Professional Documents

Culture Documents

Sang Hyun Park - Acceleration of Azidation by Microwave Irradiation

Uploaded by

RoundSTICOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sang Hyun Park - Acceleration of Azidation by Microwave Irradiation

Uploaded by

RoundSTICCopyright:

Available Formats

Notes

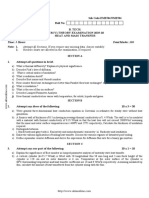

Bull. Korean Chem. Soc. 2003, Vol. 24, No. 2

253

Acceleration of Azidation by Microwave Irradiation

Sang Hyun Park Division of Isotope Application, Korea Atomic Energy Research Institute, 150 Deokjin-dong, Yuseong-gu, Daejeon 305-353, Korea Received June 27, 2002 Key Words : Microwave assisted reaction, Acceleration of azidation, Microwave assisted azidation, Synthesis of alkyl azides

Azides are versatile intermediates in organic synthesis, since they can be used for the preparation of a variety of amines or amino compounds that show interesting biological activities.1-5 As simpler, milder and more efficient methods for the reduction of azides to amines have been developed,5,6 azides have recently been drawing much attention in synthetic organic chemistry. In the context of our recent studies, it has also been shown that -amino acids can be prepared from indium-mediated reduction of the corresponding azides that are transformed chemically from microbial polymer polyhydroxyalkanoates (PHAs).7 In connection with our ongoing research project for the synthesis of biologically active modified peptides containing -amino acids,8 we require a simple and fast preparation of azides which can serve for reductive process resulting in amines or amino compounds. We describe use of microwave to promote a reaction of tosylates with azide ion. Many reactions have been accelerated by the use of microwave,9 but application to azide introduction represents a particular useful transformation. Although considered a good nucleophile, azides often react very slowly with many halides and other alkylating agents. Such reactions cannot usually be heated since the product azides frequently decompose or have the hazardous nature in general.1 Thus the microwave assisted process will be of interest to many chemists who work with azides. In this paper, we report a novel, simple and efficient method for the preparation of azides using a microwave technique9 which has been employed to reduce pollution at the source and to increase atom economy.10 Synthesis of optically active ethyl 3-azidobutyrates. Ethyl (S)-(+)-3-azidobutyrate (1) and ethyl (R)-()-3-azidobutyrate (2) were prepared by stirring of the corresponding tosylates with sodium azide at room temperature for 12 h (Scheme 1).7 It should be noted that no conventional heating under reflux was employed in order to effect this reaction with the desired configuration at the chiral center. Transposition of this procedure to a domestic microwave oven led to a huge reduction of the reaction time (5 min) in similar yield with desired configurations (Table 1). The very rapid rise of temperature of reactants via microwave irradiation favors some reaction pathways over others and thus leads to

*

Scheme 1 Table 1. Results on the preparation of optically active ethyl 3azidobutyrates (1 and 2)

Product 1 2

a

Conventional method Time 12 h 12 h Yield 76% 78% []Da +41 -35o

o

Microwave irradiation Time 5 min 5 min Yield 78% 82% []Da +42o -35o

(c 1, CHCl3).

selectivity and hence cleaner products.9d Synthesis of alkyl azides. Cyclohexyl azide (3) was prepared by the heating of the corresponding tosylate with sodium azide in N,N-dimethylformamide (DMF) at 90 oC for 12 h (Scheme 2).7 Transposition of this procedure to a domestic microwave oven led to a huge reduction of the reaction time (3 min) in a similar yield (91%) (Table 2). A simple conical flask with a loose cover was used as a reaction vessel, and no stirrer was used since the reactants

Scheme 2 Table 2. Results on the preparation of alkyl azides 3 and 4

Product 3 4 Conventional heating Time

a

Microwave irradiation Timea Temp.b 5 min 90 oC 5 min 90 oC Yield 92% 94%

Temp.

