Professional Documents

Culture Documents

RD9 - Accelerometer Needs For IMU - Final Report 23mar09

RD9 - Accelerometer Needs For IMU - Final Report 23mar09

Uploaded by

llq_nudtOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RD9 - Accelerometer Needs For IMU - Final Report 23mar09

RD9 - Accelerometer Needs For IMU - Final Report 23mar09

Uploaded by

llq_nudtCopyright:

Available Formats

Reference:

Date:

Issue 1

100329339E

25/03/2009

Page i

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

Accel er ometer Needs for IMU

ESA contract 21221/ 07/ NL/ ST

Fi nal Repor t

Written by Responsibility/signature

S. Clerc

Verified by

Pierre-Yves Renaud AOCS Department Manager

Approved by

Sbastien CLERC Study manager

Approved by

Stphane DUSSY ESA Project Manager

Reference:

Date:

Issue 1

100329339E

25/03/2009

Page ii

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

CHANGE RECORDS / ENREGISTREMENT DES EVOLUTIONS

ISSUE DATE CHANGE RECORDS / DESCRIPTION DES

EVOLUTIONS

AUTHOR

1 25/03/2009 First Issue S.C.

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page a

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

TABLE OF CONTENTS

1. Introduction..................................................................................................................... 2

1.1. Purpose................................................................................................................... 2

1.2. References.............................................................................................................. 2

1.2.1. Applicable documents....................................................................................... 2

1.2.2. Reference documents....................................................................................... 2

1.3. Acronyms & abbreviations....................................................................................... 2

2. Introduction..................................................................................................................... 4

2.1. Background and motivation ..................................................................................... 4

2.2. Presentation of the industrial team........................................................................... 5

2.3. Study logic............................................................................................................... 5

3. Technical requirements and main trade-offs ................................................................... 7

3.1. Accelerometers for orbit control ............................................................................... 7

3.2. Accelerometer needs for aerobraking...................................................................... 9

3.3. Accelerometer needs for Entry, Descent and Landing (EDL) ................................... 9

3.4. Accelerometer needs for rover navigation.............................................................. 12

4. Synthesis of requirements and identified products........................................................ 15

4.1. Summary of requirements and drivers................................................................... 15

4.2. Accelerometer classes........................................................................................... 15

4.3. Accelerometer performance requirements............................................................. 17

Measurement range and resolution........................................................................... 17

Bandwidth................................................................................................................. 17

Noise......................................................................................................................... 18

Bias and bias stability................................................................................................ 18

Scale factor and alignment stability........................................................................... 18

Interface.................................................................................................................... 18

Mass and power........................................................................................................ 18

Environment requirements ........................................................................................ 18

5. Survey of accelerometer technologies, performances and trends................................. 20

6. Simulation of IMU performances for a landing mission.................................................. 23

6.1. Description of the simulation tool ........................................................................... 23

6.2. Attitude update ...................................................................................................... 23

6.3. Velocity and position update.................................................................................. 24

6.4. Coast phase .......................................................................................................... 24

6.5. EDL ....................................................................................................................... 25

7. Preliminary design of an IMU for space applications..................................................... 28

7.1. MEMS IMU architecture......................................................................................... 28

7.2. Stand alone accelerometer architecture................................................................. 30

7.3. Budgets ................................................................................................................. 30

8. Preliminary development plan....................................................................................... 32

8.1. Products and schedule .......................................................................................... 32

8.2. Accelerometer development activities.................................................................... 32

8.3. IMU development activities.................................................................................... 33

8.4. Stand Alone Accelerometer development activities................................................ 33

9. Conclusion.................................................................................................................... 35

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 1

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 2

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

1. Introduction

1.1. Purpose

This document presents the main outcomes of the ESA study Accelerometer Needs for IMU

performed in the frame of contract 21221/07/NL/ST.

1.2. References

1.2.1. Applicable documents

[AD-1] Statement of Work of Invitation to Tender AO 03.07.2007, ESA/TEC-ECC/4.07

Issue 1. rev. 4, 2007

[AD-2] TAS Proposal, Ref. 8774145, 2007.

1.2.2. Reference documents

[RD-1.]

Accelerometer Needs for IMU: TN1 IMU and accelerometer needs for space applications,

Issue 3, TAS report n100245522W, 2008.

[RD-2.]

D. Gendre, V. Josselin, S. Dussy, High-performance accelerometer for on-orbit spacecraft

autonomy, AIAA 2004-5432, AIAA Guidance, Navigation, and Control Conference and

Exhibit, 16 - 19 August 2004, Providence, Rhode Island.

[RD-3.]

R.H. Tolson et al., Application of Accelerometer Data to Atmospheric Modeling During

Mars Aerobraking Operations, Georgia Institute of Technology, Atlanta, April 2007.

[RD-4.] Lauro Ojeda, Giulio Reina, Daniel Cruz and Johann Borenstein, University of Michigan,

The FLEXnav Precision Dead-reckoning System, International Journal of Vehicle

Autonomous Systems (IJVAS), Special Issue on "Computational Intelligence and Its

Applications to Mobile Robots and Autonomous Systems., 4, No. 2-4, 2006, pp. 173-195.

[RD-5.] Durrant, D., Dussy, S., Shackleton, B., and Malvern, A., MEMS Rate Sensor Becomes a

Reality, AIAA Guidance, Navigation, and Control Conference, AIAA, Hilton Head, NC,

2007.

[RD-6.] P.G. Savage, Strapdown Inertial Navigation Integration Algorithm Design Part1: Attitude

Algorithms, J. Guidance, Control and Dynamics, 21, 1, 1998.

[RD-7.] P.G. Savage, Strapdown Inertial Navigation Integration Algorithm Design Part 2: Velocity

and Position Algorithms, J. Guidance, Control and Dynamics, 21, 2, 1998.

1.3. Acronyms & abbreviations

In this document the following acronyms & abbreviations (in addition to standard SI units) are

or may be used:

AOCS Attitude and Orbit Control System

ASIC Application-Specific Integrated Circuit

CDR Critical Design Review

DM Descent Module

EDL Entry, Descent and Landing

EIP Entry Interface Point

EM Engineering Model

FDI Failure Detection and Isolation

FOG Fiber Optic Gyroscope

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 3

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

FPGA Field Programmable Gate Array

g Earth gravitational acceleration at sea level (9.80665 m/s)

GNC Guidance, Navigation and Control

GNSS Global Navigation Satellite System

HRG Hemi-spherical Resonating Gyroscope

IC Integrated Circuit

IMU Inertial Measurement Unit

MEMS Micro-Electro-Mechanical System

PCB Printed Circuit Board

PDR Preliminary Design Review

PFM Proto-Flight Model

ppm Parties per million (10

-6

)

SOI Silicon On Insulator

TRB Technical Review Board

VBA Vibrating Beam Accelerometer

VHDL Very high speed integrated circuit Hardware Description Language

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 4

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

2. Introduction

2.1. Background and motivation

During the last decade, the European Space Agency has promoted the development of

inertial navigation sensors in Europe. This effort has been met with success for the European

space industry, both from the point of view of technology and commercially. In the field of

gyroscopes, the following sensors have been developed:

High accuray Fiber Optic Gyros (FOG) (10

-3

deg/h class) with applications to Science or

Earth Observation missions requiring accurate pointing. This gyro family (Astrix)

completed its qualification and will be embarked on Galileo in-orbit validation satellites,

Planck, Aeolus, Gaia and Pleiades.

