Professional Documents

Culture Documents

Explosive Metal Forming - Hani Aziz Ameen

Uploaded by

Hani Aziz AmeenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Explosive Metal Forming - Hani Aziz Ameen

Uploaded by

Hani Aziz AmeenCopyright:

Available Formats

Explosive metal forming Dr.

Hani Aziz Ameen

Techni cal Col l ege Baghdad Ir aq- Di es and Tool s Eng. Dept .

((Explosive metal

Forming))

Dr. Hani Aziz Ameen

Asst . Pr of . i n M echani cal Engi neer i ng

Techni cal Col l ege - Baghdad

Di es and Tool s Engi neer i ng Depar t ment

E-mai l : hani azi zameen@yahoo.com

PDF created with pdfFactory Pro trial version www.pdffactory.com

Explosive metal forming Dr. Hani Aziz Ameen

Techni cal Col l ege Baghdad Ir aq- Di es and Tool s Eng. Dept .

Int r oduct i on:

is a met al forming t echni que t hat uses t he energy generat ed by an

expl osive det onat i on t o f orm t he met al work piece. This process can

deli ver a great deal of f lexibi lit y in t he met al-forming process.

Since explosive f orming t ransmit s t he explosively- generat ed energy

t hrough wat er, it can simul at e a vari et y of ot her convent i onal met al

f orming t echniques.

has been an accept ed met al -forming t echnique f or almost 50 years. I t

has been used in a wide variet y of appli cat ions in t he aut omot i ve,

aerospace, and marit i me indust ries. PA&E has ext ensive experience

usi ng t his t echnique t o f orm a wide variet y of met als. Typical formi ng

proj ect s yield very close t olerances and very high degrees of

repeat abilit y.

I t can of fer significant cost savings on short -run part s because it of t en

only requires a one-sided t ooling die. I n t he explosive hydro- f orming

process, t he wat er slug applies f orce evenly over t he surface of t he work

piece, as it f orms int o t he cavit y of t he forming die.

Propert ies of mat erial s at high rat es of def orming are most ly always

dif f erent of respect ive propert ies at st at i c loading. This causes much

inf luence on a great number of pract i cal advant ages.

The use of dynami c ef f ect s and increase of mat eri als pl ast icit y are

possibl e in t he cert ain i nt erval of def ormat ion velocit ies, which

det ermine t echnological process paramet ers for each kind of t he

prot ot ypes manuf act uring. To choose opt imal paramet ers of def ormat ion

t he relat ionshi p of mat erial def ormabil it y and it s propert ies should be

expressed wit h a physically subst ant iat ed regulari t y, t hat will enable t o

consider di fferent pract ical cases.

Benefits of Explosive Forming

Explosive-forming has many benef it s. I t employs lower t ooling cost s and

uses st amping t ype applicat ions whi ch only require a one-sided t ooli ng

die. Explosive energy can be t ransmit t ed dif ferent ly across t he part , in

order t o concent rat e force ont o specif ic f orming f eat ures. I t has a large

si ze capabil it y and is suit ed t o dif ficult configurat ions.

PDF created with pdfFactory Pro trial version www.pdffactory.com

Explosive metal forming Dr. Hani Aziz Ameen

Explosively- formed part s can range up t o 6 f eet and have very f ew

limit at ions. Explosive- f orming can simulat e many aspect s of all ot her

convent ional f orming met hods, wit hout t heir respect ive limit at ions.

improved qualit y of part s ( by hi gh-st rengt h mat erial s) , perf ect ing t he

inst allat ion t hrough adapt ing act ive media t o diff erent shapes of part ,

simply adapt i ng t o product ion process, reduct ion of product ion st ages,

f lexibilit y of t he process due t o quick and simple t ransformat ion of t he

t ool element s, l ow product ion cost s.

By Explosive forming as against t radit ional pract ice only one of t wo t ool s

is required eit her a die or a punch. By t hi s means labour consuming and

expensive mut ual mat ching of t oolings is excluded.

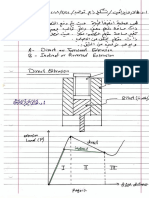

The simplified scheme of t he process is pi ct ured i n Fi g. 1. The energy

releasing upon explosion of hi gh explosi ve subst ance act s direct ly or

t hrough a conduct ive medium ( wat er) on a sheet billet and deform it t o

f it t he die prof il e. The waves generat ed at dynamic f orming cont ribut e t o

oscill at ory pressure change i n a basin t hat produce benef icial eff ect on

def ormat i on process.

