Professional Documents

Culture Documents

Machine Shop: C C C C C C C C

Uploaded by

Lakhvir SinghOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Machine Shop: C C C C C C C C

Uploaded by

Lakhvir SinghCopyright:

Available Formats

MACHINE SHOP

LAYOUT OF MACHINE SHOP

CHIEF INSTRUCTAR OFFICE OF M/C SHOP

1.UNIVERSAL MACHINE

MILLING

10.SHEARING MACHINE 11.SCRAP

2.MILLING MACHINE

3.PEDESTAL MACHINE ENTRY 4.SHAPER

GRINDER

9.BENCH WISE

5.RADIL MACHINE

DRILLING

6.LATHE MACHINE

8.POWER HACK SAW

7.SURFACE GRINDER

MACHINE AVILEBLE IN TTC MACHINE SHOP

1.Universal Milling Machine

2.Milling Machine 3.Pedestal Grinder Machine 4.Shaper 5.Radil Drilling Machine 6.Lathe Machine 7.Surface Grinder 8.Power Hack Saw 9.Shearing Machine

DISCRIPTION OF MACHINES

1.Lathe Machine :-

A lathe is a machine tool which turns cylindrical material, touches a cutting tool to it, and cuts the material. The lathe is one of the machine tools most well used by machining .

A material is firmly fixed to the chuck of a lathe. The lathe is switched on and the chuck is rotated. And since the table which fixed the byte can be

moved in the vertical direction, and the right-and-left direction by operating some handles. It touches a byte's tip into the material by the operation, and make a mechanical part. The purpose of a lathe is to rotate a part against a tool whose position it controls. It is useful for fabricating parts and/or features that have a circular cross section. The spindle is the part of the lathe that rotates. Various workholding attachments such as three jaw chucks, collets, and centers can be held in the spindle. The spindle is driven by an electric motor through a system of belt drives and/or gear trains. Spindle speed is contolled by varying the geometry of the drive train. The tailstock can be used to support the end of the workpiece with a center, or to hold tools for drilling, reaming, threading, or cutting tapers. It can be adjusted in position along the ways to accomodate different length workpices. The ram can be fed along the axis of rotation with the tailstock handwheel. The carriage controls and supports the cutting tool. It consists of: A saddle that mates with and slides along the ways. A cross slide that controls transverse motion of the tool (toward or away from the operator). A tool compound that adjusts to permit angular tool movement. A toolpost T-slot that holds the toolpost.

CAUTIONS!

When we use a lathe, the following things must take great care. (1) Don't keep a chuck handle attached by the chuck. Next, it flies at the moment of turning a lathe. (2) Don't touch the byte table into the rotating chuck. Not only a byte but the table or the lathe are damaged.

Three Important Elements

In orger to get an efficient propcess and beautiful surface at the lathe machining, it is important to adjust a rotating speed, a cutting depth and a sending speed. Please note that the important elements can not decide easily, because these suitable values are quiet different by materials, size and shapes of the part.

1.Rotating Speed:-It expresses with the number of rotations (rpm) of the chuck of a lathe. When the rotating speed is high, processing speed becomes quick, and a processing surface is finely finished. However, since a little operation mistakes may lead to the serious accident, it is better to set low rotating speed at the first stage. 2.Cutting Depth:-The cutting depth of the tool affects to the processing speed and the roughness of surface. When the cutting depth is big, the processing speed becomes quick, but the surface temperature becomes high, and it has rough surface. Moreover, a life of byte also becomes short. If you do not know a suitable cutting depth, it is better to set to small value. 3.Sending Speed (Feed):-The sending speed of the tool also affects to the processing speed and the roughness of surface. When the sending speed is high, the processing speed becomes quick. When the sending speed is low, the surface is finished beautiful. There are 'manual sending' which turns and operates a handle, and 'automatic sending' which advances a byte automatically. A beginner must use the manual sending. Because serious accidents may be caused, such as touching the rotating chuck around the byte in automatic sending.

