Professional Documents

Culture Documents

QW-482 201.1

Uploaded by

Barwin CruzOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QW-482 201.1

Uploaded by

Barwin CruzCopyright:

Available Formats

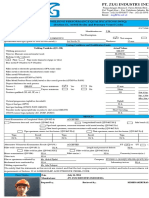

QW-482 SUGGESTED FORMAT FOR WELDING PROCEDURE SPECIFICATION (WPS)

(See QW-201.1, Section IX, ASME Boiler and Pressure Vessel Code)

Company Name

Welding Procedure Specification No.

Revision No.

SMAW

Type (s)

JOINTS (QW-402)

Joint Design

See permitted figures (right) or per constr. dwg

Root Spacing

Backing (Yes)

Yes (No) Yes

Backing Material (Type)

Material or Weld Metal

Supporting PQR No.(s)

Date

Welding Process(es)

By:

Date

:

Manual

Details

BUTT JOINT

(refer to both backing and retainers)

Metal

Nonmetalic

Nonfusing Metal

Other

FIG A (BUTT JOINT)

FIG B (CORNER JOINT)

FIG C (EDGE JOINT)

Sketches, Production Drawings, Weld Symbols or Written Description

should show the general arrangement of the parts to be welded. Where

applicable, the root spacing and the details of weld groove may be

specified.

FIG D (LAP JOINT)

(At the option of the Mfgr., sketches may be attached to illustrate joint

design, weld layers and bead sequence, e.g., for notch toughness procdures, for multiple process procedures etc.)

Other (Describe)

FIG E (TEE JOINT)

Figure A

*BASE METALS (QW-403)

P-No.

Figure B

Group No.

Figure C

Figure D

to P-No.

Figure E

Group No.

OR

Specification type and grade

to Specification type and grade

OR

Chem. Analysis and Mech. Prop.

to Chem. Analysis and Mech. Prop.

Thickness Range:

Base Metal:

Other

Groove

Maximum Pass Thickness <= 1/2 inch (13 mm)

*FILLER METALS (QW-404)

Spec. No. (SFA)

AWS No. (Class)

F-No.

A-No.

Size of Filler Metals

Filler Metal Product Form

Supplemental Filler Metal

Weld Metal

Thickness Range:

Groove

Fillet

Electrode-Flux (Class)

Flux Trade Name

Consumable Insert

Other

Fillet

(Yes)

(No)

*Each base metal-filler metal combination should be recorded individually.

QW-482 (Back)

WPS No.

POSITIONS (QW-405)

Position(s) of Groove

Welding Progression:

Position(s) of Fillet

Rev

POST WELD HEAT TREATMENT (QW-407)

Down

Up

PREHEAT (QW-406)

Preheat Temp. Min.

Interpass Temp. Max.

Preheat Maintenance

(Continuous or special heating where applicable should be recorded)

ELECTRICAL CHARACTERISTICS (QW-409)

Current AC or DC

Polarity

Amps (Range)

Volts (Range)

GAS (QW-408) Percent Composition

Gas(es)

(Mixture)

Shielding

Trailing

Backing

(Amperage and voltage range should be recorded for each electrode size,

position, and thickness, etc. This information may be listed in a tabular

form similar to that shown to the right or below.)

Tungsten Electrode Size and Type

(Pure Tungsten, 2% Thoriated, etc.)

Mode of Metal Transfer for GMAW

(Spray arc, short circuiting arc, etc.)

Electrode Wire feed speed range

TECHNIQUE (QW-410)

String or Weave Bead

Orifice or Gas Cup Size

Initial and Interpass Cleaning (Brushing, Grinding, etc.)

Method of Back Gouging

Oscillation

Contact Tube to Work Distance

Multiple or Single Pass (per side)

Multiple or Single Electrodes

Travel Speed (Range)

Peening

Other

Temperature Range

Time Range

Flow Rate

String or Weave

Brushing, grinding, chipping

Grinding

Multiple

Multiple

No Single Pass To Exceed 1/2" In Thickness Pulsed Power Supply not permitted

Flux is not to be added to the face of the joint

Filler Metal

Current

Weld

Layer(s) or

Pass (es)

Process

Classification

Diameter.