Medium performance Hemispherical Resonator Gyro (HRG)

(0.5 deg/h class) with

applications to Telecom missions with not too demanding pointing requirement. The

qualification of this gyro (REGYS-20), selected for the geostationary platforms Alphabus

and Spacebus 4000, will be completed in 2010.

Coarse MEMS Rate Sensor covering the low performance needs (5 deg/h class), for all

missions requiring rate damping, slew maneuvers, Earth or Sun acquisition, Failure

Detection and Identification (FDI), safe mode or coarse navigation functions. The

qualification of this gyro, selected for the Earth Observation mission Sentinel-3, will be

completed in 2010.

On the other hand, no space qualified European navigation accelerometer exists on the

market today, either in stand-alone configuration or integrated in an Inertial Measurement

Unit (IMU). This has led the European Space Agency to initiate an accelerometer/IMU

development effort. The present study has been the first step in this direction.

The development of the European accelerometer/IMU will support the implementation of

future European missions involving aerobraking, deep space maneuvers and fine orbit

control (for rendezvous, station keeping, coarse formation flying), but most of all landers and

rovers.

A case in point is the Exomars mission, the first European mission of the Aurora program of

robotic exploration. The Aurora missions involve a strong technology development content

which can act as building blocks to eventually support human space exploration. Technology

demonstration objectives include Entry, Descent and Landing (EDL) of a large payload on

the surface of Mars and surface mobility via a Rover having several kilometres of mobility

range. In parallel, important scientific objectives will be accomplished through a state-of-the

art scientific payload such as the search for traces of past and present life and the

characterisation of the water/geochemical environment as a function of depth in the shallow

subsurface.

Thanks to their low cost and mass, accelerometers could also be used for other applications

such as support of spin-stabilized spacecraft or monitoring of flexible modes.

Micro Electro Mechanical System (MEMS) technology has been identified early on as a most

promising path for a future European space accelerometer, a fact which was confirmed by

the present study. Indeed, the technology is now ubiquitous in Earth applications

(automotive, mining and petroleum industry, aeronautics, entertainment, medical an military

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 5

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

applications). They cover the whole range of performances, from low-cost coarse

inclinometers used in mass market applications to high-end navigation products, with the

possible exception of very fine resolution sensors (sub-g). In terms of MEMS accelerometer

technology, pendulum accelerometers with capacitive read-out are the most common. Most

of the manufacturing techniques (micromachining, wet or dry etching for silicon) are well

mastered by European manufacturers. Some European manufacturers also master Vibrating

Beam Accelerometer technology, either with piezoelectric readout (quartz) or capacitive

(silicon), mostly devoted to military applications.

The present study tried to identify the most promising sensor technologies, as well as the

development effort needed to bring a sensor to space qualification.

2.2. Presentation of the industrial team

The present study was managed by Thales Alenia Space France, acting as prime contractor.

The technical contribution was focused on the study of accelerometer uses for space

applications and the derivation of IMU and accelerometer requirements. In a second phase,

Thales Alenia Space France evaluated the expected performances of the proposed IMU for

EDL applications through numerical simulation.

The development of the simulation tool was supported by the Thales Aerospace division,

who brought their knowledge of inertial navigation systems and algorithms. Thales is a major

provider of inertial navigation solutions for aeronautics, launchers and military applications.

The requirements analysis was supported by Thales Alenia Space Italy. More specifically,

the Italian team focused on Entry Descent and Landing, Rover navigation, launchers and

science applications, building on the experience of the Exomars mission design, as well as

science missions such as GOCE.

MEMSCAP studied the existing accelerometer technology, products and manufacturers on

the current market and the evolution trends. In a second phase of the study, they proposed a

preliminary sizing of a MEMS accelerometer, and helped to define a mathematical model of

the sensor. MEMSCAP is a French MEMS manufacturer located in Grenoble, with business

units in Norway and in the USA. MEMSCAP products address a large variety of markets,

including wireless and optical communications, medical devices, and microphones.

MEMSCAP brought to the industrial team their knowledge of both mass market and high-end

MEMS products, as well as their mastering of design, production and testing issues.

The preliminary design and the development plan of the future IMU was studied by SEA in

Bristol, UK. SEA is a provider of advanced technology solutions for space, marine, defense

and transportation. More specifically, SEA has a recognized expertise in the development,

manufacturing and testing of space electronics. SEA, with the support of AIS, is responsible

for the development of the MEMS rate sensor SiREUS.

2.3. Study logic

The study was decomposed into three main phases:

In a first phase, accelerometer needs for space mission were studied. In parallel, a

market and technology survey identified the most adequate products and technology. At

the end of this phase, accelerometer products were identified as meeting point(s)

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 6

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

between technology and needs. This phase also identified the most promising

technologies, and the crucial design parameters. At the end of this phase, it appeared

that a MEMS accelerometer could meet most space applications needs, and in particular

EDL, rover navigation, aerobraking and support of chemical propulsion. Silicon vibrating

beam and silicon capacitive technologies were considered the most promising.

A second phase of the study was devoted to the verification of the expected performance

of the IMU. A main outcome of this phase was the selection of a candidate gyro to build a

future European IMU. Whereas performances for a stand alone accelerometer can be

evaluated by simple computations, the end-to-end performance of an IMU during an EDL

mission for instance requires a detailed dynamic simulations, taking into account

navigation algorithm performance and environmental constraints (mainly thermal). At the

end of this phase, it was decided to select the SiREUS MEMS rate sensor as a basis for

the preliminary IMU design. Accelerometer technical requirements were consolidated and

a specification document was issued.

The third phase dealt with the preliminary design and development plan. This activity

addressed such issues as selection of space-compatible electronics for the MEMS

accelerometer, as well as mechanical and electronic design of the IMU, based on the

current SiREUS unit. Concerning the development plan, it was decided to focus on the

spatialization of a MEMS accelerometer with a good level of maturity rather than starting

a new sensor development.

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 7

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

3. Technical requirements and main trade-offs

Accelerometers are able to determine the non-gravitational acceleration of a vehicle in a

vehicle-fixed frame. In order to be used as an inertial navigation sensor, the accelerometer

must be completed by a gyro to recover the attitude of the vehicle in the inertial reference

frame, and a gravity model to estimate the gravitational acceleration. For other uses, the

accelerometer can be used as a stand-alone sensor. This is the case, for instance, if one

wants to monitor a force with a known orientation in the vehicle frame: propulsion monitoring,

atmospheric drag for parachute opening and, to a lesser extent, aerobraking. However a low-

cost gyro could make an inertial measurement unit more interesting than a stand-alone gyro

even in these cases.

When estimating the requirements for an inertial navigation system, it is crucial to compare it

with alternative navigation solutions. These include GNSS navigation for low Earth Orbit

missions, radio-navigation for geostationary or interplanetary missions, and relative

navigation sensors (cameras, lidars, radars) for interplanetary approach, landing and rovers

as well as rendez-vous and formation flying missions. The benefits of the IMU navigation rely

on its relatively low cost and weight, its robustness, while the main drawback is the long term

drift due to the double integration needed to determine the position.