Cutting Tools for Lathe

There are vrious kinds of the cutting tools for a lathe. We must choose them by the materials and shape of a part. Three typical cutting tools are introduced in follows. Then we consider what is an easy process or a hard process.

(a)Side Tool :-It can process to cut an outside surface and an edge surface. Since the material is set at the right of lathe, then this tool can only cut the right of the material. (b)Cutting-Off Tool:-The cutting tool is used at parting and grooving processes. Its pointed end is slim, then it is too weak. Don't add a strong side-force to the tool. This tool must send vertical direction only. (c)Boring Bar:-The boring bar is used to cut at an inside surface. It can make a big hole, which cannot be process by a drill, and an high accurate hole.

Cutting Tool Terminology

Setting of a Cutting Tool

In case a cutting tool is fixed to a table, thin metal plates are put between the tool and the table, and the height of the edge is adjusted to the center of material. In the case of using the general cutting tool, when the edge is higher than the center of material, the edge of a blade does not hit the material, and it cannot cut at all. Conversely, if the edge is low, it becomes impossible to cut the center of material. Moreover, the scale of a handle does not have correct value, then accurate processing becomes impossible. Though the height of the cutting tool is adjusted in careful, we cannot unite with the center of material completely. Therefore, we have to set the tool to the direction, that the edge is easy to touch the material. The general cutting tool and the parting tool have to be set a few low position. The boring bar has to set a few high position.

Standard Cutting Tools

Lathe Accessories

Live center (top) &Dead center (bottom)

Lathe operations

1.Turning:-The lathe can be used to reduce the diameter of a part to a desired dimension.The part should not extend more that three times its diameter. Then install a roughing or finishing tool (whichever is appropriate). If you're feeding the saddle toward the headstock use a right-hand turning tool. Move the tool off the part by backing the carriage up with the carriage handwheel, then use the cross feed to set the desired depth of cut. 2. Facing:-A lathe can be used to create a smooth, flat, face very accurately perpendicular to the axis of a cylindrical part. First, clamp the part securely in a lathe chuck Then, install a facing tool. Move the tool outside the part and adjust the saddle to take the desired depth of cut. Then, feed the tool across the face with the cross slide. Be careful clearing the ribbon-like chips; They are very sharp. Do not clear the chips while the spindle is turning. After facing, there is a very sharp edge on the part. 3. Parting:-A parting tool is deeper and narrower than a turning tool. It is designed for making narrow grooves and for cutting off parts. Ensure that the parting tool is perpendicular to the axis of rotation and that the tip is the same height as the center of the part. A good way to do this is to hold the tool against the face of the part. Set the height of the tool, lay it flat against the face of the part, then lock the tool in place. When the cut is deep, the side of the part can rub

against sides of the groove, so it's especially important to apply cutting fluid. In this clip, a part is cut off from a piece of stock. 4. Drilling:-A lathe can also be used to drill holes accurately concentric with the centerline of a cylindrical part. First, install a drill chuck into the tail stock. Withdraw the jaws of the chuck and tap the chuck in place with a soft hammer. Move the saddle forward to make room for the tailstock. Move the tailstock into position, and lock the it in place (otherwise it will slide backward as you try to drill). Always use a centerdrill to start the hole. You should use cutting fluid with the centerdrill. A hole is drilled with a drill. 5. Boring:-Boring is an operation in which a hole is enlarged with a single point cutting tool. A boring bar is used to support the cutting tool as it extends into the hole. Because of the extension of the boring bar, the tool is supported less rigidly and is more likely to chatter. This can be corrected by using slower spindle speeds or by grinding a smaller radius on the nose of the tool. 6. Single Point Thread Turning:-External threads can be cut with a die and internal threads can be cut with a tap. But for some diameters, no die or tap is available. In these cases, threads can be cut on a lathe. A special cutting tool should be used, typically with a 60 degree nose angle. To form threads with a specified number of threads per inch, the spindle is mechanically coupled to the carriage lead screw. Procedures vary for different machines.

