Professional Documents

Culture Documents

OmniMeter Universal Smart Meter User Manual EKM Metering

Uploaded by

Chris CalderónOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OmniMeter Universal Smart Meter User Manual EKM Metering

Uploaded by

Chris CalderónCopyright:

Available Formats

EKM METERING

EKM-OmniMeter I v.3

EKM Metering, 363 Berkeley Way, Santa Cruz, CA 95062

Nominal Voltage Ranges: 120V to 480V, 2-wire, Single-phase, One Line & Neutral 120V to 480V, 3-wire, Single-phase, 2 Lines and Neutral 120V to 400V, 3-wire, 3-phase, 3 Lines, No Neutral 120V to 480V, 4-wire, 3-phase, 3 Lines and Neutral Range of allowable environmental conditions: Pollution Degree 2, Measurement Category III, Altitude rating 2000 meters max. Maximim Temperature Range: -30 Deg. C to 70 Deg. C. Tamper Detection Class 1. The equipment is protected throughout by double insulation as indicated by this symbol: Accuracy Class 0.5 Rated Frequency: 50Hz/60Hz Safety Precautions Meter should be installed by a qualified electrician. Turn off all power supplying the equipment before preforming any wiring operations. Use a properly rated volt meter to confirm power is off. Use of this device inconsistent with this manual can cause permanent damage to the unit and/or serious harm to the operator. Tools/Materials List Volt meter Small standard screwdriver Wire stripper DIN-Rail 16-22 AWG UL rated stranded copper wire UL rated inline fuse holder with maximum 1Amp UL Listed fuse UL Listed Type 4 Enclosure (with appropriately rated conduit and fittings) is required if meter will be installed outdoors Installation Instructions For All Systems 1. Disconnect or switch power off before attempting to install, connect, disconnect or service the meter or the external current transformers (CTs). ALL POWER MUST BE DISCONNECTED! 2. Mount the meter using 35mm DIN Rail in a protected indoor location. If installing outdoors, a UL Listed Type 4 Enclosure is required. 3. IMPORTANT: Distinguish and then identify the Neutral and the Line(s) (hot wire(s), usually black or red). Label the Neutral and then, depending on your electrical system, assign labels as described below. 4. Tightening torque of terminals:

Terminals 7,8,9 (Line) and 10 (Neutral): 10.6 to 13.2 in-lb. (1.2 to 1.5 Nm) All other terminal connections: 4.4 to 5.3 in-lb. (0.5 to 0.6 Nm)

78 100

METERING SOLUTIONS FOR FOR A MORE EFFICIENT FUTURE.

66.55 6 6.

11 1000

Load current 0.05Ib 0.1Ib~Imax 0.1Ib 0.2Ib~Imax

Power factor COS 1.0 1.0 0.5(L) 0.8(C) 0.5(L) 0.8(C)

Basic error% Class 0.5 Class 1 1.0 0.5 1.0 1.0 0.5 0.5 1.5 1.0 1.5 1.5 1.0 1.0

OmniMeter I v.3 Accuracy Class: 0.5

Fig. 1

stranded copper wire for connection to the meter. 6. L1 connects to Port 7 on the Omnimeter, Neutral connects to Port 10. (Fig 2) 7. Once the meter is properly mounted to the DIN Rail or enclosure and all wiring is completed, with terminal block covers installed, power can be turned back on. 8. Meter will then begin cycling through all meter values. For details, go to: http://www.ekmmetering.comLCD_Display_ Register_Values.html 9. A video of proper install of a 120V system can be found here: http://www.youtube.com/watch?v=ky9sgr1LTMk Blk Wht

