Professional Documents

Culture Documents

De 690-19-001 Rev 0 DM For Elevators

Uploaded by

Sarang NarkadeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

De 690-19-001 Rev 0 DM For Elevators

Uploaded by

Sarang NarkadeCopyright:

Available Formats

006. N0. REV. N0.

DE-690-19-001

0E8|CN HEH0RAN0UH F0R ELEVAT0R8

0

ISSUED FOR OWNERS REVIEW AND

APPROVAL

TRM DJS VRR 03.11.2010

0A PRELIMINARY ISSUE SS / KGK DJS VRR 23.10.2010

REV. NO. DESCRIPTION PRED. BY CHKD. BY APPD BY DATE

PROJECT 2x300 MW, COAL BASED TPP

CHANDRAPUR

OWNER

DHARIWAL INFRASTRUCTURE PVT. LTD.

OWNER'S

CONSULTANT

TATA CONSULTING ENGINEERS LIMITED,

KOLKATTA

BOP CONTRACTOR PUNJ LLOYD LIMITED,

HYDERABAD

BOP

CONSULTANT

FICHTNER Consulting Engineers (India) Private Limited

Chennai

Dhariwal Infrastructure Pvt. Ltd.

2 x 300 MW Coal based TPP

Design Memorandum for

Elevators

Doc. No. DE-690-19-001, Rev. 0 FICHTNER INDIA Page : 2 of 9

TABLE OF CONTENTS

1.0 PREAMBLE............................................................................................................................. 3

2.0 REFERENCE DOCUMENTS.................................................................................................. 3

3.0 DESIGN CRITERIA ................................................................................................................ 3

4.0 DESIGN AND CONSTRUCTION ........................................................................................... 4

5.0 TECHNICAL PARAMETERS OF ELEVATORS..................................................................... 5

Dhariwal Infrastructure Pvt. Ltd.

2 x 300 MW Coal based TPP

Design Memorandum for

Elevators

Doc. No. DE-690-19-001, Rev. 0 FICHTNER INDIA Page : 3 of 9

1.0 PREAMBLE

Coal Based Thermal Power Station consisting of 2 x 300 MW generating units is being set

up at Chandrapur by Dhariwal infrastructures Pvt Ltd. In this power plant, Boilers, Technical

building, Chimney and other buildings which is having more than 2 Floor shall be provided

with Elevators. This document covers the Design basis for the Elevators of following

locations / buildings.

Two numbers passenger cum goods elevators for Boilers (one number in each Boiler)

Two numbers passenger elevators for Technical building

One number rack & pinion type elevator for the Chimney

One number passenger elevator for buildings higher than 2 storied (CHP Building)

2.0 REFERENCE DOCUMENTS

Tender Specification-LII-GEOE09043-00003-002.

IS: 14665 (part-1 to Part-5) Electric Traction Lifts

3.0 DESIGN CRITERIA

Service Passenger Elevator

Quantity 2 Nos. for Boilers (one number in each Boiler) - passenger cum

goods elevators

2 Nos. passenger elevators for Technical building

One number rack & pinion type elevator for the Chimney

1 No. passenger elevator for buildings higher than 2 storied

(CHP Building)

Location Boilers / Technical building / CHP

Design/Construction/ a. Latest edition of BS:5655 (All parts) installation codes and also

meeting any additional requirements of IS:4666, IS:1860 and

IS:3534

b. The safety code for elevators dump waiters & moving walks

shall be as per USA Std. Inst. Code No. A17.1

Load carrying capacity

a. 884 Kg for passenger elevator

b. 2000 Kg for goods elevator

c. 400 Kg for Chimney elevator

Rated speed

0.55 m/s for passenger lift

0.7 m/s for Chimney elevator

Number of floors Boiler elevator

Ten (10) - 0M, 7.2M, 12.6M, 19.6M, 23.2M, 29.8M, 36.4M, 44.2M,

52.6M, 60.7M, 66.4M

Dhariwal Infrastructure Pvt. Ltd.