Hearing the Sound

In the case of the lathe process, sharpness is known from scraps of the material or a processing surface. In addition, it is also important to hear the sound. For example, when the sound is too high, the processing is not suitable. It is caused by the bad edge of the tool, too higher rotating speed of the lathe, or vibrating of a thin material.

Technical Specifications of Center Lathe Machine:1. Make : HMT VIKRAM. 2. Plant no : 1203-001. 3. Total bed length : 1800 mm. 4. Distance b/w centre to centre : 1200 mm. 5. Distance b/w centre to bed : 200 mm. 6. Swing : 300 mm. 7. Spindle Bore : 50 mm. 8. Type of Head stock : Geared. 9. Type of L/S thread : ACME,Angle-290 10. Thread pitch of L/S : 6 mm. 11. Speed : 25-2000 rpm. 12. Feed : 0.04-1.00 mm. 13. Gap bed length : 200 mm.

2. CAP ASTIAN LATHE

It carries the hexagonal turret on a ram or short slide. The ram slides longitudinally on a side positioned and clamped on lathe bed ways. This machine is used for smaller work piece due to its lighter construction. The feeding movement is obtained when ram moves from left to right and vice versa. In turret lathes, turret is directly mounted on saddle while in capstan lathe turret is mounted on the ram, which is mounted on the saddle.

TECHNICAL SPECIFICATIONS of Cap astian lathe:Turning length Speed range Spindle bore Feed range mm/min. Spindle drive motor Dia. Of spindle flange Max. Longitudinal traverse Max. Longitudinal cross Swing over bed : 346mm. : 40-1000rpm. : 54mm. : 5-63 : 5.6Kw. : 190.5mm. : 348mm. : 193mm. : 375 mm

3. RADIAL DRILLING MACHINE: -

It consists of vertical column with a radial arm that can be swing trough an arc of 180 degrees or more on the radial arm, which is power driven for vertical movement. Is an independently driven head fitted with power feed? The drilling head can be moved along the arm by hand or by gear mechanism. On a single fitting of work piece number of holes can be drilled by rotating the arm or sliding the dr1l1 head along the arm.

TECHNICAL SPECIFICATIONS OF RADIAL DRILLING MACHINE :Max. Drill diameter Max. Job thickness Drilling capacity Cutting speed Feed Tapping capacity Min. /Max Drilling radius Min. / Max Distance between Base plate and spindle nose. Swing arm : 100m. : l2.5mm. : For CI 60 mm : 1520mm/rev : 6 feed ranges 0.125-1.25 mm/rev. : For metric system M70 For British system 2.5"(BW) : 550/2350 mm. : 380/1645 : 360 degrees:

4.Power hacksaw

A power hacksaw is a type of hacksaw that is powered either by its own electric motor (also known as electric hacksaw) or connected to a stationary engine. Most power hacksaws are stationary machines but some portable models do exist. Stationary models usually have a mechanism to lift up the saw blade on the return stroke and some have a coolant pump to prevent the saw blade from overheating. While stationary electric hacksaws are reasonably uncommon they are still produced but saws powered by a stationary engines have gone out of fashion. The reason for using one is that they provide a cleaner cut than an angle grinder or other types of saw.

5.Shaper:-

A shaper is a machine tool used for shaping or surfacing metal and other material. Shapers have been largely superseded by milling machines or grinding machines in modern industrial practice. The basic function of a shaper machine is still sound and tooling for them is minimal and very cheap to reproduce. They can be invaluable for jobbing or repair shops where only one or a few pieces are required to be produced and the alternative methods are cost or tooling intensive. The mechanically operated machines are simple and robust in construction, making their repair and upkeep easily achievable. Shapers are mainly classified as standard, draw-cut, horizontal, universal, vertical, geared, crank, hydraulic, contour and travelling head. The horizontal arrangement is the most common. Vertical shapers are generally fitted with a rotary table to enable curved surfaces to be machined. The vertical shaper differs from a slotter (slotting machine), as the slide can be moved from the vertical. A slotter is fixed in the vertical plane. Very small machines have been successfully made to operate by hand power. Once size increases, up to a potential 36 inch stroke, the power needs increase and it becomes necessary to use an electric motor. This motor drives a mechanical arrangement (using a pinion gear, bull gear and crank) or a hydraulic motor which supplies the necessary movement via hydraulic cylinders