1 2 3 4 5 6 7 8 9 10 L1

CT1

Fuse

Fig. 2

L2/N 120V~240V 2-wire, Single Phase Load

120V, 2-Wire, Single Phase 1. Label Line 1 as L1. 2. Fit CT1 around L1. Make sure the arrow is facing towards the load (in the direction of flow). (Fig 2) 3. Black CT wire connects to Port 1 on the Omnimeter. White CT wire connects to Port 2. (Fig 2) 4. With split core CTs, clamp together until the buttons pop out. Use a zip tie to ensure the CT remains securely closed. 5. To power the meter and get a voltage reference: Use a maximum 1.0 Amp inline fuse on L1. Connect one fuse holder pigtail to the breaker, lug or an appropriate line-tap device, and connect the other pigtail to 16-22 AWG UL rated

120/240V, 120/208V, Single Phase, 3-Wire 1. Label L1 and L2. (Arbitrarily assign labels.) 2. You will be using 2 CTs for this install. Label them CT1 and CT2. 3. Fit CT1 around L1. Make sure the arrow is facing towards the load (in the direction of flow). 4. Fit CT2 around L2. 5. Black wire from CT1 connects to Port 1 on the Omnimeter. White wire from CT1 connects to Port 2. (Fig 3) 6. Black wire from CT2 connects to Port 3 on the Omnimeter. White wire from CT2 connects to Port 4. (Fig 3) 7. With split core CTs, clamp together until buttons pop out. Use a zip tie to ensure the CTs remain securely closed. 8. To power the meter and get a voltage reference: Use a maximum 1.0 Amp inline fuse on L1 and L2. Connect one fuse holder pigtail to the breaker, lug or an appropriate line-tap device, and connect the other pigtail to 16-22 AWG UL rated stranded copper wire for connection to the meter. 9. Tap into L1 at the breaker panel, with small

EKM METERING

http://ekmmetering.com (831)425-7371 info@ekmmetering.com

stranded copper wire. This L1 tap connects to Port 7 on the Omnimeter. (Fig 3) 10. Tap into L2 at the breaker panel with small stranded copper wire. This L2 tap connects to Port 8 on the Omnimeter. (Fig 3) 11. Neutral connects to Port 10. 12. Once the meter is properly mounted to the DIN Rail or enclosure and all wiring is completed, with terminal block covers installed, power can be turned back on. 13. Meter will then begin cycling through all meter values. For details, go to: http://www.ekmmetering.com/LCD_Display_ Register_Values.html 14. A video of proper install of a 120V/240V system can be found here: http://www.youtube.com/watch?v=ky9sgr1LTMk Blk Wht

1 2 3 4 5 6 7 8 9 10 L1

CT1

Fig. 3

Fuse

L2

CT2

N Load

120/240, 120/208 3-wire, Single Phase

120V-415V, 3-Phase, 3-Wire 1. Label L1, L2 and L3. (Arbitrarily assign labels.) 2. You will be using 2 CTs for this install. Label them CT1 and CT3. 3. Fit CT1 around L1. Make sure the arrow is facing towards the load (in the direction of flow). 4. Fit CT3 around L3. 5. Black wire from CT1 connects to Port 1 on the Omnimeter. White wire from CT1 connects to Port 2. (Fig 4) 6. Black wire from CT3 connects to Port 5 on the Omnimeter. White wire from CT3 connects to Port 6. (Fig 4) 7. With split core CTs, clamp together until buttons pop out. Use a zip tie to ensure the CTs remain securely closed. 8. To protect the meter and wiring, use a maximum 1.0 Amp inline fuse on each line. 9. To power the meter and get a voltage reference: Tap into L1 at the breaker panel. Connect one fuse holder pigtail to the breaker, lug or an appropriate line-tap device, and connect the other pigtail to 16-22 AWG UL rated stranded copper wire for connection to the meter. This L1 tap connects to Port 7 on the Omnimeter. Tap into L2 and L3 and repeat the connection process. L2 tap connects to Port 8. Be sure to add a jumper to Port 10. (Fig 4) L3 tap connects to Port 9. 10. Once the meter is properly mounted to the DIN Rail or enclosure and all wiring is completed, with terminal block covers installed, power can be turned back on. 11. Meter will then begin cycling through all meter values. For details, go to http://www.ekmmetering.com/LCD_Display_ Register_Values.html 12. A video of proper install of a 120V-208V, 3-Wire, 3-Phase system can be found here: http://www.youtube.com/watch?NR=1&v=upNgFNV6EDM

