Professional Documents

Culture Documents

1260853156AESB067 Safety Colours

Uploaded by

ehasayinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1260853156AESB067 Safety Colours

Uploaded by

ehasayinCopyright:

Available Formats

Engineering Standard

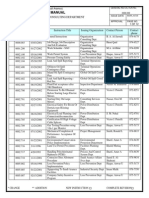

SAES-B-067 Safety Identification and Safety Colors Loss Prevention Standards Committee Members

Ashoor, E.A., Chief Fire Prevention Engr., Chairman Fadley, G.L., Vice Chairman, Loss Prevention Al-Ghobari, A.M., Abqaiq Area Loss Prevention Al-Hassar, F.A., Riyadh Area Loss Prevention Al-Janaby, M.A. Ras Tanura Area Loss Prevention Al-Sayed, S.M., Jeddah Area Loss Prevention Al-Seba, Z.A., Materials Control Al-Sultan, S.A., Dhahran Area Loss Prevention Al-Utaibi, A.S., Consulting Services Al-Zahrani, M.J., Terminal Anderson, S.V., Jeddah Refinery Bard T.E., Loss Prevention Churches, D.K., Utilities & Facilities Maintenance Cole, A.R., Fire Protection Karvois, E.F., Southern Area Producing Engrg. Solomon, C.R., Hawiyah Gas Plant

30 November, 2003

Previous Issue: 30 January, 2002

Next Planned Update: 1 December, 2008 Page 1 of 17

Revised paragraphs are indicated in the right margin Primary contact: Esam A. Ashoor on 8728431

Document Responsibility: Loss Prevention Issue Date: 30 November, 2003 Next Planned Update: 1 December, 2008

SAES-B-067

Safety Identification and Safety Colors

Saudi Aramco DeskTop Standards

Table of Contents

1 2 3 4

Scope............................................................. 2 Conflicts and Deviations................................. 2 References..................................................... 2 Requirements................................................. 4

Scope This Standard governs the minimum mandatory safety identification and use of safety colors in Saudi Aramco facilities in order to identify potential hazards and alleviate fire and safety concerns.

Exception: Cross-country pipelines, trunklines, flowlines, onshore wellheads, and marine vessels are excluded from this Standard.

Page 2 of 17

Document Responsibility: Loss Prevention Issue Date: 30 November, 2003 Next Planned Update: 1 December, 2008

SAES-B-067

Safety Identification and Safety Colors

Conflicts and Deviations 2.1 Any conflicts between this Standard and other applicable Saudi Aramco Engineering Standards (SAESs), Saudi Aramco Materials System Specifications (SAMSSs), Saudi Aramco Standard Drawings (SASDs), or industry standards, codes, and forms shall be resolved in writing by the Company or Buyer Representative through the Manager, Loss Prevention Department of Saudi Aramco, Dhahran. Direct all requests to deviate from the Standard in writing to the Company or Buyer Representative, who shall follow internal company procedure SAEP-302 and forward such requests to the Manager, Loss Prevention Department of Saudi Aramco, Dhahran.

2.2

References The selection of material and equipment and the design, construction, maintenance, and repair of equipment and facilities covered by this Standard shall comply with the latest edition of referenced Specifications, Standards, Codes, Forms, Drawings, and similar material (including all revisions, addenda, and supplements) unless stated otherwise. 3.1 Saudi Aramco References Saudi Aramco Engineering Procedures SAEP-302 Instructions for Obtaining a Waiver of a Mandatory Saudi Aramco Engineering Requirement Pressure Relief Valves - Routine Test, Quality Assurance and Regulation

SAEP-319

Saudi Aramco Engineering Standards SAES-B-014 Safety Requirements for Plant and Operations Support Buildings

Page 3 of 17

Document Responsibility: Loss Prevention Issue Date: 30 November, 2003 Next Planned Update: 1 December, 2008

SAES-B-067

Safety Identification and Safety Colors

SAES-B-018 SAES-B-069 SAES-H-001 SAES-J-600 SAES-J-601 SAES-L-310 SAES-M-008 SAES-M-100 SAES-T-481 SAES-T-911 SAES-T-928

Air Foam Systems for Storage Tanks Emergency Eyewashes and Showers Selection Requirements for Industrial Coatings Pressure Relief Devices Emergency Shutdown and Isolation Systems Design of Plant Piping Design Criteria for Lifting Equipment Aramco Building Code Powered In-Plant Communications Communication Conduit System Design Telecommunications - OSP Buried Plant