Operation:-

Shaper linkage. Note the drive arm revolves less for the return stroke than for the cutting stroke, resulting in a quicker return stroke and more powerful cutting stroke.A shaper operates by moving a hardened cutting tool backwards and forwards across the workpiece. On the return stroke of the ram the tool is lifted clear of the workpiece, reducing the cutting action to one direction only. The workpiece mounts on a rigid, box shaped table in front of the machine. The height of the table can be adjusted to suit this workpiece, and the table can traverse sideways underneath the reciprocating tool which is mounted on the ram, the table motion is usually under the control of an automatic feed mechanism which acts on the feedscrew. The ram slides back and forth above the work, at the front end of the ram is a vertical tool-slide that may be adjusted to either side of the vertical plane. This tool-slide holds the clapper box and toolpost from where the tool can be positioned to cut the straight, flat surface on the top of the workpiece. The tool-slide permits feeding the tool downwards to put on a cut it or may be set away from the vertical plane, as required. The ram is adjustable for stroke and, due to the geometry of the linkage, it moves faster on the return (non-cutting) stroke than on the forward, cutting stroke. This action is via a slotted link or whitworth link. Cutting fluid may be employed to improve the finish and prolong the tool's life.

Technical Specification of Shaper Machine:1. Make : Cooper CSH-63.

2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13.

Plant no. : 1931-001. Max length of stroke : 630 mm. Max Horizontal traverse of table : 710 mm. Max vertical traverse of table : 350 mm. Max distance of table to ram : 450 mm. Min distance of table to ram : 100 mm. Range of speed to ram strokes/min : 8-125 mm. Range of feed to table(in 10 steps) : 0.32-3.2 mm/min. Max traverse of tool slide : 160 mm. Can be swiveled through on either side of vertical : 450 Vice admits in length : 290 mm. Width & depth of vice jaw : 330 mm.

6.Milling machine:-

A milling machine is a machine tool used for the shaping of metal and other solidmaterials. Milling machines exist in two basic forms: horizontal and vertical, which terms refer to the orientation of the cutting tool spindle. Unlike a drill press, in which the workpiece is held stationary and the drill is moved vertically to penetrate the material, milling also involves movement of the workpiece against the rotating cutter, the latter which is able to cut on its flanks as well as its tip. Workpiece and cutter movement are precisely controlled to less than 0.001 inches (.025 millimeters), usually by means of precision ground slides and leadscrews or analogous technology. Milling machines may be manually operated, mechanically automated, or digitally automated via computer numerical control (CNC). Milling machines can perform a vast number of operations, some very complex, such as slot and keyway cutting, planing, drilling, diesinking, rebating, routing, etc. Cutting fluid is often pumped to the cutting site to cool and lubricate the cut.

Comparing vertical with horizontal

In the vertical mill the spindle axis is vertically oriented. Milling cutters are held in the spindle and rotate on its axis. The spindle can generally be extended (or the table can be raised/lowered, giving the same effect), allowing plunge cuts and drilling. There are two subcategories of vertical mills: the bedmill and the turret mill. Turret mills, like the ubiquitous Bridgeport, are generally smaller than bedmills, and are considered by some to be more versatile. In a turret mill the spindle remains stationary during cutting operations and the table is moved both perpendicular to and parallel to the spindle axis to accomplish cutting. In the bedmill, however, the table moves only perpendicular to the spindle's axis, while