Fig. 1

PDF created with pdfFactory Pro trial version www.pdffactory.com

Explosive metal forming Dr. Hani Aziz Ameen

(Fig. 2) Explosive f orming set up

Set up

The syst em used for st andoff dist ance operat ion consist of : -

An explosive charge.

An energy t ransmit t ed medium ( wat er, air, oil) .

A die assembly.

The workpiece.

Fi gure 2 shows an arrangement of st andof f dist ance explosive

f orming operat ion. The die assembly is put t oget her on t he bot t om

of t he t ank. Workpi ece is placed on t he die and blankholder placed

above. A vacuum is t hen creat ed in t he die cavi t y. The explosi ve

charge pl aced in posit ion over t he cent er of t he workpi ece. The

explosi ve charge is suspended over t he bl ank at a predet ermi ned

dist ance. The complet e assembly is i mmersed in a t ank of wat er.

Af t er t he det onat ion of explosive , a pressure pul se of high

int ensit y is produced. A gas bubble is also produced which expands

spherically and t hen col lapse unt il it vent s at t he surf ace of t he

wat er. When t he pressure pulse i mpinges against t he workpiece,

t he met al is displaced int o t he die cavit y.

PDF created with pdfFactory Pro trial version www.pdffactory.com

Explosive metal forming Dr. Hani Aziz Ameen

Techni cal Col l ege Baghdad Ir aq- Di es and Tool s Eng. Dept .

Ex pl osi v es

Explosives are subst ances t hat undergo rapid under chemical

react ion during whi ch heat and large quant it ies of gaseous

product s are creat ed. Explosive can be solid (T.N.T-

t ri nit rot oluene) , liqui d (Nit roglycerine) or gaseous ( Oxygen and

acet ylene mixt ures) .

Explosive are di vided int o t wo classes; Low explosive in which t he

ammuni t ion burns rapidl y rat her t han expl oding, hence pressure

build up is not large, and Hi gh explosive which have high rat e of

react ion wit h a large pressure build up. Low explosives are

general ly used as propellant s in guns and rocket s for t he propelli ng

of missile.

Di e mat er i al s

Dif f erent mat erial s are used f or t he manuf act ure of t he dies for

expl osive working, f or inst ance high st rengt h t ool st eels , plast ics,

concret e. Relat ively low st rengt h dies are used f or short run it ems

and f or part s where close t olerance are not crit ical , while for longer

runs higher st rengt h die mat erials are requi red. Kriksit e and plast ic

f aced dies are empl oyed for light forming operat ion, cast st eel s,

and duct ile iron for medium requirement s, f iberglass and kiksit e

f or low pressure and f ew part s, f iberglass and concret e for low

pressure and large part s and epoxy wit h concret e for low pressure

and large part s.

Tr ansmi ssi on medi um

Energy released by t he explosive i s t ransmit t ed t hrough medium

like wat er, air, oil, gelat in and liquid salt s. Wat er i s one of t he best

media for explosive forming since it i s available readi ly,

inexpensi ve and product s excellent result s. The t ransmissi on

medium is import ant regarding pressure magnit ude at t he

workpiece. Wat er is more desi rable medium t han ai r for produci ng

high peak pressures t o t he workpiece.

For mabi l i t y aspect s

Formabi lit y has been def ined as t he abi lit y of a sheet met al t o be

def ormed by a speci fic sheet met al forming process f rom it s

original shape t o a def ined shape wit hout f ailure. I n normal

expl osive formi ng operat ions, t he maj or charact erist ics of t he

workpiece met al t hat det ermi ne formabilit y are duct ilit y and

t oughness. I t is general pract ice not t o exceed t he elongat ion, as

PDF created with pdfFactory Pro trial version www.pdffactory.com

Explosive metal forming Dr. Hani Aziz Ameen

Techni cal Col l ege Baghdad Ir aq- Di es and Tool s Eng. Dept .

det ermined by t ension t est ing, in f orming a part f rom t he same

met al t hat .

The ex pl osi v e f or mi ng of domes

The explosive f orming of met al bl anks is accompanied by l arge

plast ic deformat ion at high rat e of st rain, under bi- axi al or t ri- axi al

st at es of st ress.