3.1. Accelerometers for orbit control

A first type of usage of on-board accelerometers is for propulsive orbit control. More

specifically, the following uses can be distinguished:

Failure detection. A typical case is the detection of a main engine anomaly during a time-

critical maneuver such as planetary orbit insertion. A reconfiguration to a back-up

propulsion system can be triggered if the anomaly is detected fast enough. Some

accelerometer redundancy is required in order to discriminate between propulsion and

accelerometer failure. A possible solution consists in placing the three-axis accelerometer

set in a skewed configuration with respect to the propulsion axis. Performance

requirements are relatively mild in this case, even taking into account large confidence

intervals to avoid false alarms.

Navigation: in this case the accelerometer is used to improve the a posteriori knowledge

of the executed V maneuver, which in turns improves the future orbit propagation

accuracy. This can be useful for instance for a nadir-pointing orbital mission, to determine

more accurately the nadir direction.

V execution control: in this last case, the propulsion burn is stopped when the

commanded V has been reached. This is possible only when the burn lasts

(significantly) more than the accelerometer readout period.

Since the acceleration is nearly constant during the V execution, the accelerometer

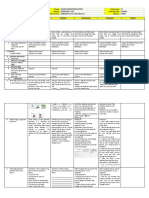

performance requirements for orbit control can be easily analyzed by summing the

contribution of the various error sources thanks to a simple spreadsheet, see example in

Figure 3-1. The accelerometer characteristics can be optimized so as to meet the

requirements for the largest class of maneuvers.

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 8

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

CASE V = 0.1 m/s

Required precision 1.0%

confidence interval 3

Resulting precision @ 1

3.33E-04 m/s

Thruster acceleration 0.075 m/s

Manoeuvre time 1.326 s

Meas. Frequency 10.0 Hz

Number of meas. 14

Error budget

measurement

error [m/s]

Scale factor 500 ppm 5.00E-05

Non-linearity 300 g/g 2.22E-05

Bias (calibrated) 3.2 g 4.20E-05

Bias drift 45 g/hr 1.08E-07

White noise 20 g/ Hz 2.26E-04

Read out noise 0.06 mm/s 2.24E-04

Misalignment 500 rad 5.00E-05

RSS 3.30E-04

contribution

0.0E+00

5.0E-05

1.0E-04

1.5E-04

2.0E-04

2.5E-04

3.0E-04

3.5E-04

S

c

a

l

e

f

a

c

t

o

r

N

o

n

-

l

i

n

e

a

r

i

t

y

B

i

a

s

(

c

a

l

i

b

r

a

t

e

d

)

B

i

a

s

d

r

i

f

t

W

h

i

t

e

n

o

i

s

e

R

e

a

d

o

u

t

n

o

i

s

e

M

i

s

a

l

i

g

n

m

e

n

t

Figure 3-1: Example of a measurement error budget for a 0.1 m/s trajectory control maneuver.

When analyzing the requirements for orbit control, the main parameters are the effective

acceleration and the length of the burn. Accelerations vary from 0.5 m/s for a main engine to

0.1 mm/s for cold gas thrusters or electric propulsion, with a direct impact on the required

accelerometer resolution. Longer burns are easier to measure because the measurement

noise is filtered over the integration time. The bias stability in itself is never a critical aspect

even for very long burns (orbit insertion). On the other hand measuring small accelerations

require a careful bias calibration beforehand. The required calibration residual places an

indirect requirement on the bias stability.

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 9

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

Low thrust propulsion (electric propulsion and cold gas) is a very specific case. Applications

could include fine formation control, autonomous station-keeping for geostationary and

Lagrange point missions, and interplanetary cruise. The very low acceleration requires a fine

resolution accelerometer, in the m/s range. While geostationary station keeping requires a

bandwidth of about 1 Hz, interplanetary missions involve very long thrust arcs (10

-4

Hz). A

multi-mission accelerometer for electric propulsion support should therefore have a

measurement bandwidth of at least [10

-4

: 1] Hz.

3.2. Accelerometer needs for aerobraking

Since the pioneering Magellan aerobraking mission at Venus (1993), the role of

accelerometers to support aerobraking operations has steadily increased. Originally seen as

an engineering sensor to monitor the structural load on spacecraft surfaces, its role has been

extended to autonomous inertial navigation and to the determination of atmospheric

properties for science purposes. The recent Mars Reconnaissance Orbiter mission has been

equipped with a high-precision accelerometer (resolution of 5 m/s), allowing an

unprecedented measurement of the atmospheric drag [RD-3.]

We have analyzed the performance requirements for an aerobraking mission. For

autonomous inertial navigation, a 1 mm/s resolution seems sufficient, although a general

trend toward more autonomy during aerobraking could lead to more demanding

requirements in the future.

The determination of atmospheric properties (density and wind) on the other hand could in

principle benefit from a finer resolution. However the precision of the determination is limited

by a number of system-level errors and biases. The first and probably the most important

one is the uncertainty on the aerodynamics coefficient database used to recover the density

from the drag. The position uncertainty coming from the inertial navigation process has also

a strong impact, especially on the recovery of the lateral wind. Finally, structural and slosh

modes can induce low frequency disturbances of the measured acceleration which can

interfere with the determination of the atmospheric structure. For these reasons, we suspect

that in the near future improvements on the determination of atmospheric properties should

be obtained by tackling the system-level error sources rather than improving the

accelerometer resolution.

3.3. Accelerometer needs for Entry, Descent and Landing (EDL)

The IMUs are widely used in EDL applications for the following purposes

Inertial Navigation during the Coasting, Entry and initial Descent phases

Entry Interface Point (EIP) Detection

Parachute Deployment Trigger detection

Terrain Based Navigation

A last function, the detection of the touchdown instant, may also rely on specific

accelerometers (different from the ones in the navigation IMUs) for some mission scenarios.

Inertial Navigation

Inertial Navigation is active from the instant of separation until navigation becomes terrain-

based (with Doppler radar altimeters as for the case of ExoMars- or to stereo-

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 10

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

cameras/lidars). The fundamental purposes of the inertial navigation are 1) to propagate the

rotational state vector through integration of the gyroscope measurements and 2) propagate

the translational state vector through integration of the accelerometer measurements

(transformed in the inertial frame through the gyro-based attitude knowledge). Both

integration processes have effect on the accuracy at landing: the former process gives the

knowledge of the body frame in the inertial frame, the latter determines the knowledge of the

local vertical in the inertial frame, their combination identifies the attitude of the descent

module in the local vertical frame of the landing site. The inertial navigation error, along with

environmental effects, control inaccuracy (reaction control system) and guidance

uncertainties contribute to the total attitude error at touch-down. The inertial navigation error

allocation in this budget is in turn decomposed into a contribution from gyro and

accelerometer errors.

