Professional Documents

Culture Documents

Flange Design Mmcobc 3.1 2010

Uploaded by

bakellyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flange Design Mmcobc 3.1 2010

Uploaded by

bakellyCopyright:

Available Formats

27-March-2012

ASME BPVC-VIII-1 (2010)

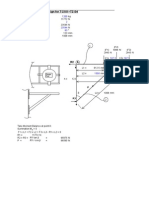

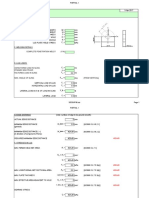

DESIGN OF CIRCULAR STEEL FLAT-FACE FLANGE WITH METAL-TO-METAL CONTACT OUTSIDE THE BOLT CIRCLE - INTEGRAL TYPE FLANGE & BLIND FLANGE WITH SELF-SEALING GASKET LOCATION: REFERENCE DRAWING: DESIGN CONDITIONS: DESIGN CODE =

ASME BPVC SECT. VIII - DIV. 1 [2010] [CLASS 3 ASSEMBLY / CATEGORY 1 FLANGE] C MPa

DESIGN TEMPERATURE DESIGN PRESSURE NON-REDUCING FLANGE MATERIAL DATA: FLANGE MATERIAL DESIGN TENSILE STRENGTH @ AMBIENT DESIGN TENSILE STRENGTH @ DESIGN TEMP. HUB MATERIAL: DESIGN TENSILE STRENGTH @ AMBIENT DESIGN TENSILE STRENGTH @ DESIGN TEMP. MODULUS OF ELASTICITY @ OPERATING TEMP. BLIND FLANGE MATERIAL DATA: PLATE MATERIAL DESIGN TENSILE STRENGTH @ AMBIENT DESIGN TENSILE STRENGTH @ DESIGN TEMP. MODULUS OF ELASTICITY @ OPERATING TEMP. BOLT/STUD DATA: MATERIAL PROOF STRENGTH DESIGN TENSILE STRENGTH @ AMBIENT DESIGN TENSILE STRENGTH @ DESIGN TEMP. MODULUS OF ELASTICITY @ OPERATING TEMP. NOMINAL DIAMETER AREA NO. OF THREADED ENDS (BOLT = 1 STUD = 2) FLANGE DIMENSIONS (REFER FIG. Y-3.2 FOR NOTATION): OUTSIDE DIAMETER INSIDE DIAMETER BOLT CIRCLE DIAMETER THICKNESS OF HUB @ SMALL END THICKNESS OF HUB @ BACK OF FLANGE HUB LENGTH (h > 0) NO. OF BOLTS BOLT HOLE DIAMETER GASKET DATA: MATERIAL DIAMETER GASKET FACTOR MIN DESIGN SEATING STRESS OUTSIDE DIAMETER INSIDE DIAMETER DIA. @ LOCATION OF GASKET LOAD REACTION BOLT-FORCES / MOMENT ARMS (REFER FIG. Y-3.2 FOR NOTATION): HYDROSTATIC END-FORCE H'STATIC END FORCE ON AREA I/S OF FLANGE GASKET LOAD HYDROSTATIC END FORCE MOMENT ARM MOMENT ARM MOMENT ARM FLANGE MOMENTS: MOMENT MOMENT MOMENT MOMENT

= P=

= Sf = Sf = = Sn = Sn = EI =

MPa MPa MPa MPa MPa

SECT II-D T (1A) SECT II-D T (1A) SECT II-D T (1A) SECT II-D T (1A) SECT II-D T (TM-1)

= Sf = Sf = EII =

MPa MPa MPa

SECT II-D T (1A) SECT II-D T (1A) SECT II-D T (TM-1)

Fy Sa Sb E db Ab/n

= = = = = = = =

MPa MPa MPa MPa mm mm

SECT II-D T (3) SECT II-D T (3) SECT II-D T (TM-1)

