Professional Documents

Culture Documents

H&S Checklist

Uploaded by

Ankita MishraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

H&S Checklist

Uploaded by

Ankita MishraCopyright:

Available Formats

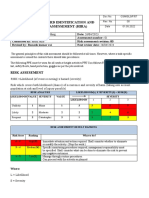

HEALTH & SAFETY CHECKLIST

Prepared by: ANM Consultants S.no Parameter OHSAS Norms 1 Health & Safety Policy 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 Hazard Identification & Risk assesment Record List Of significant Hazards IMS Manual Procedure Manual safety Work instruction Significant Hazard - ocp/management program Patrolling record Patrolling Procedure Accident Investigation Records Accident Investigation procedure Health certificates of workers working at crane, canteen training schedule training records health checkup procedure the scope of occupational health and safety management hazard Identification & Risk assesment procedure Designation of responsibilities and authority for achieving objectives at relevant functions and levels of organizations The means and time frame by which the objectives are to be achieved. Responsibility Matrix Waste Management Schedule for the maintenance of the fire tender Yes/No Observation

Pr

18

19 20 21 22

23

Maintenance record of fire tender

Communication 1 Are training needs identified 2 Internal communication Communication from external interested parties. Documents remain legible and readily 4 identifiable? 5 Communication records/file Legal Compliance 1 List Of Applicable acts 2 legal compliance evaluation procedure 3 Do you keep legal compliance evaluation records 4 compliance audit report 5 Legal requirement against applicable acts Corrective & Preventive action 1 identify the need for corrective actions; 2 3 4 identify opportunities for preventative action; identify opportunities for continual improvement; communicate the results of such investigations. 3

Emergency & incedent response Is there documented emergency procedure 1 well communicatedregularly tested in practiseregularly updatedeasy underestanble and usableunderstood responsibilitytrainingregular drill regularly availableregularly tested in practise-

2 3 4

Clearly emergency responsive organisation Emergency response control procedure Emergency escape routes and procedures

5 6 7 8 9 10 11 12 13 14

Procedures to be followed by workers who remain to perform critical operations before they evacuate The evacuation of the worksite Procedures to account for all workers after the emergency Evacuation is complete Rescue, medical and other duties for workers who are assigned to perform them The means for reporting fire and other emergencies Incident investigation documented and maintained Whether accident investigation reports are submitted to top management? Whether root causes of accidents are analysed? from accident investigation reports communicated to workers?

Providing relevant information and training to all personnel of the facility, at all levels, including regular exercises in emergency First Aid 1 Provisions for first aid 2 Are first aid officers appointed? 3 4 5 6 7 8 9 10 11 Are the names of first aid officers displayed? Are first aid kits full stocked? Are first aid kits readily accessible? Are there sufficient numbers of first aid kits? Are the contents of the first aid kits checked regularly? Are first aid kits replenished as necessary? Are first aid rooms appropriately equipped? Are qualified/ trained first aider available in each shift? Are the Medical Attendants/Doctors available in each shift?

12 13 14 15 16

What facilities are available for transportation of the injured to hospital? Are the names of the trained first aiders displayed? Is ambulance posted in proper place & Is it available whenever required? Are medical facilities available to treat the serious injuries? Are the workers / contractor workers aware of emergency medical facilities? Whether pre-employment medical examination is being conducted for employees?

17 Operating and safety procedure Wriiten procedure for routine operation 1 Available at site where operation takes place Reviewed and updated in consultation with employee performing the procedure Defined Documented Followed Updated Permit to work Equipment inspection

Safe working practices 2 Effective work control system in place 3 Working Condition 1 Waste bins are emptied regularly 2 Work surfaces are kept clean and clear Is there any system of periodical cleaning and replacing the light fittings/ lamps in order to ensure that they give the intended illumination levels? Are the name of nearest hospitals and its telephone number available with dept Are the applicable safety signs posted? Is there a competent person on site?