A. St rain energy of deformat ion

I n order t o reach at a rat ional met hod f or predict ing t he

amount of explosive charge it i s necessary t o comput e t he

st rain energy of plast ic energy of plast ic def ormat ion of t he

met al part of workpiece: -

U =

( 1 )

Where U is st rain energy

(

)

+ (

)

+ (

.( 2)

(

)

+ (

)

+ (

)

. ( 3)

For most st rain hardening mat erials: -

= K

. ( 4)

K is const ant and n is t he st rain hardening exponent

For st rain hardeni ng mat erial

U =

( 5)

Ef f ect of ex pl osi v e st andof f di st an ce on st r ai n di st r i b ut i on

i n t he ex pl osi v e f or mi ng of f l at ci r cu l ar bl ank s

Using cent rally l ocat ed charge as shown in t he f ig. 3 t o explosivel y

f orm of a fl at circular blank, t he dist ri but ion of st rain across a

diamet er of t he blank will vary wit h t he rat io of st andof f dist ance,

( L) t o t he diamet er of t he die opening, ( D) .

PDF created with pdfFactory Pro trial version www.pdffactory.com

Explosive metal forming Dr. Hani Aziz Ameen

Fig. 3

Est i mat i ng of t ot al st r ai n ener gy an d t h e w ei g ht ch ar ge r eq ui r ed

f or an ex pl osi v el y f or med dome i n si ngl e sh ot .

a- Comput ing t he value of D

o

and B

o

Do= D + r e (6)

Bo= 4w

+ B

. . (7)

R

w

W

1

PDF created with pdfFactory Pro trial version www.pdffactory.com

Explosive metal forming Dr. Hani Aziz Ameen

Techni cal Col l ege Baghdad Ir aq- Di es and Tool s Eng. Dept .

1 1 4(

(8)

b- Calculat ing of max. permissible dept h of draw

w

( 2n + 1) ( 4n + 13) . ( 9)

A- I f w

t hi s means we are needi ng only one shot .

B- I f w

< t his means we are needing mult iple shot ( more

t han one shot ) .

c- I f A condit ion is sat isf ied t hen ef f ect i ve draw dept h( w

) should be

calculat ed as follows: -

U

=

( Bo D

) .. ( 10)

w

= w | U

| + 0.57 r

. . ( 11)

U

4

D

2

h

o

K

n+1

jln j1 + 4(

w

D

) [ [

n+1

. . (12)

U

F

= [

3

3

n+1

K

n( n+1)

h

o

j[

Bo-B

2

Bo[

n+1

_[

D

o

2

-2n

[

Bo

2

-2n

_.( 13)

d- Est imat ing of t he charge weight using t he geomet rical met hod: -

W=

2 U

T

1

( 1-cos) c

.( 14)

e = specific ene r gy of t he char ge

1

1

= 4.23 3.7 [

L

for

L

0.5 .. ( 15)

1

1

= 4.02 3.7 [

L

for

L

1 . ( 16)

cos = [t an

-1

D

2L

. . ( 17)

PDF created with pdfFactory Pro trial version www.pdffactory.com

Explosive metal forming Dr. Hani Aziz Ameen

Techni cal Col l ege Baghdad Ir aq- Di es and Tool s Eng. Dept .

= t an

-1

D

2L

.( 18)

e- I f B condit ion is sat isf ied one must comput e t he dept h of t he draw

of t he f irst shot and t he required weight exact ly as in t he st ep c

and d t hen must comput e t he dept h of t he dome and weight of t he

charge for second shot as f ollows: -

Mul t i ple shot explosive formi ng

I f h

1

is a mat erial t hi ckness af t er f irst shot and

h

2

is a mat erial t hickness af t er second shot t hen: -

h

1

h

2

=

R

2

w

2

R

1

w

1

. . ( 19)

h

1

h

2

=

1+

4v

1

2

D

2

1+

4v

2

2

D

2

( 20)

t he t hickness st rain

t

i s t hen given by: -

t

= ln

h

1

h

2

= ln

1 +

4w

1

2

D

2

1 +

4w

2

2

D

2

. (21)

cII

= t

w

2

w

1

2

char ge

Fi g.5 M ul t i pl e shot f or mi ng seq uen ce

h

1

h

2

PDF created with pdfFactory Pro trial version www.pdffactory.com

Explosive metal forming Dr. Hani Aziz Ameen

Techni cal Col l ege Baghdad Ir aq- Di es and Tool s Eng. Dept .

cII

= ln

1+

4v

1

2

D

2

1+

4v

2

2

D

2

.( 22)

