Professional Documents

Culture Documents

Grinding by A Proven Concept Makes Your Choice Simple

Uploaded by

Milling and Grain magazineOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Grinding by A Proven Concept Makes Your Choice Simple

Uploaded by

Milling and Grain magazineCopyright:

Available Formats

Digital Re-print - March | April 2012

Grinding by a proven concept makes your choice simple

Grain & Feed Milling Technology is published six times a year by Perendale Publishers Ltd of the United Kingdom. All data is published in good faith, based on information received, and while every care is taken to prevent inaccuracies, the publishers accept no liability for any errors or omissions or for the consequences of action taken on the basis of information published. Copyright 2010 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. Printed by Perendale Publishers Ltd. ISSN: 1466-3872

www.gfmt.co.uk

NEXT PAGE

FEATURE Two directions of rotation possible Motor capacities up to 400kW Open rotor design Temperature control on main bearings and chamber Feeder with magnet and stone trap Ergonomic design Already, five years ago, the Wynveen hammer mill underwent a complete makeover and there was the idea to develop a hammer mill that will be prepared for the future and can deal with the challenges of the future. This means minimal energy consumption and the possibility to answer to the

FEATURE

Grinding by a proven concept makes your choice simple

by Willem de Vaan, General Director, Wynveen International BV, The Netherlands

ogether with mixing and pelleting, grinding is one of the important processes when producing animal feed. Traditionally, hammer mills are used in the feed industry for grinding raw materials, which is mainly caused by the relatively simple construction and high variation in particle reduction compared to other techniques

60 tones/hour. For the smaller capacities the 3000-rpm versions are still used. In the enclosed table you will find the various possibilities. By introducing frequency control on the motor, it became possible to grind ideal structures and particle size. In fact you can create a new screen set-up but still using the same screen perforation. When using a high speed you are able to create fine grinding, while with a lower speed a coarser grinding is achieved.

the ergonomic design already available at the hammer mills with manual screen exchange, which means a horizontal movable screen cassette in which 4 screens (so also four different perforations selectable) are mounted. The big advantage versus vertical screen exchange is the space needed. Often an upper hopper is positioned above the hammer mill, which reduces the possibilities for vertical screen exchange. To avoid dust and waste of product during

Frequent changing

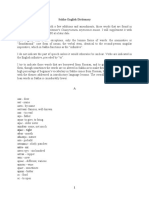

1 2 3 4 5 6 7 8 Magnet Air inlet Stone trap Material direction flap Pre braking plates Temperature sensor Screen Rotor met beaters

Table 1:

Type

450-150 650-275 650-375 650-550 670-750 670-1150 GHM-750 GHM-1000 GHM-1250

Capacity t/h*

1-2 2-3 3-5 7-12 15-20 20--30 20-35 30-50 45-60

Diameter Chamber

450 650 650 650 650 650 1200 1200 1200

*= depending on raw materials

used at roller mills and crackers. Roller mills and crackers showed better results when it comes to energy consumption, but the new designed mills feature adjustable pre-breaker plates, variable speed drives and automatic screen change systems. This results in an energy saving which brings the hammer mill again in a favoured position, certainly when taking in consideration the relatively high costs for wearing parts on roller mills and crackers. Given the fact that a hamLength RPM. mer mill also Chamber allows grinding of mixed 150 3000 products, 275 3000 it becomes 275 3000 clear that 550 3000 hammer mills 750 3000 still are the 1150 3000 majority. 750 1500 Wynveen 1000 1500 International BV has a rich 1250 1500 tradition in manufactur-

ing machines and equipment for the animal feed industry, petfood industry and fish industry. Recently the company has moved into its new premises, which means a doubling of the office and production floor compared to the old building. With this new office Wynveen International BV is prepared of the future and has made the logical next step to meet the growth targets it is aiming for. With its new website, introduced during the opening of the new building, one can see in a glance what capabilities can be offered. Besides the design and delivery of complete turnkey feed mills, Wynveen International BV is manufacturing the main equipment like hammer mills, mixers, coater and sifters and conveying equipment. Wynveen International BV is manufacturing hammer mills in a wide range. The features of the of hammer mills that can be delivered are: Big diameter 1200mm - 1500rpm Diameter 650mm - 3000rpm Capacities from 2t/h up to 60t/h Frequency controlled drives Manual or automatic screen exchange With or without adjustable breaker plates