3 4 5 6

Is someone on site certified in First Aid Has the emergency data form been filled out and posted? 8 Has a site-specific emergency rescue plan been 9 developed and documented? Is there a documented procedure for any 10 overhead electrical hazards? Are MSDSs available for the material being used 11 on CONDITIONS (INCLUDE JOB SITEsite? ENVIRONMENTALS) 1 Is the work site clean of trash? 2 Are materials stored properly and orderly? Are measures taken to prevent access by unauthorized personnel to the site? 3 4 Are areas barricaded as required? 5 Is drinking water available? Are chemical, flammable and combustible liquids 6 stored properly? Are fire extinguishers of the appropriate size and type available, and with current inspection tags? Are plant and animal hazards addressed and documented? SAFETY Is there an effective fire alarm? Is the fire alarm tested every three months? Is the fire alarm functioning correctly? Are fire exits clearly marked and easily identifiable? Are fire exits free from obstruction? Are emergency procedures displayed? Are the telephone numbers of emergency services clearly displayed? Are there regular fire evacuation practices? Have fire wardens been appointed and trained? Are fire extinguishers available?

7 8 FIRE 1 2 3 4 5 6 7 8 9 10

11 12 13 14 15 16 17 18

Are the fire extinguishers suitable to the type of fire that may occur (eg carbon dioxide for electrical fires). Are fire extinguishers serviced regularly? Are smoke detectors installed? Is a fire sprinkler system installed? Are fire sprinklers unobstructed? Are hose reels available and connected to water supply? Is access to the hose reels unobstructed? Are flammable materials properly stored?

LIGHTING 1 Are all areas adequately lit? 2 Is natural light utilised to best advantage? 3 Is task lighting available where required? Have measures been taken to reduce glare created by unshielded lights, sunlight or from bright reflecting surfaces? Is there an emergency lighting system that is adequately maintained? Are light fittings in good repair and clean? Are all the light fittings shielded with a good cover? Is there a program for the checking and replacement of faulty bulbs and tubes at regular periods? Are fittings accessible for routine maintenance? Are illuminated signs and notices in lifts and exits in working order?

4 5 6 7

8 9 10

VENTILATION/AIR CONDITIONING 1 2 3 Are individuals satisfied with thermal comfort? Are individuals satisfied with quality of air conditioning? Are air conditioning filters/vents cleaned regularly?

4 5 6

Are cooling towers treated regularly? Are readings retained in a register? Are the air conditioning controls easy to access and check?

HOUSEKEEPING Floors 1 Even surface (no holes) 2 Pits and drains covered when not in use 3 Suitable guarding around pit 4 Floor area obstruction free 5 Matting, floor coverings in good condition 6 Surface non-slip 7 Surface spills wiped up (grease, oil, etc) 8 Dropped items picked up Aisles 1 Wide enough for traffic 2 1.2m passage 3 810mm doors 4 5 6 7 8 1 2 3 4 1 2 3 4 1 600mm temporary storage in passage Adequately lit Marked with white/yellow lines Clear of cases, materials and rubbish Clear of electrical cords Stairs and Landings No worn or broken treads Handrails present and in good repair Landings clear of obstructions Mezzanine floors adequately guarded Windows and Doors Safety/reinforced glass where appropriate Clean, no broken panes Ledge, free of dust or rubbish Mesh under skylights Rubbish Bins located at suitable points

2 PPE 1 2 3 4 5

Bins emptied regularly

Are employees wearing helmets? Are employees wearing proper work boots? Are safety glasses being used? (if applicable) Are employees wearing gloves? (if applicable) Are employees dressed in appropriate work clothing?

6 Is hearing protection being used? (if applicable) 7 Head protection 8 Face and eye protection 9 Upper and lower limb protection 10 Respiratory protective equipment 11 Hearing protection 12 Protection from falls 13 Work clothing FALL PROTECTION EQUIPMENT Do employees that are exposed to falls, have documented training? 1 Is fall protection equipment being inspected daily and documented? 2 Are all fall protection equipment tags legible? If the work being performed requires fall protection, is it being used 100%? 4 Is the proper equipment on the site to complete 5 the task? HOISTS Are daily inspections being completed with documentation on site? 1 Is hoist operator qualified? (Certified through training or qualified through experience) 3

3 4 5 6 7 8 9 10 11 12

Are load charts posted and readily available to hoist operator? Is there an operators manual for the unit on site? Are headache ball markings legible? Is end connection properly secured? Are all hoists secured and properly anchored for the load intended? Are hoist controls clearly identified? Are hoist controls easily accessible to the operator? Is the hour meter operational and functioning properly? Are two-way radios being tested daily, if being used?