A B C go g1 h n D

= = = = = = = =

mm mm mm mm mm mm mm

F (Y-3.2) F (Y-3.2) F (Y-3.2)

C (Y.3(a)) F (Y-3.2)

= = m= y= = = G=

mm MPa mm mm 0.0 mm T (2-5.1) T (2-5.1)

F (Y-3.2)

H= HD HG HT hD hG hT = = = = = =

0 N 0 0 0 0.0 0.0 0.0 N N N mm mm mm

C (Y.3(a)) C (Y.3(a)) C (Y.3(a)) C (Y.3(a)) T (2.6) T (2.6) T (2.6)

MD = MG = MT = MP=

0 N.mm 0 N.mm 0 N.mm 0 N.mm

C (Y.3(a)) C (Y.3(a)) C (Y.3(a)) C (Y.3(a))

90078849.xls.ms_office

Page 1

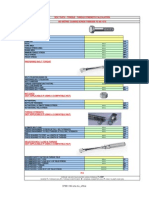

SUGGESTED TRIAL VALUES: FLANGE THICKNESS FLANGE THICKNESS FLANGE THICKNESS BOLT AREA SUGGESTED SUGGESTED SUGGESTED SUGGESTED TRIAL FLANGE THICKNESS TRIAL BLIND FLANGE THICKNESS TOTAL AREA OF BOLTS AREA OF BOLT

ta = tb = tc = A b' = tI tII Ab Ab/n = = = =

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

mm mm mm mm mm mm mm mm 0 mm

E (39) E (40) C Y.9(b)) E (42) T T T T (Y-9.1) (Y-9.1) (Y-9.1) (Y-9.1)

RADIAL DIST. FROM B.C.D. TO BEARING CIRCLE SELECTED VALUES: SELECTED FLANGE THICKNESS SELECTED BLIND FLANGE THICKNESS SELECTED AREA OF BOLT RADIAL DIST. FROM B.C.D. TO BEARING CIRCLE

hC =

C Y-4(a)(2)

tI = tII = Ab/n = hC = hCmax = =

mm mm 0 mm mm 0 mm mm

C (Y.3(a))

THICKNESS OF WASHERS, ETC MISCELLANEOUS CALCULATIONS:

g1/go = ho = h/ho = K= T= U= Y= Z= F= V= f= e= d= L= B1 = SHAPE FACTOR SHAPE FACTOR BOLT HOLE ASPECT RATIO a AR rB = = = = #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

#DIV/0! 0.0 #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

C Y.3(a) F 2-7.1 F 2-7.1 F 2-7.1 F 2-7.1 F 2-7.1 T 2-7.1 T 2-7.1 T 2-7.1 C Y.3(a) C Y.3(a) C Y.3(a) C Y.3(a) C C C C (Y.3(a)) (Y.3(a)) (Y.3(a)) (Y.3(a))

Jp = Js = CALCULATED STRAIN LENGTH OF BOLT ELASTICITY FACTOR l= rEI = F I' = FACTOR FACTOR FACTOR FACTOR RIGID BODY ROTATION OF FLANGES TIMES E*: FACTOR FACTOR FACTOR C1 C2 C3 C4 = = = =

C (Y.3(a)) C (Y.3(a)) 0.0 mm C (Y.3(a)) C (Y.3(a)) E (6a) E E E E (1) (2) (3) (4)

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

E I* = EII* = X= EI*.rbI = EII*rbII =

0 0 #DIV/0! #DIV/0! #DIV/0!

