Professional Documents

Culture Documents

TA126

Uploaded by

Yamin MohdOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TA126

Uploaded by

Yamin MohdCopyright:

Available Formats

Thermal Analysis & Rheology

Thermal Analysis Application Brief

Summary

Epoxy - glass prepregs are widely used in the electronic and aerospace industries in the fabrication of laminate products ranging from printed circuit boards to helicopter rotors. The properties of these products are a function of resin formula, resin/substrate ratios, degree of cure and processing conditions. One of the most important factors affecting the processing of prepreg materials is gel time. Gel time is the time from when the material begins to soften until gelation occurs, where gelation is the irreversible transformation from a viscous liquid to an "elastic gel" (1). Thermomechanical Analysis (TMA), specifically parallel plate rheometry mode, provides a rapid, sensitive, reproducible means for monitoring gel time.

Gelation of Epoxy - Glass Prepreg by Parallel Plate Rheometry

Number TA-126 arrangement is subsequently placed on the TMA quartz stage and a macroexpansion probe brought in contact with the top plate. As the sample flows due to applied force, or more typically increased temperature (or time at an isothermal temperature), probe displacement is measured. Although not used here because gel time is the parameter of interest, an equation is available which converts dimensional change into viscosity values. (2) Conditions in the TMA (e.g. atmosphere, temperature, heating rate) can be varied to simulate actual process conditions. In this study, a circular wafer of appropriate size and thickness (the PPR accommodates samples 9.5mm in diameter and 0.25 - 1.00mm thick) was punched from a glass-epoxy prepreg sheet. After mounting in the TMA with 10 gram load on the probe, the sample was heated at 10oC/minute from ambient to 150oC under a 100 ml/minute nitrogen purge.

Introduction

Gel time is a critical processing time, since after the gel point the material is no longer able to flow and is therefore unprocessable. Traditional methods for the measurement of gel time are of questionable reliability because they tend to be very operator dependent. For example, in the electronics (printed circuit board) industry, a prepreg is evaluated by grinding it to a fine powder, passing the powder through a sieve to remove the glass reinforcement particles, placing the filtered resin powder on a preheated plate, and then stirring with a glass rod until the resin adheres to the stirring rod. The time from initial softening until adhesion occurs as monitored by a stop watch is considered to be the gel time. Thermomechanical Analysis (TMA), which is a thermal analysis technique that measures material dimensional changes with temperature, provides a convenient and more reproducible, scientific approach to gel time measurement. Using a specific TMA probe configuration (parallel plate rheometer), TMA measured dimensional changes can be converted to gel time and viscosity values.

Results

Figure 2 demonstrates the dimensional change occurring as a result of the gelation process. The curve shows that as the prepreg is heated from room temperature, a slight expansion occurs. After approximately six minutes, the curve starts to drop, indicating softening of the resin. This continues until approximately eight minutes when the curve begins to flatten due to the cross-linking process of gelation. The gel time of the prepreg is observed as the difference between time to the onset of gelation minus the time to the onset of softening (Figure 3). The total displacement during cure, 147.26 m, in conjunction with a knowledge of the initial sample thickness, can be used to calculate the percent displacement during flow. Such data is useful for optimization of resin bleed versus void formation during laminate processing, as in a "scaled flow" test. Additional information on resin performance can be gained by studying the derivative curve, or the rate of dimension change. The height of the derivative curve will vary in intensity with flow of the resin. The peak temperature, equivalent to the inflection temperature shown in Figure 4, represents the point of maximum flow rate. A close study of these parameters will thus yield further valuable information on the characteristics of prepreg, and lead to a more accurate definition of the analysis limits for the calculation of gel time.

