Professional Documents

Culture Documents

Techno - Mosaic4u - Final-2

Uploaded by

stephen_glad6189Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Techno - Mosaic4u - Final-2

Uploaded by

stephen_glad6189Copyright:

Available Formats

Techno-Isel Robots Automate Creation of Mosaics at Substantial Reduction in Cost

Mosaic4u of Herzelia, Israel, produces mosaic murals from tens of thousands of little tiles glued face on to 300 by 300 mm (12 by 12 inches) transparent film sheets as a ready-to- install kit. Mosaic4us proprietary technology consists of a mosaic editor and an automated manufacturing process. The company originally assembled its mosaics using an off-theshelf robot but discovered that it was much too slow. So Mosaic4u created its own robot using Blueline motion components from Techno-Isel that fits its needs perfectly. The custom robot operates at a speed of 2.4 meters per second yet costs about $9,200. The new robot places 9000 3/8 tiles, enough to make a one square meter mosaic, in about 9 hours. Two Mosaic4u technicians got the Blueline robot working in this application in only one day. Using a robot to assemble mosaics from the same glass tiles makes it possible for Mosaic4u to provide mosaics of equal quality as hand-made mosaics at a significantly lower price, said Boaz Glass, Chief Executive Officer of Mosaic4u. Designing the mosaic The process of creating a mosaic begins when the customer sends a photograph or painting to Mosaic4u. Glass says that for best results that original image should be at least 1.5 square meters (16 square feet). When the company receives the image from the customer, it uses special software to make several mosaic alternatives for the customer to choose from based on the same original image. The mosaic is not intended to be identical to the original image, but rather be inspired by it. Mosaic murals are an ancient art form and like any art should be judged for themselves. Mosaic4us technicians then make changes as needed to the images until the customer is completely satisfied. Traditionally, mosaics are manually assembled by hand by skilled craftsmen in an extremely time-consuming and costly process which puts them out of reach of all but the very affluent. Mosaic4u has revolutionized the mosaic industry by using robots to produce mosaics. Use of a robot to assemble the mosaic makes it possible to offer the product at a substantially lower cost than a hand-made mosaic while also increasing the accuracy of tile

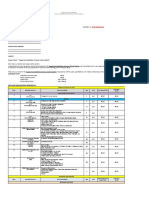

placement and reducing leadtime. However, the company had a difficult time finding a robot that would fit the requirements of the application. The robot requirements for this application are primarily speed, low costs and the ability to operate for millions of cycles. Most industrial robots are designed to lift heavier weights and maintain higher levels of accuracy than are required in this application. As a result, they are so expensive that they would be difficult to justify here. Mosaic4u first purchased an off-the-shelf robot but had difficulty making it work and when the company finally did get it running it turned out to be much too slow. The company made a comprehensive survey of industry robots but could not find one that met its needs. Robots meet tough requirements Then it discovered Technos Blueline series of belt-driven robots which are available in kits at a lower cost than off-the-shelf robots and can be configured to meet the needs of specific applications. Techno's Blueline robots can be configured up to 1550 x 2600 mm (61 x 102 inches) of travel with maximum speeds up to 2.4 meters per second. This gives the user a large format, high speed robot at a low price. A complete system for $9,200.00 includes a completely assembled 3 axis robot with travel of 1043 x 1043 x 143 mm, PCI motion controller that plugs into a PC, power electronics assembled in enclosure with power supply and Windows-based automation software. Each axis is contained in an aluminum housing with a protective top cover. This allows the robots to stand up to industrial applications. Three axes of simultaneous motion can be provided to perform difficult multi-axis motions. Techno's Cartesian robots provide smooth and continuous motion to avoid puddling when dispensing fluids or working with solder. The system can be mounted over very large parts or conveyor systems. This gives the unit great flexibility. An optional library of motion routines is available for software development for OEM applications. Mosaic4u purchased a Blueline robot kit and two technicians got it working in this assembly application in just one day. The robot quickly demonstrated its ability to assemble 1000 tiles per hour or 16 tiles per minute, which exceeds the requirements of the application. Now, as soon as the customer approves the computerized mosaic design, Mosaic4us proprietary software