Saudi Aramco Materials System Specification 04-SAMSS-003 Additional Requirements for Low Temperature Valves

Saudi Aramco General Instruction GI-0150.003 Ionizing Radiation Protection

Saudi Aramco Materials Instruction Manual Saudi Aramco Standard Drawing AA-036248 Helidecks Offshore: Types 1 & 2 Plans & Elevation

3.2

Industry Codes and Standards American National Standards Institute ANSI Z535.1 Safety Color Code

Page 4 of 17

Document Responsibility: Loss Prevention Issue Date: 30 November, 2003 Next Planned Update: 1 December, 2008

SAES-B-067

Safety Identification and Safety Colors

ANSI Z535.2 ANSI Z535.3 ANSI Z535.4 ANSI Z535.5

Environmental and Facility Safety Signs Standard for Criteria for Safety Symbols Product Safety Signs and Labels Standard for Accident Prevention Tags (for Temporary Hazards)

American Petroleum Institute API STD 1542 Airport Equipment Marking for Fuel Identification

American National Standards Institute - Compressed Gas Association, Inc. ANSI/CGA C-4 ANSI/CGA C-7 Method of Marking Portable Compressed Gas Containers to Identify the Material Contained Precautionary Labeling and Marking of Compressed Gas Containers

British Standards Institution BS 381C Colours for Identification, Coding and Special Purposes

German Standard RAL U.S. Federal Standard FS 595B Colors Used in Government Procurement German Specification for Colors (RAL)

National Fire Protection Association NFPA 55 Storage, Use and Handling of Compressed and Liquefied Gases in Portable Cylinders

Page 5 of 17

Document Responsibility: Loss Prevention Issue Date: 30 November, 2003 Next Planned Update: 1 December, 2008

SAES-B-067

Safety Identification and Safety Colors

Requirements 4.1 General 4.1.1 Pipes, vessels, valves, and related structural supports shall be painted a neutral background color such as aluminum, gray, or black, which will not detract from the high visibility of the safety colors set out in this specification. For coating selection, see SAES-H-001. Color-coding shall not be used as a substitute for mandatory labeling in paragraphs 4.3 and 4.4. 4.1.2 Safety signs for gas cylinder storage areas, gas cylinder labeling and marking requirements, including lettering in Arabic and English for gas cylinders, shall meet CU 15.4 of the Saudi Aramco Materials Instruction Manual, ANSI/CGA C-4, ANSI/CGA C-7, and NFPA 55. This includes all industrial, medical, laboratory, and aviation bottled gases. Utility Stations in Plants: The water, steam, air, and nitrogen lines shall be marked and color-coded as specified in SAES-L-310. Aviation Fuel Systems: Color identification for aviation fuel system piping and accessories including valves, fittings, pumps and switches shall be per API STD 1542. Specific requirements are as follows (refer to Table 1, API STD 1542): a) The color-coding for system piping shall be in the form of bands of the identifying color printed or taped around the piping. Jet A-1 and JP-8 piping shall be marked by an aluminum stripe on a black band. JP-8 is the military equivalent of Jet A-1 with certain additives. For JP-4 (Jet B), piping shall be with three yellow bands. JP-4 is the military equivalent of Jet B with certain additives. The bands shall be at least 100 mm wide and shall be placed at intervals of no more than 6 m.

4.1.3

4.1.4

Page 6 of 17

Document Responsibility: Loss Prevention Issue Date: 30 November, 2003 Next Planned Update: 1 December, 2008

SAES-B-067

Safety Identification and Safety Colors

b)

The color of jet fuel system accessories shall be gray for Jet A-1 (JP-8), yellow for JP-4 (Jet B). The labels for jet fuel grades shall be clearly printed in white letters and numbers on a black background.

c)

4.1.5

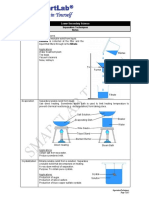

Bulk Plant and air fuel terminal product identification for the transfer points at loading and unloading facilities such as unloading stations, loading and unloading racks, associated pumps and tank storage truck connections related to bulk plant operations shall use labeling in Arabic and English and color identification as listed in Table 1 in addition to the labeling requirements of this Standard. a) b) c) Markings should be as close as possible to the points of product transfer. Background colors shall be indicated by a 300 mm wide band per Table 1. The identifying color shall be indicated by a 50 mm wide stripe over the band per Table 1.