the spindle itself moves parallel to its own axis. Also of note is a lighter machine, called a mill-drill. It is quite popular with hobbyists, due to its small size and lower price. These are frequently of lower quality than other types of machines, however. A horizontal mill has the same sort of x y table, but the cutters are mounted on a horizontal arbor (see Arbor milling) across the table. A majority of horizontal mills also feature a +15/-15 degree rotary table that allows milling at shallow angles. While endmills and the other types of tools available to a vertical mill may be used in a horizontal mill, their real advantage lies in arbor-mounted cutters, called side and face mills, which have a cross section rather like a circular saw, but are generally wider and smaller in diameter. Because the cutters have good support from the arbor, quite heavy cuts can be taken, enabling rapid material removal rates. These are used to mill grooves and slots. Plain mills are used to shape flat surfaces. Several cutters may be ganged together on the arbor to mill a complex shape of slots and planes. Special cutters can also cut grooves, bevels, radii, or indeed any section desired. These specialty cutters tend to be expensive. Simplex mills have one spindle, and duplex mills have two. It is also easier to cut gears on a horizontal mill.

Technical Specification of Vertical Milling Machine:1. Make/type 2. Plant no. 3. Working table length & width 4. Longitudinal traverse 5. Vertical traverse 6. Cross traverse 7. Distance b/w main spindle to table surface min & max 8. Distance b/w main spindle centre to column slide 9. Swivel of spindle head on either side 10. Vertical movement of spindle : : : : : : : : : : BATLIBOI-FA3V 1310-001. 1250x300 mm. 800 mm. 390 mm. 265 mm. 0 & 450 mm. 300 mm. 450 75 mm.

Technical Specification of Universal Milling Machine:1. Make/type : BFW-UF-I 2. Plant no. : 1307-001 3. Table overall size : 1175x230 mm. 4. Table clamping area : 1000x230 mm. 5. Table longitudinal movement automatic : 560 mm. 6. Table longitudinal movement manual : 590 mm. 7. Table traverse movement automatic : 250 mm. 8. Table traverse movement manual : 270 mm. 9. Table vertical movement manual : 340 mm. 10. Table swivel to either side : 450 mm. 11. Distance of spindle centre to table surface : 0-330 mm. 12. Distance of spindle centre to left hand end of table : 250 mm.

7. Grinding machine:-

Rotating abrasive wheel A grinding machine is a machine tool used for grinding, which is a type of machining using an abrasive wheel as the cutting tool. Each grain of abrasive on the wheel's surface cuts a small chip from the work piece via shear deformation. The grinding machine consists of a power driven grinding wheel spinning at the required speed and a bed with a fixture to guide and hold the work-piece Grinding machines remove material from the workpiece by abrasion, which can generate substantial amounts of heat; they therefore incorporate a coolant to cool the workpiece so that it does not overheat and go outside its tolerance. The coolant also benefits the machinist as the heat generated may cause burns in some cases. In very high-precision grinding machines (most cylindrical and surface grinders) the final grinding stages are usually set up so that they remove about 2/10000mm (less than 1/100000 in) per pass - this generates so little heat that even with no coolant, the temperature rise is negligible.

8.Surface grinding:-

Surface grinding is a widely used process of machining in which a spinning wheel covered in rough particles cuts chips of metallic or non metallic substance making them flat or smooth. Spark out is a term used when precision values are sought and literally means "until the sparks are out (no more)". It involves passing the workpiece under the wheel, without resetting the depth of cut, more than once and generally multiple times. This ensures that any inconsistencies in the machine or workpiece are eliminated. As with any grinding operation, the condition of the wheel is extremely important. Diamond dressers are used to maintain the condition of the wheel, these may be table mounted or as the first image shows, mounted in the wheel head where they can be readily applied

Effects on work material properties

The high temperatures encountered at the ground surface create residual stresses and a thin martensitic layer may form on the part surface; this decreases the fatigue strength. In ferromagnetic materials, if the temperature of the surface is raised beyond the Curie temperature then it may lose some magnetic properties. Finally, the surface may be more susceptible to corrosion.