C (Y.3(a)) C (Y.3(a)) C (Y.3(a)) E (17) E (18)

TOTAL FLANGE MOMENT AT DIAMETER B 1: MSI = MSII = #DIV/0! #DIV/0! N.mm N.mm E (19) E (20)

90078849.xls.ms_office

Page 2

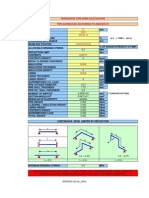

UNBALANCED FLANGE MOMENT AT DIAMETER B 1: MuI = MuII = BALANCED FLANGE MOMENT AT DIAMETER B 1: MbI = MbII = SLOPE OF FLANGE AT DIAMETER B 1 TIMES E: FLANGE I: SLOPE #DIV/0! #DIV/0! N.mm N.mm E (23) E (24) #DIV/0! #DIV/0! N.mm N.mm E (21) E (22)

EI.BI =

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

MPa.rad rad deg MPa.rad rad deg

E (25)

BI = =

EIIBII =

FLANGE II: SLOPE

E (26)

BII = =

CONTACT FORCE BETWEEN FLANGES AT h C: HC = BOLT LOAD AT OPERATING CONDITIONS: W m1 = BOLT AREAS: REQUIRED BOLT-AREA TOTAL BOLT-AREA OPERATING BOLT STRESS: #DIV/0! N E (28) #DIV/0! N E (27)

Am = Ab =

#DIV/0!

mm2 0 mm2

C (Y-4(b))

b =

DESIGN PRESTRESS IN BOLTS: Si = % OF BOLT PROOF STRESS TYPE OF LUBRICANT NUT FACTOR (TORQUE CO-EFFICIENT) BOLT PRELOAD BOLT TORQUE RADIAL STRESS IN FLANGE I AT BOLT CIRCLE: SRI = RADIAL STRESS IN FLANGE I AT INSIDE DIAMETER: SRI = TANGENTIAL STRESS IN FLANGE I AT INSIDE DIAMETER: STI = LONGITUDINAL HUB STRESS IN FLANGE I : SHI = (SHI+SRI)/2 = (SHI+STI)/2 = RADIAL STRESS IN FLANGE II AT BOLT CIRCLE: SRII = RADIAL STRESS IN FLANGE II AT DIAMETER B 1: SRII = TANGENTIAL STRESS IN FLANGE II AT DIAMETER B 1: STII = RADIAL & TANGENTIAL STRESS AT CENTRE OF FLANGE II: SRII = STII = = = = = =

#DIV/0!

MPa

E (29)

#DIV/0! #DIV/0!

MPa %

E (30)

#DIV/0! #DIV/0!

kN N.m

#DIV/0!

MPa

E (31)

#DIV/0!

MPa

E (32a)

#DIV/0!

MPa

E (33a)

#DIV/0! #DIV/0! #DIV/0!

MPa MPa MPa

E (34a)

#DIV/0!

MPa

E (35)

#DIV/0!

MPa

E (36)

#DIV/0!

MPa

E (37)

#DIV/0!

MPa

E (38)

90078849.xls.ms_office

Page 3

ALLOWABLE FLANGE DESIGN STRESSES: BOLTS: Sb FLANGE I: SR ST SH (SH+SR)/2 (SH+ST)/2 FLANGE II: SR ST DESIGN SUMMARY: FLANGE I STRESSES FLANGE II STRESSES BOLT STRESS = = 0.0 MPa 0.0 MPa C (Y-7(c)) C (Y-7(d)) = = = = = 0.0 0.0 0.0 0.0 0.0 MPa MPa MPa MPa MPa C C C C C (Y-7(c)) (Y-7(d)) (Y-7(b)(1)) (Y-7(e)) (Y-7(e)) = 0.0 MPa C (Y-7(a))

Sact/Sall = Sact/Sall = sb/Sb =

#DIV/0! #DIV/0! #DIV/0!

90078849.xls.ms_office

Page 4

A = C =

#DIV/0! #DIV/0!