Lets consider first of all the gyroscope requirements determination. The following error

contributions can be considered:

the attitude knowledge error at initialization (i.e. at separation from the Carrier) in []

the residual bias from the calibration in [/hour]

the variable drift terms in [/hour]

the residual scale factor error around the spin axis in [ppm]

The ability to estimate a constant bias is limited by the variable drift. For a medium accuracy

gyroscope with a fixed bias of 1/hour, the calibration algorithm can be assumed to provide a

residual of 10%. (0.1/hour @ 1 ). The same value (0.1/hour @ 1 ) can be assigned for

the contribution of variable drift terms, An attitude knowledge error of 0.1 at separation is a

reasonable figure in the ExoMars case. The angular error after three hours of integration

reaches 0.44 @ 1. Around the spin axis the error allocation is relaxed to include also the

integration of the scale factor error (0.8 @ 1). This figure has been derived fixing a

maximum threshold of 0.57@ 1, compatible with the above described error allocation

methodology, for the errors allowed around the two axes orthogonal to the spin axis. In turn,

a specification for the maximum scale factor error residual is derived. For the case of the

ExoMars Descent Module (DM) an error of 6 ppm is determined considering a reference spin

rate of 15 /s. These requirements have been relaxed more recently after evaluation of the

relatively contained impact of IMU incremented errors in a simulated environment.

Before lander release, radar measurements are rotated in the local vertical local horizontal

frame thanks to the inertial attitude integration. A sudden variation of the incremental angle

due to the gyro noise coupled with the terrain-based sensor measurement creates a fictitious

horizontal velocity error that degrades the attitude profile generation. At lander release this

error shall be negligible w.r.t. the noise level in velocity of the terrain-based sensor. This

rationale gives a gyro noise requirement of 4 /Hz.

For the definition of accelerometer requirements we have to consider the following error

contributions:

the error for neglecting the environmental disturbances during the coasting outside the

atmosphere (gyro-integration only)

the error due to the assumption of a flat Mars surface when the navigation changes from

inertial to terrain-based

the error due to accelerometer bias

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 11

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

the inaccuracy due to the accelerometer scale factor error

the error in the knowledge of the descent module position at separation from the Carrier

the error in the knowledge of the descent module velocity at separation from the Carrier

The first and second contributions are one magnitude order lower than the allocation (0.2 @

1 ) and in practice negligible. The bias and scale factor errors have a large contribution on

the final accuracy of the local vertical knowledge. The determination of this impact has been

studied by a parametric study of the final angular displacement after integration of the

trajectory. Over the Entry phase, the accumulation of angular displacement due to a scale

factor error in the order of 300 ppm and a bias in the order of 0.3 mg yields a 0.1 error. The

allocation of the Position Error and Velocity Error in the knowledge of the DM at separation is

consistent with the overall budget and the technological limits of the state reconstruction

techniques from ground.

Planar Angle Error

-0,5

-0,4

-0,3

-0,2

-0,1

0

0,1

0,2

0,3

0,4

0,5

0 50 100 150 200 250 300 350

Time [s]

E

r

r

o

r

[

d

e

g

]

err acc+

err acc-

err acc+,fpa+

err acc+,fpa-

err acc-,fpa+

err acc-,fpa-

Main Parachute

Retrorockets Firing

Figure 3-2: Evolution of the planar angle related to the accelerometer error, from EIP to landing

point. Cases of positive or negative bias and scale factor are represented by the blue and

magenta curves respectively. Error evolutions are only slightly impacted by the gyro error of

0.2 deg.

EIP detection

While the entry phase, thanks to its short duration, does not seem to impose a stringent

accelerometer calibration, the same doesnt apply to the EIP detection. Analyses show that:

Calibration of bias around X axis before separation (handled by the Carrier/Mission

Control Center) shall be guaranteed with a residual error of 10% of the nominal bias

If necessary, the descent module GNC shall be able to improve this result with a further

reduction of the residual to 23%

As far as the accelerometer noise is concerned, the most demanding algorithm is again EIP

detection. In this algorithm we must identify the instant when a specific load factor threshold

is encountered, typically 1.5 e

-3

m/s. The noise must be therefore filtered to be sufficiently

lower than this threshold. A filtering time of 5 s is consistent with an altitude range over the

Mars surface between 100 and 120 km. Finally, an Accelerometer Noise better than about

0.1 mg/Hz and a Quantization Noise better than 600 g @ 100 Hz are required.

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 12

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

Parachute Deployment Trigger detection

The sensitivity of two candidate algorithms has been analyzed: 1) a time-tagged propagation

derived from two time evaluations along the Entry acceleration time history (Time Tagged

criterion); 2) direct measurement of the acceleration in proximity of the opening point (g-

switch criterion). Combining those algorithms allows a reliable determination of the

parachute opening point.

Sensor errors can be split in two categories:

errors mainly influencing the mean of the Mach number, the dynamic pressure and the

altitude errors (i.e. sensor bias error and scale factor error)

errors mainly influencing the standard deviation of the Mach number, the dynamic

pressure and the altitude errors (white noise error and quantization error)

Results demonstrated that both algorithms are quite insensitive to these sensor errors.

Furthermore, the sensitivity curves show a quite flat trend for errors between 1 and 4 times

the figures specified by the other mission needs: therefore parachute deployment trigger

algorithms are not important drivers for the choice of the accelerometers in the frame of EDL

applications.

Terrain Based Navigation

Terrain Based Navigation uses the IMU to complement the measurements for terrain

approach and landing. This auxiliary contribution to the navigation is two-fold. The rotational

state estimation, fed by gyroscopes, is used to control the attitude in the landing terrain

reference frame. The accelerometer measurements are fused with the measurements of the

terrain-based sensors for the descent and horizontal translational navigation and

compensate the delays of the terrain-based sensors. This phase is not a main driver for the

selection of the IMU since this unit is not the main sensor any longer.

3.4. Accelerometer needs for rover navigation

Utilisation of the IMU in the Rover GNC

The determination of the state vector in most rover exploits largely the so-called visual

odometry, a process of stereoscopic elaboration of the images in successive steps that

permits determination of depth of specific reference features and evaluation of the motion

with respect to them. However the IMU plays an important role in the rover navigation. With

respect to other rover sensors (mainly encoders connected to the wheels, Sun sensors or

star trackers and cameras) IMU sensors have the advantage to give absolute measurements

in an inertial reference frame but the drawback of the slow drift in the estimated states due to

the presence of biases requiring periodic reset. The following main functions can be

envisaged for utilisation of the IMU in the Rover GNC:

Determination of Roll and Pitch

Fixing of Azimuth

Propagation of Azimuth

Wheel slippage evaluation

Determination of Roll and Pitch

Determination of roll and pitch angles strongly relies on the IMU information. If the rover is

still, the accelerometers measure the components of the gravity vector in the axis normal to

the chassis plane. From these measurements it is immediate to determine the roll and pitch

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 13

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

angles. If the rover is moving, the gyros can be used to integrate the initial roll and pitch

fixed angles. If the rover is operated with sequences of moving and rest periods, the IMU

platform is able to guarantee a good propagation of the roll and pitch angles even in

presence of quite large drifts. A heuristic approach can be used to combine the

accelerometer and gyroscope measurements depending on the status of the rover in order to

get the best accuracy [RD-4.]

X

Nominal

Y

Nominal

Z

Actual

Z

Nominal

e

roll

e

yaw

X

Actual

e

pitch

Y

Actual

Sun

Figure 3-3: Identification of the azimuth (yaw) error.

