, Buhei , Development of a low emission twostroke cycle engine SAE Special Publications Two-Stroke Engines and Emissions Proceedings of the 1998 SAE International Congress & Exposition Feb 23-26 1998 v 1327 Feb 1998 Detroit, MI, , USA, SAE Warrendale PA USA p 79-89 Paper : 980761 SAESA2 Nuti, Marco; Pardini, Roberto Twenty years of Piaggio direct injection research to mass produced solution for small 2T SI engines SAE Special Publications TwoStroke Engines and Emissions Proceedings of the 1998 SAE International Congress & Exposition Feb 23-26 1998 v 1327 Feb 1998 Detroit, MI, , USA, SAE Warrendale PA USA p 65-78 Paper : 980760 SAESA2

[5]

Zhao F., Lai M.C. and Harrington D.L Automotive spark-ignited direct injection gasoline engines Department of Mechanical Engineering, Wayne State University, 5050 Anthony Wayne Dr.,Detroit, Ml 48202, ETATS- UNIS, Thermal and Energy systems Laboratory, General Motors Research and Development Center, 30500, Mound Road, Warren, Ml 48202,ETATS- UNIS.

[2]

[3]

Fansler, Todd D.; French, Donald T.; Drake, Michael C. Individual-cycle measurements of exhaust-hydrocarbon mass from a direct-injection two-stroke engine SAE Special Publications TwoStroke Engines and Emissions Proceedings of the 1998 SAE International Congress & Exposition Feb 23-26 1998 v 1327 Feb 1998 Detroit, MI, , USA, SAE Warrendale PA USA p 33-53 Paper : 980758 SAESA2 Johnson, Daren E.; Wong, Hoi-Ching Electronic direct fuel injection system applied to an 1100cc two-stroke personal watercraft engine SAE Special Publications Two-Stroke Engines and Emissions Proceedings of the 1998 SAE International Congress & Exposition Feb 23-26 1998 v 1327 Feb 1998 Detroit, MI, , USA, SAE Warrendale PA USA p 11-23 Paper : 980756 SAESA2

[4]

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- HEUI Systems Operation 3126Document25 pagesHEUI Systems Operation 3126विशाल पुडासैनी89% (9)

- Function, Structure, Operation of Engine Null (4JK1)Document36 pagesFunction, Structure, Operation of Engine Null (4JK1)jonathan100% (3)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- CodeDocument187 pagesCodeIzz Bahar82% (17)

- ENGINE - 1KD-FTV AND 2KD-FTV ENGINES Supply Pump OperationDocument8 pagesENGINE - 1KD-FTV AND 2KD-FTV ENGINES Supply Pump OperationSultan Ahmed Khan100% (23)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Mack Colobia 2008Document291 pagesMack Colobia 2008Vicente Ortiz Delgado100% (2)

- How To Keep Your VW Alive OCR Done PDFDocument480 pagesHow To Keep Your VW Alive OCR Done PDFzip100% (1)

- Bagi 'MR - PDF'Document15 pagesBagi 'MR - PDF'Syarifuddin RahmanNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Cat C15 BxsDocument2 pagesCat C15 BxsDenis Greshilov100% (2)

- Stavic Ewd LHDDocument239 pagesStavic Ewd LHDERMINSUL VICUÑA SALASNo ratings yet

- Manual lb75b PDFDocument178 pagesManual lb75b PDFnery ardila100% (1)

- 2003 - 2003 Yzf-R1 Ecu WiringDocument1 page2003 - 2003 Yzf-R1 Ecu Wiringlombardiacm75% (4)

- 12 and 16v92 Ta Spec SheetDocument4 pages12 and 16v92 Ta Spec SheetBrandon Atz50% (2)

- DENSO SystemsDocument34 pagesDENSO Systemsthailan100% (3)

- F250TXRDDocument390 pagesF250TXRDAnonymous Jw74aayApGNo ratings yet

- Control Electronico Del Motor GM 2Document18 pagesControl Electronico Del Motor GM 2adelmomouraNo ratings yet

- wb97s 5e0 S N f30003 Up PDFDocument924 pageswb97s 5e0 S N f30003 Up PDFTamquadistu AlexNo ratings yet

- Adjustments of Fuel Oil SystemsDocument16 pagesAdjustments of Fuel Oil SystemsndlongndNo ratings yet

- File - Fe1c9e D55e26 68f0ed 62ae34 B44C0C 1a682cDocument4 pagesFile - Fe1c9e D55e26 68f0ed 62ae34 B44C0C 1a682cYasser JaviNo ratings yet

- SYLLABUS OF MECHANIC MOTOR VEHICLE TRADEDocument43 pagesSYLLABUS OF MECHANIC MOTOR VEHICLE TRADEswami061009No ratings yet

- Diesel Turbo Direct Injection (TDI) system servicing overviewDocument149 pagesDiesel Turbo Direct Injection (TDI) system servicing overviewuriiiNo ratings yet

- Codes ErreursDocument16 pagesCodes ErreursVincent TrenyNo ratings yet

- 3mitsubishi Gensets Brochure Rgb1Document12 pages3mitsubishi Gensets Brochure Rgb1Redah HamedNo ratings yet

- VW Passat b5 Motronic Injection 1 8 LTR EngDocument160 pagesVW Passat b5 Motronic Injection 1 8 LTR EngChiulafli FediaNo ratings yet

- Kits de inyección para motores de la Línea CDocument77 pagesKits de inyección para motores de la Línea CJorge AguadoNo ratings yet

- ARRIEL 2B1 维修手册空气系统翻译Document18 pagesARRIEL 2B1 维修手册空气系统翻译13421301508No ratings yet

- 8860 ManualDocument100 pages8860 ManualAli Shafique0% (1)

- Redline ProductsLDocument2 pagesRedline ProductsLflanker_13No ratings yet

- PG Mau SyllabusDocument71 pagesPG Mau SyllabusMaruthiNo ratings yet

- SPE-198035-MS Chemical EOR Pilot Design Optimization Through Dynamic Reservoir CharacterizationDocument11 pagesSPE-198035-MS Chemical EOR Pilot Design Optimization Through Dynamic Reservoir Characterizationyogs6666No ratings yet