Type and

Polarity

Amperage

Range

Voltage

Range

Travel

Speed

Range

Other

(e.g., Remarks, Comments, Hot Wire

Addition, Technique,

Torch Angle, Etc.)

You might also like

- BPVC Ix QW-482Document2 pagesBPVC Ix QW-482ganesh82No ratings yet

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document8 pagesQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad HannanNo ratings yet

- 2010 SECTION IX WPS FORMATDocument5 pages2010 SECTION IX WPS FORMATAjay ChodankarNo ratings yet

- QW-482 WPS FormatDocument2 pagesQW-482 WPS FormatMardeOpamen100% (1)

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)mohammadNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- PQR REV. 2010a Interactive FormDocument2 pagesPQR REV. 2010a Interactive FormcosmicbunnyNo ratings yet

- WPS PQR-05Document10 pagesWPS PQR-05Ranjan KumarNo ratings yet

- BPVC Ix Qw-484aDocument1 pageBPVC Ix Qw-484aTC Capulcu Mustafa MNo ratings yet

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 pagesSample Wps Carbon Steel GTAW SMAW PDFirwanNo ratings yet

- PQRDocument2 pagesPQRafqzfieNo ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- PQR TipsDocument4 pagesPQR TipsWaqas WaqasNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Graycor WPS 19 SampleDocument5 pagesGraycor WPS 19 SampleRaul SebastiamNo ratings yet

- WPQDocument1 pageWPQjuda823No ratings yet

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- 177-Gmaw-Zug-Asme (Asep Wahyudi-3g) - WPQDocument4 pages177-Gmaw-Zug-Asme (Asep Wahyudi-3g) - WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Baosteel hot rolled steel plate quality certificateDocument3 pagesBaosteel hot rolled steel plate quality certificateDang TranNo ratings yet

- QW-483 BlankDocument2 pagesQW-483 BlankCraftyBob100% (1)

- Aws N-1 WPS-PQR FormDocument2 pagesAws N-1 WPS-PQR FormEdwin MariacaNo ratings yet

- Wps & PQR For Valve Installation - XLSX Fix TerbaruDocument20 pagesWps & PQR For Valve Installation - XLSX Fix TerbarufebriNo ratings yet

- BPQ REV. 0 Interactive FormDocument2 pagesBPQ REV. 0 Interactive FormcosmicbunnyNo ratings yet

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocument19 pagesJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeeNo ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPS for FCAW of steel pipe and fittingsDocument9 pagesWPS for FCAW of steel pipe and fittingsCesar ArellanoNo ratings yet

- Duplex Stainless Steel - Part 2 - TWIDocument6 pagesDuplex Stainless Steel - Part 2 - TWItuanNo ratings yet

- PQR Saw ProcessDocument1 pagePQR Saw ProcessARUL ARON JOSENo ratings yet

- PQR Editable SampleDocument2 pagesPQR Editable SampleKoya ThangalNo ratings yet

- Gtaw 106Document2 pagesGtaw 106ganeshkumarg_1No ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- QCF312 WPQRDocument2 pagesQCF312 WPQRminhnnNo ratings yet

- GMAWDocument12 pagesGMAWsushant47No ratings yet

- Test Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)Document1 pageTest Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)yskushwah16No ratings yet

- AECOM ASME PQR for SA-516 Pipe WeldsDocument3 pagesAECOM ASME PQR for SA-516 Pipe Weldscorey jacobsNo ratings yet

- GTL WPSDocument6 pagesGTL WPSYoucef ChorfaNo ratings yet

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- Welding Procedure Qualification Record: Shipyard LogoDocument4 pagesWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Wps PQRDocument7 pagesWps PQRsobariNo ratings yet