C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37

= = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = =

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

E E E E E E

1 2 3 4 5 6

= = = = = =

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

You might also like

- Flange Design Mmcobc 3.3 2010Document3 pagesFlange Design Mmcobc 3.3 2010bakellyNo ratings yet

- Radial Thrust CalculatorDocument2 pagesRadial Thrust CalculatorkbasawaNo ratings yet

- U-V-673 - Manual Flange and GussetDocument8 pagesU-V-673 - Manual Flange and GussetDarshan PanchalNo ratings yet

- Desuperheater Boiler Feed Water RequirementDocument2 pagesDesuperheater Boiler Feed Water RequirementMichael HaiseNo ratings yet

- Reff: A Text Book of Machine Design - Chapter 10, RS. KHURMIDocument5 pagesReff: A Text Book of Machine Design - Chapter 10, RS. KHURMIAsep MulyadiNo ratings yet

- Axial ThrustDocument2 pagesAxial ThrustGerman ToledoNo ratings yet

- Calculations For: Calculations No. Asme Viii Div 1 Ed 2019Document21 pagesCalculations For: Calculations No. Asme Viii Div 1 Ed 2019David Vanegas100% (1)

- Normalizing NPSH: Calculating Suction Specific SpeedDocument5 pagesNormalizing NPSH: Calculating Suction Specific Speedorchids28No ratings yet

- Reciprocating Pump (Api 674-2Nd) Data Sheet U.S. Customary UnitsDocument10 pagesReciprocating Pump (Api 674-2Nd) Data Sheet U.S. Customary UnitsÆmanuel J Silva100% (1)

- Calculating pump head and specific speed using Euler's equationDocument9 pagesCalculating pump head and specific speed using Euler's equationspdhimanNo ratings yet

- Cone Development CalcDocument2 pagesCone Development CalcbabuNo ratings yet

- 0.0bolt Torque Calculation - R0Document9 pages0.0bolt Torque Calculation - R0Darshan PanchalNo ratings yet

- NASA CC3 ImpellerDocument22 pagesNASA CC3 ImpellerPaul BarlowNo ratings yet

- LESON 3.4 Forces & PressureDocument5 pagesLESON 3.4 Forces & PressureRais RahimiNo ratings yet

- Clearance CalculationDocument12 pagesClearance CalculationshazanNo ratings yet

- Af KSB 049-1504103-045Document3 pagesAf KSB 049-1504103-045johannes angga panjaitanNo ratings yet

- Calculation of PipeReinforcement ASMEB31 1Document4 pagesCalculation of PipeReinforcement ASMEB31 1threedlabsNo ratings yet

- Is 202 Pipe StiffnessDocument4 pagesIs 202 Pipe StiffnessshrwncmNo ratings yet

- API 682 Accumulator Data SheetDocument1 pageAPI 682 Accumulator Data SheetBhyrappaNo ratings yet

- Nozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)Document17 pagesNozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)SingoNo ratings yet

- 2004A Rev 7Document78 pages2004A Rev 7Sri Dhar0% (1)

- Pipe Thickness & RF Pad Calculations As Per Asme b313Document3 pagesPipe Thickness & RF Pad Calculations As Per Asme b313Gaurav BhendeNo ratings yet

- Sa516 70Document3 pagesSa516 70Thinh ViproNo ratings yet

- Design of Pressure Vessel Cone under Internal & External PressureDocument391 pagesDesign of Pressure Vessel Cone under Internal & External Pressureantonio gutierrezNo ratings yet

- Calculation For Gauge Pole SupportsDocument7 pagesCalculation For Gauge Pole SupportsrichardchiamNo ratings yet

- Press Fit Pressure CalculatorDocument4 pagesPress Fit Pressure CalculatorBhadresh ShahNo ratings yet

- Pipe Elbow PaperDocument7 pagesPipe Elbow PaperP_I_P_HNo ratings yet

- Checking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumberDocument1 pageChecking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumbershazanNo ratings yet

- Pressure & Temperature ClassificationDocument1 pagePressure & Temperature Classificationkeo85100% (1)

- Welding Neck Flanges 1Document3 pagesWelding Neck Flanges 1bikkelbobNo ratings yet