Commentary Note: The background color band represents groups of materials with similar volatility. The identifying color stripe identifies the specific material as listed in Table 1 below. Also see Figure 1.

Page 7 of 17

Document Responsibility: Loss Prevention Issue Date: 30 November, 2003 Next Planned Update: 1 December, 2008

SAES-B-067

Safety Identification and Safety Colors

Table 1 Colors for Marking Product Truck Transfer Points

Base Color (Band) Gasoline (premium unleaded) Gasoline (super premium unleaded) LP Gas Kerosene Diesel oil (white) Diesel oil (black) Fuel oil Asphalt Stabilized Sweet Crude Oil Jet A-1 Fuel Orange Orange Orange Oxide Red Oxide Red Oxide Red Black Black Gray Black Identifying Color (Stripe) White Blue Oxide Red Green White Black Yellow Green Aluminum Aluminum

4.1.6

Signs within buildings shall meet SAES-M-100 and SAES-B-014, where applicable. New safety sign symbols and colors, shall meet ANSI Z535.1, ANSI Z535.2, ANSI Z535.3 and ANSI Z535.4. Together, these standards contain the information needed to specify formats, colors, and symbols for safety signs used in environmental and facility applications. New safety accident prevention tags for temporary hazards shall meet ANSI Z535.5.

4.1.7

4.2

The colors red, green, yellow, yellow and black, orange, blue, and white are reserved for safety uses described herein. The color criteria for safety colors shall meet ANSI Z535.1. In addition, the following safety color designations have been used in company facilities and shall continue to be acceptable for use as safety colors for existing and new facilities: Safety Red Safety Green Safety Yellow Safety Orange RAL 3000 (BS 538), 9006, 9010; FS 11120, 17925 RAL 6016, 9010; FS 14120, 17925 RAL 1018, 1021, 1023, 9005; FS 13591, 14084, 23655 RAL 2000, 9005; FS 12300, 14084

Page 8 of 17

Document Responsibility: Loss Prevention Issue Date: 30 November, 2003 Next Planned Update: 1 December, 2008

SAES-B-067

Safety Identification and Safety Colors

Safety Blue Safety Black Safety White

1

RAL 5015; FS 15092 RAL 9005; FS 14084 RAL 9010; FS 17925

RAL indicates a German Color Register "Ausschusz fur Lieferbedingungen and Gutesicherung" (German Organization for Specifications and Certification); originally "(R)eichs(A)usschu fr (L)ieferbedingungen in 1925. FS indicates United States Federal Color Standard (FS 595B) BS indicates British Standard for Colors (BS 381C)

2 3

For purposes of identification and accident prevention, equipment and facilities shall be safety color-coded in accordance ANSI Z535.1, Section 6 as modified by the following: 4.2.1 Safety red shall be used as the color indicator for fire protection equipment and piping, as well as emergency stop push button devices. Specific requirements are as follows: a) Fire water piping: all exposed aboveground fire water piping and fittings shall be painted red.

Exceptions:

1) Runs of aboveground outdoor fire water piping longer than 65 meters may be painted an aluminum rather than a red color; however, all valves, tees, elbows, and connected piping within 3 meters of those valves and fittings shall be painted safety red. The piping shall have a safety red band at least every 30 m. Bands shall be 0.3 m (12 inches) long. Sprinkler and deluge piping may be painted an aluminum color. However, in the header/riser piping all valves, tees, elbows, strainers, and their connected piping within 3 meters shall be painted red. Block valves to safety relief valves. Refer to 4.2.4.

2)

3)

b)

Fire protection equipment: fire water pumps, fire water pump control panels, portable and fixed fire protection systems, the

Page 9 of 17

Document Responsibility: Loss Prevention Issue Date: 30 November, 2003 Next Planned Update: 1 December, 2008

SAES-B-067

Safety Identification and Safety Colors

mounting background for fire extinguishers, portable fire-fighting equipment, and shelters for portable fire-fighting equipment shall be safety red.