Fixing of Azimuth: Sun sensor and accelerometer data fusion

A Sun sensor is used to fix the heading by processing the sensor measurements with the

information of Sun ephemeredes, rover location (latitude and longitude on the planet), and

knowledge of the body vertical axis (as described in the previous paragraph). The heading

error augments with the inverse of the declination of the Sun (see Figure 3-3). For instance,

a minimum declination of 10 implies an amplification of the error of 5.7. To obtain a 0.5

heading angle error, the maximum error for each axis of the accelerometer shall be of the

order of 0.3 mg. This constraint corresponds to a sizing figure for a number of accelerometer

error sources.

Bias, bias stability and noise < 0.1 mg (each)

Misalignment < 0.03 deg

Scale Factor < 100 ppm

where the values for the systematic errors have to be understood as residuals of the in-line

calibration processes.

Propagation of Azimuth: Encoder and gyro measurements fusion

The azimuth angle evolution is related to the differential velocity of the wheels on the right

and left side of the vehicle. Exploiting this concept it is possible to build a Kalman filter fed

from the odometric and gyro measurements. Three problems must be solved:

A periodic fixing is necessary as put in evidence in the previous point

Yaw propagation is mainly affected by the gyro drift so that periodic calibration is

necessary

Actual encoders information are affected by slippage that must be purged out through

non-trivial algorithms

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 14

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

Wheel slippage evaluation

An IMU-based principle for slippage detection criterion consists in comparing encoder

outputs with outputs from an accelerometer mounted in longitudinal direction. Maximum

longitudinal acceleration for a current rover is in the order of few tens of mm/s

2

. To detect

perturbations in the longitudinal acceleration or braking phases due to slippage a resolution

of few mm/s

2

is needed. This is in general a very stringent requirement for the light and small

accelerometers used in the rover applications. Other strategies based on inclinometers,

steering potentiometers and rocker-boogie potentiometers for the slippage detection are

generally preferable.

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 15

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

4. Synthesis of requirements and identified products

4.1. Summary of requirements and drivers

Table 4-2 summarizes the main drivers and requirements for space applications of

accelerometers.

4.2. Accelerometer classes

The mission requirements have been gathered to define three accelerometer classes:

A specific accelerometer for launcher applications. This accelerometer will be tailored to

measure high accelerations with a very different environment than space missions (high

vibration, low radiation, short lifetime), and specific constraints in terms of cost and

availability. For these reasons, it is considered that the launcher-oriented accelerometer

would not be similar to the accelerometer for space missions.

A high-resolution accelerometer for micro-propulsion applications (electric and cold gas

propulsion). A sub-g resolution is required, which cannot be met with current MEMS

technology. An accelerometer based on electrostatic suspension could be used for this

application, see [RD-2.]

Finally, a generic accelerometer covering most space applications. The corresponding

requirements are detailed in the next section.

The potential market for each accelerometer has been studied, based on planned ESA

missions in the next decade. The reduced number of units would justify a relatively high

recurrent price.

Application Coarse Medium High Science grade

Geostationary 200 D (main engine) C (SKM)

Lagrange points 3 C (SKM)

Interplanetary mission 4 A (FDIR) B (TCM) C (TCM)

w/ Aerobraking 1 A

Fine Orbit Control / RdV 3 C (chemical) D (-prop.)

Launcher 150 A

Passive Landing 5 A (parachute)

Controlled Landing 1 A

Rover 1 A (local vertical) B (wheel slippage)

Drag-Free 3 A

Formation flying 3 C (deployment) D (position control)

Electric Propulsion 1 D

Number of

missions

A mandatory (only possible solution)

B useful (probably the best solution)

C possible (balanced trade-off)

D unlikely (probably not the best solution)

no use

Table 4-1: Synthesis of the foreseen accelerometer and IMU needs

for the 2015-2025 time frame.

Accelerometer precision ranges from coarse (0.1 mg) to Science grade (better than 10

-9

g).

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 16

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

Missions Applications Range Precision Drivers

Launcher GTO 100 m/s 1 mm/s

Cost, availability

Very good linearity (< 100 g/g)

Lifetime/radiation less important

Main engine FDIR 500 mm/s 8 mm/s Robustness/reliability

V 0.1-10 m/s 30 mm/s 0.1 mm/s Low noise (read out < 0.09 mm/s)

Fine orbit control

(1 mm/s)

30 mm/s 0.1 mm/s

Very low noise ( white < 10 g/ Hz,

read out < 0.01 mm/s)

Propulsive

maneuvers

GEO Station

keeping

(10 mm/s)

10 mm/s 0.1 mm/s

Low noise (read out < 0.09 mm/s)

Bias stability (< 3 g/hr)

Cost, availability

Navigation 6 mm/s 0.5 mm/s

Low noise

inertial navigation algorithm

Aerobraking Atmosphere

reconstruction

(science)

6 mm/s 50 m/s

Very low noise (read out < 0.05

mm/s)

Navigation algorithm design

Fusion with thermal sensors

Inertial navigation 100 m/s 0.5 mm/s

Bias stability (thermal drift < 20

g/C)

Robustness

Mass/power

Gyro quality (< 1/h) and navigation

algorithm key drivers

Entry detection 1 mm/s 0.5 mm/s

Bias stability (thermal drift)

Mass/power

Parachute

deployment

10 m/s 7 mm/s

Bias stability (thermal drift < 15

g/C)

Scale factor stability (< 300 ppm)

EDL

Airbag venting 400 m/s 1 mm/s

Low cost/mass

Robustness

High bandwidth (> 500 Hz)

Navigation/roll pitch 4 m/s 4 mm/s

Low power/mass

Bias stability (< 100 g/hr)

Navigation/azimuth 4 m/s 3 mm/s Low power/mass Rover

Wheel slippage

detection

10 mm/s 0.5 mm/s

Low noise

Alignment stability (<150 rad)

Formation

Flying

Fine position control 1 mm/s 1 m/s

Very fine resolution

Bandwidth > 0.5 Hz

Low mass/power

GEO station

keeping

5 mm/s 0.5 m/s

Very fine resolution

Low mass/power

Cost, availability Electric

propulsion

Interplanetary

cruise

5 mm/s 1 m/s

Very fine resolution

High bias stability (> 2 hours)

Table 4-2: Main drivers for accelerometer applications

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 17

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

4.3. Accelerometer performance requirements

The specified performance requirements are summarized in Table 4-3 below and detailed in

this section.

Parameter Value Unit Comment Driver

range 20 g i.e. 20 m/s at 10 Hz EDL

acquisition rate 10 Hz settable ; goal: up to 100 Hz 100 Hz for EDL

bias 300 mg will be calibrated

bias stability 1 hour 45 g with 3C temp change TCM 1 m/s

bias stability 90 s 3 g with 3C/hr temp change calibration, TCM 1 m/s

bias stability 200 s 1 mg with 60C temp change Entry

white noise 20 g/ Hz TCM 1 m/s, entry detection

Scale Factor 500 ppm parachute opening

Alignment 300 rad

Non-linearity 400 g/g i.e. 0.8% full range SF error EDL

read out noise 0.06 mm/s i.e. LSB < 12 * 0.1 = 0.21 mm/s TCM 1 m/s, Aerobraking

Table 4-3: Characteristics of Accelerometer / IMU for generic space applications.

Measurement range and resolution

In terms of measurement range and resolution, the EDL application appears as a specific

case, requiring a measurement range of 20 Earth gs, and relatively coarse resolution. Most

other space applications would be covered with 1 g range sensor and a resolution of 0.6

mm/s.