2 x 300 MW Coal based TPP

Design Memorandum for

Elevators

Doc. No. DE-690-19-001, Rev. 0 FICHTNER INDIA Page : 4 of 9

Technical building

As per approved architectural drawing

Chimney

Ten (10) - 0M, 9M, 20M, 25M, 65M, 105M, 145M, 185M, 225M,

265M

CHP building

As per approved architectural drawing (to be provided by CHP

vendor)

Drive/Motor Worm geared traction machine driven by suitable motor or Two

speed motor with proven microprocessor based controls

Power Supply 415 V, 3 phase, 50 cycles, AC supply

Method of Control

Single Speed Servo drive control type with automatic level

adjustment

Type of doors Vertically split, Imperforated collapsible door of hollow metal

construction from 16 gauge thick steel sheet.

Machine room Machine room shall be located at top of Elevator. Machine shall be

Pressurized dust proof. Sound reducing material below machines

in machine room shall be provided

Operation of Elevator a. Selective duplex collective automotive operation with or without

attendant.

b. Provision for locking control in auto or attendant position.

4.0 DESIGN AND CONSTRUCTION

The Elevator shall be of industrial duty, rugged and suitable for the dusty power plant

environment. The drives and control shall have appropriate degree of protection. Metallic wire

mesh/screen in the area of lift travel shall be provided where car and the counter weight cross

each other. Elevator shaft shall be enclosed with 3.15 mm thick galvanized MS cladding sheet

from top of elevator pit upto machine room level.

Appropriate sealing shall be provided for the cladding sheet to prevent dust/ water entry in the

shaft. Construction of the elevators shall have the following features:

Flooring of

Cabin

: Chequered plate flooring with heavy timber underlay over steel

sheeting and replaceable felt spreading, each 25 mm thick.

Design

Construction

: Car inside enclosure shall be scratch proof SS sheet.

Car entrance

and landing

doors

:

Type F doors of BS: 5655 (Part-I) fire resistant doors defined and

tested as per Appendix F of BS: 5655 (Part-I).

Landing doors shall have fire resistance of atleast one hour. These

Dhariwal Infrastructure Pvt. Ltd.

2 x 300 MW Coal based TPP

Design Memorandum for

Elevators

Doc. No. DE-690-19-001, Rev. 0 FICHTNER INDIA Page : 5 of 9

doors shall also be smoke tight as far as possible.

Car Door

Construction

:

Imperforated collapsible door of hollow metal construction from 16

gauge thick steel sheet.

Signals :

Car position indicator with directional arrows both audio and visual,

hall position indicator at all floors, tell lights at all floors, battery

operated alarm bell and emergency light with suitable battery,

charger & controls, fan and telephone

Type of

indicators

:

Standard indicators or alternatively luminous hall buttons and

luminous button in car operating panel and digital hall position

indicator on all floors. (All fixtures in stainless steel face plates)

Emergency

indicator

:

In case of Emergency hold-ups in between the floors, automatic

flashers should indicate its location of hold-up both audio & visually

as well.

Further, Elevators shall have provisions to meet following operational requirements as minimum.

(i) Selective collective, automatic operation with or without operator through illuminated push

button station located inside the lift car.

(ii) Power operated with automatic opening / closing car and landing doors.

(iii) Two push buttons, one for upward movement and the other for downward movement at each

intermediate landing, and one push button at each terminal landing shall be provided in order

to call the car.

(iv) Push buttons shall be fixed in the car for holding the doors open for any length of the time

required.

(v) All other safety / protection / operation interlocks as required by BS:5655 (Part-I)

(vi) Indication for position and call indication inside the car, and up/down travel direction

indication in car and at each landing.

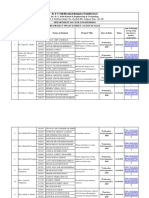

5.0 TECHNICAL PARAMETERS OF ELEVATORS

5.1 Boiler & Building Elevator

Sl.