Grain

need of the various applications required in nowadays-feed mills. Most animal feed mills are looking for a grinding concept that can produce the particle size that fits with the specific required coarseness of ingredients needed for the feed to produce. The latest version of the Wynveen hammer mills type GHM has a grinding chamber diameter of 1200mm, which gives at a speed of only 1500rpm a hammer tip speed at the ideal level of approximately 90m/seconds. The length of the chamber can vary from 750 to 1250mm, depending on the required capacity. The low speed gives a lower noise level, less wear and tear and lower bearing load compared to a 3000-rpm hammer mill. To suit the various demands in feed mill capacities, Wynveen International BV can deliver hammer mills that can deal with different capacities from two tones/hour up to

To answer the growing need for producing a great number of recipes, the screens need to be changed frequently, for which reason Wynveen has designed the GHM version with an optional automatic screen change system. This gives more possibilities to grind on various perforations without the need to stop the motor during production and loose a lot of production time. Wynveen has chosen to make use of

Your partner in technology, equipment and plants for animaland aqua feed and petfood.

VA C U U M C O AT E R

Wynveen International b.v. P.O. Box 38 6666 ZG Heteren The Netherlands

Tel: +31 (0)26 - 479 06 99 Fax: +31 (0)26 - 479 06 98 info@wynveen.com www.wynveen.com

march - april 2012 | 15

14 | march - april 2012

&feed millinG technoloGy

Grain

&feed millinG technoloGy

enables the use of very low doses of Exosex SPTab, a unique pheromone they are unable to locate females. product for stored product A male carrying Entostat powder active ingredient and has potential moth control, will be exclusively will form a mobile pheromone March - April 2012 distributed in Spain by Comercial dispenser, producing false ews Qumica Mass, a market leader in pheromone trails, which attract speciality chemicals for a range of additional males. industries including agriculture and Contact between the males ensures that the Entostat pest control. Commenting from Expocida, powder and the confusion s demand for non-GMO Foundation has recently become and preservation of the Amazon Michael products worldwide effect is automatically the highly and other high conservation value Niven, Exosects key the new custodian of passed account manager said, We have on, this process is called Autoincreases, a new not- successful ProTerra Certification areas (HCVAs). been working with Masshas well Confusion. This product helps for-profit organisation for been Standard against which non-GM The strength of ProTerra over a year and having recently processors to reduce and/or launched in The Netherlands to soy producers and supply chain Certification helps mitigate brands obtained the Europeanregistration eliminate insecticide sprays and support the Spanish food and feed suppliers have been certifying exposure and liability related to for use in post-harvest storage and consequently, reduces subsequent industries in sourcing sustainably millions of tonnes of soy for more GMOs and the full range of social food production, we are absolutely down-time in production and environmental issues. produced, non-genetically modified than six years. delighted to be launching here atin associated with fumigation andby It is anticipated that EU retailers The program, originally created grains, cereals and derivatives and spray regimes. already significantly and brands will use the new Expocida. soy. Cert ID, has particular Exosex SPTab* is a unique mating Exosex SPTab was first developed contributed to improving the ProTerra certification Trustmark the UK where was awarded disruption product forstakeholders insustainability ofitthe soy supply to identify on-pack to consumers Backed by industry the control of the five key stored product the UKs Societyanticipated that products produced without from both Europe and South chain. It is of Food Hygiene moths which infestFoundation Technology (SOFHT) Award for placing the ProTerra certification GMOs and according to advanced America, The ProTerra stored commodities including genetically Best new product in 2008 and was program under the governance sustainability practices. claims that the growth in cereals, cocoa, pulses and tobacco as an Agrow Awards finalistnon-profit modified crops is not only a risk to of an independent in 2009. well assafety and food security, but The product has since been rolled foundation, managed through Effect upon food flour mills, confectionary, herbs, spices, dried fruit and nut out throughout Europe where it causes a devastating impact on the a broad multi-stakeholder environment shocking now available in UK, France, production facilities.of farmers and isconsultation process, will amplify The truth about farming welfare and lives Exosex SPTab isin acountries Netherlands, Germany, Italy andas genetically modified soy capable small its application and effectiveness rural communities tablet as Brazil and Exosects now Spain. The product standing as of withstanding being drenched such consisting of Argentina, well further enhance its was also Entostatpowder formulated launched in Japan in 2011 and is from where millions of tonnes of an independent quality mark. in toxic pesticides and their effect with minute quantities ofoil are fully registered in the USA. ProTerra certification requires upon the environment and soil soymeal, soybeans and soy the female sex into the EU every year. Derived from a natural food grade a strict non-GMO limit of less fertility is shocking, says Augusto imported pheromone common to fiveFoundation is dedicated to wax whichpercent adventitious EU Freire, Managing Director of Cert than 0.1 is sustainably harvested The of the major moth pests of food processing; Plodia from palm trees, Entostat powder providing the agricultural and authorised GM contamination, ID Brazil. interpunctella, Ephestia tools that acts as a delivery system for atesting Understandably EU consumers strong traceability, PCR wide food industries with the elutella, Ephestia Kuehniella, Ephestia range of chemistry. points, as well are therefore sensitive about the they need to achieve improved at critical control Even through ofver y rights of impact of food production on figulilella, Cadra cautella. as protection the slight sustainability performance. The Exosex SPTab tablet works movement, it develops an As a result, The ProTerra workers and indigenous people people and the planet, and VERY