120V-480V, 3-Phase, 4-Wire 1. Label L1, L2 and L3. (Arbitrarily assign labels.) 2. You will be using 3 CTs for this install. Label them CT1, CT2 and CT3. 3. Fit CT1 around L1. Make sure the arrow is facing towards the load (in the direction of flow). 4. Fit CT2 around L2. 5. Fit CT3 around L3. 6. Black wire from CT1 connects to Port 1 on the Omnimeter. White wire from CT1 connects to Port 2. (Fig 5) 7. Black wire from CT2 connects to Port 3 on the Omnimeter. White wire from CT2 connects to Port 4. (Fig 5) 8. Black wire from CT3 connects to Port 5 on the Omnimeter. White wire from CT3 connects to Port 6. (Fig 5) 9. With split core CTs, clamp together until buttons pop out. Use a zip tie to ensure the CTs remain securely closed. 10. To protect the meter and wiring , use a maximum 1.0 Amp inline fuse on each line. 11. To power the meter and get a voltage reference: Tap into L1 at the breaker panel. Connect one fuse holder pigtail to the breaker, lug or an appropriate line-tap device, and connect the other pigtail to 16-22 AWG UL rated stranded copper wire for connection to the meter. L1 connects to Port 7. Tap into L2 and L3 and repeat the connection process. L2 connects to Port 8. L3 connects to Port 9. Neutral connects to Port 10. (Fig 5) 12. Once the meter is properly mounted to the DIN Rail or enclosure and all wiring is completed, with terminal block covers installed, power can be turned back on. 13. Meter will then begin cycling through all meter values. For details, go to: http://www.ekmmetering.com/LCD_ Display_Register_Values.html 14. A video of proper install of a 120V-208V, 3-Phase, 4-Wire system can be found here: http://www.youtube.com/watch?v=DeKiZddR0K8 Blk Wht

1 2 3 4 5 6 7 8 9 10 L1

CT1 CT2 CT3

Fig. 5

Fuse

L2 L3 N

120~480V Line to Line Load 3-Phase, 4-Wire

RS-485 and Pulse Output Terminal 11 (A) connects to RS-485+ or T+ on the RS-485 network. Terminal 12 (B) connects to RS-485- or T-. Terminal 13 (G) is used for the RS-485 network (signal) ground if needed. Observe proper RS-485 network topology. Twistedpair wiring is recommended. Shielded twisted pair may be benificial in electrically noisy environments or for very long runs. RS-485 supports up to 256 devices on up to 4000 feet of network length. Terminating resistors may be beneficial. Terminals 14 and 15 are for pulse output. Pulse rate: 800 Impulse/kWh. Polarity sensitive. Maximum 27VDC, 27mA. Red LED on the meter face flashes 800 times per kWh. 1 flash = 1.25 Wh.

Blk Wht

1 2 3 4 5 6 7 8 9 10 Line1

Fig. 4

Fuse

CT1

Line2 Line3 120V~415V 3-Phase, 3-Wire

CT3

Load

EKM METERING

http://ekmmetering.com (831)425-7371 info@ekmmetering.com

You might also like

- Inductance and Capacitance Meter Adapter Using 74HC132Document6 pagesInductance and Capacitance Meter Adapter Using 74HC132Miguelangel Bravo MigoneNo ratings yet

- Ivi6000c Im 12Document4 pagesIvi6000c Im 12Giulio MoroNo ratings yet

- Full Chapter 1 PDFDocument211 pagesFull Chapter 1 PDFEdward SolomonNo ratings yet

- COV34636802 English PDFDocument32 pagesCOV34636802 English PDFNessaFajcikNo ratings yet

- SC 8162Document3 pagesSC 8162John Hinderaker100% (1)

