Professional Documents

Culture Documents

Refrigeration Laboratory Unit

Uploaded by

khalijahjamalOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Refrigeration Laboratory Unit

Uploaded by

khalijahjamalCopyright:

Available Formats

POLITEKNIK KOTA KINABALU SABAH

MECHANICAL ENGINEERING DEPARTMENT

CODE COURSE :

J2006

THERMODYAMICS 1 : REFRIGERATION

TOPIC LABORATORY UNIT

EXPERIMENT 1: VAPOR-COMPRESSION REFRIGERATOR

1.0

Objectives

i. ii.

To understand the basic working principles of a vapor-compression refrigerator and its components. To sketch the Ts and P-h diagrams for a vapor-compression refrigerator.

2.0

Theory

3.0

Equipments / Tools

4.0

Safety and Health

i. ii. iii. iv.

Always make sure that water supply is connects before the experiment start. Set the spring scale to zero before experiment start. Do not try to change the setting of the meter. Ensure that the electrical console is dry at all times to prevent electrical shock.

5.0

Procedures

5.1

Setup Procedures

i.

Connect the hose to connector of the machine, one to water supply and the other one to drain. Fully open the flow meter control valve, after that slowly open the water supply as well. Do not let the water flow rate over the maximum level (50g/s). Plug the 3 pin plug to the 240 AC main power supply. Turn ON the power supply. Switch ON the main switch at the side of the machine panel.

ii. iii.

iv. v. vi.

Check all the display meters. Ensure that they are function by turning the selector switch to check each temperature point reading. Switch ON the heater and compressor. The indicator of refrigerator flow meter will float up and shows the refrigerant flow rate as the compressor being turn ON. Meanwhile the spring scale also will show the loading on the motor. Disconnect water supply hose once the experiment finish.

vii.

5.2

Experiment Procedures

i. ii.

Switch ON the main switch located at the side of control panel. Record down all the initial reading display on the meter and gauge by turning the selector a) Temperature b) Pressure c) Water Mass flow rate d) Refrigerant - Mass flow rate e) Current and voltage (Heater) f) Current and voltage (Compressor) turning the selector. g) Motor speed.

iii. iv. v. vi. vii. viii.

For the spring scale, level the arm to the pointer. Record the initial value of it. Turning the water control valve on the flow meter to get the desire flow rate. Switch ON the compressor. The spring scale now will move down and not level to the pointer. Loose the knob and pull the holder to adjust back to previous position. Let the machine to run about 10 minutes. After 10 minutes, records down all the reading.

ix. x. xi.

Let the machine to stable in 10 minutes before start the other experiment. The first experiment can be test with others cooling load by switch ON the heater and adjust the heat power regulator to get to desired power. By refer to the R 134a properties table, get the values of the specific entropy and specific enthalpy to plot the graph of T-s and P-h diagram.

5.3

Experiment Data

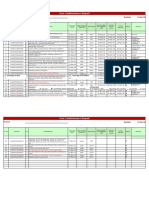

Initial Value Heater Voltage, V1 Heater Ampere, A1 T1 T2 T3 T4 T5 T6 Motor Voltage, V2 Motor Ampere, A2 Force (N) Pressure (P1) Pressure (P2) Motor Speed, (RPM) Mass Flow Rate

You might also like

- Test On Vapor Compression Refrigeration FINALDocument8 pagesTest On Vapor Compression Refrigeration FINALUdara ManawaduNo ratings yet

- Heat Engines ExplainedDocument78 pagesHeat Engines ExplainedKhushank MNo ratings yet

- RAC Experiments FinalDocument31 pagesRAC Experiments FinalEr Nikhil KakadeNo ratings yet

- Lab 4 Reciprocating CompressorDocument36 pagesLab 4 Reciprocating CompressorJowesh Avisheik GoundarNo ratings yet

- Chapter 11 PDFDocument8 pagesChapter 11 PDFVisakan ParameswaranNo ratings yet

- Ideal Rankine Cycle ExplainedDocument12 pagesIdeal Rankine Cycle ExplainedAarvin GeorgeNo ratings yet