- WPS PQR-06Document9 pagesWPS PQR-06Ranjan KumarNo ratings yet

- Sample of Procedure Qualification Record (PQR) : Joint DetailsDocument4 pagesSample of Procedure Qualification Record (PQR) : Joint Detailshancur_27No ratings yet

- WPQ Flux CoreDocument1 pageWPQ Flux Corealberto jayaNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKAnonymous Ij6VfaNo ratings yet

- WPQ Certificates Klis14Document8 pagesWPQ Certificates Klis14AdhicharanNo ratings yet

- Sabari Engineering PQRDocument3 pagesSabari Engineering PQRAdvanced Quality Centre AQC100% (1)

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocument2 pagesProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXNo ratings yet

- SMAW DuniDocument4 pagesSMAW DuniMuhammad Fitransyah Syamsuar PutraNo ratings yet

- A2 Multitrac welding tractor for SAW & GMAWDocument1 pageA2 Multitrac welding tractor for SAW & GMAWcarlosNo ratings yet

- WPS - 006Document13 pagesWPS - 006MAT-LIONNo ratings yet

- Madina Trading WPS No. 017Document12 pagesMadina Trading WPS No. 017MAT-LIONNo ratings yet

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Document12 pagesPoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXNo ratings yet

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- Wps Format (Qw-482)Document2 pagesWps Format (Qw-482)Sebastian RajeshNo ratings yet

- Proposed Welding Procedure Specification FormatDocument2 pagesProposed Welding Procedure Specification FormatAli MoghiNo ratings yet

- QW 406 Asme CodeDocument3 pagesQW 406 Asme CodeMardeOpamenNo ratings yet

- QW 482Document2 pagesQW 482MuchamadAsyhariNo ratings yet

- WPS Format PDFDocument2 pagesWPS Format PDFHimansu Sekhar JenaNo ratings yet

- Wps Gmaw SawDocument2 pagesWps Gmaw Sawupedro26No ratings yet

- A1A, Class150Raisedface CarbonsteelDocument1 pageA1A, Class150Raisedface CarbonsteelBarwin CruzNo ratings yet

- Chennai Port Information : Loa (M) Beam (M) Draft (M) Cargoes Handled Low Flash RestrictionDocument1 pageChennai Port Information : Loa (M) Beam (M) Draft (M) Cargoes Handled Low Flash RestrictionBarwin CruzNo ratings yet

- 90º Elbows 2Document1 page90º Elbows 2Barwin CruzNo ratings yet

- Aquagroup PumpsDocument2 pagesAquagroup PumpsBarwin CruzNo ratings yet

- Star Delta Motor PDFDocument1 pageStar Delta Motor PDFLow Shen WeiNo ratings yet

- List of StandardsDocument5 pagesList of StandardsBarwin Cruz100% (2)

- Welspun Corp OTC Brochure2012Document6 pagesWelspun Corp OTC Brochure2012Barwin CruzNo ratings yet

- PIPE PROPERTIES (Imperial) : Pipe Size NPS Wall Thk. Weigh T LBS/FTDocument4 pagesPIPE PROPERTIES (Imperial) : Pipe Size NPS Wall Thk. Weigh T LBS/FTBarwin CruzNo ratings yet

- Cargo Calculation Program Oil SurveyDocument3 pagesCargo Calculation Program Oil SurveyJohn Green80% (5)

- MCI to introduce common exit test for medical graduatesDocument4 pagesMCI to introduce common exit test for medical graduatesBarwin CruzNo ratings yet

- Lesson-Script-G9-Q2, M1 Tle Eim 9Document12 pagesLesson-Script-G9-Q2, M1 Tle Eim 9Genevieve CaedoNo ratings yet

- Waste ManagementDocument53 pagesWaste ManagementBenison MathewNo ratings yet

- ASTM D566-16 Dropping Point of Lubricating GreaseDocument2 pagesASTM D566-16 Dropping Point of Lubricating GreaseHydrocarbonE.C AdminNo ratings yet