Tel: 02380 603939 Email: georgina.donovan@exosect.com

NEWS

Sustainably farmed non-GM crops on the agenda of new industry body

sensitive about GM in their foods. Richard Werran, Managing Director of Cert ID Europe adds, The aim of The ProTerra Foundation is to support the feed and food industries in supplying non-GM soy with improved sustainability performance. A rigorous cer tif ication programme such as ProTerra which addresses every aspect of the crops journey, from farm to fork can contribute significantly to this goal. As part of its educational agenda, the ProTerra Foundation is hosting a conference on April 24, 2012 at The Natural History Museum London. The conference will bring together participants from all stages of the soy supply chain, from South America, Asia and Europe including retailers, food manufacturers, feed suppliers, farmers and other stakeholders to explore in-depth the sustainability of the soy supply chain. More inforMation: The ProTerra Foundation

Website: www.proterrafoundation.org.

march - april 2012 | 31

Grain

&feed millinG technoloGy

ite we b s ou r Vi sit vigan.com www.

VIGAN manufactures dry agribulk materials handling systems:

Portable pneumatic conveyors or grain pumps (100 - 250 tph); Pneumatic Continuous barge & Ship Unloaders (160 - 800 tph); Mechanical Continuous Ship Unloaders (up to 1,500 tph); Mechanical loaders (up to 1,200 tph). as well as complete storage systems in ports and the agricultural industries.

From project design to complete turnkey bulk handling solutions and port terminals with mechanical and/or pneumatic Grain&feed millinG technoloGy reliable and cost effective equipment.

Latest references

PYEONGTAEK PORT

South Korea 1 NIV 400 tph On rails with cable reels

LATTAKIA PORT

Syria 2 Mobile T200 2 x 250 tph

march - april 2012 | 9

SWINOUJSCIE

Poland (BUNGE GROUP) 1 Loader 600 tph

An affiliate company of VAN DE WIELE group.

VIGAN Engineering s.a. Rue de lIndustrie, 16 B-1400 Nivelles (Belgium) Phone : +32 67 89 50 41 Fax : +32 67 89 50 60 Web : www.vigan.com E-mail : info@vigan.com

Ann A5 victam 0212.indd 1 Grain feed millinG technoloGy

&

21/02/12 | 7 march - april 2012 15:37:04

FEATURE The hammer mills of Wynveen International BV allow a drive motor up to 400kW. Furthermore, a so-called open rotor has been designed with two functions. One is to create sufficient stiffness and balance and secondly to minimise the temperature increase while grinding. For monitoring purposes the main bearings and the chamber are fitted with temperature sensors. All components can also be delivered in an Atex execution. To make use of all four corners of the hammers and reduce the downtime of the machine, the direction of rotation of the hammer mill can be changed and the rotor has double holes for the hammer axles. To ensure a good product entrance to the mill, a feeder is developed which contains an integrated, (automatically cleaned) magnet and a stone trap. This will make sure that possible metal parts and/or stones are prevented from ending up in the feed mix. The combination of the two makes the feeder unique.