Usi ng Hill formula ( e

=

1

2

( 2n + 1) ) for max. per missibl e bi- axial

st rain energy and equat ing it t o t he max. ef fect ive st rain at

t he end of t he second shot we get : -

1+

4v

1

2

D

2

1+

4v

2

2

D

2

= cxp j

4

11

( 2n + 1) [ ( 23)

Solving f or

w

2

D

we have

w

2

D

=

1

2

_

[1 +

4w

1

2

D

2

exp j

4

11

( 2n + 1) [ 1 ( 24)

Aft e r obt aining w2 , now we can calculat e s t r ain ener gy per unit volume

for t he second shot:-

U

2

=

K

n+ 1

_ln (

1 +

4w

2

2

D

2

1 +

4w

1

2

D

2

_

n + 1

.( 25)

t he t ot al st rai n energy of t he deformat ion can be calcul at ed by: -

( U

T

)

2

=

4

D

2

h

o

K

n+1

_ln (

1+

4v

2

2

D

2

1+

4v

1

2

D

2

_

n+1

( 26)

The expl osi ve energy ( E

T

)

2

deli vered t o t he bl ank by t he second

shot may be est imat ed as foll ows: -

( E

T

)

2

=

1

2

2

( 1 cos

2

) W

2

e . ( 27)

Where

2

is defi ned i n fi gure 5, w

2

is t he weight of second charge

and e is t he speci fic energy of t he expl osi ve i. e. energy per uni t

wei ght of t he charge.

PDF created with pdfFactory Pro trial version www.pdffactory.com

Explosive metal forming Dr. Hani Aziz Ameen

Techni cal Col l ege Baghdad Ir aq- Di es and Tool s Eng. Dept .

Case study of domed shape forming

Estimate the required (TNT) charge weight (W) to produce flanged dome

shape made of Aluminium alloy 2014-0 with the following dimensions:-

B =3.3m , D = 3m, w = 1m, h

o

= 0.02m and r

e

=0.01m.

-----------------------------------------------------------------------------

Solution

From tables:

K = 320.4Mpa, n = 0.244,

1

1

= 4.23 3.7 [

L

= 3.6 and

e = 0.393 10

6

m.N/Kg and chose

L

=

1

6

= 0.167.

1- Do= D + 2 x r e = 3.02 m.

2- Bo= 4w

2

+ B

2

= 3.86 m, is a blank diameter.

3- To calculat e max. pe r mis sible dept h:

w

1

=

D

11

( 2n + 1) ( 4n + 13) =1.072 m.

w

1

> w so we need just a single shot to achieve the process.

4. w

= w j

B

o

2D

o

( B

o

B) [ + 0.57 r

c

= 0.64 m.(but we apply w = 1m).

5. To calculate the energy required to form the dome:

U

D

=

4

D

2

h

o

K

n+1

jln j1 + 4(

w

D

) [ [

n+1

= 10.5 10

6

N.m.

6. To calculate the energy required to form the flange:

U

F

= [

3

3

n+1

K

n( n+1)

h

o

j[

Bo-B

2

Bo[

n+1

_[

D

o

2

-2n

[

Bo

2

-2n

_

= 0.98 10

6

N.m

The total energy required to form the dome:

E

T

= U

T

= U

D

+ U

F

= 11.48 10

6

N. m.

PDF created with pdfFactory Pro trial version www.pdffactory.com

Explosive metal forming Dr. Hani Aziz Ameen

Techni cal Col l ege Baghdad Ir aq- Di es and Tool s Eng. Dept .

So the explosive charge (W) can be calculated :

W =

2L

T

1

( 1cos

1

) e

1

= tan

-1

[

D

2L

Since

L

D

= 1.67

L= 0.5 m

So W required is 17 kg.

Conclusions and disruptions

In explosive metal forming chemical energy from the explosive is used to

generate shock waves through a medium which are direct to the workpiece at

very high velocities. This process was mostly used to form large and bulky

components typically for military and aerospace components and now can be

used for small parts with complex shapes and low capital investment also the

ability to vary energy levels over wide ranges provides greater capabilities

than conventional forming methods. The process can be achieved by the

simplest requirements such as one side die, the workpiece and an explosive

charge.

Beside all advantage with some limitations and although it is not new process

but one feel that the information about explosive forming is still not enough,

may be due to the difficulty of understanding what happens exactly during the

process so someone trying to simulate the method, another reason is dealing

with explosive so the informations are not available and forbidden.