*****************

You might also like

- Shop-4-Cross Peen Hammer HeadDocument8 pagesShop-4-Cross Peen Hammer HeadJag MasterNo ratings yet

- Lathe ReportDocument11 pagesLathe ReportWan Syafiq Wan Syamsulbahri100% (2)

- LATHEDocument9 pagesLATHEArun PrasadNo ratings yet

- Mashop Theory and PracticeDocument38 pagesMashop Theory and PracticeCel Caren MakidatoNo ratings yet

- MTM Lab Report..517Document78 pagesMTM Lab Report..517Furqan AhmadNo ratings yet

- Lab MannualsDocument15 pagesLab MannualsJatin PahujaNo ratings yet

- Threading Operations of Lathe SystemDocument37 pagesThreading Operations of Lathe SystemResshille Ann T. SalleyNo ratings yet

- Make a Pin Hammer with Hand & Machine ToolsDocument17 pagesMake a Pin Hammer with Hand & Machine ToolsTan YikcongNo ratings yet

- JOB REPORT ON MACHINE SHOP TURNINGDocument8 pagesJOB REPORT ON MACHINE SHOP TURNINGNur Akmal100% (1)

- Production Technology: Department of Mechanical EngineeringDocument17 pagesProduction Technology: Department of Mechanical Engineeringrahul bhattNo ratings yet

- Lab 1Document8 pagesLab 1Khurram SattarNo ratings yet

- Operations in TurningDocument8 pagesOperations in Turningcanavarsanayok100% (1)

- Lathe Facing Operation Reduces Cylindrical Workpiece LengthDocument32 pagesLathe Facing Operation Reduces Cylindrical Workpiece Lengthusmaniqbal15No ratings yet

- Lathe MachineDocument20 pagesLathe MachineNor Faizal Nuroddin100% (2)

- Shop Exercise 5Document7 pagesShop Exercise 5marisonNo ratings yet

- Machine ShopDocument21 pagesMachine ShopBiladenNo ratings yet

- Lathe Safety ProceduresDocument6 pagesLathe Safety ProceduresbrodyNo ratings yet

- MTM FinalDocument59 pagesMTM FinalQasim AliNo ratings yet

- A LatheDocument7 pagesA LathePassmore DubeNo ratings yet

- Lathe Machine Guide: Components, Operations & SafetyDocument34 pagesLathe Machine Guide: Components, Operations & SafetyIxora My0% (2)

- DJM1012 Mechatronic Workshop Practice-Machining ReportDocument16 pagesDJM1012 Mechatronic Workshop Practice-Machining ReportRachel Ramirez100% (7)

- Various Types of Operations Performed in Lathe Machine - Education Discussion PDFDocument13 pagesVarious Types of Operations Performed in Lathe Machine - Education Discussion PDFtinku meenaNo ratings yet

- Shop Practice Number 4Document9 pagesShop Practice Number 4JantzenCaliwliwNo ratings yet

- Experiment No. 2: To Perform Facing Operation On LatheDocument3 pagesExperiment No. 2: To Perform Facing Operation On LatheHasnain Ashraf100% (1)

- Hammer Full ReportDocument9 pagesHammer Full ReportVince Ong100% (3)

- Machining ProcessDocument23 pagesMachining ProcessAshish KatariaNo ratings yet

- c5 Lathe 120203152613 Phpapp02Document30 pagesc5 Lathe 120203152613 Phpapp02Preavin Kutty Thamotharan100% (1)

- Machine Tools Guide in 40 CharactersDocument16 pagesMachine Tools Guide in 40 CharactersKarNo ratings yet

- Lathe MachineDocument7 pagesLathe MachineJacTomlinNo ratings yet

- Lab Report 3Document7 pagesLab Report 3mamoona noreenNo ratings yet

- Quiz1 ReviewerDocument17 pagesQuiz1 ReviewerJag MasterNo ratings yet

- Facing OperationsDocument8 pagesFacing OperationsRaihan KabirNo ratings yet

- A Milling MachineDocument8 pagesA Milling MachinepedjaNo ratings yet

- Machine Tool and Maching Lab ReportDocument20 pagesMachine Tool and Maching Lab ReportFurqan AhmadNo ratings yet