- Vapour Compression RefrigerationDocument38 pagesVapour Compression RefrigerationArvind75% (4)

- 2 Carnot CycleDocument6 pages2 Carnot CycleSamujawal Kumar SumanNo ratings yet

- Design and Analysis of Central Air-Conditioning System With Air Cooled Chiller of Multi-Storey Office BuildingDocument16 pagesDesign and Analysis of Central Air-Conditioning System With Air Cooled Chiller of Multi-Storey Office BuildingSajjad HasanNo ratings yet

- ThermodynamicsDocument26 pagesThermodynamicsManikanta Reddy100% (1)

- Air Compressor Lab PDFDocument4 pagesAir Compressor Lab PDFbernabas100% (2)

- Vapor Power CyclesDocument55 pagesVapor Power CyclesTarikuNo ratings yet

- Refrigeration Laboratory Manual 2011Document19 pagesRefrigeration Laboratory Manual 2011Himanshu Uniyal0% (1)

- 2 Piping Requirements Pme CodeDocument44 pages2 Piping Requirements Pme CodeVincent MartinezNo ratings yet

- Vapor Compression Refrigeration System LabDocument7 pagesVapor Compression Refrigeration System LabKurtNo ratings yet

- SBS5311 1718 07-Refrigeration PDFDocument66 pagesSBS5311 1718 07-Refrigeration PDFRatnin PanityingNo ratings yet

- Auxiliary System of Diesel Electric Power PlantDocument12 pagesAuxiliary System of Diesel Electric Power PlantAllen EspeletaNo ratings yet

- 1 - A Review On Fabrication of Combined Refrigerator Cum Air Conditioning Cum Water Heater Unit by VCRS - MDocument6 pages1 - A Review On Fabrication of Combined Refrigerator Cum Air Conditioning Cum Water Heater Unit by VCRS - Mnadeemq_0786100% (2)

- Refrigeration Cycle Performance AnalysisDocument33 pagesRefrigeration Cycle Performance AnalysisastigeNo ratings yet

- Vapor Absorption Refrigeration CycleDocument11 pagesVapor Absorption Refrigeration CycleUSHA PAWARNo ratings yet

- Assignment Thermal UiTMDocument26 pagesAssignment Thermal UiTMAmirul 'Pit'No ratings yet

- Refrigeration Unit (DONE)Document33 pagesRefrigeration Unit (DONE)Eimint Mansor Applez100% (1)

- Design and Fabrication of Domestic Refrigeration UnitDocument81 pagesDesign and Fabrication of Domestic Refrigeration UnitSadhana DhepaleNo ratings yet

- CH 3 Gas Refrigeration CycleDocument20 pagesCH 3 Gas Refrigeration CycleMeleseNo ratings yet

- Table of Content Heat Pump ExperimentDocument16 pagesTable of Content Heat Pump ExperimentDaniel Razak0% (1)

- ICE Lab ManualDocument68 pagesICE Lab ManualAkhilNagNo ratings yet

- BDA 37201 Engineering Lab V: Thermodynamics Air Conditioning SystemDocument18 pagesBDA 37201 Engineering Lab V: Thermodynamics Air Conditioning SystemMuhd I-dilNo ratings yet

- Lecture 30 Thermal Engineering II (22.09.2020)Document36 pagesLecture 30 Thermal Engineering II (22.09.2020)Dr. BIBIN CHIDAMBARANATHANNo ratings yet

- Refrieration Unit Lab ReportDocument29 pagesRefrieration Unit Lab ReportNor Elina Ahmad100% (9)

- Test Performance of Air Conditioning SystemsDocument20 pagesTest Performance of Air Conditioning SystemsZa YonNo ratings yet

- Power Plant Engineering by S K Mondal PDFDocument109 pagesPower Plant Engineering by S K Mondal PDFShrinivas Subhash Hulsure100% (3)

- Question Bank Thermal Engineering UPDATEDDocument6 pagesQuestion Bank Thermal Engineering UPDATEDIrfan ShaikhNo ratings yet