Are all exposed moving parts properly guarded? Is a hand signal chart posted and visible to all 13 personnel on site? PERSONNEL LIFTING 1 Is the hoist approved for lifting personnel? Has a pre-lift meeting been held, documented and made available on site? 2 In the pre-lift plan, was the trial lift completed and 3 documented? If a personnel platform is on site, does it have an identification plate with the 4 proper data in place? (Proper data includes: weight of the platform, maximum 5 6 intended load, and employee capacity) If a gin pole is being used, does it have a load chart? 7 RIGGING & BLOCKS 1 Are proper rigging practices being utilized? 2 Is rigging equipment in good condition? 3 Are the tags on synthetic slings legible? Is rigging equipment being inspected daily and the inspection documented? 4

5 Are tag lines in good condition? GIN POLES Is gin pole rigging in good condition? (If visible) Does the gin pole have an identification tag? (If visible) 2 Is the gin pole pre-job inspection form filled out and on site or readily available? 3 Does the sheave in the rooster head match the 4 wire rope? (If visible) LADDERS Are units well maintained and in good working 1 order? 2 Are ladders at the proper slope? (4:1 ratio) Does the ladder extend 36 inches past the 3 landing? 4 Is the ladder stable, on good ground? 5 Is the ladder set up correctly? Contingency and emergency preparedness 1

1 2

Any comprehensive OSH programme should include plans for emergency response. Contingency and emergency preparedness

(a) the roles and responsibilities of the workers assigned to respond; (b) emergency escape routes and procedures;

(c) procedures to be followed by workers The emergency response plans should include, at who remain to perform critical operations a minimum, the following: before they evacuate; (d) the evacuation of the worksite; (e) procedures to account for all workers after the emergency evacuation is complete; (f) rescue, medical and other duties for workers who are assigned to perform them;

(g) the means for reporting fire and other emergencies; (h) provisions for first aid;

(i) providing relevant information and training to all personnel of the facility, at all levels, including regular exercises inemergency prevention, preparedness and response procedures

Escape and rescue An appropriate escape and rescue plan should be 1 prepared in every plant. An adequate number of emergency exits should be arranged. The routes to the emergency exits should be free of any materials. The emergency exit sign should be visible in the nearest pathway of every post. Where necessary, all persons at the facility should be supplied with equipment necessary to escape, such as emergency escape respirators.

2 3

Prepared For: Status

S.No 1 Records of white washing 2 Ventilation & Temprature 3 Lighting Of interior 4 Prevention of glare 5 Drinking water 6 Source of Drinking water 7 Cleniness of Well or Reservoirs 8 Report From Health Officer

Health & Safety Requirement Form No. 7

sterilised once a week report of water quality 1st march-30th june , water centre for every 150 person one for 25 male conform to public health requirement

9 Cooling of water

10 Latrine Accomodation 11 Signboard Dispaly 12 Urinal Accomodation 13 White wash of L&U 14 Construction and maintenance of drain

one for 50 male conform to public health requirement Form No. 7 three full time sweeper with one full time with additional 500 worker place on stand, three feet high as far as possible Galvanised iron container with a conical shape covered, container filled with dry, clean sand Once in every day

15 Number of sweeper(3)

16 Number and location of spitoons

17 Type of spitoons

18 Cleaning

Status

VARIOUS ACTS WERE SAFETY MEASURES ARE INCLUDED: 1.Apprentices act, 1961 2.Workmen's compensation act 1923 3.The Child Labour (Prohibition & Regulation) Act, 1986