No.

Item Description Boiler Elevator

(Passenger cum Goods

Elevator)

Building Elevator (Passenger

Elevator)

a) No of Elevators Two (one number in each

boiler)

a) 2Nos. - Technical Building

b) 1No. - CHP Building

b) Type Floor Elevator System with Car Floor Elevator System with Car

c) Applicable standard IS: 14665 (Parts 1 to 5) IS: 14665 (Parts 1 to 5)

d) Rated Load 2000 kg 884 kg (6 8 persons)

e) Rated Speed 0.55 m / sec 0.55 m / sec

f) Total Rise 66.4 M

g) Number of floors Ten (10) including ground floor

Shall be furnished after the

finalisation of architectural

drawing

Dhariwal Infrastructure Pvt. Ltd.

2 x 300 MW Coal based TPP

Design Memorandum for

Elevators

Doc. No. DE-690-19-001, Rev. 0 FICHTNER INDIA Page : 6 of 9

Sl.

No.

Item Description Boiler Elevator

(Passenger cum Goods

Elevator)

Building Elevator (Passenger

Elevator)

served

h) Landing Levels

0M, 7.2M, 12.6M, 19.6M,

23.2M, 29.8M, 36.4M, 44.2M,

52.6M, 60.7M, 66.4M

i) Lift well Size Will be furnished during

engineering

Will be furnished during

engineering

j)

Leveling Zone

5 mm 5 mm

k)

Leveling Device

Two way automatic maintaining Two way automatic maintaining

l)

No. of door in car

One, Centre Opening Automatic

Horizontal sliding

One, Centre Opening Automatic

Horizontal sliding

m)

Type of control

AC Variable Voltage Variable

Frequency (ACVVVF) control

AC Variable Voltage Variable

Frequency (ACVVVF) control

n)

Operation

With / Automatic without

attendant

With / Automatic without

attendant

o)

Automatic Operation

type

Selective Duplex Collective Selective Duplex Collective

p)

Operating Devices

As listed clause 5.2 As listed clause 5.2

q)

Indicating Devices

As listed clause 5.2 As listed clause 5.2

r) Car enclosure Stainless Steel Stainless Steel

s) Accessories

Car Lighting (Fluorescent

Tube)

Car Ventilation fan with

manual / automatic through

selector switch

Inbuilt hand free Telephone

Hand rail

Emergency DC Light

Fire extinguisher

Over load device

Energy saving device

Emergency switch

Car Lighting (Fluorescent

Tube)

Car Ventilation fan with

manual / automatic through

selector switch

Inbuilt hand free Telephone

Hand rail

Emergency DC Light

Fire extinguisher

Over load device

Energy saving device

Emergency switch

t) Degree of protection

IP 55 & weather proof IP 55 & weather proof

u) Landing, operating

devices & indicating

devices

Weather proof and rain proof -

v) Car Door

Non contact type protective

device extending to the full

height, Electric contact &

mechanical interlock with

auxiliary closing device will be

provided

Non contact type protective

device extending to the full

height, Electric contact &

mechanical interlock with

auxiliary closing device will be

provided

w) Power supply

415V, 3 phase, 4 wire, 50Hz

supply

415V, 3 phase, 4 wire, 50Hz

supply

x) Power supply Main

Lockable as per requirements

of IS 1860

Lockable as per requirements of

IS 1860

Dhariwal Infrastructure Pvt. Ltd.

2 x 300 MW Coal based TPP

Design Memorandum for

Elevators

Doc. No. DE-690-19-001, Rev. 0 FICHTNER INDIA Page : 7 of 9

Sl.

No.

Item Description Boiler Elevator

(Passenger cum Goods

Elevator)

Building Elevator (Passenger

Elevator)

y) Maintenance Tool Kit

A maintenance tool kit will be

kept machine room

A maintenance tool kit will be

kept machine room

5.2 Chimney Elevator

Sl.

No.

