Professional Documents

Culture Documents

Lay Planning Types

Uploaded by

Gaurav ShakyaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lay Planning Types

Uploaded by

Gaurav ShakyaCopyright:

Available Formats

LESSON 8: LAY PLANNING & TYPES OF LAY PLANS

Objectives: Examine lay planning as a factor impacted by the type of fabric Understand the types of lays and their functional advantage

A lay is a stack of fabric plies that have been prepared for cutting. Lay Planning is the basis of managing cutting room labor and table space. Spreading and cutting schedules are affected by table length, type of equipment, spread length, spreading time, and cutting time. The cutting room manager must minimize throughput time by efficient use of equipment, table space, and personnel. Half Garment Lay: This includes only half of the garment pieces (for example the right side). They are used for folded or tubular fabrics and for fabrics, which are spread face to face Whole Garment Lay: All of the garment pieces, left and right sides are included in the lay. Used for open width fabrics. Single Size Lay: The lay includes all of the pieces for a single size. Restricting the lay to a single size makes order planning and laying up the fabric easier, but the disadvantage is a somewhat higher material consumption, compared to multi-size pays. Multi-size Lays: Sectional lay: The lay is made in at least two distinct rectangular sections. Each section contains all of the parts for a single size. Adjacent sections may be the same or a different size. Interlocking lay: Two or more sections, one after the other, usually different sizes, but the sections are not confined to strict rectangular areas; the pieces for the different sections may merge at the borders. Mixed multi-size lay: In this case there are no distinct sections: the pieces for the two or more different garment sizes are intermingled. This is the arrangement, which normally gives the best material utilization.

You might also like

- SpreadingDocument39 pagesSpreadingPratik MinjNo ratings yet

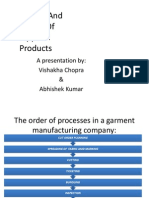

- Spreading and Cutting of Apparel ProductsDocument42 pagesSpreading and Cutting of Apparel ProductsVishakha Chopra86% (7)

- Spreading and Cutting of Apparel ProductsDocument43 pagesSpreading and Cutting of Apparel ProductsDaniela JakimovaNo ratings yet

- Marker MakingDocument12 pagesMarker MakingsachipalNo ratings yet

- Spreading and Cutting of Apparel ProductsDocument77 pagesSpreading and Cutting of Apparel ProductskbalabalaNo ratings yet

- Types of Lay PlansDocument4 pagesTypes of Lay Plansnatarajan1234100% (1)

- L-5 (Marker Making)Document17 pagesL-5 (Marker Making)Kashfmm100% (1)

- Spreading Fabric for CuttingDocument4 pagesSpreading Fabric for CuttingarunkadveNo ratings yet

- Fabric Spreading ProcessDocument8 pagesFabric Spreading ProcessRatul Hasan100% (1)

- Lay PlanningDocument23 pagesLay PlanningArjun Yadav80% (10)

- Methods of SpreadingDocument10 pagesMethods of Spreadingarunkadve67% (3)

- SCAP Session 10 Fabric LossesDocument21 pagesSCAP Session 10 Fabric LossesReena VermaNo ratings yet

- Marker EfficiencyDocument2 pagesMarker EfficiencyGaurav ShakyaNo ratings yet

- Objective of Marker Planning and Marker MakingDocument4 pagesObjective of Marker Planning and Marker MakingSanthosh KannanNo ratings yet

- Fabric Cutting Methods and Techniques in 40 CharactersDocument28 pagesFabric Cutting Methods and Techniques in 40 CharactersNitta Mallik100% (1)

- Spme-2 Final AssignmentDocument30 pagesSpme-2 Final AssignmentIshikaNo ratings yet

- Cutting RoomDocument13 pagesCutting RoomLasitha NawarathnaNo ratings yet

- Cut Order PlanningDocument12 pagesCut Order PlanningShirisha Bala100% (3)

- GMM - Fabric Cutting AssignmentDocument10 pagesGMM - Fabric Cutting AssignmentsatexNo ratings yet

- Fabric Design Lecture 20 Cover FactorDocument2 pagesFabric Design Lecture 20 Cover FactorAtul NaikNo ratings yet