To provide a fully picture about explosive forming there must be additional

information available.

PDF created with pdfFactory Pro trial version www.pdffactory.com

Explosive metal forming Dr. Hani Aziz Ameen

Exampl es t hat have been pr oduced by expl osi ve f or mi ng

PDF created with pdfFactory Pro trial version www.pdffactory.com

Explosive metal forming Dr. Hani Aziz Ameen

References

1. Herold, K.P.; Vovk, V.; Taran, V.; Vovk, A: Explosive forming of high-

strength sheet material. 10-th International conference Sheet Metal, Ulster, E;

April, 2003.

2. Hydroforming - Wikipedia, the free encyclopedia.

3. Taran, V.*; Vovk, V.* ; Sabelkin, V.**; Vovk, A.* . * Otto-von-Guericke-

University Magdeburg, Magdeburg, Germany** IMP, Mexico(Explosive

Forming of Metal Blanks).

4. Principals and practice of explosive metal working by A.A. EZRA.

The Aut hor

Dr . Hani Azi z Am een , Bi r t h dat e 1971 i n Baghdad- Ir aq, has Ph.D. i n

M echan i cal Engi neer i ng Appl i ed M ech ani cs f r om t he Un i ver si t y of

Techno l ogy Ir aq i n 1998. He has mor e t han 50 publ i shed paper s and he i s an

exper t i n t h e ANSYS sof t war e and f i ni t e el emen t anal ysi s.

Wor ki n g i n sever al uni ver si t i es and col l eges (Technol ogy Un i ver si t y-

Al Nahr een Uni ver si t y- Ti kr i t Uni ver si t y Techni cal Col l ege Al M u sai b).

And now h e i s Asst . Pr of essor i n t he Techni cal Co l l ege Baghdad / Di es and

Too l s Engi neer i ng Depar t men t .

E-mai l : hani azi zameen@yahoo.com

PDF created with pdfFactory Pro trial version www.pdffactory.com

You might also like

- 8-High Rate Enfergy Forming-Prof - Dr.haniDocument7 pages8-High Rate Enfergy Forming-Prof - Dr.haniHani Aziz AmeenNo ratings yet

- Formability of Laser WeldingDocument9 pagesFormability of Laser WeldingHani Aziz AmeenNo ratings yet

- Stess Elasticity Prof - Dr.hani Aziz AmeenDocument53 pagesStess Elasticity Prof - Dr.hani Aziz AmeenHani Aziz AmeenNo ratings yet

- The Effect of Coupled Field On The Vibration Characteristics and Stresses of Turbomachinery System - Hani Aziz AmeenDocument21 pagesThe Effect of Coupled Field On The Vibration Characteristics and Stresses of Turbomachinery System - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- 2-Wire Drawing-Prof - Dr.Hani Aziz Ameen PDFDocument15 pages2-Wire Drawing-Prof - Dr.Hani Aziz Ameen PDFHani Aziz AmeenNo ratings yet

- 4-Extrusion Process-Prof - Dr.hani Aziz AmeenDocument42 pages4-Extrusion Process-Prof - Dr.hani Aziz AmeenHani Aziz AmeenNo ratings yet

- 7-Blanking and Piercing-Prof - Dr.hani AzizDocument4 pages7-Blanking and Piercing-Prof - Dr.hani AzizHani Aziz AmeenNo ratings yet

- Rolling Process-Prof - Dr.hani Aziz AmeenDocument18 pagesRolling Process-Prof - Dr.hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Effect of Post-Buckling On The Stiffness and Stress of Plate - Hani Aziz AmeenDocument16 pagesEffect of Post-Buckling On The Stiffness and Stress of Plate - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Finite Element Analysis of Large Diameter Concrete Spherical Shell Domes - Hani Aziz AmeenDocument16 pagesFinite Element Analysis of Large Diameter Concrete Spherical Shell Domes - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- شهادة تقديرية - دكتور هاني عزيز أمين PDFDocument1 pageشهادة تقديرية - دكتور هاني عزيز أمين PDFHani Aziz AmeenNo ratings yet