- Compress EvaluateDocument23 pagesCompress EvaluateVishalDhiman100% (1)

- API 650 5.11.2 and F.4.2 Uplift CriteriaDocument1 pageAPI 650 5.11.2 and F.4.2 Uplift Criteriaonin007No ratings yet

- Calculator - U Tubes - HSA & QtyDocument4 pagesCalculator - U Tubes - HSA & QtyRey Fiedacan100% (1)

- Calculation of RC PAD2Document1 pageCalculation of RC PAD2m 418No ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- WI06-0260 Calculations For Obround Nozzle ConnectionsDocument4 pagesWI06-0260 Calculations For Obround Nozzle ConnectionskumarNo ratings yet

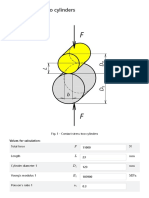

- Contact Stress Two CylindersDocument3 pagesContact Stress Two Cylindersmet-calcNo ratings yet

- Topic - Tension MembersDocument28 pagesTopic - Tension MembersNikola Arsovski100% (1)

- Pulsating Heat Pipe ReportDocument65 pagesPulsating Heat Pipe ReportIdul Azharul HoqueNo ratings yet

- An Analysis On The Pressure Loss Through Perforated Plates at Moderate Reynolds NumberDocument8 pagesAn Analysis On The Pressure Loss Through Perforated Plates at Moderate Reynolds NumberapitbhuNo ratings yet

- WRC 107 Stress Calculation For Sustained Loads:: Dimensionless Loads For Cylindrical Shells at Attachment JunctionDocument5 pagesWRC 107 Stress Calculation For Sustained Loads:: Dimensionless Loads For Cylindrical Shells at Attachment JunctionmsmrizhwanNo ratings yet

- Questions Related To Stress Analysi1Document12 pagesQuestions Related To Stress Analysi1Jagadish JasNo ratings yet

- Nozzle Load CheckDocument4 pagesNozzle Load CheckpipestressNo ratings yet

- Design Pressure and Temperature for Flanges and GasketsDocument4 pagesDesign Pressure and Temperature for Flanges and GasketsSergio SmithNo ratings yet

- NozzleDocument11 pagesNozzleharyfadlyNo ratings yet

- Cone Development CalculationsDocument5 pagesCone Development CalculationssaudimanNo ratings yet

- Internal Pipe Distributor Design ProcedureDocument5 pagesInternal Pipe Distributor Design Proceduresenthil kumarNo ratings yet

- Asme - Shell External Pressure REV ADocument1 pageAsme - Shell External Pressure REV APohn Myint HanNo ratings yet

- Correlation table for two-phase flow modelsDocument4 pagesCorrelation table for two-phase flow modelssouthliNo ratings yet

- PSVDocument3 pagesPSVDhananjay NilkuteNo ratings yet

- Calculo de Brida Segun ASMEDocument29 pagesCalculo de Brida Segun ASMEakarcz6731No ratings yet

- Thk. S.F. K.R.: Dish - Dish 2100Document3 pagesThk. S.F. K.R.: Dish - Dish 2100jayvant jadhavarNo ratings yet

- Steel Heads of Vesse SDocument18 pagesSteel Heads of Vesse SAshu DinNo ratings yet

- KSB Know-How, Volume 0 - Selecting-Centrifugal-Pumps-data PDFDocument92 pagesKSB Know-How, Volume 0 - Selecting-Centrifugal-Pumps-data PDFRodrigo Astudillo AedoNo ratings yet

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7From EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7No ratings yet

- Company Name: Calculation SheetDocument7 pagesCompany Name: Calculation SheetVenkatesha HebbarNo ratings yet

- UG-37 F FactorDocument7 pagesUG-37 F FactorjamesNo ratings yet

- Design Parameter:-Geo-ParameterDocument50 pagesDesign Parameter:-Geo-ParameterpandyatusharNo ratings yet