- GP Report QC 1Document50 pagesGP Report QC 1Rohan JetlingNo ratings yet

- Fabric Spreading - Types of Fabric Spreading - Requirements of Spreading ProcessDocument2 pagesFabric Spreading - Types of Fabric Spreading - Requirements of Spreading ProcessSubrata Mahapatra100% (2)

- In-Plant Training Report PresentationDocument60 pagesIn-Plant Training Report Presentationrajhossie9335100% (3)

- Cutting Room Cost ReductionDocument34 pagesCutting Room Cost ReductionKumar AnkurNo ratings yet

- UAQ 2nd Assignment (Pooja Kumari)Document14 pagesUAQ 2nd Assignment (Pooja Kumari)Reena VermaNo ratings yet

- Industrial EngineeringDocument32 pagesIndustrial Engineeringpradeep_vsp1077100% (1)

- Automation in Garment ManufacturingDocument43 pagesAutomation in Garment ManufacturingvagueNo ratings yet

- Cycle Sewing Machines: Simple AutomaticsDocument31 pagesCycle Sewing Machines: Simple AutomaticsPrashant Gaurav75% (4)

- Spreading MachinesDocument23 pagesSpreading MachinesManish SinghNo ratings yet

- Fabric ClassificationDocument7 pagesFabric Classificationshrutiagarwal92290% (1)

- Preparatory Processes (Cutting Part 1) : Learn Apparel Merchandising Learn Fashion DesigningDocument7 pagesPreparatory Processes (Cutting Part 1) : Learn Apparel Merchandising Learn Fashion DesigningZaman ParvezNo ratings yet

- Cutting Room ProjectDocument26 pagesCutting Room ProjectSakshi Yadav100% (1)

- Marker making modes and methodsDocument15 pagesMarker making modes and methodssamchikkuNo ratings yet

- Denim Bottom: Textile Merchadising and Marketing Akmal JavedDocument9 pagesDenim Bottom: Textile Merchadising and Marketing Akmal JavedAkmal JavedNo ratings yet

- SpreadingDocument29 pagesSpreadingyuvarajNo ratings yet

- Fabric CuttingDocument10 pagesFabric CuttingRatul HasanNo ratings yet

- Different Types of Fabric Cutting MachineDocument14 pagesDifferent Types of Fabric Cutting MachineShreyasiSaxena100% (1)

- Apparel Manufacturing TechniqueDocument160 pagesApparel Manufacturing TechniquejemalNo ratings yet

- Fashion Merchandising: Orient Craft Limited, ManesarDocument10 pagesFashion Merchandising: Orient Craft Limited, Manesarjawed_akhtar100% (3)

- Marker EfficiencyDocument8 pagesMarker EfficiencyMeeta Arora100% (1)

- Textiles and Garment Production GuideDocument29 pagesTextiles and Garment Production Guidezeeshan_220No ratings yet

- Productivity Improvement in Apparel Industry .PPT PesentationDocument14 pagesProductivity Improvement in Apparel Industry .PPT Pesentationsudincr100% (3)

- Cutting and Spreading Fabric EfficientlyDocument7 pagesCutting and Spreading Fabric EfficientlyAlemu HaileNo ratings yet

- Sewing Machine Beds: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKDocument9 pagesSewing Machine Beds: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKP. Lakshmanakanth100% (1)

- Knitwear Technology (Cutting & Sewing) - APM 7402 - Note Book-1Document25 pagesKnitwear Technology (Cutting & Sewing) - APM 7402 - Note Book-1shahinrezaNo ratings yet

- Costing of Apparel ProductsDocument30 pagesCosting of Apparel ProductsSugandha Rathore100% (2)

- Buttonhole MachinesDocument12 pagesButtonhole Machinesskknitman100% (1)

- Costing and thread consumption of casual shirtDocument6 pagesCosting and thread consumption of casual shirtAmar Nath PrasadNo ratings yet

- Cutting MarkerDocument66 pagesCutting MarkerTanushree RoyNo ratings yet

- Catalogue of Visual Textile Defects Aasim AhmedDocument20 pagesCatalogue of Visual Textile Defects Aasim AhmedAdi TtaNo ratings yet