Item Description Technical Parameters

a)

Type Rack & Pinion type

b)

Travel Length 9M to 268M (Chimney Height = 275M)

c)

Landing Levels 9 M, 20 M, 25 M, 65 M, 105 M, 145 M, 185 M,

225 M, 265 M

d)

Number of Landings Ten

e)

Type of Operation With attendant

f)

Minimum Carrying Capacity (Pay

load)

400 kg

g)

Speed 0.7 m /sec

h)

Controls Semi Automatic Control

i)

Car enclosure Aluminium sheet

j)

Landing entrance door Mild steel perforated sheet

k)

Operation of car door Manually operated

l)

Car floor MS Plates

m)

Controls & Indications Dead man type controls in the car, Push buttons

for up, down, stop next landing, stop &

emergency stop, cage light / key switch, fan

switch, hooter switch, thermal overload

indicating lamp.

n)

Safety Features Over travel protection.

Over speed governor

Emergency stop push button

o)

Essential Features a. Cage with frame guide rollers and

mechanical safety hooks.

b. Cage of welded steel structure with wire

mesh covered walls, with one door

electrically and mechanically interlocked.

c. Electrically and mechanically interlocked

trapped door in cage roof, safety railing on

top of cage and ladder inside cage.

Dhariwal Infrastructure Pvt. Ltd.

2 x 300 MW Coal based TPP

Design Memorandum for

Elevators

Doc. No. DE-690-19-001, Rev. 0 FICHTNER INDIA Page : 8 of 9

d. Semi-automatic control system for operation

of lift from inside the cage as well as on

landing with automatic stop equipment stop

next landing

e. Overspeed governor for controlling

excessive descending speed.

f. An external brake release mechanism

located inside the cage for descending cage

in case of power failure.

g. Progressive type positive action safety

device driven by a separate pinion engaged

in the rock (Alimak patented or equivalent)

h. Emergency alarm system

p)

Power Supply 415V , 3 phase, 4wire 50 Hz supply

5.3 Operating devices / Indicating devices

The following operating devices shall be provided in the car / on the landing / in the machine

room as indicated below:

Operating devices

In the car In the landing In the m/c room On top of the car

Up push button (PB)

Up PB Up PB Up

Down PB

Down PB Down PB Down

Number PB s for each

landing

Bell

Hand cranking

device

Stop

Bell PB, Phone

Lift PB Stop PB 240 V 1 receptacle

Non-stop PB

- -

Door open PB

- - -

Door close PB

- - -

Alarm PB

- - -

Emergency stop PB

- - -

Key operated selector

for attendant operation

- - -

Indicating devices

The following indicating devices shall be provided in the car / on the landing as indicated below:

In the Car

On the landing

Up direction of travel

Up direction of travel

Dhariwal Infrastructure Pvt. Ltd.

2 x 300 MW Coal based TPP

Design Memorandum for

Elevators

Doc. No. DE-690-19-001, Rev. 0 FICHTNER INDIA Page : 9 of 9

Down direction of travel

Down direction of travel

Floor position indicator

Car position indicator with direction

(Illuminated numeral for each landing)

(Illuminated numeral for each landing)

Landing car registering unit

Call registered Up indicator

Thermal Overload Indication Lamp Call registered Down indicator

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Designation System of Screws and BoltsDocument3 pagesDesignation System of Screws and BoltsGiri DharanNo ratings yet

- T.O.S (Surface Active Structures)Document18 pagesT.O.S (Surface Active Structures)Riddhi Aggarwal100% (1)

- U-Bolt Clamps HRRBS Flat Steel Bolt Clamps HRFBSDocument8 pagesU-Bolt Clamps HRRBS Flat Steel Bolt Clamps HRFBSFakeNo ratings yet

- Evaluation of Modified Truss Model Approach For Beam in ShearDocument10 pagesEvaluation of Modified Truss Model Approach For Beam in ShearKinjal DaveNo ratings yet