4. The Building & Other Construction Workers (Regulation of Employment & Conditions of Service) A

5.The Dock Workers (Safety, Health & Welfare) Act, 1986

6. The Contract Labour (Regulation & Abolition) Act, 1970

7.The Motor Transport Workers Act, 1961

8. The Factories Act, 1948 9. The Industrial Disputes Act, 1947

You might also like

- PPE Hazard Assessment Certification FormDocument4 pagesPPE Hazard Assessment Certification FormHaleem Ur Rashid BangashNo ratings yet

- Toolbox TalksDocument1 pageToolbox TalksMohammad Abubakar SiddiqNo ratings yet

- Measurement of Building Work (A)Document34 pagesMeasurement of Building Work (A)kazafive85% (13)

- Daily Tool Box MeetingDocument1 pageDaily Tool Box MeetingVipul ShankarNo ratings yet

- JHA Maintenance Tech HVACDocument2 pagesJHA Maintenance Tech HVACMdavaNo ratings yet

- Personal Protective Equipment Hazard Assessment: Location: Conducted By: Date: Tasks Performed at This LocationDocument4 pagesPersonal Protective Equipment Hazard Assessment: Location: Conducted By: Date: Tasks Performed at This LocationAnge JuanNo ratings yet

- Qcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work SysteDocument20 pagesQcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work Systebryanpastor106No ratings yet

- HSE-201-PR - Form 1 - Toolbox Meeting FormDocument1 pageHSE-201-PR - Form 1 - Toolbox Meeting FormCobbinah MarkNo ratings yet

- Sample BOQDocument4 pagesSample BOQapi-3769014No ratings yet

- Office EHS Audit ChecksheetDocument3 pagesOffice EHS Audit ChecksheetPanbarasan GanapathyNo ratings yet

- Self-Inspection Check List: RecordkeepingDocument11 pagesSelf-Inspection Check List: Recordkeepingernie pNo ratings yet

- Safe Working PracticesDocument7 pagesSafe Working PracticesDiana ParkerNo ratings yet

- Workplace Inspection ChecklistDocument5 pagesWorkplace Inspection ChecklistVepxvia NadiradzeNo ratings yet

- Safety Inspection ChecklistDocument3 pagesSafety Inspection ChecklistVivienne IrvingNo ratings yet

- Safety ProceduresDocument7 pagesSafety ProceduresRuwan MadhushankaNo ratings yet

- Storage Area Inspection Form: NO. Items To Be Checked YES NO N/A Observations / CommentsDocument1 pageStorage Area Inspection Form: NO. Items To Be Checked YES NO N/A Observations / CommentsArshad MahmoodNo ratings yet

- Ladder Safety Tips <40Document2 pagesLadder Safety Tips <40Ange JuanNo ratings yet

- FRM-2530-03 Daily Site Inspection Checkllist Ver - 00Document4 pagesFRM-2530-03 Daily Site Inspection Checkllist Ver - 00Ali KaziNo ratings yet

- General Safety Inspection ChecklistDocument1 pageGeneral Safety Inspection ChecklistAyşe BalamirNo ratings yet

- 01-Ppe Eng PDFDocument17 pages01-Ppe Eng PDFZaki AdamouNo ratings yet

- Machine Guarding Checklist: Questions Requirements For All SafeguardsDocument2 pagesMachine Guarding Checklist: Questions Requirements For All SafeguardsAVENON MardocheeNo ratings yet

- Risk Assessment ActivityDocument5 pagesRisk Assessment ActivityHarthwell CapistranoNo ratings yet

- Hazard Communication Program 1Document4 pagesHazard Communication Program 1myo lwinNo ratings yet

- General HSE Checklist - FacilityDocument4 pagesGeneral HSE Checklist - FacilityHtoo Htoo KyawNo ratings yet

- On-Site Emergency Plan and Reporting FlowchartDocument4 pagesOn-Site Emergency Plan and Reporting FlowchartMd Nurul IslamNo ratings yet

- Hse Emergency Preparedness and ResponseDocument6 pagesHse Emergency Preparedness and ResponsenagaaNo ratings yet

- Monthly ladder checklistDocument1 pageMonthly ladder checklistJohn Rey AbarcaNo ratings yet