Yield 91% 92%

12 h 90 oC 12 h 90 oC

Corresponding author: Phone: +82-42-868-8514; Fax: +82-42868-8448; e-mail: parksh@kaeri.re.kr

a The progress of reaction was monitored by the thin layer chromatography every minute. bThe approximate temperature of the reaction mixture was determined by using a thermometer immediately after the microwave irradiation was stopped, and the temperature of the reaction mixture was controlled by a beaker of water as a heat sink.9d

254

Bull. Korean Chem. Soc. 2003, Vol. 24, No. 2

Notes

Scheme 3

are energized directly due to the characteristic heating properties of microwave. Since DMF has a reasonably high boiling point (153 oC) and a substantial dipole resulting in absorption of microwave, it was used as the reaction medium as in conventional heating. Octyl azide (4) was also prepared in DMF by both conventional heating and microwave irradiation (Scheme 3), and the results are summarized in Table 2. In summary, we have developed a novel, simple and efficient method for the small- scale preparation of azides for laboratory use in which tosylates were treated with sodium azide in water or DMF under microwave irradiation to afford the corresponding azides 1-4 in quantitative yields. The results obtained with azides demonstrated the generality of the reaction. This methodology is expected to be applicable to the simple and efficient preparation of amines or amino compounds from the corresponding alcohols or hydroxy compounds via rapid microwave assisted synthesis of azides. Currently, we are in the process of using this method for the preparation of -amino acids from diverse members of microbial polyester PHAs11 as a chiral pool, the results of which will be reported in due course. Experimental Section Flash column chromatography was performed on silica gel 60 (230-400 mesh, Merck) and all chromatographic separations were monitored by TLC analyses, performed using glass plates precoated with 0.25-mm, 230-400 mesh silica gel impregnated with a fluorescent indicator (254 nm). Optical rotations were measured on a JASCO DIP-181 Digital Polarimeter. IR spectra were recorded on a Bomen MB154 FTIR (KBr pellets or neat). 1H NMR and 13C NMR were recorded on a Bruker 500-MHz FTNMR spectrometer in CDCl3, DMSO-d6, or D2O solution, and chemical shifts were recorded in ppm units using SiMe4 as an internal standard. Mass spectra were measured on a Varian MAT 371 Mass Spectrometer at 70 eV. Preparation of Ethyl (S)-(+)-3-azidobutyrate (1). Conventional method7: Reaction mixture of tosylate (854 mg, 2.98 mmol), hexadecyltributylphosphonium bromide (150 mg, 0.30 mmol) and sodium azide (387 mg, 5.96 mmol) in water (2.5 mL) was vigorously stirred at room temperature. After 12 h, ether (20 mL) was added and the organic layer was collected and dried over sodium sulfate. Evaporation under reduced pressure gave 355 mg (76%) of the title compound as a light-yellow oil: []D +41o (c 1, CHCl3); IR (neat) 2982, 2936, 2122, 1742, 1377, 1295, 1254, 1185, 1028 cm1; 1H NMR (CDCl3) 1.27 (q, J = 7.0 Hz, 3H, OCH2CH3), 1.34 (d, J = 6.5 Hz, 3H, CH3CH(N3)), 3.95-4.04 (m, 1H, CHN3), 4.18 (q, J = 7.0 Hz, 2H, OCH2); 13 C NMR (CDCl3) 14.17, 19.51, 41.17, 54.34, 60.87,