The technology survey (see chapter 5. ) indicated that the sensor intrinsic errors of a 20 g

sensor could be compatible with the precision requirements for the 1 g applications. This is

especially clear for the VBA technology whose performances are relatively independent of

the measurement range.

Nevertheless, the resolution of the accelerometer could be limited by the quantization error.

A 20 g range leads to a LSB of 610 g (6 mm/s) for 16 bits quantization. The resulting

quantization error is equivalent to 0.2 mm/s at 10 Hz, which is too high to monitor small

thruster pulses or perform navigation during aerobraking. A reduction of the scale factor gain

(by a factor of 4 or more) would bring the LSB to the expected value. It is therefore thought

that the same sensor can meet all the requirements thanks to a limited modification of the

readout electronics. Alternatively the use of a higher bit depth, if possible, would solve the

problem. Also note that the full range (20 g) is required for EDL applications at 100 Hz,

while the 0.6 mm/s requirement for other applications holds at 10 Hz.

Bandwidth

Most AOCS applications run at a relatively low frequency (8-10 Hz). However simulations

showed that for EDL, some improvement could be gained by performing navigation at a

higher rate (50 to 100 Hz, see chapter 6. ) This is especially true for the gyro measurements,

but the same output rate should be used for gyro and accelerometer measurements.

On the other hand measurements of a constant low thrust could benefit from a lower rate to

limit the impact of the readout noise. As a goal, a settable measurement frequency in the

range [2 100] Hz (bandwidth 150 Hz) is therefore specified.

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 18

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

Noise

White noise and quantization error dominates the budget for the measurement of small

thruster pulses (typically 0.1 m/s). A value of 20 g/Hz is specified (63 g rms at 10 Hz).

Bias and bias stability

A first important remark is that the absolute value of the bias is never an issue for space

applications because bias calibration is almost always possible before the measurement

begins. This is a major difference with Earth applications were calibration is more delicate or

impossible. An exception is of course rover navigation applications which involve a more

intricate calibration procedure using sensor fusion, see section 3.4.

On the other hand a particular care should be devoted to the bias stability when designing

the sensor. As mentioned earlier, the bias in itself does not have a direct impact because of

the relatively short integration times of space applications (a few minutes at most). The

indirect effect of limiting the reachable calibration residual on the other hand is critical. Based

on typical accelerometer characteristics, we have estimated that the optimal calibration time

to reach a given calibration residual. This requirement is naturally expressed as a maximum

Allan deviation of 30 m/s over a 90 s horizon. This requirement shall hold against typical

temperature variations of t3 C/hr.

Scale factor and alignment stability

A scale factor error of 500 ppm and an alignment stability of 500 rad (at unit level) are

specified. The full range scale factor error may affect the navigation for EDL applications

around the peak deceleration point. A maximum error of 0.8% can be tolerated.

Interface

In term of interfaces, a RS422 bus is considered as a primary target for an IMU. Mass is

indeed a strong driver for missions considered here (mostly interplanetary missions), while

the exchange data rate will remain low.

Mass and power

For a stand-alone accelerometer axis, the mass of the sensor is expected to be lower than

50 g and the power input limited to 0.5 W.

Environment requirements

The environment is specified Table 4-4 below. Shock survival could be an issue for some

detector design. The operating temperature range requirement would probably necessitate a

temperature calibration process.

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 19

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

Parameter Value Unit Comment Driver

mass 50 g

power 0.5 W

diameter 25 mm

Min Op Temp -20 C Rover, Landing

Max Op Temp 65 C Landing

Min Non-Op Temp -30 C

Max Non-Op Temp 65 C

pressure 0-1100 mbar

Sinusoidal vibration 10 mm 520 Hz Launch

20 g 20100 Hz

Random vibration 3 db/octave 20100 Hz

1 g/Hz 1002000 Hz

Shock 1000 g 1500 Hz half-sine Pyro

Radiation 100 Krad total dose full performance interplanetary missions

Table 4-4: Desired system and environment characteristics for the accelerometer

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 20

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

5. Survey of accelerometer technologies, performances

and trends

A survey of existing accelerometer technologies has been performed and the best

candidates for space applications have been identified. The main findings are summarized in

Table 5-1 and detailed hereafter.

The best performance is obtained with Vibrating Beam Accelerometers made in Quartz. They

are considered as high end MEMS components to be used in navigation systems for civil and

military avionics and for ammunitions guidance (missiles for instance). Only a few providers

are making these units (among others Safran and Thales Avionics in France, former LITEF in

Germany) and they are usually vertically integrated. As they are quite costly and are parts of

strategic systems, the devices are usually sold in Inertial Measurement Units and/or full

Inertial Navigation Systems, not as stand-alone components for custom integration. These

devices are commonly known as the best choice for long term stability of the performances

(bias drift, scale factor drift), low thermal dependency (due to the material itself but also due

to the decades of efforts spent to optimize their assembly lines and materials). Technically-

wise, they are obviously the less risky solution for the 0.1mg range required by the space

applications. Built out of Quartz, they benefit from the piezoelectric effect which simplifies the

electronics read-out circuitry (shift of resonant frequency with acceleration load).

Manufactured in low volumes, they are quite expensive to manufacture and do not exist in

single chip three axis versions (technology limitations). Some improvements are in the

research phase using Deep Reactive Ion Etching for Quartz. One can expect that either

performance will improve or that the number of players in the field will increase and drive the

costs lower.

Two other alternative approaches to Vibrating Beam Accelerometers made of Quartz can be

foreseen as potentially suitable to reach the medium quality requirements for Space

applications:

Vibrating Beam Accelerometers (VBA) based on single crystal Silicon

Variable capacitance accelerometers based on either Bulk Micromachining or Silicon on

Insulator (SOI) technologies.

VBAs on Silicon are based on the same principle than VBAs in Quartz but use a capacitive

detection scheme rather than the piezoelectric effect of Quartz. Implementing VBAs in Silicon

would require expertise in the electronics field similar than for state-of-the-art MEMS gyros.

The drive and detection schemes are very similar and European expertise in the field of

MEMS gyros could be leveraged to develop this technology.

State-of-the-art variable capacitance accelerometers (based on bulk or SOI) are today mainly

used for cost driven high volume market places (low performance). Most European

companies using that technology are addressing the consumer and automotive markets (e.g.

ST Microlectronics, VTI Hamlin, German companies) and very few companies in Europe are

committed to the navigation market place (mainly Colibrys, MEMSCAP). Current

performance is today in the mg range. There are no obvious limitations from the technology

point of view (Single crystal Silicon) and probably gaining an order of magnitude is possible

with careful design of the accelerometer component (MEMS + ASIC + Packaging) at the cost

of a higher technical risk than for a Quartz VBA but with probably decent costs reductions.

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 21

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

Nevertheless, for a given IC architecture for capacitive detection, it is possible to evaluate

bias drifts only arising from the IC. This should give us a first limiting factor for this type of

devices. For instance, lets consider two options:

Open loop with sigma-delta signal conversion

Closed loop with sigma-delta signal conversion.

Both systems require a Voltage reference (V

ref

) as stable as possible.