Experimental

Figure 1 shows the parallel plate rheometer configuration for TMA. The sample in disk form is placed between two stainless steel plates to form a "sandwich-type" arrangement which is kept together by a coaxial alignment cage. This whole

PARALLEL PLATE HELOMETER

] Dimension Change (m)

EPOXY - GLASS PREPREG

80 40 0 -40 -80 -120 -160

[ GELATION PROCESS SOFTENING PROCESS

160 140 120 100 80 60 40 20 0.0 2.0 4.0 6.0 8.0 10.0 12.0 14.0 Time (min) 16.0 18.0 20.0 22.0

o [----------] Temperature ( C)

Upper Cylinder

Sample Pellet (or Film)

Lower Cylinder

Coaxial Alignment Cage

-200

Figure 1

Figure 2

EPOXY - GLASS PREPREG (GEL TIME & FLOW)

80

GEL TIME 102 SECONDS ] Dimension Change (m)

] Dimension Change ( m)

EPOXY - GLASS PREPREG (DERIVATIVE CURVE)

80 40 0 -40 -80 -120 -160

[

72.9o C

120 100 80 60 40 20 0 -20 0.0 2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0 22.0 Time (min)

[----------] Derivative (m/min)

40

67.6C

0 -40 -80 -120 -160

83.8C 72.9C 147.26m

-200

-200 0.0 2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0 22.0 Time (min)

Figure 4

Figure 3

References

1. E. A. Turi, Thermal Characterization of Polymeric Materials, Academic Press, 1981, Orlando, FL 2. TA Instruments TMA 2940 Operators Manual.

For more information or to place an order, contact:

TA Instruments, Inc., 109 Lukens Drive, New Castle, DE 19720, Telephone: (302) 427-4000, Fax: (302) 427-4001 TA Instruments S.A.R.L., Paris, France, Telephone: 33-1-30489460, Fax: 33-1-30489451 TA Instruments N.V./S.A., Gent, Belgium, Telephone: 32-9-220-79-89, Fax: 32-9-220-83-21 TA Instruments GmbH, Alzenau, Germany, Telephone: 49-6023-30044, Fax: 49-6023-30823 TA Instruments, Ltd., Leatherhead, England, Telephone: 44-1-372-360363, Fax: 44-1-372-360135 TA Instruments Japan K.K., Tokyo, Japan, Telephone: 813-5434-2771, Fax: 813-5434-2770

TA-126A

Thermal Analysis & Rheology

A SUBSIDIARY OF WATERS CORPORATION

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- French Revolution ChoiceDocument3 pagesFrench Revolution Choiceapi-483679267No ratings yet

- Peptan - All About Collagen Booklet-1Document10 pagesPeptan - All About Collagen Booklet-1Danu AhmadNo ratings yet

- Lim vs. CA DigestDocument2 pagesLim vs. CA Digestsamme1010100% (1)

- Douglas Frayne Sargonic and Gutian Periods, 2334-2113 BCDocument182 pagesDouglas Frayne Sargonic and Gutian Periods, 2334-2113 BClibrary364100% (3)

- Release emotions with simple questionsDocument10 pagesRelease emotions with simple questionsDubravko ThorNo ratings yet

- Industrial/Organi Zational Psychology: Alday, Angeli Camille M. - 2P2Document51 pagesIndustrial/Organi Zational Psychology: Alday, Angeli Camille M. - 2P2SteffanyNo ratings yet

- Operator Manual Air GrinderDocument32 pagesOperator Manual Air GrinderYamin MohdNo ratings yet

- Renewable Resources in Coatings Technology A ReviewDocument9 pagesRenewable Resources in Coatings Technology A ReviewYamin MohdNo ratings yet

- Cytec LCRProductGuideDocument62 pagesCytec LCRProductGuideYamin Mohd0% (2)

- Industrial Utilization of Castor Oil-2 - Alkyd Resin Synthesis and Evaluation.Document8 pagesIndustrial Utilization of Castor Oil-2 - Alkyd Resin Synthesis and Evaluation.Yamin MohdNo ratings yet

- Water A Cause For War in Coming Decades - US Intel - TheDocument2 pagesWater A Cause For War in Coming Decades - US Intel - TheYamin MohdNo ratings yet

- The Optimal Solution in Distillation TestingDocument4 pagesThe Optimal Solution in Distillation TestingYamin MohdNo ratings yet

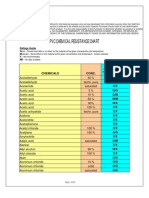

- PVC Chemical ResistanceDocument20 pagesPVC Chemical ResistanceYamin MohdNo ratings yet