Exception: CO2 pressure cylinders are not required to be safety red.

c)

Emergency stop pushbutton devices and switches shall be safety red, per SAES-J-601. The emergency panels or boxes containing these devices are not required to be red. Safety red shall be used for the background of "DANGER" and "STOP" signs, "EMERGENCY ROOM" signs and arrows, and "EMERGENCY SHUTDOWN" signs. The lettering shall be safety white.

d)

4.2.2

Safety green shall be used as the background color indicator for locations of emergency safety equipment. Specific requirements are as follows: a) Locations of emergency safety equipment, such as first aid equipment, shall be identified by green backgrounds with 100 mm border beyond the equipment outline and with safety white lettering 50 mm high within the border where practicable. Refer to SAES-B-069 for emergency eyewash and shower requirements. Where wall mounting is used, locations of permanently installed boxes for emergency equipment such as field boxes for breathing apparatus shall be marked by a safety green border or background. Locations of safety instructions shall be marked by a safety green border or background. Bellows-type pressure relief valves shall have safety green bonnets to indicate that they must have vented bonnets. Refer to SAES-J600 and SAEP-319. For relief valve isolation valves, see 4.2.4.

b)

c)

d)

Page 10 of 17

Document Responsibility: Loss Prevention Issue Date: 30 November, 2003 Next Planned Update: 1 December, 2008

SAES-B-067

Safety Identification and Safety Colors

4.2.3

Safety yellow or yellow and black shall be the color indicator for physical and radioactive hazards. Specific requirements are as follows: a) Physical hazards such as stumbling and tripping hazards and outlines of traffic aisles in shops and warehouses shall be painted safety yellow. Where additional caution is required, such as concrete supports at the base of stairways or ladders, passageway pinch points, unguarded edges, tripping hazards, barricades including access road overpass railings in plant areas, and obstructions that present bump hazards, safety yellow-and-black stripes shall be used. The stripes shall be 100 mm wide. Manhole covers and any associated concrete structure that may protrude above grade (for communications manhole covers, see 4.2.4). Radioactive hazards shall be identified by signs in safety yellow and black in accordance with GI-0150.003. "Warning" and "Caution" signs shall have black lettering on safety yellow background. Locations of plant public address systems shall be marked by safety yellow stripes on a safety black background, per SAES-T-481. Unmanned offshore platforms' top coat color shall be safety yellow. This includes the entire platform as practicable including its jacket, structural supports, decks, boat landings, piping, valves, and other equipment above the elevation of the lowest astronomical tide. Manned offshore platforms shall have jackets, spider decks, and boat landings painted solid safety yellow. Piping, decks, and other areas of manned platforms shall be painted with colors typical for onshore facilities.

b)

c)

d)

e)

f)

g)

Page 11 of 17

Document Responsibility: Loss Prevention Issue Date: 30 November, 2003 Next Planned Update: 1 December, 2008

SAES-B-067

Safety Identification and Safety Colors

Exception for f) and g): Electrical and instrumentation equipment are not required to be painted yellow.

h)

Offshore Helidecks shall meet the marking requirements of Drawing AA-036248 and shall otherwise meet the requirements of the Helicopter Chief Pilot, Aviation Department. Lifting equipment and devices such as davits, monorails, and lifting beams (whether permanent or used only for construction) shall be painted safety yellow. In offshore locations where solid yellow is for the entire structure (see f and g above) bump hazards such as swing jibs, cantilever beams, and spreader/lifting devices safety shall be marked by yellow-and-black stripes. For labeling, see 4.4 below. Emergency exit gates through fences.

i)

j) 4.2.4

Safety orange shall be used as the color indicator for the following: a) Inlet and outlet maintenance block valves for pressure relief valves and other automated emergency isolation and depressuring valves shall be painted orange.

Commentary Note: This applies only to the maintenance block valves. The pressure relief valve itself should not be painted orange.

b)

Car-sealed valves of any type shall be painted safety orange.

Exception: Car-sealed valves on firewater pump systems.