- Experiment 1 RefrigerationDocument4 pagesExperiment 1 RefrigerationErlangga Sulaiman Razak100% (1)

- MECHANICAL ENGINEERING DEPARTMENT DATE: 15/7/2013 COURSE CODE: MBB 42223Document11 pagesMECHANICAL ENGINEERING DEPARTMENT DATE: 15/7/2013 COURSE CODE: MBB 42223Muhammad Khuzairi33% (3)

- Experiment 4-Heat Pump July 2018Document8 pagesExperiment 4-Heat Pump July 2018Salihah AbdullahNo ratings yet

- Projeect PPT-1Document28 pagesProjeect PPT-1Shubham PawarNo ratings yet

- Discussion Cooling TowersDocument2 pagesDiscussion Cooling TowersHanny100% (1)

- Basic Principles of RefrigerationDocument16 pagesBasic Principles of Refrigerationgenas7265No ratings yet

- Fluid Mechanics Lab Instructor Manual FinalDocument138 pagesFluid Mechanics Lab Instructor Manual FinalMuhammad Ali100% (1)

- Flow and Heat Transfer in A Mixing ElbowDocument5 pagesFlow and Heat Transfer in A Mixing Elbowjose antonioNo ratings yet

- CH 7 PowerCyclesDocument12 pagesCH 7 PowerCyclescarleston thurgoodNo ratings yet

- Effect of Capillary Tube Length On The Vcrs Performance: Experiment No. (1) Mechanical LabDocument15 pagesEffect of Capillary Tube Length On The Vcrs Performance: Experiment No. (1) Mechanical LabDilshad S FaisalNo ratings yet

- Lab 1 Refrigeration CycleDocument8 pagesLab 1 Refrigeration Cycletengku30No ratings yet

- Combustion: Dr. Yusli Yaakob FKM Uitm Pulau PinangDocument36 pagesCombustion: Dr. Yusli Yaakob FKM Uitm Pulau PinangFaris Halim0% (1)

- Stoichiometric CombustionDocument3 pagesStoichiometric CombustionKhairil MunawirNo ratings yet

- 06 Thermodynamic CyclesDocument47 pages06 Thermodynamic CyclesRabi SharmaNo ratings yet

- Literature Review Spur GearDocument3 pagesLiterature Review Spur Gearthai avvaiNo ratings yet

- Measuring Temperature Methods Lab KitDocument2 pagesMeasuring Temperature Methods Lab KitAhmed M. El-DyastyNo ratings yet

- MAPÚA UNIVERSITY WRITTEN REPORT ON HYDRAULICS EXPERIMENTDocument16 pagesMAPÚA UNIVERSITY WRITTEN REPORT ON HYDRAULICS EXPERIMENTAndreNo ratings yet

- Chapter 1Document57 pagesChapter 1Satyam JhaNo ratings yet

- HVAC Unit 2Document52 pagesHVAC Unit 2Rohini Shinde0% (1)

- Thermodynamics I: Mass and Energy, Analysis of Control VolumesDocument24 pagesThermodynamics I: Mass and Energy, Analysis of Control VolumesManmit SinghNo ratings yet

- Proposal Lab Thermo Topic 2 COMPLETEDocument10 pagesProposal Lab Thermo Topic 2 COMPLETEsaperuddinNo ratings yet

- Literature ReviewDocument11 pagesLiterature ReviewAsif RahmanNo ratings yet

- Design Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationFrom EverandDesign Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationNo ratings yet

- Temperature Control Trainer: Experiment No: 04Document3 pagesTemperature Control Trainer: Experiment No: 04Musa KhanNo ratings yet

- Circular Cylinder APPM 4350Document7 pagesCircular Cylinder APPM 4350Atenea SilverioNo ratings yet

- Steam TurbineDocument7 pagesSteam TurbineWaleed NasirNo ratings yet

- TRseries Repair Manual2ENG SmallDocument42 pagesTRseries Repair Manual2ENG SmallKabi RockNo ratings yet