- PVC Chemical ResistanceDocument20 pagesPVC Chemical ResistanceYamin MohdNo ratings yet

- CH 6 - Alkene + PeracidDocument1 pageCH 6 - Alkene + PeracidYamin MohdNo ratings yet

- Caustic Soda: Safe Handling ofDocument29 pagesCaustic Soda: Safe Handling ofYamin MohdNo ratings yet

- Imidazole Curing AgentsDocument4 pagesImidazole Curing AgentsYamin MohdNo ratings yet

- Ezequiel Reyes CV EngDocument1 pageEzequiel Reyes CV Engezequiel.rdNo ratings yet

- LSAP 423 Tech Data 25kVA-40KVA - 3PH 400VDocument1 pageLSAP 423 Tech Data 25kVA-40KVA - 3PH 400Vrooies13No ratings yet

- Biology 11th Edition Mader Test BankDocument25 pagesBiology 11th Edition Mader Test BankAnthonyWeaveracey100% (44)

- Volume 4-6Document757 pagesVolume 4-6AKNo ratings yet

- Learner's Activity Sheet: English (Quarter 4 - Week 5)Document5 pagesLearner's Activity Sheet: English (Quarter 4 - Week 5)Rufaidah AboNo ratings yet

- 1-2-Chemical Indicator of GeopolymerDocument4 pages1-2-Chemical Indicator of GeopolymerYazmin Alejandra Holguin CardonaNo ratings yet

- Analysis I - SyllabusDocument3 pagesAnalysis I - SyllabusJUan GAbrielNo ratings yet

- The Teacher and The LearnerDocument23 pagesThe Teacher and The LearnerUnique Alegarbes Labra-SajolNo ratings yet

- UNDERSTANDING CULTURE SOCIETY & POLITICS12 - LAS - Week7Document6 pagesUNDERSTANDING CULTURE SOCIETY & POLITICS12 - LAS - Week7Bergonsolutions AingelNo ratings yet

- Din en 912-2001Document37 pagesDin en 912-2001Armenak BaghdasaryanNo ratings yet

- Year 2 - Push and Pull FPDDocument18 pagesYear 2 - Push and Pull FPDRebecca LNo ratings yet

- Conditional Sentences in NT Greek Ruben VideiraDocument62 pagesConditional Sentences in NT Greek Ruben Videiraruviso100% (1)

- Plant Processes: Lesson 3Document3 pagesPlant Processes: Lesson 3Kayla Ta’jaeNo ratings yet

- Database Case Study Mountain View HospitalDocument6 pagesDatabase Case Study Mountain View HospitalNicole Tulagan57% (7)

- APA - 7thed - UCW Student Paper TemplateDocument4 pagesAPA - 7thed - UCW Student Paper Templatesimerpreet3No ratings yet

- Day 2 TaskDocument4 pagesDay 2 TaskYaathriganNo ratings yet

- MRP Format MbaDocument6 pagesMRP Format Mbasankshep panchalNo ratings yet

- Material Safety Data Sheet: Development Associates, IncDocument3 pagesMaterial Safety Data Sheet: Development Associates, IncDedi MulyadiNo ratings yet

- Nurses Week Program InvitationDocument2 pagesNurses Week Program InvitationBenilda TuanoNo ratings yet

- ZO 503 Physiological Chemistry by Dr.S.S.KunjwalDocument22 pagesZO 503 Physiological Chemistry by Dr.S.S.KunjwalAbhishek Singh ChandelNo ratings yet

- Catalogue PDFDocument4 pagesCatalogue PDFShivam GuptaNo ratings yet

- PPPoE Packet Format - HCNADocument6 pagesPPPoE Packet Format - HCNARobert Sanchez OchochoqueNo ratings yet

- Psyclone: Rigging & Tuning GuideDocument2 pagesPsyclone: Rigging & Tuning GuidelmagasNo ratings yet

- CFC KIDS FOR CHRIST 2020 FINAL EXAMDocument13 pagesCFC KIDS FOR CHRIST 2020 FINAL EXAMKaisser John Pura AcuñaNo ratings yet