In the case of an open loop architecture, the signal is proportional to Delta Capacitance times

V

ref

. It is possible to get rid of any fluctuation of V

ref

by carefully choosing the output signal

formulation. The drift would then mainly come from the charge migrations in the circuitry, and

hence an excellent bias stability is expected. In the case of a closed loop system, the output

signal is proportional to V

ref

squared. The best commonly available voltage sources today

have variations of 5 ppm/C. Since the output signal is proportional to the square of V

ref

, this

would lead to 10 ppm/C variations for the bias values.

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 22

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

QuartzVBA Silicon VBA Capacitive SOI Capacitive

Bulk

Material

Quartz Single crystal

Silicon

Single crystal

SOI

Single crystal

Silicon

Sensor die

design

complexity

- -

Resonant , cross

talk due to

asymmetries

- -

Resonant device

+

Cross-talk

+

Cross-talk

Sensor die

volume

=

Typically 55 mm

= = =

Manufacturing

complexity

-

Typically wet etch

control is critical

(time etch)

-

Side walls etch

control critical

+

Aspect ratio and

trench quality are

critical

+

Typically 3 wafer

stack, wafer to

wafer alignment is

critical

Packaging

volume

=

Typically ceramics

= =

Typically ceramics

=

Typically ceramics

or TO cans

IC volume

+ -

-

max 15mm

2

-

max 15mm

2

IC Complexity

- - -

Resonant type of

device, feedback

loop needed

- - -

Resonant type of

device, feedback

loop needed

-

Delta-Sigma with pF

values

-

Delta-Sigma with pF

values

Thermal

sensitivity

-

Unknown

+

+

Stack of wafers

Shock

resistance

-

Quartz

+

Buckling

acceleration

++

Single wafer but

overloads difficult

+

Stack of wafers but

overloads available

Noise

+

Operates under

vacuum, noise

mainly from

electronics

=

=

Small mass,

Requires reduced

pressure in the

MEMS die cavity

=

Large mass

Bias stability

= =

Voltage reference in

closed loop

configuration

=

Charging effect,

voltage reference in

closed loop

configuration

=

Charging effect,

voltage reference in

closed loop

configuration

Scale Factor

Stability

++ =

Mainly IC design

dependent

-

IC design

-

IC design

Yield - - - - + -

Costs - = + +

Table 5-1: Comparison table between MEMS technologies for accelerometers

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 23

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

6. Simulation of IMU performances for a landing mission

6.1. Description of the simulation tool

The performance of the IMU and associated inertial navigation algorithms was investigated

by simulation. The high-fidelity Safe-to-Mars software was used to generate 6-degree-of-

freedom trajectories representative of a Martian landing mission. This software uses the

EMCD atmosphere model, a reference aerodynamic database, a J

2

gravity model and a

specific model of parachute opening. The trajectories are sampled at 1 kHz. They are used

to feed the Real-World angular and linear accelerations to the sensor models and as

reference to compute the navigation error. A fixed offset between the IMU and the lander

center-of-mass can be specified. Finally, the Real-World model includes a user-provided

temperature profile during the EDL timeline.

The gyro model used for these simulations is a high-fidelity model of the SiREUS. This model

includes a noise shaping filter to reproduce the sensor power spectrum density (PSD) and an

ad-hoc statistical model of the temperature sensitivity of the bias. A constant scale factor

error and quantization effects are also taken into account. The accelerometer model on the

other hand is a generic mathematical model including white noise, scale factor and non-

linearity errors, quantization errors. The accelerometer bias is assumed to be calibrated at

entry. Bias drift is taken into account as a random linear function of both time and

temperature.

6.2. Attitude update

The inertial navigation algorithm relies on first an integration of the measured angular rate in

order to determine the attitude quaternion, thanks to the following equation

,

0

2

1

q q

,

`

.

|

& , (1)

where (0, ) denotes the angular rate seen as a pure quaternion and is the quaternion

product. High-rate gyro measurements are integrated over the AOCS period to get a rotation

vector :

.

1

+

n

n

t

t

i

t (2)

Let denotes the norm of the 3-dimensional vector . Then the quaternion is updated with

the integration scheme

( )

( )

n n

q q

,

`

.

|

2 sin

2 cos

1

. (3)

This scheme is exact whenever the direction of the angular rate vector remains constant

during the integration time. If this is not the case, an integration error is introduced: the so-

called coning error, see [RD-6.] In practice, the impact of this error depends on the high

frequency vibration environment of the sensor. This environment is not faithfully reproduced

by our simulator so the importance of coning cannot be directly investigated. Nevertheless,

one can get an idea of this impact by looking at the integration error introduced on the 1 kHz-

sampled trajectories. In fact, even a 1 kHz integration of equation (3) yields a small error

(typically 0.01) with respect to the higher-order reference simulation. This error increases

with the AOCS integration period. With a 10 Hz integration rate more representative of flight

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 24

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

GNC software, the error reaches 0.06. This error can be reduced by using a coning

compensation algorithm

4

. For instance, one can replace equation (2) by equation

.

2

1

1

,

`

.

|

+

n

n

t

t

i i i

t (4)

It can indeed be shown that equation (4) is equivalent to equation (1) up to second order in

time. But equation (4) is much simpler than (1) and can therefore be integrated at high rate.

In practice, integration of equation (4) at 1 kHz combined with quaternion update (3) at 10 Hz

is equivalent to quaternion integration at 1 kHz with a much reduced computational

throughput.

Although the coning compensation algorithm was shown to efficiently reduce the integration

error, it was not deemed useful for current EDL applications. Indeed the error introduced by

the sensor is two orders of magnitude larger than the integration error, making the latter in

practice negligible. Therefore the coning compensation algorithm has not been considered in

the rest of the study. Similarly, integration errors arise for velocity and position update,

referred to as sculling and scrolling errors, see [RD-7.] These errors are even more negligible

with respect to IMU errors for current EDL applications. Sculling and scrolling compensation

algorithms have therefore not been considered.

6.3. Velocity and position update

The velocity is updated by integrating accelerometer measurements and the adding

gravitational acceleration term. The attitude quaternion is used to perform the update in the

reference inertial frame. A second order algorithm uses the half-sum of the attitudes at time

time t

n

and t

n+1

:

.

~ ~

2

1

1 1

1 1

,

`

.

|

]

]

]

]

+

]

]

]

]

+ +

+ +

n

t

t

n n

t

t

n

q dt q q dt q

n

n

n

n

a a A (5)

The velocity update reads:

( ) .

1

1

+

+ + +

+

n

n

t

t

n

grav

n n

dt t d x F A v v

The gravitational acceleration F

grav

is computed at time t

n

. The last term is the compensation

of the lever-arm d between the sensor and the body center-of-mass.

Finally, the position is updated thanks to second-order half-sum velocity integration:

( ) .

2

1

1 1

t

n n n n

+ +

+ + v v x x

6.4. Coast phase

The IMU-based inertial navigation starts after separation from the carrier module. During the

coast phase outside the planetary atmosphere, attitude is updated from gyro measurements

while non-gravitational acceleration is essentially zero. The length of the coast phase can be

longer than the EDL phase itself, as is the case for the Exomars mission. The coast phase

will therefore account for a significant part of the inertial navigation error, especially as far as

attitude is concerned. Because of the relatively large spin rate, the gyro scale factor error can

have catastrophic consequences on the attitude around the spin axis. A scale factor error of

0.4% results in 11of error after 30 minutes of coast. Note that the inertial direction of this

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 25

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

axis during cruise is almost normal to the local vertical at the landing point, so the coast

phase attitude error directly impacts the knowledge of the local vertical at touch-down. On

the other hand, the spinning motion reduces the impact of biases around transverse axes. A

typical error of 1around transverse axes arises from the misalignment error, but this error

does not grow with time, A calibration of these terms is not required.