- Fire Safety - Fire InspectionDocument42 pagesFire Safety - Fire InspectionSaid Massinissa Elhadj AliNo ratings yet

- Safe Work Method Statement - Part 1: Asbestos Removal (Bonded) Company DetailsDocument22 pagesSafe Work Method Statement - Part 1: Asbestos Removal (Bonded) Company DetailsNick Elliott-BondNo ratings yet

- Fire Fighting Equipments Checklist: No. Items Inspected Status (Yes or No) Fire PumpDocument4 pagesFire Fighting Equipments Checklist: No. Items Inspected Status (Yes or No) Fire PumpAbeSanNo ratings yet

- Emergency Response Procedures For Chemical SpillsDocument7 pagesEmergency Response Procedures For Chemical SpillsLawrence adeleke Omisakin100% (1)

- BP Safety AlertDocument2 pagesBP Safety AlertRikza AhmadNo ratings yet

- Hse Team Tour Checklist ProcessDocument2 pagesHse Team Tour Checklist Processf.B100% (1)

- Jobsite Safety Checklist Long Ver 1Document5 pagesJobsite Safety Checklist Long Ver 1Usman ShahidNo ratings yet

- HSE Manual NRC GroupDocument65 pagesHSE Manual NRC GroupPurnomo JarodNo ratings yet

- Weekly Progress Report 21 To 27 OCT2017Document2 pagesWeekly Progress Report 21 To 27 OCT2017Mehdi MessNo ratings yet

- Personal Protective Equipment ProceduresDocument3 pagesPersonal Protective Equipment ProceduresLwandziso DlaminiNo ratings yet

- Appendix 3 01 Health Safety and Fire Regulations 3rd EditionDocument168 pagesAppendix 3 01 Health Safety and Fire Regulations 3rd EditionB.Peer Muhammad NishathNo ratings yet

- Inspection Checklist: A. Tools and Equipment YES NODocument1 pageInspection Checklist: A. Tools and Equipment YES NOHENJEL PERALESNo ratings yet

- Workplace InspectionDocument11 pagesWorkplace Inspection123alNo ratings yet

- Health and Safety T-NETDocument229 pagesHealth and Safety T-NETPieter HerbstNo ratings yet

- Manual Handling Safety TipsDocument1 pageManual Handling Safety TipsNishadh NishNo ratings yet

- JSA ScaffoldingDocument2 pagesJSA Scaffoldingmyco samNo ratings yet

- Hira - 01Document3 pagesHira - 01Angw BasumataryNo ratings yet

- HSE Alert - LTI Fall From Heights TBTDocument12 pagesHSE Alert - LTI Fall From Heights TBTrodman823No ratings yet

- Fire Safety Work PlacesDocument11 pagesFire Safety Work PlacessyooloveNo ratings yet

- Unsafe and Unhealthy Acts and ConditionsDocument41 pagesUnsafe and Unhealthy Acts and ConditionsclandestineamorousNo ratings yet

- Building Safety Inspection ChecklistDocument5 pagesBuilding Safety Inspection Checklistwidodo6286No ratings yet

- Monthly Fire Extinguisher ChecklistDocument4 pagesMonthly Fire Extinguisher Checklistberkah meidraNo ratings yet

- Index: Cv. Dira Utama SejahteraDocument12 pagesIndex: Cv. Dira Utama SejahteraFreshop SurabayaNo ratings yet

- HSE Induction Checklist-ContractorDocument1 pageHSE Induction Checklist-ContractorAnil SaiNo ratings yet

- Workplace Safety SurveyDocument2 pagesWorkplace Safety SurveyBuddy KertunNo ratings yet

- PPE Disposal SOPDocument2 pagesPPE Disposal SOPAmit MakwanaNo ratings yet

- Manual Handling ChartDocument20 pagesManual Handling ChartTatak Bay Ahmed100% (1)

- Ohs Legal - Ohsa Act 1994Document1 pageOhs Legal - Ohsa Act 1994Nurul HidayahNo ratings yet

- Primavera P6 7.0 Project Management Reference ManualDocument560 pagesPrimavera P6 7.0 Project Management Reference ManualCristian Cornejo Catalán100% (1)