- Experimental and Theoretical Investigation of Impact Dynamic Plasticity For CK45 - Hani Aziz AmeenDocument9 pagesExperimental and Theoretical Investigation of Impact Dynamic Plasticity For CK45 - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- RESIDUAL ELASTO-PLASTIC STRESSES ANALYSIS OF POLYMERIC THICK - WALLED PRESSURIZED CYLINDER - Hani Aziz AmeenDocument14 pagesRESIDUAL ELASTO-PLASTIC STRESSES ANALYSIS OF POLYMERIC THICK - WALLED PRESSURIZED CYLINDER - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Deep Drawing - Prof - Dr.hani Aziz AmeenDocument17 pagesDeep Drawing - Prof - Dr.hani Aziz AmeenHani Aziz AmeenNo ratings yet

- The Effect of Coupled Field On The Vibration Characteristics and Stresses of Turbomachinery System - Hani Aziz AmeenDocument21 pagesThe Effect of Coupled Field On The Vibration Characteristics and Stresses of Turbomachinery System - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Finite Element Analysis of The Dish Multi-Point FormingDocument10 pagesFinite Element Analysis of The Dish Multi-Point FormingHani Aziz AmeenNo ratings yet

- Moving and Repeating Load in Ansys APDL - Hani Aziz AmeenDocument4 pagesMoving and Repeating Load in Ansys APDL - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Hani Aziz Ameen هاني عزيز امينDocument3 pagesHani Aziz Ameen هاني عزيز امينHani Aziz AmeenNo ratings yet

- Professor DR Hani Aziz AmeenDocument1 pageProfessor DR Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Ansys Analysis of Concrete Planter Round PDFDocument6 pagesAnsys Analysis of Concrete Planter Round PDFHani Aziz AmeenNo ratings yet

- PDF Created With Pdffactory Pro Trial VersionDocument1 pagePDF Created With Pdffactory Pro Trial VersionHani Aziz AmeenNo ratings yet

- Static and Dynamic Characteristics of Slotted Cylinder SpringDocument12 pagesStatic and Dynamic Characteristics of Slotted Cylinder SpringHani Aziz AmeenNo ratings yet

- Manufacturing Cosine Die Profile For Tubes Hydroforming Test (Bulging)Document19 pagesManufacturing Cosine Die Profile For Tubes Hydroforming Test (Bulging)Hani Aziz AmeenNo ratings yet

- Effect of Loading Path On Stress DistributionDocument12 pagesEffect of Loading Path On Stress DistributionHani Aziz AmeenNo ratings yet

- ANSYS of Groundwater Flow Problem-Hani Aziz AmeenDocument10 pagesANSYS of Groundwater Flow Problem-Hani Aziz AmeenHani Aziz Ameen100% (2)

- Slotted Cylinder SpringDocument11 pagesSlotted Cylinder SpringHani Aziz AmeenNo ratings yet

- Hani Aziz Ameen هاني عزيز امينDocument3 pagesHani Aziz Ameen هاني عزيز امينHani Aziz AmeenNo ratings yet

- PDF Created With Pdffactory Pro Trial VersionDocument1 pagePDF Created With Pdffactory Pro Trial VersionHani Aziz AmeenNo ratings yet

- Manufacturing Cosine Die Profile For Tubes Hydroforming Test (Bulging)Document19 pagesManufacturing Cosine Die Profile For Tubes Hydroforming Test (Bulging)Hani Aziz AmeenNo ratings yet

- Hani Aziz Ameen هاني عزيز امينDocument3 pagesHani Aziz Ameen هاني عزيز امينHani Aziz AmeenNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Sheet Metalworking 1 - Chapter 19Document99 pagesSheet Metalworking 1 - Chapter 19xharpreetxNo ratings yet

- Checklist of Bats From Iraq-Mammalian Biology 2020Document14 pagesChecklist of Bats From Iraq-Mammalian Biology 2020Adil DalafNo ratings yet

- XG25-XG30: 44208060100 REV.003 03/2008 This Catalogue Is Valid For Trucks As From Serial NumbersDocument153 pagesXG25-XG30: 44208060100 REV.003 03/2008 This Catalogue Is Valid For Trucks As From Serial Numbersalexandre donizetiNo ratings yet

- Murat Kenedy: Bu Içerik Tarafından HazırlanmıştırDocument2 pagesMurat Kenedy: Bu Içerik Tarafından HazırlanmıştırChatorg. orgNo ratings yet

- What Is The Procedure For Graceful Shutdown and Power Up of A Storage System During Scheduled Power OutageDocument5 pagesWhat Is The Procedure For Graceful Shutdown and Power Up of A Storage System During Scheduled Power OutageNiraj MistryNo ratings yet

