Professional Documents

Culture Documents

Artikel Pangan 2

Uploaded by

Muhammad Irsan KurniawanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Artikel Pangan 2

Uploaded by

Muhammad Irsan KurniawanCopyright:

Available Formats

Preservatives in liquid pharmaceutical preparations

by Chawki Boukarim, Sarah Abou Jaoude, Rita Bahnam, Roula Barada, Soula Kyriacos

INTRODUCTION Preservatives have been commonly used as additives in pharmaceutical products, cosmetics, and food. Liquid preparations are particularly susceptible to microbial growth because of the nature of their ingredients. Such preparations are protected by the addition of preservatives that prevent the alteration and degradation of the product formulation.' Preservatives are mainly effective in controlling mold, inhibiting yeast growth, and protecting against bacterial proliferation. Their antimicrobial and antifungal properties make them an integral part of the product formulation. Among the most commonly used preservatives in the conservation of liquid pharmaceutical preparations are sodium benzoate, potassium sorbate, and methyl hydroxybenzoate (methylparaben). Their typical allowed concentrations range respectively from 0.1-0.2%,0.1-0.2%, and 0.1-0.25% (w/w). (1) The purpose of this study is to determine the amount of the former preservatives in liquid pharmaceuticals for quality assurance purposes as well as for patient safety. Accrued interest is given to preservatives as recent studies have reported serious side effects associated with these substances. Skin reactions such as rash, urticaria, and contact dermatitis have been reported after topical application of potassium sorbate, methylparaben,- and sodium benzoate-containing products. (1,2,3) Other side effects have been reported after ingestion of medications containing these preservatives such as the allergic potential and estrogenic potential of parabens, (2,4) or the genotoxic activity potential of sodium benzoate. (3) MATERIALS AND METHODS Thirty seven liquid pharmaceutical preparations were purchased from randomly selected pharmacies in Lebanon. Not all preparations were labeled with respect to their preservative content: 19, 8, and 1 preparation(s) were labeled for their methylparaben, sodium benzoate, and potassium sorbate content respectively, while 14 preparations were unlabeled with respect to one or more preservatives. Commercial brands of the liquid preparations were coded using letters (A to AL). Acetonitrile (HPLC grade) and sodium acetate (analytical grade) were purchased from Sigma, Germany. Sodium benzoate, potassium sorbate, and methylparaben standards were purchased from Fluka, UK. Standards were used to prepare standard working solutions using distilled water, to obtain stock solutions of 1 g/L concentration. Stock solutions were used to prepare solutions of lower concentrations (50, 100, 200, and 400 mg/L) to build the calibration curve. The correlation coefficients were above 0.999 in all cases. Preparations were analyzed in triplicate for their preservative content using a sensitive and reproducible HPLC method (5-8) modified in our laboratory. The HPLC system consisted of LC-10 pump (Shimadzu), a variable ultraviolet detector monitor set at 229 nm (Shimadzu, SPD-10), and a Chromatopac Shimadzu (C-R8A) integrator. Separation was done using a pre-packed stainless steel column (15 cm x 0.46 cm) filled with Shimpack C18 10 hum Silica (Waters, Germany), and the flow rate was set to 1.5 mL per