- Installation and Maintenance Manual for High Shear Duplex Batch Mixer Model KDDDocument21 pagesInstallation and Maintenance Manual for High Shear Duplex Batch Mixer Model KDDالسماني احمدNo ratings yet

- SKS Service - B 1-28-10 (426337 2nd Ed) PDFDocument970 pagesSKS Service - B 1-28-10 (426337 2nd Ed) PDFIsrael Miranda Zamarca100% (9)

- LEATHER CHEMISTRY GUIDEDocument16 pagesLEATHER CHEMISTRY GUIDESaravana Vel50% (2)

- C275D5 Data SheetDocument3 pagesC275D5 Data SheetnandanaNo ratings yet

- Raft Foundation Analysis & DesignDocument9 pagesRaft Foundation Analysis & DesignPoru Man100% (3)

- Helico Flex CatalogDocument12 pagesHelico Flex CatalogUbanAirlanggaNo ratings yet

- IACS Common Structural Rules Knowledge Centre Q&AsDocument10 pagesIACS Common Structural Rules Knowledge Centre Q&Astotoq51No ratings yet

- Din Handbook 402Document4 pagesDin Handbook 402fivehours5No ratings yet

- Engineering Material Specification: Not To Be Used For New DesignDocument5 pagesEngineering Material Specification: Not To Be Used For New Designjavier ortizNo ratings yet

- Separating Substances Methods PDocument7 pagesSeparating Substances Methods PMohan Reddy KothapetaNo ratings yet

- Internal Combustion Engine TypesDocument35 pagesInternal Combustion Engine TypesMuhammad FaizNo ratings yet

- Asme Addenda 2011Document59 pagesAsme Addenda 2011ricardodelatorreNo ratings yet

- APMRG1 Series: Packaged Air ConditionersDocument32 pagesAPMRG1 Series: Packaged Air Conditionerszaid jamaluNo ratings yet

- Time Flow Basin Pillar Tap - Push ButtonDocument6 pagesTime Flow Basin Pillar Tap - Push ButtonDota NgNo ratings yet

- Chromite Ore Beneficiation: Prepared by Mukesh Ranjan BeheraDocument33 pagesChromite Ore Beneficiation: Prepared by Mukesh Ranjan BeheraKhalid IkhsanuddinNo ratings yet

- Ips Energy Available Relay Models 2013 07Document27 pagesIps Energy Available Relay Models 2013 07Mareeswaran RamasamyNo ratings yet

- Modified Air Cooler With Split Cooling Unit (Original)Document41 pagesModified Air Cooler With Split Cooling Unit (Original)girish100% (4)

- Sangio Aquaflow HDPE Brochure 12 PageDocument12 pagesSangio Aquaflow HDPE Brochure 12 PageMohammed sabatin100% (1)

- India's Sugar Technology Mission drives industry improvementsDocument2 pagesIndia's Sugar Technology Mission drives industry improvementssalmanabu25No ratings yet

- Flushing Air Conditioner ProcedureDocument3 pagesFlushing Air Conditioner Proceduredimchien100% (1)

- 349, Cat02-04 Eng GRP Rev05b Xp-Intelli-s.pdf0Document36 pages349, Cat02-04 Eng GRP Rev05b Xp-Intelli-s.pdf0sithulibraNo ratings yet

- Permatex Thread CompoundDocument1 pagePermatex Thread CompoundGolden LeopardsNo ratings yet

- C-9 Fender SystemDocument31 pagesC-9 Fender Systemanupbhansali2004No ratings yet

- Dodge BushingsDocument30 pagesDodge BushingstopirceanNo ratings yet

- Perkins 1100 SeriesDocument48 pagesPerkins 1100 Seriesjrodríguez_658168100% (4)

- University of Texas Report On Galvanized Slip Coefficients Draft Final 4915Document37 pagesUniversity of Texas Report On Galvanized Slip Coefficients Draft Final 4915Jay ZengNo ratings yet

- Bill of Materials Cast Iron Double Door Foot ValveDocument1 pageBill of Materials Cast Iron Double Door Foot ValveTanmoy DuttaNo ratings yet