170.56; CIMS, m/z 157 (M+), 155, 149, 131, 115, 91 (base), 88, 84, 73, 70, 69, 60, 57, 56, 55, 49. Microwave method: Reaction mixture of tosylate (854 mg, 2.98 mmol), hexadecyltributylphosphonium bromide (150 mg, 0.298 mmol) and sodium azide (387 mg, 5.96 mmol) in water (5 mL) was irradiated in a domestic microwave oven at an output of 1000 watts for 5 min. The progress of azidation was monitored by TLC analysis every minute. Water (100 mL) was placed in another vessel and irradiated simultaneously. After cooling to room temperature, ether (20 mL) was added and the organic layer was collected and dried over sodium sulfate. Evaporation under reduced pressure gave 365 mg (78%) of the title compound as a light-yellow oil: []D +42o (c 1, CHCl3); IR (neat) 2982, 2936, 2122, 1745, 1377, 1295, 1254, 1185, 1028 cm1; 1H NMR (CDCl3) 1.27 (q, J = 7.0 Hz, 3H, OCH2CH3), 1,34 (d, J = 6.5 Hz, 3H, CH3CH(N3)), 3.95-4.04 (m, 1H, CHN3), 4.18 (q, J = 7.0 Hz, 2H, OCH2); 13C NMR (CDCl3) 14.2, 19.5, 41.2, 54.3, 60.9, 170.6; CIMS, m/z 157 (M+), 155, 149, 131, 115, 91 (base), 88, 84, 73, 70, 69, 60, 57, 56, 55, 49. Preparation of Ethyl (R)-(-)-3-azidobutyrate (2) Same as 1 except for the opposite sign of the specific rotation: []D -35 o (c 1, CHCl3). Preparation of Cyclohexyl azide (3). Conventional method7: Reaction mixture of tosylate (765 mg, 3.00 mmol) and sodium azide (390 mg, 6.00 mmol) in DMF (5.0 mL) was heated at 90 oC for 12 h. After cooling to room temperature, ether (20 mL) was added and the organic layer was washed with water, collected and dried over sodium sulfate. Evaporation under reduced pressure and flash column chromatography gave 341 mg (91%) of the title compound as a light-yellow oil. Microwave method: Reaction mixture of tosylate (765 mg, 3.00 mmol) and sodium azide (390 mg, 6.00 mmol) in DMF (5.0 mL) was irradiated in a domestic microwave oven at an output of 1000 watts for 5 min. The progress of azidation was monitored by TLC analysis every minute. Water (100 mL) was placed in another vessel and irradiated simultaneously. After cooling to room temperature, ether (20 mL) was added and the organic layer was collected, washed with water and dried over sodium sulfate. Evaporation under reduced pressure and flash column chromatography gave 345 mg (92%) of the title compound as a light-yellow oil: IR (neat) 3116, 2306, 2097 cm1; 1H NMR (500 MHz, CDCl3) 1.15-1.45 (m, 5H), 1.60-1.65 (m, 1H), 1.70-1.82 (m, 2H), 1.85-1.95 (m, 2H), 3.34 (m, 1H, N3CH); 13C NMR (500 MHz, CDCl3) 24.3, 25.3, 31.6, 59.9; CIMS, m/z 125 (M+), 68, 55, 49 (base), 54, 40, 26. Preparation of Octyl azide (4): IR (nujol) 2955, 2900, 2845, 2310, 2090, 1465, 1375 cm1; 1H NMR (CDCl3) 0.93 (t, J = 7.1 Hz, 3H, CH3), 1.12-1.82 (m, 12H), 3.49 (t, J = 6.5 Hz, 2H, CH2N3); 13C NMR (CDCl3) 28.6, 29.9, 31.2, 51.2; CIMS, m/e 155 (M+), 113, 85, 71, 57, 43 (base), 41, 29. Acknowledgement. This work was supported by the Korea Ministry of Science and Technology.

Notes

Bull. Korean Chem. Soc. 2003, Vol. 24, No. 2

255

References

1. Sheradsky, T. In Chemistry of the Azido Group; Patai, S., Ed.; Inter Science: New York, 1971; p 331. 2. Kabalka, G. W.; Li, G. Tetrahedron Lett. 1997, 38, 5777. 3. Kamal, A.; Arifuddin, M.; Rao, M. V. Tetrahedron Asymmetry 1999, 10, 4261. 4. Schildknegt, K.; Agrios, K. A.; Jeffrey, A. Tetrahedron Lett. 1998, 39, 7687. 5. Butcher, J. W.; Liverton, N. J.; Selnick, H. G.; Elliot, J. M.; Smith, G. R.; Tebben, A. J.; Pribush, D. A.; Wai, J. S.; Claremon, D. A. Tetrahedron Lett. 1996, 37, 6685. 6. Reddy, G. V.; Rao, G. V.; Iyengar, D. S. Tetrahedron Lett. 1999, 40, 3937.