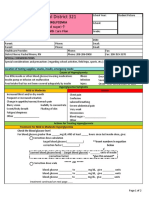

minute for sodium benzoate and potassium sorbate and 2 mL/min for methylparaben. The precision of the assay method was determined by calculating the relative standard deviation (inter- and intea-days) of the peak areas obtained after repeated injections (n=3) of all standard solutions. The relative standard deviations of the areas were found to be less than 3.5%, which confirms the precision of the method. One gram of each of the samples was accurately weighed and transferred to a 100 mL volumetric flask. Mobile phase was added to volume and mixed. The mobile phase was an aqueous solution of acetonitrile 0.02 M sodium acetate buffer (20:80, v/v), adjusted to a pH 4.3 with acetic acid. The mobile phase was filtered through a 0.45 Im filter and degassed before use. Twenty microliters of the filtrate were injected into the HPLC. The retention times for sodium benzoate, potassium sorbate and methylparaben were 5.2, 6.7, and 7.6 minutes, respectively. RESULTS AND DISCUSSION In the eight samples labeled as containing sodium benzoate as a preservative, concentrations of the latter ranged between 0.012 - 0.85 % (w/w). Two samples (A and G) included sodium benzoate in amounts significantly exceeding the typical allowed concentrations (up to four-fold difference) whereas two other products had a sodium benzoate concentration slightly exceeding that range (Figure 1). After screening the 12 unlabeled samples, six were found to contain sodium benzoate in concentrations ranging from 0.05-0.48 % (w/w). Only Product K contained the preservative in concentrations above the typical allowed concentrations (Figure 2). Two products exhibited sodium benzoate concentrations below typical allowed concentrations. Additionally, as much as 50% of the pharmaceutical products containing sodium benzoate are formulated at a pH>5, at which the preservative is ineffective. As for potassium sorbate, the only labeled product included a higher amount of preservative. Many unlabeled samples were found to contain potassium sorbate as a preservative. As shown in Figure 3, products E and O exceeded the typical allowed concentrations for its use. Nineteen samples were labeled as having methylparaben as a preservative. It was found in concentrations ranging from 0.03-0.55 % (w/w). Only one labeled product included methylparaben in concentration exceeding the maximal allowed amount and 14 out of the 19 samples had concentrations below the allowed range (Figure 4). None of the unlabeled samples exhibited concentrations exceeding the typical allowed range (Figure 5). All, however, had their methylparaben concentration below the allowed range. CONCLUSION Preservatives levels were found to fall outside the typical allowed concentration range for 70% of the samples, with some exhibiting significant higher concentrations. The present study highlights the high amount of preservatives that may be found in some liquid pharmaceutical preparations. The reason behind such finding is unclear and could be due to poor quality control or to intentionally extend the shelf life of the products. Consequences to patients' health need to be evaluated, especially since most liquid pharmaceutical products are administered to the pediatric population. ACKNOWLEDGEMENTS This work was supported by a grant from the Research Council at the Lebanese American University.

REFERENCES

(1.) E Beringer, A. derMarderosian, L. Felton, et al. Remington: The Science and Practice of Pharmacy, 21" edition, Lippincott Williams & Wilkins, Philadelphia, 2006. (2.) M.G. Soni, I.G. Carabin, G.A. Burdock. Safety Assessment of esters of p-hydroxybenzoic acid (parabens). Food. Chem 9)xicol. 43(7): 985-1015 (2005). (3.) B. Nair. Final Report on the Safety Assessment of Benzyl Alcohol, Benzoic Acid, and Sodium Benzoate. Int.JToxicol. 20 (Suppl 3): 23-50 (2001). (4.) M.G. Soni, S.L. Taylor, N.A. Greenberg, G.A. Burdock. Evaluation of the health aspects of methyl paraben: a review of the published lit erature. Food Chem Toxicol. 40(10):1335-73 (2002). (5.) G. Shabir. Determination of combined phydroxy benzoic acid preservatives in a liquid pharmaceutical formulation by HPLC. J Pharm Biomed. Anal. 34:207-213 (2004). (6.) D. Satinsky, J. Huclova, R.L.C. Ferreira, et al. Determination of ambroxol hydrochloride, methylparaben and benzoic acid in pharma ceutical preparations based on sequential injection technique coupled with monolithic column. J Pharm Biomed. Anal. 40:287-293 (2006). (7.) H.M. Pylypiw Jr., M.T. Grether. Rapid highperformance liquid chromatography method for the analysis of sodium benzoate and potassium sorbate in foods. Journal of Chromatography A. 883: 299-304 (2000). (8.) K. Kuprovskyt?, B. Pranaityt?, and A. Padarauskas. Isocratic HPLC determination of preservatives in beverages. Chemija (Vilnius). T.13, Nr. 3 (2002). Chawki Boukarim,* Sarah Abou Jaoude, Rita Bahnam, Roula Barada, Soula Kyriacos Department of Pharmaceutical Sciences, School of Pharmacy, Lebanese American University, Byblos, Lebanon.

You might also like

- Calcium Oxalate Dyhidrat (NIOSH) PDFDocument6 pagesCalcium Oxalate Dyhidrat (NIOSH) PDFMuhammad Irsan KurniawanNo ratings yet

- English Course AssignmentDocument4 pagesEnglish Course AssignmentMuhammad Irsan KurniawanNo ratings yet

- Back Up Sanitasi BelfoodDocument2 pagesBack Up Sanitasi BelfoodMuhammad Irsan KurniawanNo ratings yet

- CV MIKDocument2 pagesCV MIKMuhammad Irsan KurniawanNo ratings yet

- ConclusionDocument1 pageConclusionMuhammad Irsan KurniawanNo ratings yet

- Two Treatises of GovernmentDocument116 pagesTwo Treatises of GovernmentMartin SyjucoNo ratings yet