- Dr. D. Y. Patil School of Engineering & Technology Department of Civil Engineering Be Project Phase Ii Sheet (Ay2019-20) Sem IiDocument3 pagesDr. D. Y. Patil School of Engineering & Technology Department of Civil Engineering Be Project Phase Ii Sheet (Ay2019-20) Sem IiRao SahabNo ratings yet

- 32 Samss 022Document11 pages32 Samss 022naruto256No ratings yet

- Calculation of Longitudinal Forces in BridgesDocument155 pagesCalculation of Longitudinal Forces in BridgesamirNo ratings yet

- Plastering Techniques and MethodsDocument6 pagesPlastering Techniques and MethodsYazhisai SelviNo ratings yet

- Installation & Maintenacne Manual: Variable-Frequency One-Drive-Two Split Room Air Conditioner SeriesDocument35 pagesInstallation & Maintenacne Manual: Variable-Frequency One-Drive-Two Split Room Air Conditioner SeriesKostas AstrinisNo ratings yet

- Modified Guidelines For Geopolymer Concrete Mix Design Using Indian StandardDocument13 pagesModified Guidelines For Geopolymer Concrete Mix Design Using Indian StandardDl Divakar LNo ratings yet

- Behaviour of Masonry StructuresDocument27 pagesBehaviour of Masonry StructuresvarshaNo ratings yet

- QAP Format - QA 01 F 01Document1 pageQAP Format - QA 01 F 01Murukan PadmanabhanNo ratings yet

- Accumulators Catalogue EngDocument21 pagesAccumulators Catalogue EngThái Mai ĐìnhNo ratings yet

- Superior Solutions For Industrial Heating and VentilatingDocument24 pagesSuperior Solutions For Industrial Heating and VentilatingKhamis YHNo ratings yet

- M 171 Specs for Curing Concrete SheetsDocument1 pageM 171 Specs for Curing Concrete SheetsFranz Richard Sardinas MallcoNo ratings yet

- Instrument Manifold (Monoflange) : SpecificationsDocument1 pageInstrument Manifold (Monoflange) : Specificationshisaj4uNo ratings yet

- amm 467 349Document6 pagesamm 467 349Dinesh JagadisanNo ratings yet

- DomesDocument18 pagesDomesbhansalianiket96100% (1)

- Ducting DesignDocument31 pagesDucting DesignIrwan SattuNo ratings yet

- Prevention, Fishing and Casing Repair - Jim Short - Part 2Document249 pagesPrevention, Fishing and Casing Repair - Jim Short - Part 2MitsúMilagrosToroSayasNo ratings yet

- NTRBTDocument12 pagesNTRBTRanjanDsNo ratings yet

- Research Paper Proposal TemplateDocument3 pagesResearch Paper Proposal TemplatePablo MoralesNo ratings yet

- SSV Design Options - IIDocument28 pagesSSV Design Options - IISATHISHKUMAR RNo ratings yet

- Serenity Hot Tubs Owner's Manual GuideDocument39 pagesSerenity Hot Tubs Owner's Manual GuideGisell ZapataNo ratings yet

- Plaxis: Computational Geotechnics Course (2D Plaxis Course)Document2 pagesPlaxis: Computational Geotechnics Course (2D Plaxis Course)Fajar Adi NugrohoNo ratings yet

- Prevent Negative Volume in Foam ModelsDocument9 pagesPrevent Negative Volume in Foam ModelsGustavo Yippeekayyay GusNo ratings yet

- Cylinder Head - Install: Cerrar SIS Pantalla AnteriorDocument21 pagesCylinder Head - Install: Cerrar SIS Pantalla AnteriorReymundo Enrique Dominguez Hernandez100% (1)

- Boiler Basics, Operation and MaintenanceDocument121 pagesBoiler Basics, Operation and MaintenanceCosmin IulianNo ratings yet

- Casting: Aim of The ExperimentDocument7 pagesCasting: Aim of The Experimentsanskar mittalNo ratings yet