- Stair CaseDocument15 pagesStair CasePremasiri KarunarathnaNo ratings yet

- Horizontal Cylindrical Pressure Vessvessel Zick 03Document12 pagesHorizontal Cylindrical Pressure Vessvessel Zick 03bakelly0% (1)

- Yield Strength 01Document2 pagesYield Strength 01bakellyNo ratings yet

- Linear Thermal Expansion b4 2010Document2 pagesLinear Thermal Expansion b4 2010bakellyNo ratings yet

- Lifting Lug Design AnalysisDocument22 pagesLifting Lug Design AnalysisbakellyNo ratings yet

- Metric Bolt Data - Torque - Thread StrengthDocument10 pagesMetric Bolt Data - Torque - Thread StrengthbakellyNo ratings yet

- Expansion Loop Flexibility Analysis (Weaver)Document3 pagesExpansion Loop Flexibility Analysis (Weaver)bakellyNo ratings yet

- Metric Bolt Torque - Thread StrengthDocument7 pagesMetric Bolt Torque - Thread StrengthbakellyNo ratings yet

- Youngs Modulus b3 2010Document2 pagesYoungs Modulus b3 2010bakellyNo ratings yet

- Asme BPVC II Part D Material Strengths 01Document7 pagesAsme BPVC II Part D Material Strengths 01bakellyNo ratings yet

- Monorail Beam Design 07Document5 pagesMonorail Beam Design 07bakellyNo ratings yet

- Bolt Torque ASME B16.5 Flanges - Sheet Gaskets 02Document26 pagesBolt Torque ASME B16.5 Flanges - Sheet Gaskets 02bakelly100% (7)

- Bolt Torque ASME B16.5 Flanges - Spiral Wound GasketsDocument31 pagesBolt Torque ASME B16.5 Flanges - Spiral Wound Gasketsbakelly100% (5)

- Pipe Pressure RatingDocument1 pagePipe Pressure RatingbakellyNo ratings yet

- ASME B16.5 Class 150 & 300 Flanges Studbolt LengthDocument3 pagesASME B16.5 Class 150 & 300 Flanges Studbolt LengthbakellyNo ratings yet

- Metric Bolt Data - Torque - Thread StrengthDocument10 pagesMetric Bolt Data - Torque - Thread StrengthbakellyNo ratings yet

- Pipe Span Without Point LoadsDocument36 pagesPipe Span Without Point Loadsbakelly100% (4)

- Pipe Span Without Point LoadsDocument36 pagesPipe Span Without Point Loadsbakelly100% (4)

- Bolt Torque ASME B16.5 Flanges - Sheet Gaskets 02Document26 pagesBolt Torque ASME B16.5 Flanges - Sheet Gaskets 02bakelly100% (7)

- Design of Flanges - Welded-On Integral Type 2010Document59 pagesDesign of Flanges - Welded-On Integral Type 2010bakellyNo ratings yet

- Design of Flanges - Loose Type 2010Document53 pagesDesign of Flanges - Loose Type 2010bakellyNo ratings yet

- Design of Flanges - Optional Type 2010Document59 pagesDesign of Flanges - Optional Type 2010bakellyNo ratings yet

- Design of Flanges - Weld Neck Type 2010Document58 pagesDesign of Flanges - Weld Neck Type 2010bakellyNo ratings yet

- Design of Flanges - Loose Hub Type 2010Document58 pagesDesign of Flanges - Loose Hub Type 2010bakellyNo ratings yet

- Flange Design Mmcobc 1.1 2010Document5 pagesFlange Design Mmcobc 1.1 2010bakellyNo ratings yet

- Flange Design Mmcobc 1.3 2010Document3 pagesFlange Design Mmcobc 1.3 2010bakellyNo ratings yet

- Design of Flanges - Full-Face Gasket 2010Document29 pagesDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)