7. Park, S. H.; Lee, S. H.; Lee, S. Y. J. Chem. Research (S) 2001, 2001, 498. 8. Gademann, K.; Ernst, M.; Hoyer, D.; Seebach, D. Helv. Chim. Acta 2000, 83, 16. 9. For recent overviews on microwave assisted chemistry, see: (a) Varma, R. S. Green Chem. 1999, 1, 43. (b) Bose, A. K.; Banik, B. K.; Lavlinskaia, N.; Jayaraman, M.; Manhas, M. S. Chemtech. 1997, 27, 18. (c) Majetich, G.; Hicks, R. J. Microwave Power Electomagn. Energy 1995, 30, 27. (d) Manhas, M. S.; Banik, B. K.; Mathur, A.; Vincent, J. E.; Bose, A. K. Tetrahedron 2000, 56, 5587. (e) Bose, A. K.; Banik, B. K.; Mathur, C.; Wagle, D. R.; Manhas, M. S. Tetrahedron 2000, 56, 5603. 10. Trost, B. M. Science 1991, 254, 1471. 11. Lee, S. Y. Biotechnol. Bioeng. 1996, 49, 1.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- (1908) Mack's Barbers' Guide: A Practical Hand-BookDocument124 pages(1908) Mack's Barbers' Guide: A Practical Hand-BookHerbert Hillary Booker 2nd100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Amphetamine StimulantsDocument141 pagesAmphetamine StimulantsMichael Lawton JenkinsNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- God Reborn - The Birth of God and The Creation of The UniverseDocument204 pagesGod Reborn - The Birth of God and The Creation of The UniverseTony Bermanseder100% (1)

- Python Versus Matlab: Examples in Civil EngineeringDocument32 pagesPython Versus Matlab: Examples in Civil EngineeringNiranjanAryan100% (1)

- EL2 - Raise Organic Small RuminantsDocument62 pagesEL2 - Raise Organic Small RuminantsButch Demayo100% (1)

- Accuracy of Transferring Analog Dental Casts To A Virtual ArticulatorDocument9 pagesAccuracy of Transferring Analog Dental Casts To A Virtual ArticulatorNetra TaleleNo ratings yet

- Intercostal Drainage and Its ManagementDocument36 pagesIntercostal Drainage and Its ManagementAnusha Verghese67% (3)

- 3250-008 Foundations of Data Science Course Outline - Spring 2018Document6 pages3250-008 Foundations of Data Science Course Outline - Spring 2018vaneetNo ratings yet

- Computer Forensics ReportDocument7 pagesComputer Forensics ReportMatias IacobuzioNo ratings yet

- 5G, 4G, Vonr Crash Course Complete Log AnaylsisDocument11 pages5G, 4G, Vonr Crash Course Complete Log AnaylsisJavier GonzalesNo ratings yet

- Eric Parquet and Qun Lin - Microwave-Assisted Wolff-Kishner Reduction ReactionDocument1 pageEric Parquet and Qun Lin - Microwave-Assisted Wolff-Kishner Reduction ReactionRoundSTICNo ratings yet

- S.D. Burke and R.L. Danheiser - Handbook of Reagents For Organic Synthesis: Oxidizing and Reducing AgentsDocument6 pagesS.D. Burke and R.L. Danheiser - Handbook of Reagents For Organic Synthesis: Oxidizing and Reducing AgentsRoundSTICNo ratings yet

- R. Jason Herr - A Whirlwind Tour of Current Mitsunobu ChemistryDocument36 pagesR. Jason Herr - A Whirlwind Tour of Current Mitsunobu ChemistryRoundSTICNo ratings yet

- DuPont - Recovery of Tetrahydrofuran (THF)Document12 pagesDuPont - Recovery of Tetrahydrofuran (THF)RoundSTICNo ratings yet

- Buchi Training Papers - Distillation With A Rotary EvaporatorDocument16 pagesBuchi Training Papers - Distillation With A Rotary EvaporatorRoundSTICNo ratings yet

- Sally Solomon Et Al - Using Ice-Cooled Condensers in Chemistry LaboratoryDocument3 pagesSally Solomon Et Al - Using Ice-Cooled Condensers in Chemistry LaboratoryRoundSTICNo ratings yet

- Ángel M. Montaña and Pedro M. Grima - Effective Cooling System in Bulb-to-Bulb DistillationDocument1 pageÁngel M. Montaña and Pedro M. Grima - Effective Cooling System in Bulb-to-Bulb DistillationRoundSTICNo ratings yet

- Lloyd N. Ferguson - The Synthesis of Aromatic AldehydesDocument28 pagesLloyd N. Ferguson - The Synthesis of Aromatic AldehydesRoundSTICNo ratings yet