Page 12 of 17

Document Responsibility: Loss Prevention Issue Date: 30 November, 2003 Next Planned Update: 1 December, 2008

SAES-B-067

Safety Identification and Safety Colors

c)

Break-away spools that are used to temporarily connect utilities to process systems to process equipment shall be painted safety orange with black stripes. For other requirements, see SAES-L-310. Marine-related life safety devices such as escape capsules and flotation work vests shall be orange in accordance with international convention. Orange paint, orange dye, and orange marker tape shall be used to identify buried concrete communications ducts and manhole covers, per SAES-T-911, and SAES-T-928. Low-temperature valves purchased under 04-SAMSS-003 shall be identified by safety orange stripes, as described by 04-SAMSS-003.

d)

e)

f)

4.2.5

Safety blue shall be used as the color indicator for potable water (sweet water and domestic raw water). Specific requirements: Aboveground potable water piping in plant areas shall be painted blue. Also see 4.1.3.

Exception: This does not apply to piping in plants producing potable water, i.e., Reverse Osmosis (RO) units.

4.3

Piping and valves shall be identified as follows: 4.3.1 A label in English shall be used as the primary and explicit means of identification for the contents of all aboveground piping. A lettered label shall give the name of the contents in full or abbreviated form. Arrows shall be used to indicate direction of flow. Additional details such as temperature or pressure shall be added as necessary to highlight the degree of hazard. Labels shall be applied close to valves or flanges and adjacent to changes in direction, branches, and where pipes pass over or through walls,

4.3.2

Page 13 of 17

Document Responsibility: Loss Prevention Issue Date: 30 November, 2003 Next Planned Update: 1 December, 2008

SAES-B-067

Safety Identification and Safety Colors

floors, fences, or roads, and on straight pipe runs, sufficient for identification. 4.3.3 Emergency isolation and depressuring valves shall be labeled with P&ID or OSPAS valve numbers or such descriptive labeling as needed to permit easy identification. Fire water system sectionalizing block valves shall be identified by their fire water system identification number. The size of the label letters shall not be less than 13 mm, nor greater than 89 mm, varying in size depending on the outside diameter of the pipe. For pipes 52 mm and smaller, use stamped metal tags or signs clamped to the pipe. For piping 52 mm and smaller running between equipment where the total length is less than 15 meters, no labeling is necessary. For piping on pipe racks, labels shall be oriented so as to be visible from grade level as well as from any nearby platform. 4.3.6 Unless otherwise specified herein, the color of the label letters shall be safety black or white, whichever provides the greater contrast to the background color.

4.3.4

4.3.5

4.4

All lifting equipment and devices shall be clearly marked with the rated capacity of the equipment in Arabic and English in metric tons to meet SAES-M-008. All lifting equipment and devices shall be safety yellow to meet 4.2.3. Tankage and equipment shall be identified in Arabic and English as follows: Letters shall be at least 150 mm high. Labels or signs shall be painted at 90 degree intervals around the tanks or equipment at an elevation (line-of-sight and visible from outside the diked area). Letters shall be a size easy to read from normal approach directions and distance. Refer to ANSI Z535.2.

4.5

Page 14 of 17

Document Responsibility: Loss Prevention Issue Date: 30 November, 2003 Next Planned Update: 1 December, 2008

SAES-B-067

Safety Identification and Safety Colors

4.6

For tanks equipped with fixed foam protection, lateral terminals shall be labeled per SAES-B-018.

30 November, 2003

Revision Summary Revised the "Next Planned Update". Reaffirmed the contents of the document, and reissued with minor changes.

Page 15 of 17

Document Responsibility: Loss Prevention Issue Date: 30 November, 2003 Next Planned Update: 1 December, 2008

SAES-B-067

Safety Identification and Safety Colors

GASOLINE (PREMIUM UNLEADED)

Orange base stripe with white band

GASOLINE (SUPER PREMIUM UNLEADED)

Orange base stripe with blue band

LP GAS

Orange base stripe with oxide red

KEROSENE

Oxide red band with green stripe

DIESEL OIL (WHITE)

Oxide Red band with white stripe

DIESEL OIL (BLACK)

Oxide red band with black stripe

FUEL OIL

Black band with yellow stripe

ASPHALT

Black band with green stripe

STABILIZED SWEET CRUDE

Gray band with aluminum stripe

JET A-1

Black band with aluminum stripe

Page 16 of 17

Document Responsibility: Loss Prevention Issue Date: 30 November, 2003 Next Planned Update: 1 December, 2008