Risk analyses

To meet the latest stringent guidelines of CE regulations, Wynveen International BV has conducted a risk analyses for its hammer mills. This has been done for both non-hazardous environments and ATEX environments. To meet both as a standard, the hammer mills are equipped with proper earthing and sensors to detect possible increase of heat. Where required we make use of a pressure release membrane and/or flame arrestors. For reducing the noise and vibration our hammer mills are provided with shock absorbers. Much attention was spent to the ergonomic aspect. By designing two big doors, the hammer mills are very easy accessible for screen and hammer exchange. Both doors easily roll sideways via a rail and wheels and are equipped with safety switches to make sure that no mistakes can be made during maintenance. Other important points to keep in mind when designing a grinding plant are not only the right choice of hammer mill, but also the correct energy efficient motor type and very important, an adequate aspiration set-up. Especially the last item needs special attention. The capacity of the aspiration fan should not only be in the right relation to the screen area of the mill but also depends on products, which have to be ground. Depending on the air volume, the necessary filter surface can be determined. In general, reverse air cleaned filters are used, which allow for an air load on the filter cloth of approximately two m3/minute of air per m2 of filtering area. Finally, it is important that the filter unit is not directly positioned beside the outlet product stream of the hammer mill to make sure that a good airflow and aspiration is safeguarded. More

inforMation:

exchange of the screen, while the motor is still running, it is important to maintain, an under pressure in the grinding chamber of the hammer mill. Special inflatable sealings with labyrinth ensure a correct tightness of the sealing in operation and stops the product leaving the grinding chamber. To minimise energy consumption adjustable breaker plates are introduced. Tests have proven that hardly any grinding takes place below the level of the main shaft. By designing two adjustable breaker plates in the top of the machine, an energy saving of approximately 3035 percent compared to the old designs has been achieved.

16 | march - april 2012

The lower part of the hammer mill is executed with screens; by making use of the gravity force a good discharge of product is possible. The idea of adjustable breaker plates was to create an asymmetric form (ellipse instead of circle) in the grinding chamber. Because of this the product is forced to leave their natural flow and, because of the centrifugal force the product will hit the breaker plate, as a result it is bounced back and then again gets a hit of the hammer. So a more frequent frontal collision is achieved between hammers, breaker plates and product. By making the breaker plates adjustable we can create this ellipse in both directions.

Website: www.wynveen.com

Grain

&feed millinG technoloGy

This digital Re-print is part of the March | April 2012 edition of Grain & Feed Milling Technology magazine. Content from the magazine is available to view free-of-charge, both as a full online magazine on our website, and as an archive of individual features on the docstoc website. Please click here to view our other publications on www.docstoc.com.

LINKS

March - April

2012

See the full issue

In this issue:

Improving supply from farm to fork Victam Asia Product Showcase Global grain & feed markets

Assessing cereal quality parameters

Visit the GFMT website Contact the GFMT Team Subscribe to GFMT

Grinding by a proven concept makes your choice simple

Controlling Insects

with heat

A subscription magazine for the global flour & feed milling industries - first published in 1891

To purchase a paper copy of the magazine, or to subscribe to the paper edition please contact our Circulation and Subscriptions Manager on the link adove.

INFORMATION FOR ADVERTISERS - CLICK HERE

Article reprints

All Grain & Feed Milling Tecchnology feature articles can be re-printed as a 4 or 8 page booklets (these have been used as point of sale materials, promotional materials for shows and exhibitions etc). If you are interested in getting this article re-printed please contact the GFMT team for more information on - Tel: +44 1242 267707 - Email: jamest@gfmt.co.uk or visit www.gfmt.co.uk/reprints

www.gfmt.co.uk

PREVIOUS PAGE

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- CASE STUDY: The Use of Posi-Flate Butterfly ValvesDocument2 pagesCASE STUDY: The Use of Posi-Flate Butterfly ValvesMilling and Grain magazineNo ratings yet

- Commodities - Grain and Feed Annual: 2016 Grain and Feed Annual MexicoDocument4 pagesCommodities - Grain and Feed Annual: 2016 Grain and Feed Annual MexicoMilling and Grain magazineNo ratings yet

- Industry Profile: LambtonDocument2 pagesIndustry Profile: LambtonMilling and Grain magazineNo ratings yet