divides the mosaic into 300 by 300 mm (12 by 12 inch) sheets and generates G-code programs for the Blueline robot to automatically assemble each sheet. The robot picks each tile with a vacuum gripper and glues it face-on to a transparent carrier sheet. Each mosaic sheet is labeled with the mosaic sheets xy coordinates. Assembling the mosaic A typical four square meter mosaic weighs about 25 kg and fits into a box measuring 320 by 320 by 300 millimeters. Assembly of the mosaic murals is simple and requires the same skills required to install any mosaic wall covering. The company does not design its mosaics in straight rows and columns unless requested by the customer. This means that the edges of the sheets are not straight lines but rather consist of a step-like pattern. This feature helps eliminate visible stitch marks between the sheets. The sheets combine in such a way that the film edges are almost touching each other and the tiles flow naturally from one sheet to the next. Mosaic4u recommends that after placing each sheet the customer should fasten it to neighboring sheets with the supplied transparent adhesive strips that are supplied with its mosaics. The customer glues each sheet to all of the adjoining sheets using one stripe for each stitch. After the glue has bonded completely, the transparent sheets can be removed. The back side of each carrier board is then glued to the wall. Grout can be applied between the mosaic tiles if desired. When you look at a mosaic mural from a longer distance (2 meters away for 1 square meter mosaics or 6 meters away for 4 square meter mosaics) a new perspective kicks in, Glass said. Light projection at an appropriate angle on the mosaic creates a fascinating effect of light and color. From a longer distance you will notice details that are not apparent at a close distance. Our unique design software provides three-dimensional effects that make certain image features jump out of the wall. Mosaic4u uses high quality glass tiles of the type that last for decades in pools, wall coverings and other applications. The tiles are water resistant, will not wear and will not fade even under direct sunlight. Across the globe there are many mosaics that have survived for centuries and even

millenniums. If the customer does not like their mosaic mural, they can return it in its original package within 30 days and Mosaic4 u will refund the entire payment. Tedious to make and long lasting, sometimes image related but never realistic mosaics are found in many of the worlds monuments, historical sites and contemporary buildings, Glass concluded. A large mosaic mural provides a unique splendor, luxury and grace unlike any other type of decoration. The main difference between our mosaic murals and a handmade mosaic is that robotic assembly makes it possible to sell our murals for considerably less. This makes it possible for nearly everyone to enjoy the beauty of one of the oldest known art forms. The Blueline robot has been instrumental in our ability to make mosaics available at lower cost than ever before. It has already delivered twelve months of flawless operation at a remarkably low price. For more information on the CNC Machine described in this article, contact Techno Inc., 2101 Jericho Turnpike, New Hyde Park, NY 11040. Phone: 1.800.819.3366/1.516.328.3970, Fax: 1.516.358.2576, E-mail: support@technocnc.com, Web site: http://www.technocnc.com/ ###

You might also like

- Techno - Mosaic4u - Final-2Document4 pagesTechno - Mosaic4u - Final-2stephen_glad6189No ratings yet

- Troubleshooting Commercial Lighting LoadsDocument2 pagesTroubleshooting Commercial Lighting Loadsstephen_glad6189No ratings yet

- Power System ResonanceDocument2 pagesPower System Resonancestephen_glad6189No ratings yet

- A Line-Up of Culprits That Can Harm Power QualityDocument2 pagesA Line-Up of Culprits That Can Harm Power Qualitystephen_glad6189No ratings yet

- Power System ResonanceDocument2 pagesPower System Resonancestephen_glad6189No ratings yet

- Polyphase Induction MotorsDocument3 pagesPolyphase Induction Motorsstephen_glad6189No ratings yet

- Vibration GlossaryDocument4 pagesVibration Glossarystephen_glad6189No ratings yet

- Applying Power Quality Measurements To Predictive MaintenanceDocument4 pagesApplying Power Quality Measurements To Predictive Maintenancestephen_glad6189No ratings yet