To asses the impact of the coast phase, we have simulated a 2 hour phase with a constant

spin rate of 15/s. The scale factor is calibrated during the first 20 minutes of the simulation.

The results are displayed on Figure 6-1 show that the error remains below 2after one hour.

Figure 6-1: MEMS rate sensor integration error during coast phase.

Left and right: two different random seeds.

6.5. EDL

The coast phase final attitude error is used to initialize the EDL simulation. The attitude error

increases during the entry because of the nutation induced by aerodynamic forces. At the

end of the entry phase the parachute is opened. A verticalization of the trajectory occurs and

the error along the spin axis is transferred to transverse axes. Results shown in Figure 6-2

show a resulting attitude error of approximately 5. This figure is deemed compatible with the

touch-down requirements. The velocity and position error are displayed in Figure 6-3. As

expected, neither the lateral velocity nor altitude can be predicted accurately enough to initial

and control the powered descent phase. Additional sensors are required such as a radar

altimeter, a Doppler velocimeter, or a vision-based system. Finally, we show in Figure 6-4 the

evolution of the error on the knowledge of the local vertical. The figure also shows the

relatively small contribution of the position error to this value. These preliminary results seem

to indicate that an Inertial Measurement Unit based on the SiREUS MEMS rate sensor could

be compatible with a landing mission with a 5requirement on the local vertical at touch-

down.

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 26

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

Figure 6-2: SiREUS MEMS rate sensor integration error during EDL.

Left and right: two different random seeds.

Figure 6-3: Position error during EDL: SiREUS MEMS rate sensor combined with model of

future European accelerometer. Left and right: two different random cases.

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 27

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

Figure 6-4: Evolution of the error on local vertical during EDL: SiREUS MEMS rate sensor

combined with model of future European accelerometer.

Left and right: two different random cases.

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 28

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

7. Preliminary design of an IMU for space applications

7.1. MEMS IMU architecture

The reference rate sensor for this activity was selected to be the European MEMS rate

sensor SiREUS [RD-5.] The reference accelerometer was the capacitive MEMS technology

which, as discussed above, has been assessed to provide a suitable level of performance

compared to the Technical Requirements presented in chapter 3.

Experience from the MEMS rate sensor development highlights a number of key factors in

achieving the best possible performance from this technology, which can be brought to bear

in the foreseen accelerometer development. In particular it is evident that MEMS technology

there is a very strong interaction between the detector, the proximity electronics and the

related control loops that must be optimized to achieve a good level of performance. This is

balanced by the ever-present constraints of availability of space components, in particular

following the SiREUS approach of using ITAR-free parts.

The following design drivers were therefore considered in the derivation of the design:

Meeting key performance parameters discussed above.

Matching accelerometer proximity electronics as close a possible to the host (SiREUS)

architecture and component selection; minimizing component cost and integration cost.

Mechanical integration of the accelerometer detectors and support electronics with a

minimal impact on the unit mass/power/volume characteristic.

Integration of accelerometers within requirements for misalignment (absolute and

stability).

An outline of the IMU Electrical Architecture is shown in Figure 7-1. The majority of the

accelerometer functionality is provided by an extension of the host unit; in this case SiREUS.

This provides:

Telecommand and Telemetry Support

Secondary Power

The detector baseline is a pendulum style capacitive MEMS accelerometer as discussed

above and accelerometer detectors are accommodated on a single printed circuit board

(PCB) with their associated proximity electronics. In order to not introduce new component

types which can increase unit costs (MOQs, parts qualification costs, etc) an initial proximity

electronics design has been derived using the same component types present in the SiREUS

parts list. This approach includes the same electrical architecture as the SiREUS unit using

lower cost sample & hold circuits to minimize the use of more expensive Digital-to-Analogue

Converters (DACs). An assessment of this approach confirms operation is feasible up to 100

kHz for detector drive and sense circuits.

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 29

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

Figure 7-1: Outline of the IMU electrical architecture.

Figure 7-2: Outline of the IMU mechanical architecture

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 30

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

The remainder of the accelerometer functionality is integrated into the existing SiREUS

FPGA design. Here VHDL IP CORES already developed are used to interface to the

proximity electronics ADCs and DACs. Similarly a sub-set of the rate sensor processing IP

COREs can be used to perform the key accelerometer functions of synchronous

demodulation, filtering and frequency decimation to provide the accelerometer outputs in the

required bandwidths. An initial sizing indicates that the required accelerometer functions can

be readily accommodated in the FPGA within the current spare 50% of the capacity of the

Actel RTAX2000 device. As for the current SiREUS development it is understood that the

FGPA design would requires migration to a European ASIC as a final step to support a fully

ITAR free status.

For the mechanical integration consideration again maximum experience has been derived

from the SiREUS development in the accommodation and management of a similar class of

detector. The preliminary approach is outlined in Figure 7-2.

7.2. Stand alone accelerometer architecture

A proposed tri-axis accelerometer architecture is described in Figure 7-3. A single axis

configuration could also be envisaged. The support electronics could also be hosted in a

separate processing unit.

Figure 7-3: Tri-axis stand-alone accelerometer architecture.

7.3. Budgets

From this preliminary design activity a comparison table of the impact of integrating the

accelerometer functions is indicated in Table 7-1.

For the Stand-Alone accelerometer, the estimation depends on the choice between a

discrete electronics FPGA and a mixed signal ASIC. Predicted values are indicated in Table

7-2, based on a tri-axis accelerometer design.

Accelerometer needs for IMU

Doc.

Date: 25/03/2009

Page 31

All rights reserved THALES ALENIA SPACE All rights reserved

M032-6

Parameter

Predicted

IMU Value

Actual

SiREUS

Value

Requirement Estimate

Power

< 5.5 W @

28Vdc

< 5.2 W @

28Vdc

< 0.5W / axis

Accelerometer PCB +

FPGA delta

approx 300 mW = 100

mW/axis

Mass < 750 g 750 g < 50 g / axis

Accelerometer PCB

(ignores FPGA)

approx 60 g = 20 g/axis

Volume

100*100*90

mm

110*110*70

mm

< 25 mm /axis

Accelerometer PCB

(ignores FPGA)

Approx 70 * 70 mm = 40 *

40 mm /axis

Table 7-1: Budget Comparison for Accelerometer Integration

Parameter

Predicted Stand Alone

Value

Estimate

Power

Mass

<1.6 W @ +/- 5Vdc

< 158 g

Accelerometer PCB = 100

mW/60g

CSI PCB = 1500 mW/48g

Mechanical and misc = 50 g

Volume 90*90*35 mm Two PCB module

Power

Mass

<0.9 W @ +/- 5Vdc

60 g

Accelerometer & ASIC

PCB = 100 mW/60g

Volume 90*90*35 mm One PCB module

Table 7-2: Predicted Stand Alone Accelerometer Budgets. Top rows: discrete electronics