- Spreading in Cutting RoomDocument11 pagesSpreading in Cutting RoomZain AlviNo ratings yet

- Spreading and Cutting MachinaryDocument21 pagesSpreading and Cutting Machinarypsyish100% (1)

- SCAP Session 9 Cut Order PlanDocument30 pagesSCAP Session 9 Cut Order PlanReena VermaNo ratings yet

- Plant Layout - IDocument16 pagesPlant Layout - ITanya rajNo ratings yet

- Anti Treatment Knits PrintDocument22 pagesAnti Treatment Knits Printn.tNo ratings yet

- Seam Classes: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKDocument12 pagesSeam Classes: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKP. Lakshmanakanth100% (2)

- Carr and Latham's Technology of Clothing ManufactureFrom EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerRating: 4 out of 5 stars4/5 (1)

- Lay-Up FabricDocument5 pagesLay-Up Fabrictom100% (1)

- The World of The AftermathDocument63 pagesThe World of The AftermathGaurav Shakya100% (1)

- Management Vs Leadership - Linked 2 LeadershipDocument119 pagesManagement Vs Leadership - Linked 2 LeadershipTom Schulte100% (20)

- Making Things Better Competing in ManufacturingDocument243 pagesMaking Things Better Competing in ManufacturingGaurav ShakyaNo ratings yet

- Loading BundlingDocument1 pageLoading BundlingGaurav ShakyaNo ratings yet

- Method Time Study1Document2 pagesMethod Time Study1Gaurav ShakyaNo ratings yet

- India Strategic Overview by Shabbir GhadialiDocument46 pagesIndia Strategic Overview by Shabbir GhadialiKushal KhemkaNo ratings yet

- Method Time StudyDocument1 pageMethod Time StudyGaurav ShakyaNo ratings yet

- Marker EfficiencyDocument2 pagesMarker EfficiencyGaurav ShakyaNo ratings yet

- Marker PlanningDocument2 pagesMarker PlanningGaurav Shakya100% (2)

- Lay Planning TypesDocument1 pageLay Planning TypesGaurav Shakya100% (1)

- Marker PlanningDocument2 pagesMarker PlanningGaurav Shakya100% (2)

- Materials HandlingDocument1 pageMaterials HandlingGaurav ShakyaNo ratings yet

- Development and The Changing Dynamics of Global Production Global Value Chains and Local Clusters in Apparel ManufacturingDocument27 pagesDevelopment and The Changing Dynamics of Global Production Global Value Chains and Local Clusters in Apparel ManufacturingGaurav ShakyaNo ratings yet

- Lock Stitch MachineDocument4 pagesLock Stitch MachineGaurav ShakyaNo ratings yet

- Marker ModesDocument2 pagesMarker ModesGaurav Shakya100% (1)

- Analysis of Luxury Goods and Apparel and Footwear IndustriesDocument23 pagesAnalysis of Luxury Goods and Apparel and Footwear IndustriesDr. Firoze KhanNo ratings yet

- Marker EfficiencyDocument2 pagesMarker EfficiencyGaurav ShakyaNo ratings yet

- Lock Stitch MachineDocument4 pagesLock Stitch MachineGaurav ShakyaNo ratings yet

- Apparel Considerations For Clean ManufacturingDocument2 pagesApparel Considerations For Clean ManufacturingGaurav ShakyaNo ratings yet

- Line Balancing in The Real World: Emanuel FalkenauerDocument10 pagesLine Balancing in The Real World: Emanuel FalkenauerhonnohoaNo ratings yet

- Developing Female Size Charts For Facilitating Garment ProductionDocument7 pagesDeveloping Female Size Charts For Facilitating Garment ProductionGaurav ShakyaNo ratings yet

- BhelDocument24 pagesBhelsheetaltandonNo ratings yet

- For Coin & Blood (2nd Edition) - SicknessDocument16 pagesFor Coin & Blood (2nd Edition) - SicknessMyriam Poveda50% (2)

- May, 2013Document10 pagesMay, 2013Jakob Maier100% (1)

- Reflection Paper #1 - Introduction To Action ResearchDocument1 pageReflection Paper #1 - Introduction To Action Researchronan.villagonzaloNo ratings yet