SAES-B-067

Safety Identification and Safety Colors

Figure 1 Marking Product Truck Transfer Points (See Table 1)

Page 17 of 17

You might also like

- ARAMCO Material SpecificationDocument21 pagesARAMCO Material Specificationkhorzoo83% (6)

- 0000 - 000saudi Aramco GIDocument12 pages0000 - 000saudi Aramco GIRaheel Ahmed83% (6)

- SAES-Q-010 Cement Based, Non-Shrink GroutDocument8 pagesSAES-Q-010 Cement Based, Non-Shrink GroutWaqar AhmedNo ratings yet

- SAES-B-069 Editorial Revision (10-28-2021)Document11 pagesSAES-B-069 Editorial Revision (10-28-2021)Daniel Meana100% (1)

- Aramco Quick Standard GuideDocument18 pagesAramco Quick Standard GuideJawed Alam89% (19)

- Gi-0006 006Document7 pagesGi-0006 006malika_00No ratings yet

- !indx SaepDocument3 pages!indx SaepHamid Ali JoyiaNo ratings yet

- General Instruction Manual: Organization Consulting DepartmentDocument12 pagesGeneral Instruction Manual: Organization Consulting DepartmentSathi sh94% (16)

- List of SAESDocument8 pagesList of SAESSyed NaseemuddinNo ratings yet

- AE-036411-001 INDEX For Drawing and EquipmentDocument1 pageAE-036411-001 INDEX For Drawing and Equipmentnarutothunderjet216No ratings yet

- Saes B 064Document14 pagesSaes B 064Engr HafeezullahNo ratings yet

- Saes B 055Document33 pagesSaes B 055Tarek Mustafa100% (1)

- Aramco (Standards) Electrical Area ClassificationDocument20 pagesAramco (Standards) Electrical Area ClassificationMudassir Mirza80% (5)

- Aramco Contractor's Pre-Qualification IndexDocument2 pagesAramco Contractor's Pre-Qualification IndexMohammed Afzal AliNo ratings yet

- General Instruction Manual: ScopeDocument14 pagesGeneral Instruction Manual: ScopeJithuRajNo ratings yet

- Aramco Standard ListDocument34 pagesAramco Standard ListAnonymous EarAM2100% (3)

- 00-SAES-D-109 (7 Types Small Tanks at SA)Document23 pages00-SAES-D-109 (7 Types Small Tanks at SA)Manoranjan NayakNo ratings yet

- Aramco GenDocument21 pagesAramco GenHaleem Ur Rashid Bangash0% (1)

- Saep 342Document5 pagesSaep 342munnaNo ratings yet

- Saudi Aramco Engineering Procedures (Index of Active Saeps) June 2006Document5 pagesSaudi Aramco Engineering Procedures (Index of Active Saeps) June 2006Raheleh JavidNo ratings yet

- Saudi Aramco StandardsDocument23 pagesSaudi Aramco Standardsbalaji100% (3)

- Saudi Aramco PresentationDocument20 pagesSaudi Aramco PresentationInsinyur_07760% (5)

- Aramco Standard List (Total)Document188 pagesAramco Standard List (Total)Norman Morales100% (5)

- GI 2.718, Contractor Site Allotment ProcedureDocument12 pagesGI 2.718, Contractor Site Allotment ProcedureSajid Hussain100% (1)

- ARAMCO SAES-M-006, General Purpose Fencing (SecurDocument16 pagesARAMCO SAES-M-006, General Purpose Fencing (Securshuang zhang100% (3)

- Saudi Aramco GI Manual 2.710 PDFDocument33 pagesSaudi Aramco GI Manual 2.710 PDFAbu Ali Abdur Rahman93% (30)

- Additional Requirements for Saudi Aramco ProjectDocument27 pagesAdditional Requirements for Saudi Aramco Projectmunna100% (2)

- Quick Guide To Saudi Aramco Standards and ProceduresDocument18 pagesQuick Guide To Saudi Aramco Standards and ProceduresJeck MaquitedNo ratings yet

- Saudi Aramco General Instruction Manual IndexDocument12 pagesSaudi Aramco General Instruction Manual IndexRiaz ahmed100% (2)