- Milling and GRain Magazine - November 2016 - FULL EDITIONDocument116 pagesMilling and GRain Magazine - November 2016 - FULL EDITIONMilling and Grain magazine100% (2)

- STORAGE - Safe T Homes® SAVE LivesDocument2 pagesSTORAGE - Safe T Homes® SAVE LivesMilling and Grain magazineNo ratings yet

- Are Sprouted Grains The Future?Document2 pagesAre Sprouted Grains The Future?Milling and Grain magazineNo ratings yet

- How To Maximise The Life of Your Flaking RollsDocument4 pagesHow To Maximise The Life of Your Flaking RollsMilling and Grain magazine100% (1)

- Preventive and Predictive Maintenance For Optimal PerformanceDocument4 pagesPreventive and Predictive Maintenance For Optimal PerformanceMilling and Grain magazineNo ratings yet

- New Panama Canal Expansion Sees Grain Transportation Costs TumbleDocument4 pagesNew Panama Canal Expansion Sees Grain Transportation Costs TumbleMilling and Grain magazineNo ratings yet

- Commodities - MARKETS OUTLOOKDocument6 pagesCommodities - MARKETS OUTLOOKMilling and Grain magazineNo ratings yet

- CEREALSDocument4 pagesCEREALSMilling and Grain magazineNo ratings yet

- "Wheat, Flour and OCRIM's 6th Technical ConferenceDocument6 pages"Wheat, Flour and OCRIM's 6th Technical ConferenceMilling and Grain magazineNo ratings yet

- The Balance of PowerDocument4 pagesThe Balance of PowerMilling and Grain magazineNo ratings yet

- Combustible Dust Control - Part 2Document4 pagesCombustible Dust Control - Part 2Milling and Grain magazineNo ratings yet

- Milling and Grain Magazine - October 2016 - FULL EDITIONDocument116 pagesMilling and Grain Magazine - October 2016 - FULL EDITIONMilling and Grain magazine100% (1)

- Enzymatic Flour StandardisationDocument4 pagesEnzymatic Flour StandardisationMilling and Grain magazine100% (1)

- Rotary Batch Mixer - Achieving Precise Ratios For Feed SupplementsDocument2 pagesRotary Batch Mixer - Achieving Precise Ratios For Feed SupplementsMilling and Grain magazineNo ratings yet

- Combustible Dust Control - Part 1Document4 pagesCombustible Dust Control - Part 1Milling and Grain magazineNo ratings yet

- CASE STUDY: 20% Increase in Production CapacityDocument2 pagesCASE STUDY: 20% Increase in Production CapacityMilling and Grain magazineNo ratings yet

- From Grain To BreadDocument4 pagesFrom Grain To BreadMilling and Grain magazineNo ratings yet

- Industry Profile: GRANDS MOULINS DE PARISDocument2 pagesIndustry Profile: GRANDS MOULINS DE PARISMilling and Grain magazineNo ratings yet

- CASE STUDY: Improving Raw Material Quality For MillersDocument6 pagesCASE STUDY: Improving Raw Material Quality For MillersMilling and Grain magazineNo ratings yet

- A New Protein Source For FeedDocument4 pagesA New Protein Source For FeedMilling and Grain magazineNo ratings yet

- STORAGE - Dryer Tips For A More Financially Beneficial HarvestDocument4 pagesSTORAGE - Dryer Tips For A More Financially Beneficial HarvestMilling and Grain magazineNo ratings yet

- Milling and Grain Magazine - September 2016 - FULL EDITIONDocument116 pagesMilling and Grain Magazine - September 2016 - FULL EDITIONMilling and Grain magazineNo ratings yet

- STORAGE - Bentall Rowlands Storage Systems Limited Talks Grain StorageDocument4 pagesSTORAGE - Bentall Rowlands Storage Systems Limited Talks Grain StorageMilling and Grain magazineNo ratings yet

- Storage - Si-LowDocument4 pagesStorage - Si-LowMilling and Grain magazineNo ratings yet

- Industry Profile: MolinoDocument2 pagesIndustry Profile: MolinoMilling and Grain magazineNo ratings yet

- Commodities - The Other Side of The StoryDocument2 pagesCommodities - The Other Side of The StoryMilling and Grain magazineNo ratings yet

- The Bühler Networking DaysDocument10 pagesThe Bühler Networking DaysMilling and Grain magazineNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Data CollectionDocument4 pagesData CollectionjochukoNo ratings yet