- Overview of Quality Gurus Deming, Juran, Crosby, Imai, Feigenbaum & Their ContributionsDocument11 pagesOverview of Quality Gurus Deming, Juran, Crosby, Imai, Feigenbaum & Their ContributionsVenkatesh RadhakrishnanNo ratings yet

- Timely characters and creatorsDocument4 pagesTimely characters and creatorsnschober3No ratings yet

- Test Bank For Core Concepts of Accounting Information Systems 14th by SimkinDocument36 pagesTest Bank For Core Concepts of Accounting Information Systems 14th by Simkinpufffalcated25x9ld100% (46)

- EnerSys Global Leader in Industrial BatteriesDocument32 pagesEnerSys Global Leader in Industrial BatteriesAshredNo ratings yet

- Failure Analysis Case Study PDFDocument2 pagesFailure Analysis Case Study PDFScott50% (2)

- Reservoir Rock TypingDocument56 pagesReservoir Rock TypingAffan HasanNo ratings yet

- Standard Deviation IntroductionDocument3 pagesStandard Deviation IntroductionShyam ShresthaNo ratings yet

- Tygon S3 E-3603: The Only Choice For Phthalate-Free Flexible TubingDocument4 pagesTygon S3 E-3603: The Only Choice For Phthalate-Free Flexible TubingAluizioNo ratings yet

- Chapter 1: The Critical Role of Classroom Management DescriptionDocument2 pagesChapter 1: The Critical Role of Classroom Management DescriptionJoyce Ann May BautistaNo ratings yet

- The Teacher and The Community School Culture and Organizational LeadershipDocument10 pagesThe Teacher and The Community School Culture and Organizational LeadershipChefandrew FranciaNo ratings yet

- Identifying The TopicDocument2 pagesIdentifying The TopicrioNo ratings yet

- Recycle Used Motor Oil With Tongrui PurifiersDocument12 pagesRecycle Used Motor Oil With Tongrui PurifiersRégis Ongollo100% (1)

- 2007 Bomet District Paper 2Document16 pages2007 Bomet District Paper 2Ednah WambuiNo ratings yet

- NetsimDocument18 pagesNetsimArpitha HsNo ratings yet

- Quiz-Travel - Beginner (A1)Document4 pagesQuiz-Travel - Beginner (A1)Carlos Alberto Rodriguez LazoNo ratings yet

- Active and Passive Voice of Future Continuous Tense - Passive Voice Tips-1Document5 pagesActive and Passive Voice of Future Continuous Tense - Passive Voice Tips-1Kamal deep singh SinghNo ratings yet

- S2 Retake Practice Exam PDFDocument3 pagesS2 Retake Practice Exam PDFWinnie MeiNo ratings yet

- ĐỀ SỐ 3Document5 pagesĐỀ SỐ 3Thanhh TrúcNo ratings yet

- Modified Release Drug ProductsDocument58 pagesModified Release Drug Productsmailtorubal2573100% (2)

- Transformer Oil Testing MethodsDocument10 pagesTransformer Oil Testing MethodsDEE TOTLVJANo ratings yet

- Obiafatimajane Chapter 3 Lesson 7Document17 pagesObiafatimajane Chapter 3 Lesson 7Ayela Kim PiliNo ratings yet

- Exor EPF-1032 DatasheetDocument2 pagesExor EPF-1032 DatasheetElectromateNo ratings yet

- Programming Manual Magic 308/616-CLI Quick ReferenceDocument16 pagesProgramming Manual Magic 308/616-CLI Quick ReferencekrishnamarajublrNo ratings yet

- Periodic ClassificationDocument4 pagesPeriodic ClassificationtusharNo ratings yet

- Urodynamics Griffiths ICS 2014Document198 pagesUrodynamics Griffiths ICS 2014nadalNo ratings yet

- Board 2Document1 pageBoard 2kristine_nilsen_2No ratings yet

- Ramdump Memshare GPS 2019-04-01 09-39-17 PropsDocument11 pagesRamdump Memshare GPS 2019-04-01 09-39-17 PropsArdillaNo ratings yet