- Lathe ExperimentDocument7 pagesLathe ExperimentMd Sajib SheikhNo ratings yet

- Lathe Operations & Cutting Tools GuideDocument16 pagesLathe Operations & Cutting Tools Guideohfwo nsfjdfNo ratings yet

- Facing Operations: Using A 4-Jaw ChuckDocument8 pagesFacing Operations: Using A 4-Jaw ChuckMajida AdilNo ratings yet

- Machine ShopDocument22 pagesMachine Shopanurag6866No ratings yet

- Presentation On Lathe and Shaper MachineDocument13 pagesPresentation On Lathe and Shaper Machinemukul anand jhaNo ratings yet

- Lathe and DrillingDocument13 pagesLathe and DrillingwableamolmechNo ratings yet

- Lathe MachineDocument8 pagesLathe MachineMarc Augustus GarciaNo ratings yet

- Up Workshop Manual 2020Document62 pagesUp Workshop Manual 2020Yash MittalNo ratings yet

- BTEC Assignment - Unit 30Document18 pagesBTEC Assignment - Unit 30Muthu RajanNo ratings yet

- Machine Lab - ReportDocument11 pagesMachine Lab - Reportsaiq kamranNo ratings yet

- JJ 104 Workshop Technology 1 MillingDocument44 pagesJJ 104 Workshop Technology 1 MillingHusaini Zamzury0% (1)

- Lathe MachineDocument38 pagesLathe Machinealmir_rimlaNo ratings yet

- Experiment No 8: To Perform Boring Operation On Lathe: Theoretical BackgroundDocument3 pagesExperiment No 8: To Perform Boring Operation On Lathe: Theoretical BackgroundHasnain AshrafNo ratings yet

- ME2207 Lab ManualDocument45 pagesME2207 Lab ManualchristadcrNo ratings yet

- Chapter Two: Turning and Related OperationsDocument78 pagesChapter Two: Turning and Related OperationsElwy MustafaNo ratings yet

- Lathe Accessories and Attachments Lathe Accessories:: 1. Face PlateDocument7 pagesLathe Accessories and Attachments Lathe Accessories:: 1. Face PlateRohan SahaNo ratings yet

- Facing Operations LatheDocument7 pagesFacing Operations LatheJennifer Nicky ShakerNo ratings yet

- Lathe Machine ReportDocument28 pagesLathe Machine ReportFaizal64% (11)

- Ex. No. Date Name of The Experiment Page No. Remarks Staff SignatureDocument18 pagesEx. No. Date Name of The Experiment Page No. Remarks Staff SignatureDivin Kumar MNo ratings yet

- Basic Operation of A LatheDocument6 pagesBasic Operation of A LatheRex GalichaNo ratings yet

- Lathe MachineDocument16 pagesLathe MachineM Arslan AshrafNo ratings yet

- Machine ShopDocument12 pagesMachine ShopAmmad Ud DinNo ratings yet

- Shop Practice No. 7 Off Hand Method: Ball-Peen HammerDocument13 pagesShop Practice No. 7 Off Hand Method: Ball-Peen HammerEriane Garcia100% (2)

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- CarAV AVH 3750DVDDocument1 pageCarAV AVH 3750DVDgerardo perezNo ratings yet

- 5000 Gantry ReplacementDocument8 pages5000 Gantry ReplacementkarlwizardNo ratings yet

- CS-341 Chain Saw: Parts CatalogDocument36 pagesCS-341 Chain Saw: Parts CatalogГоран СтанишићNo ratings yet

- MEP FP Inspection Checklist PDFDocument6 pagesMEP FP Inspection Checklist PDFRichard RajkumarNo ratings yet

- Production Schedule MonitoringDocument34 pagesProduction Schedule Monitoringamma mimuNo ratings yet