- Tug As 4Document6 pagesTug As 4Muhammad Irsan KurniawanNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Srs 30 PDFDocument3 pagesSrs 30 PDFMichelle Joy Delos ReyesNo ratings yet

- SO - APOTEK VIVA GENERIK DUKUH SETRO (21 May 2014)Document84 pagesSO - APOTEK VIVA GENERIK DUKUH SETRO (21 May 2014)Diditz Putera Bangsa100% (1)

- DEA Pharmacists Manual 2022Document124 pagesDEA Pharmacists Manual 2022TammyNo ratings yet

- Shana McTee Probable Cause StatementDocument2 pagesShana McTee Probable Cause StatementAdam Forgie50% (2)

- Pre/Post Operative Care Breast AugmentationDocument10 pagesPre/Post Operative Care Breast AugmentationMaci HalalujkaNo ratings yet

- DMC FinalsDocument64 pagesDMC Finalskaye agustinNo ratings yet

- Dream Job AssignmentDocument3 pagesDream Job Assignmentapi-354947009No ratings yet

- Supac by DGDocument39 pagesSupac by DGRitesh GhasadiyaNo ratings yet

- Pharam GuideDocument4,386 pagesPharam Guideابُوالبَتُول ڈاکٹر صفدر علی قادری رضوی100% (1)

- Chapter 11 Parenteral Drug Calculations PDFDocument42 pagesChapter 11 Parenteral Drug Calculations PDFjames smithNo ratings yet

- ST UWH I 16Document146 pagesST UWH I 16Lina Ramadhani Anan AsrawiNo ratings yet

- GEMS Chronic Medicine Benefit Application PDFDocument4 pagesGEMS Chronic Medicine Benefit Application PDFBUYELWANo ratings yet

- Drugs & Pharmaceutical Technology HandbookDocument13 pagesDrugs & Pharmaceutical Technology Handbookإلياس صادقNo ratings yet

- Type Drug ChartDocument3 pagesType Drug ChartKarina Rodriguez100% (3)

- Missouri Counties Sue Drug Companies Over Opioid CrisisDocument274 pagesMissouri Counties Sue Drug Companies Over Opioid CrisisSam ClancyNo ratings yet

- Visit To The Doctor Role PlayDocument5 pagesVisit To The Doctor Role PlayMaria MolinaNo ratings yet

- Orthosiphon Stamineus: Ethnopharmacology, Extraction & Bioprocesses and Anti-Cancer ActivitiesDocument21 pagesOrthosiphon Stamineus: Ethnopharmacology, Extraction & Bioprocesses and Anti-Cancer ActivitiesqabasssNo ratings yet

- Medicaid: Health Policy BriefDocument2 pagesMedicaid: Health Policy BriefArnold VenturesNo ratings yet

- Drug LisinoprilDocument1 pageDrug LisinoprilSrkocherNo ratings yet

- Benzyl Alcohol (BA) As A Disinfectant & Dry Heat Sterilization of GlasswareDocument4 pagesBenzyl Alcohol (BA) As A Disinfectant & Dry Heat Sterilization of GlasswareVinicius AlvesNo ratings yet

- EP Web Catalog CRS PDFDocument84 pagesEP Web Catalog CRS PDFramaiaNo ratings yet

- Diabetes Hyperglycemia Emergency Care PlanDocument2 pagesDiabetes Hyperglycemia Emergency Care Planapi-405196113No ratings yet

- LAMOTRIGINEDocument9 pagesLAMOTRIGINEDiffa RahmanNo ratings yet

- Clinica Applications of Mass Spectrometry in Drug Analysis - Methods and Protocols GARG 2016 PDFDocument289 pagesClinica Applications of Mass Spectrometry in Drug Analysis - Methods and Protocols GARG 2016 PDFjavier chavezNo ratings yet

- Dry Powders, Capsules, and LozengesDocument18 pagesDry Powders, Capsules, and LozengesKurt JarlosNo ratings yet

- OBcheetsheetDocument6 pagesOBcheetsheetapi-3807143No ratings yet

- GP Manual FinalDocument111 pagesGP Manual Finalskumara0% (1)

- Formularium Nasional: Analgetik Non NarkotikDocument2 pagesFormularium Nasional: Analgetik Non Narkotikyauminnisa hapsariNo ratings yet

- Tylenol Acetaminophen)Document3 pagesTylenol Acetaminophen)ENo ratings yet

- GIT DrugsDocument180 pagesGIT DrugsMaria Linevel Balderamos Dalida100% (1)