- Sakha DictionaryDocument14 pagesSakha DictionarySojeong MinNo ratings yet

- 4 - Microsoft PowerPoint - JDC Company ProfileDocument12 pages4 - Microsoft PowerPoint - JDC Company ProfileBill LiNo ratings yet

- Section 08500 - Windows: Whole Building Design Guide Federal Green Construction Guide For SpecifiersDocument7 pagesSection 08500 - Windows: Whole Building Design Guide Federal Green Construction Guide For SpecifiersAnonymous NMytbMiDNo ratings yet

- Male Hijab: Cover in RighteousnessDocument11 pagesMale Hijab: Cover in RighteousnessIbn SadiqNo ratings yet

- Insurance - Unit 3&4Document20 pagesInsurance - Unit 3&4Dhruv GandhiNo ratings yet

- Clarke 1973 Loss of InnocenceDocument13 pagesClarke 1973 Loss of InnocencePaula TralmaNo ratings yet

- The American School of Classical Studies at AthensDocument23 pagesThe American School of Classical Studies at AthensDanilo Andrade TaboneNo ratings yet

- Ingredient Branding: P. Kotler, Northwestern University, Evanston, USA W. Pfoertsch, China EuropeDocument1 pageIngredient Branding: P. Kotler, Northwestern University, Evanston, USA W. Pfoertsch, China EuropeCristea GianiNo ratings yet

- MEL - Math 10C Item Writing - MC & NR ReviewDocument71 pagesMEL - Math 10C Item Writing - MC & NR ReviewMya TseNo ratings yet

- Anatolii PapanovDocument8 pagesAnatolii PapanovKyrademNo ratings yet

- E44 - Wet Cooling Tower: InstructionsDocument3 pagesE44 - Wet Cooling Tower: InstructionsMarc AnmellaNo ratings yet

- Awfpc 2022Document7 pagesAwfpc 2022Jay-p BayonaNo ratings yet

- Letter of RecommendationDocument2 pagesLetter of RecommendationnaveenNo ratings yet

- Cissp NotesDocument83 pagesCissp NotesRobert Mota HawksNo ratings yet

- B2+ UNIT 9 Test Answer Key HigherDocument2 pagesB2+ UNIT 9 Test Answer Key HigherMOSQUITO beatsNo ratings yet

- Ideas For Income Generating Projects PDFDocument29 pagesIdeas For Income Generating Projects PDFheart AquinoNo ratings yet

- Contractor base list in UsaDocument8 pagesContractor base list in Usamytech206No ratings yet

- EOS Web and Multimedia L3Document53 pagesEOS Web and Multimedia L3ብርሃነ ኣፅብሃNo ratings yet

- Biografia Buerkli-ZieglerDocument7 pagesBiografia Buerkli-ZieglerJesús Ángel Ortiz OrdazNo ratings yet

- Lec # 10 Earthing and GroundingDocument68 pagesLec # 10 Earthing and GroundingSaddam jatt786No ratings yet

- Present Si̇mple or Present ContinuousDocument3 pagesPresent Si̇mple or Present ContinuousfercordobadelcastilloNo ratings yet

- ZEOLITEDocument13 pagesZEOLITEShubham Yele100% (1)

- Specialty Fibers: Select SheetDocument4 pagesSpecialty Fibers: Select SheetсергейNo ratings yet

- Post Office Challan - RRB RECRUITMENT PDFDocument1 pagePost Office Challan - RRB RECRUITMENT PDFGaurav KashyapNo ratings yet

- Unit 4 FSQCDocument28 pagesUnit 4 FSQCvaralakshmi KNo ratings yet

- Spartan-3E FPGA Starter Kit Board User Guide: UG230 (v1.2) January 20, 2011Document120 pagesSpartan-3E FPGA Starter Kit Board User Guide: UG230 (v1.2) January 20, 2011Alex XanderNo ratings yet

- Principle Principle PrincipleDocument12 pagesPrinciple Principle PrincipleDarshana JuvekarNo ratings yet

- The Metatronic KeysDocument10 pagesThe Metatronic KeysArnulfo Yu Laniba100% (1)

- Improving PerformanceDocument2 pagesImproving PerformanceYidne MasreshaNo ratings yet