- Branch Circuits SimplifiedDocument60 pagesBranch Circuits SimplifiedEmman Joshua BustoNo ratings yet

- Suzuki GSX400 Parts CatalogDocument218 pagesSuzuki GSX400 Parts CatalogNino AlicNo ratings yet

- MR337CLIO6Document33 pagesMR337CLIO6Linas Vr100% (2)

- IND Drawworks DLS 163Document11 pagesIND Drawworks DLS 163Jose Luis MazzoniNo ratings yet

- CatalogueDocument132 pagesCataloguesamsungmkNo ratings yet

- Design and Function of Spray GunDocument5 pagesDesign and Function of Spray GunHomayoon GeramifarNo ratings yet

- General Purpose Machine Tools GuideDocument33 pagesGeneral Purpose Machine Tools GuidemecoolguysNo ratings yet

- Latihan Combase Excel Universitas UTI 2022Document9 pagesLatihan Combase Excel Universitas UTI 2022Maria Dewinta AgustinNo ratings yet

- Catalogo - Claves SatDocument8 pagesCatalogo - Claves SatAngeles SanchezNo ratings yet

- MSP Duct Installation ManualDocument48 pagesMSP Duct Installation ManualPablo DenisNo ratings yet

- Lathe Milling Tools Flute Slot Drills 2Document4 pagesLathe Milling Tools Flute Slot Drills 2enricoNo ratings yet

- Daywaise Diary of ITRDocument8 pagesDaywaise Diary of ITRIsha Awhale PatilNo ratings yet

- 938K Eletrico Serie AltaDocument39 pages938K Eletrico Serie AltaEmanoel FelipeNo ratings yet

- 1326AB Motor Junction Box: Installation InstructionsDocument8 pages1326AB Motor Junction Box: Installation InstructionsNelson MartinezNo ratings yet

- Installation Procedure for Evans Waterless Coolant and ResistorPac in 2011 Navistar MaxxForce 13LDocument9 pagesInstallation Procedure for Evans Waterless Coolant and ResistorPac in 2011 Navistar MaxxForce 13LVeterano del CaminoNo ratings yet

- Bettis 2000 Series E796 M2CP: Installation and Maintenance ManualDocument27 pagesBettis 2000 Series E796 M2CP: Installation and Maintenance ManualCristian GarcíaNo ratings yet

- Electrical Wiring Components and AccessoriesDocument21 pagesElectrical Wiring Components and Accessoriesanshuman singhNo ratings yet

- Installation Operation Maintenance: Chilled Water Fan Coil Unit Maxxum Model:HCCA Size:10 24Document20 pagesInstallation Operation Maintenance: Chilled Water Fan Coil Unit Maxxum Model:HCCA Size:10 24mgs nurmansyahNo ratings yet

- Lathe, Lathe Tools and WorksDocument5 pagesLathe, Lathe Tools and WorksHafsah M. MohammadaliNo ratings yet

- Volkswagen Engine and Transmission Codes: DTC DescriptionDocument27 pagesVolkswagen Engine and Transmission Codes: DTC DescriptionDanyBobNo ratings yet

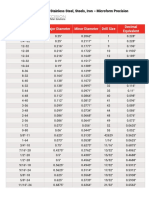

- TapDrill Chart Stainless Steel Iron Steel Microform PrecisionDocument2 pagesTapDrill Chart Stainless Steel Iron Steel Microform PrecisionOdanasNo ratings yet

- Emplacement Article Listing with Product DetailsDocument77 pagesEmplacement Article Listing with Product DetailsamineNo ratings yet

- Sony Kv-xf21 ManualDocument26 pagesSony Kv-xf21 ManualMuns BadillaNo ratings yet

- Scott Service ManualDocument68 pagesScott Service ManualzokiNo ratings yet

- Turbine Area LCP: S.N. Description Specification Material CodeDocument99 pagesTurbine Area LCP: S.N. Description Specification Material CodeYadav AkhileshNo ratings yet