- Chemical Behaviour of Red Phosphorus in WaterDocument16 pagesChemical Behaviour of Red Phosphorus in WaterRoundSTICNo ratings yet

- James Grimshaw and Cheng Hua - The Conversion of Isosafrole To Piperonal and Anethole To Anisaldehyde: Electrochemical Active Manganese OxideDocument3 pagesJames Grimshaw and Cheng Hua - The Conversion of Isosafrole To Piperonal and Anethole To Anisaldehyde: Electrochemical Active Manganese OxideRoundSTICNo ratings yet

- David J. Dale Et Al - The Chemical Development of The Commercial Route To Sildenafil: A Case HistoryDocument6 pagesDavid J. Dale Et Al - The Chemical Development of The Commercial Route To Sildenafil: A Case HistoryRoundSTICNo ratings yet

- Paper 19 AugustDocument552 pagesPaper 19 AugustUma Sankar Pradhan100% (1)

- Removal of Chloride in The Kraft Chemical Recovery CycleDocument8 pagesRemoval of Chloride in The Kraft Chemical Recovery CycleVeldaa AmiraaNo ratings yet

- Five Star Env Audit Specification Amp Pre Audit ChecklistDocument20 pagesFive Star Env Audit Specification Amp Pre Audit ChecklistMazhar ShaikhNo ratings yet

- The Necessary Art of PersuasionDocument14 pagesThe Necessary Art of PersuasionAnugragha SundarNo ratings yet

- Salik Sa Mga Estudyante NG Hindi Wastong Pagsuot NG Uniporme NG Senior High School Sa Paaralang Ama Computer College Fairview CampusDocument1 pageSalik Sa Mga Estudyante NG Hindi Wastong Pagsuot NG Uniporme NG Senior High School Sa Paaralang Ama Computer College Fairview CampusIsrael ManansalaNo ratings yet

- A3 Report Template Checklist - SafetyCultureDocument4 pagesA3 Report Template Checklist - SafetyCulturewarriorninNo ratings yet

- North Rig 4Document1 pageNorth Rig 4avefenix666No ratings yet

- Tadano450xl PDFDocument12 pagesTadano450xl PDFmunawar0% (1)

- Industrial Marketing Module 2Document32 pagesIndustrial Marketing Module 2Raj Prixit RathoreNo ratings yet

- 6 1 Maxima and MinimaDocument10 pages6 1 Maxima and MinimaSebastian GarciaNo ratings yet

- Parker (T6, T6D) Hydraulic Vane PumpsDocument12 pagesParker (T6, T6D) Hydraulic Vane PumpsMortumDamaNo ratings yet

- Btech Me 5 Sem Heat and Mass Transfer Eme504 2020Document2 pagesBtech Me 5 Sem Heat and Mass Transfer Eme504 2020SuryaNo ratings yet

- Class XI-Writing-Job ApplicationDocument13 pagesClass XI-Writing-Job Applicationisnprincipal2020No ratings yet

- A Review of Automatic License Plate Recognition System in Mobile-Based PlatformDocument6 pagesA Review of Automatic License Plate Recognition System in Mobile-Based PlatformadiaNo ratings yet

- Think Feel DoDocument3 pagesThink Feel DoHardik MehtaNo ratings yet

- Syllabus (2020) : NTA UGC-NET Computer Science and ApplicationsDocument24 pagesSyllabus (2020) : NTA UGC-NET Computer Science and ApplicationsDiksha NagpalNo ratings yet

- Design and Fabrication of Light Electric VehicleDocument14 pagesDesign and Fabrication of Light Electric VehicleAshish NegiNo ratings yet

- April FoolDocument179 pagesApril FoolrogeraccuraNo ratings yet

- ADP ObservationDocument15 pagesADP ObservationSanjay SNo ratings yet

- Solution Manual For Understanding Business 12th Edition William Nickels James Mchugh Susan MchughDocument36 pagesSolution Manual For Understanding Business 12th Edition William Nickels James Mchugh Susan Mchughquoterfurnace.1ots6r100% (51)

- 1 Raven's™ Standard Progressive Matrices Plus (SPM Plus) - PSI OnlineDocument1 page1 Raven's™ Standard Progressive Matrices Plus (SPM Plus) - PSI OnlineVINEET GAIROLANo ratings yet