- Lesson Plan in Science 10 2nd QuarterDocument5 pagesLesson Plan in Science 10 2nd QuarterJenevev81% (21)

- SAP PPM 5.0 Certification Exam TopicsDocument7 pagesSAP PPM 5.0 Certification Exam TopicsongkecanthoNo ratings yet

- 268US03 Oiltech Technical & Product Catalogue Letter WDocument48 pages268US03 Oiltech Technical & Product Catalogue Letter WMauricio CarestiaNo ratings yet

- Article 680 Swimming Pools, Spas, Hot Tubs, Fountains, and Similar InstallationsDocument13 pagesArticle 680 Swimming Pools, Spas, Hot Tubs, Fountains, and Similar InstallationsDocente 361 UMECITNo ratings yet

- Ata 47-NGS R25Document148 pagesAta 47-NGS R25NadirNo ratings yet

- Specification of PCB800099 Controller Board V1.0Document10 pagesSpecification of PCB800099 Controller Board V1.0benabdullahNo ratings yet

- VUCG Guia de Instalacion y Comisionamiento en Ingles 1ZSC000562-AAY en Rev 1 - LowDocument56 pagesVUCG Guia de Instalacion y Comisionamiento en Ingles 1ZSC000562-AAY en Rev 1 - Lowarmandoa71565No ratings yet

- London Business School Interview Guide Clear Admit 2015Document38 pagesLondon Business School Interview Guide Clear Admit 2015Nakul RathiNo ratings yet

- Resultados de La Web: GDDS - Traducción Al Español - Ejemplos Inglés - Reverso ..Document3 pagesResultados de La Web: GDDS - Traducción Al Español - Ejemplos Inglés - Reverso ..Jo PaterninaNo ratings yet

- Desktop HDD, Processors, and Memory DocumentDocument13 pagesDesktop HDD, Processors, and Memory DocumentsonydearpalNo ratings yet

- Cathodic Disbonding TesterDocument1 pageCathodic Disbonding TesterfelavinNo ratings yet

- EPC Contractor Rep. Authority/Authority's EngineerDocument6 pagesEPC Contractor Rep. Authority/Authority's Engineersunil kuldeepNo ratings yet

- FlowTradersSOP PDFDocument1 pageFlowTradersSOP PDFAvinash IyerNo ratings yet

- Asphalt Laboratory Manual RevDocument13 pagesAsphalt Laboratory Manual RevKurian C ChackoNo ratings yet

- ResumeDocument4 pagesResumeBazlaa HasmanNo ratings yet

- Research Proposal of SheepDocument37 pagesResearch Proposal of SheepDabalo Garama67% (3)

- Nordson EFD Ultimus I II Operating ManualDocument32 pagesNordson EFD Ultimus I II Operating ManualFernando KrauchukNo ratings yet

- Managing Change Leading TransitionsDocument42 pagesManaging Change Leading TransitionsSecrets26No ratings yet

- GF - 4 - GF - 6 - 790 700 337 - 01 - enDocument2 pagesGF - 4 - GF - 6 - 790 700 337 - 01 - enAdrianNo ratings yet

- #C C C$ C%C& C' C (CDocument4 pages#C C C$ C%C& C' C (CThong Chee WheiNo ratings yet

- ECOSYS FS-2100D Ecosys Fs-2100Dn Ecosys Fs-4100Dn Ecosys Fs-4200Dn Ecosys Fs-4300Dn Ecosys Ls-2100Dn Ecosys Ls-4200Dn Ecosys Ls-4300DnDocument33 pagesECOSYS FS-2100D Ecosys Fs-2100Dn Ecosys Fs-4100Dn Ecosys Fs-4200Dn Ecosys Fs-4300Dn Ecosys Ls-2100Dn Ecosys Ls-4200Dn Ecosys Ls-4300DnJosé Bonifácio Marques de AmorimNo ratings yet

- Work Instruction For Coil Taping Process of EE14 (1&4 Pin)Document6 pagesWork Instruction For Coil Taping Process of EE14 (1&4 Pin)k.mehaboob bashaNo ratings yet

- Volume 5 Issue 1Document625 pagesVolume 5 Issue 1IJAET Journal0% (1)

- Rules of the Occult UndergroundDocument247 pagesRules of the Occult UndergroundIsaak HillNo ratings yet

- TableDocument9 pagesTableShamlakan elghaoucheNo ratings yet