- Introduction To Vibration, Introduction To Vibration FLUKEDocument3 pagesIntroduction To Vibration, Introduction To Vibration FLUKEwilliamb285No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- All MCQ 2021 ICT EDEXCEL IGCSEDocument32 pagesAll MCQ 2021 ICT EDEXCEL IGCSESyed Moinul Hoque100% (2)

- TEAC MP-200-512 - User ManualDocument28 pagesTEAC MP-200-512 - User ManualtiponatisNo ratings yet

- Symac CQM1 Omron Operation ManualDocument155 pagesSymac CQM1 Omron Operation ManualsunhuynhNo ratings yet

- Use Your Canon EOS 1000D As WebcamDocument5 pagesUse Your Canon EOS 1000D As Webcamdstv2005No ratings yet

- Accounting Software For Small BusinessDocument2 pagesAccounting Software For Small Businesseccountant coNo ratings yet

- Reviewinfotech-Đã M KhóaDocument12 pagesReviewinfotech-Đã M KhóaNam ĐặngNo ratings yet

- Cherry KeyboardDocument2 pagesCherry KeyboardKheshav JhundooNo ratings yet

- LM Chs 140627062037 Phpapp01Document77 pagesLM Chs 140627062037 Phpapp01Lawrence RolluquiNo ratings yet

- Phased Array & TOFD Ultrasonic Flaw DetectorDocument12 pagesPhased Array & TOFD Ultrasonic Flaw Detectorsealion72No ratings yet

- Laptop Simatic Field PG PDFDocument20 pagesLaptop Simatic Field PG PDFBlAdE 12No ratings yet

- QVIS Viewer Guide PC Version V3.0 15.07.15Document25 pagesQVIS Viewer Guide PC Version V3.0 15.07.15Alberto TorreNo ratings yet

- Assignment - IT - 5Document51 pagesAssignment - IT - 5AanchalNo ratings yet

- IM IT Tools 2023 PDFDocument97 pagesIM IT Tools 2023 PDFArvie LorenzoNo ratings yet

- Eie Instruments PVT LimitedDocument76 pagesEie Instruments PVT LimitedKuldeep ChakerwartiNo ratings yet

- Tsreader Rod HewittDocument5 pagesTsreader Rod HewittAlexander WieseNo ratings yet

- TOR-IT Support OutsourceDocument1 pageTOR-IT Support OutsourceHerry SusantoNo ratings yet

- Ts ReportDocument24 pagesTs Reportrohith kuruvaNo ratings yet

- ICT Training ManualDocument87 pagesICT Training ManualYaronBaba100% (4)

- ACS ICT Proposal For Author's SolutionDocument34 pagesACS ICT Proposal For Author's SolutionBan Darl PonshiNo ratings yet

- Marketing Strategy and PlanningDocument50 pagesMarketing Strategy and PlanningglanNo ratings yet

- DL2020 User ManualDocument27 pagesDL2020 User ManualSaniFani80No ratings yet

- Demonstrate An Understanding of Hardware Components For Personal ComputersDocument3 pagesDemonstrate An Understanding of Hardware Components For Personal ComputersSakthimurugan SupramaniNo ratings yet

- Case Study 7.5 SPMDocument2 pagesCase Study 7.5 SPMgiscapindyNo ratings yet

- PJE 0801 enDocument126 pagesPJE 0801 enSamir SabicNo ratings yet

- RaceChrono Touchscreen v1420 Full ManualDocument25 pagesRaceChrono Touchscreen v1420 Full Manualetaho1No ratings yet

- Siemense SM 06 04 23 76Document17 pagesSiemense SM 06 04 23 76skidamdnevnoNo ratings yet

- Data Sheet: Protection and Power Management PPM 300Document65 pagesData Sheet: Protection and Power Management PPM 300Hasni Md HassanNo ratings yet

- AB - Pressostato 836Document32 pagesAB - Pressostato 836chnanduNo ratings yet

- Frequently Asked Questions: PC RefreshDocument7 pagesFrequently Asked Questions: PC Refreshdebmaj007No ratings yet