- Basic Cost Management ConceptsDocument33 pagesBasic Cost Management ConceptsMarcela Nichol RaymundoNo ratings yet

- SS 3 Dyeing and Bleaching Revision Week TwoDocument4 pagesSS 3 Dyeing and Bleaching Revision Week TwoFrancisca AgbedoNo ratings yet

- td1437-01 TAD750VE Operaters ManualDocument73 pagestd1437-01 TAD750VE Operaters ManualArtur Daneshwar100% (1)

- Cupling Gear 02Document22 pagesCupling Gear 02Ilse Achanty Barradas100% (1)

- Guide To VRLA Batteries 1927Document8 pagesGuide To VRLA Batteries 1927caplukNo ratings yet

- BLD-CSTN Andhra Pradesh Standard Data for Earthwork Excavation Labour and Machinery RatesDocument977 pagesBLD-CSTN Andhra Pradesh Standard Data for Earthwork Excavation Labour and Machinery Ratestapankumardas100% (1)

- Hindalco EverlastDocument2 pagesHindalco EverlastbipulpalNo ratings yet

- Effect of Case Depth On Fatigue Performance of AISI 8620 Carburized SteelDocument7 pagesEffect of Case Depth On Fatigue Performance of AISI 8620 Carburized SteelthisisjineshNo ratings yet

- Project Solutions Cost Estimating MethodDocument8 pagesProject Solutions Cost Estimating Methodelmfp7774676No ratings yet

- Lubricant Viscocities 140hDocument8 pagesLubricant Viscocities 140hPablo Gaspar D'Agostini AmengualNo ratings yet

- VTT10000 Manual PDFDocument6 pagesVTT10000 Manual PDFalekyaNo ratings yet

- S154-1209 IomDocument66 pagesS154-1209 IomAlfredo GodinezNo ratings yet

- Mitsubishi Hiden SystemsDocument3 pagesMitsubishi Hiden SystemsMedha Jog KatdareNo ratings yet

- External NCR MonitoringDocument7 pagesExternal NCR MonitoringGhayas JawedNo ratings yet

- Voice 487Document1 pageVoice 487Momen AyassrhNo ratings yet

- Environmetal ENG 05-2021 WebDocument10 pagesEnvironmetal ENG 05-2021 WebFernando CastroNo ratings yet

- IO - 20190107 - ABB MV Switchgear 36kV - Installation and Operating Instructions - V20 - ENDocument24 pagesIO - 20190107 - ABB MV Switchgear 36kV - Installation and Operating Instructions - V20 - ENFranco MolinaNo ratings yet

- 20122Document111 pages20122Chandan PathakNo ratings yet

- Building Envelope Compliance FormsDocument9 pagesBuilding Envelope Compliance FormsJWNo ratings yet

- ConductivityDocument36 pagesConductivityThangadurai Senthil Ram PrabhuNo ratings yet

- Bulk BOQUpload TemplateDocument12 pagesBulk BOQUpload TemplatemargamvivekkumarNo ratings yet

- Krytox Chemical StabilityDocument2 pagesKrytox Chemical StabilityMichael PimentelNo ratings yet

- Centrometal Touch TechnicalDocument58 pagesCentrometal Touch TechnicalLuka BardicNo ratings yet

- Centralized Suply of Gas SystemDocument43 pagesCentralized Suply of Gas SystemAmir ChakaNo ratings yet

- Lab ReportDocument65 pagesLab ReportWilliam Liew75% (8)

- Exercise 23 - Sulfur OintmentDocument4 pagesExercise 23 - Sulfur OintmentmaimaiNo ratings yet

- Minolta Ep1050 ServiceDocument266 pagesMinolta Ep1050 ServiceSunny SinghNo ratings yet

- Everything You Need to Know About the Roller IndustryDocument26 pagesEverything You Need to Know About the Roller IndustryAshwani SharmaNo ratings yet

- ACI 211.1 - Mix Deisgn of ConcreteDocument7 pagesACI 211.1 - Mix Deisgn of ConcreteleorNo ratings yet