- 04-Samss-035 (11-09-2013)Document18 pages04-Samss-035 (11-09-2013)MubinNo ratings yet

- Saep 14 PDFDocument48 pagesSaep 14 PDFRami Elloumi100% (1)

- Saudi Aramco LOTO GuideDocument8 pagesSaudi Aramco LOTO GuideMusharaf Shah100% (3)

- Aramco Safety Talk QSMDocument1 pageAramco Safety Talk QSMHaleem Ur Rashid BangashNo ratings yet

- List of Active Engineering Standards Documents Due Date (March 31 2012)Document38 pagesList of Active Engineering Standards Documents Due Date (March 31 2012)aneelbaig100% (2)

- General Instruction Manual: Organization Consulting DepartmentDocument12 pagesGeneral Instruction Manual: Organization Consulting DepartmentChaudhary Wasim MurtazaNo ratings yet

- Saes B 053Document4 pagesSaes B 053malika_00No ratings yet

- Starting and Testing Motors GuideDocument61 pagesStarting and Testing Motors Guidesyedsalmanali9193% (15)

- Saes o 201Document15 pagesSaes o 201Abdulrahim ShaikhNo ratings yet

- Saep 303Document60 pagesSaep 303brecht1980100% (2)

- SaudiAramco SupplierGuideDocument21 pagesSaudiAramco SupplierGuidemangeshNo ratings yet

- Design & Constr'n. of Pipeline in Saudi AramcoDocument55 pagesDesign & Constr'n. of Pipeline in Saudi AramcoPageduesca Rouel100% (3)

- Saes A 007Document29 pagesSaes A 007NagarjunNo ratings yet

- Obtaining Waivers for Mandatory Engineering RequirementsDocument8 pagesObtaining Waivers for Mandatory Engineering Requirementsxiongweijun100% (1)

- SAES B 055 Plant LayoutDocument34 pagesSAES B 055 Plant Layoutnavaronefra100% (1)

- Saes B 014Document39 pagesSaes B 014Ahmed100% (2)

- G.I. 298.010 Contractor Camps ProceduresDocument73 pagesG.I. 298.010 Contractor Camps ProceduresYoung Guns82% (56)

- !indx Saes PDFDocument8 pages!indx Saes PDFhafezasadNo ratings yet

- Saep 127Document9 pagesSaep 127brecht1980No ratings yet

- Gi-0155 005Document7 pagesGi-0155 005Srinivas Maddenapelli100% (1)

- Saes B 067 PDFDocument12 pagesSaes B 067 PDFRashid ArshadNo ratings yet

- Saes B 063Document6 pagesSaes B 063hasanmnhNo ratings yet

- 32 Samss 005Document34 pages32 Samss 005ரமேஷ் பாலக்காடுNo ratings yet

- Aramco Safety Color CodesDocument6 pagesAramco Safety Color CodesjerinNo ratings yet

- 100 Yer Pe Yss 0438Document36 pages100 Yer Pe Yss 0438Mohammad Aamir PerwaizNo ratings yet

- Materials System SpecificationDocument8 pagesMaterials System SpecificationGOSP3 QC MechanicalNo ratings yet

- Coating Selection & Application RequirementsDocument93 pagesCoating Selection & Application RequirementsHarish Kumar Kannepalli50% (2)

- East/west Finish CodesDocument14 pagesEast/west Finish CodesEastWest IndustriesNo ratings yet

- 32 Samss 005Document33 pages32 Samss 005naruto256100% (1)

- 32 Samss 005Document33 pages32 Samss 005Selvakpm06No ratings yet

- 09 Samss 069Document10 pages09 Samss 069Selvakpm06No ratings yet

- Continental Fuel Injection Contamnimation SB08-4ADocument4 pagesContinental Fuel Injection Contamnimation SB08-4AAMSNo ratings yet

- Turbo ChargerDocument28 pagesTurbo ChargerCharles ChivengahNo ratings yet

- PA28 D ChecklistDocument3 pagesPA28 D ChecklistWilliam RiosNo ratings yet

- Exposing The Oil and Gas Industry's False Jobs Promise For Shale Gas DevelopmentDocument16 pagesExposing The Oil and Gas Industry's False Jobs Promise For Shale Gas DevelopmentFood and Water WatchNo ratings yet