- CPT Workshop Guide for International StudentsDocument24 pagesCPT Workshop Guide for International StudentskhajaimadNo ratings yet

- Cdisc Glossary Terms Version7.1 Final 2008Document54 pagesCdisc Glossary Terms Version7.1 Final 2008chennasunkaraNo ratings yet

- Tendering Code of Practice PDFDocument48 pagesTendering Code of Practice PDFkhajaimad100% (1)

- Tern Engineering & Construction Services PVT - LTD: Quantity Surveying Quantity SurveyingDocument4 pagesTern Engineering & Construction Services PVT - LTD: Quantity Surveying Quantity Surveyingjode2213No ratings yet

- Project Management PDFDocument97 pagesProject Management PDFkhajaimadNo ratings yet

- Project Management PDFDocument97 pagesProject Management PDFkhajaimadNo ratings yet

- Primavera P6 Project Management Reference Manual PDFDocument700 pagesPrimavera P6 Project Management Reference Manual PDFkhajaimadNo ratings yet

- Quantity SurveyDocument24 pagesQuantity SurveykhajaimadNo ratings yet

- Design Report (Stair Case & Ramp) PDFDocument26 pagesDesign Report (Stair Case & Ramp) PDFanuj3936No ratings yet

- CV - Quantity SurveyorDocument3 pagesCV - Quantity Surveyorgo2aliNo ratings yet

- Buildingconstructionproject2zz 141209020348 Conversion Gate01 PDFDocument77 pagesBuildingconstructionproject2zz 141209020348 Conversion Gate01 PDFkhajaimadNo ratings yet

- RC Column Design BS8110Document5 pagesRC Column Design BS8110dantevariasNo ratings yet

- Bill of Quantities (BOQ)Document1 pageBill of Quantities (BOQ)Azil14No ratings yet

- Brickwork Calculating Quantities of BrickDocument5 pagesBrickwork Calculating Quantities of BrickAtish Kumar89% (9)

- Main construction items and descriptionsDocument6 pagesMain construction items and descriptionskhajaimadNo ratings yet

- Cesmm3 15616 FMDocument7 pagesCesmm3 15616 FMantscar0% (1)

- Analysesanddesignofatwo Storiedrcbuilding 140523063724 Phpapp02 PDFDocument67 pagesAnalysesanddesignofatwo Storiedrcbuilding 140523063724 Phpapp02 PDFkhajaimadNo ratings yet

- Cost Estimation: 5.1 Costs Associated With Constructed FacilitiesDocument38 pagesCost Estimation: 5.1 Costs Associated With Constructed FacilitieskhajaimadNo ratings yet

- Qs Syllabus UnescoDocument169 pagesQs Syllabus UnescoVinoj MnoNo ratings yet

- 49 82 1 SM PDFDocument9 pages49 82 1 SM PDFkhajaimadNo ratings yet

- Shear and Moment Equations and Diagrams Shear and Moment Equations and DiagramsDocument21 pagesShear and Moment Equations and Diagrams Shear and Moment Equations and DiagramsPrasanth KumarNo ratings yet

- 311 ch133552 100107183003 Phpapp01Document26 pages311 ch133552 100107183003 Phpapp01khajaimad100% (1)

- Shear and Moment Equations and Diagrams Shear and Moment Equations and DiagramsDocument21 pagesShear and Moment Equations and Diagrams Shear and Moment Equations and DiagramsPrasanth KumarNo ratings yet

- Presentation On T-Beam Design by WSD MethodDocument20 pagesPresentation On T-Beam Design by WSD Methodkhajaimad100% (1)

- Lecture No.7 Construction Site: Building Construction Technology IDocument78 pagesLecture No.7 Construction Site: Building Construction Technology IkhajaimadNo ratings yet

- Slab DesignDocument20 pagesSlab Designmanoj_structureNo ratings yet

- Lecture No.7 Construction Site: Building Construction Technology IDocument78 pagesLecture No.7 Construction Site: Building Construction Technology IkhajaimadNo ratings yet