- UOP 9 Hydrogen Sulphide in Gases by The Tutweiller MethodDocument4 pagesUOP 9 Hydrogen Sulphide in Gases by The Tutweiller MethodmkmejavierNo ratings yet

- Baumann BGXDocument10 pagesBaumann BGXslawny77100% (1)

- Equivalencias de Aceites CATERPILLAR PDFDocument1 pageEquivalencias de Aceites CATERPILLAR PDFMARCO ANTONIO100% (1)

- October 2016: 2010/SR10 2010/SR11 2011/SR3 2011/SR10 2012/SR6 2013/SR1 2013/SR7 2016/SR02 2016/SR04 2016/SR10Document2 pagesOctober 2016: 2010/SR10 2010/SR11 2011/SR3 2011/SR10 2012/SR6 2013/SR1 2013/SR7 2016/SR02 2016/SR04 2016/SR10Arun SNo ratings yet

- Lubrication of Cement PlantDocument5 pagesLubrication of Cement PlantMin Zayar100% (1)

- SK200 Da 2Document15 pagesSK200 Da 2yoga_jpbmbm91% (11)

- 206 DV4TD ENGINE PRESENTATIONDocument17 pages206 DV4TD ENGINE PRESENTATIONCadet Raparivo100% (1)

- Deutz 1011 SpecsDocument6 pagesDeutz 1011 SpecsmusicomineroNo ratings yet

- Our World in 100 Years: Predicting Major Developments in Travel, Population, Energy and MoreDocument2 pagesOur World in 100 Years: Predicting Major Developments in Travel, Population, Energy and MoreEmir ŠemšićNo ratings yet

- Production EngineeringDocument15 pagesProduction EngineeringMuhammad Mujahid100% (1)

- AbstractDocument3 pagesAbstractsreeramyadingariNo ratings yet

- Tebma Shipyard Internship ReportDocument128 pagesTebma Shipyard Internship ReportGuddu Yadav100% (1)

- Gph13m R-22 Tech Manual Rt6332003r11Document73 pagesGph13m R-22 Tech Manual Rt6332003r11mwd1323No ratings yet

- Qualified Welder ListDocument1 pageQualified Welder ListErwin Timbayo SuleNo ratings yet

- 3512 Fire Pump EngineDocument2 pages3512 Fire Pump EngineSuat YamanNo ratings yet

- Gas Cooled ReactorDocument10 pagesGas Cooled ReactorJan Edward L. SuarezNo ratings yet

- M.I.L. "ON" DTC P043E, P043F, P2401, P2402, and P2419: T-SB-0098-09 March 24, 2009Document4 pagesM.I.L. "ON" DTC P043E, P043F, P2401, P2402, and P2419: T-SB-0098-09 March 24, 2009vanhostingwebNo ratings yet

- The Electric Bike Book Turner JimDocument55 pagesThe Electric Bike Book Turner Jimsayantan9650% (2)

- 78 Manual - Weil Mclain BoilerDocument32 pages78 Manual - Weil Mclain Boilerchetmilboi7757No ratings yet

- WECO Hammer Union AlertDocument22 pagesWECO Hammer Union Alertharsha alapatiNo ratings yet

- Proecess Optimization For Production of Liquid Fuels From Waste Plastics - PHD - Thesis - DR - A - K - PandaDocument241 pagesProecess Optimization For Production of Liquid Fuels From Waste Plastics - PHD - Thesis - DR - A - K - Panda3900100% (1)

- KLINGERsil C-4430 Asbestos-Free Gasket MaterialDocument2 pagesKLINGERsil C-4430 Asbestos-Free Gasket MaterialR.Gaspar BaltaNo ratings yet

- Notes - Separation TechniquesDocument5 pagesNotes - Separation TechniquesAdtNo ratings yet

- Abbas - Bilgrami CNG Transportation Trans CanadaDocument48 pagesAbbas - Bilgrami CNG Transportation Trans CanadaMustafa100% (1)

- PRPDocument1 pagePRPMONALINo ratings yet

- PREPARED MS For Piping FabricationDocument9 pagesPREPARED MS For Piping Fabricationvishal bailurNo ratings yet