- FMT Syndemics Agenda Final - 3.10.21Document3 pagesFMT Syndemics Agenda Final - 3.10.21Natalie Winters100% (1)

- Letter Regarding Leader McConnell 5 Sept 2023Document1 pageLetter Regarding Leader McConnell 5 Sept 2023ABC News PoliticsNo ratings yet

- Certified Electronic Voting Systems As of Dec. 7, 2021 Meeting - 2021-12-21 (CURRENT)Document2 pagesCertified Electronic Voting Systems As of Dec. 7, 2021 Meeting - 2021-12-21 (CURRENT)Trent BakerNo ratings yet

- Rochelle Walensky Talk at Washington University School of Medicine at St. Louis On March 3, 2022Document12 pagesRochelle Walensky Talk at Washington University School of Medicine at St. Louis On March 3, 2022Kyle BeckerNo ratings yet

- PX 2531 2013-11-13 Drake-Wiebe Letter Re Montgomery Hard DrivesDocument3 pagesPX 2531 2013-11-13 Drake-Wiebe Letter Re Montgomery Hard DrivesJack RyanNo ratings yet

- 1 32409 PDFDocument13 pages1 32409 PDFNew York Post100% (2)

- Antrim County Forensics ReportDocument23 pagesAntrim County Forensics ReportMaurA Dowling100% (6)

- Climate Change by John Nicol: (A Fundamental Analysis of The Greenhouse Effect)Document27 pagesClimate Change by John Nicol: (A Fundamental Analysis of The Greenhouse Effect)PipeburNo ratings yet

- The Gateway Pundit Lawsuit Against EIP, Stanford Internet, Graphika, Atlantic Council, 2023-05-02 - Hines v. Stamos - Complaint - FinalDocument88 pagesThe Gateway Pundit Lawsuit Against EIP, Stanford Internet, Graphika, Atlantic Council, 2023-05-02 - Hines v. Stamos - Complaint - FinalJim HoftNo ratings yet

- 2008-03-10 Dennis Montgomery Declaration (Montgomery V Etreppid)Document6 pages2008-03-10 Dennis Montgomery Declaration (Montgomery V Etreppid)Jack RyanNo ratings yet

- Address by DR Tal Becker - 11 Jan 2024 - FinalDocument16 pagesAddress by DR Tal Becker - 11 Jan 2024 - FinalBreitbart NewsNo ratings yet

- ESS RedTeam Jake Stauffer Vulnerability Security Assessment ReportDocument16 pagesESS RedTeam Jake Stauffer Vulnerability Security Assessment ReportUncoverDCNo ratings yet

- Overview of RoadmapDocument7 pagesOverview of RoadmapAred XINo ratings yet

- Mooer Pe100 Manual Pedal Guitarra GuitarDocument20 pagesMooer Pe100 Manual Pedal Guitarra Guitarana sal100% (1)

- Gov - Uscourts.lawd.189520.301.0 1Document13 pagesGov - Uscourts.lawd.189520.301.0 1Susie MooreNo ratings yet

- 2021 02 01 - Memorandum-of-LawDocument12 pages2021 02 01 - Memorandum-of-LawNatalie WintersNo ratings yet

- 2017 12 01 Flynn Statement of OffenseDocument6 pages2017 12 01 Flynn Statement of OffenseMaxwell Anderson0% (1)

- Dusty Johnson July 2021 FEC ReportDocument178 pagesDusty Johnson July 2021 FEC ReportPat PowersNo ratings yet

- 2007-11-02 Dennis Montgomery Declaration (Montgomery V Etreppid)Document4 pages2007-11-02 Dennis Montgomery Declaration (Montgomery V Etreppid)Jack RyanNo ratings yet

- (DAILY CALLER OBTAINED) - Protect Childrens Innocence Act (Draft Text)Document20 pages(DAILY CALLER OBTAINED) - Protect Childrens Innocence Act (Draft Text)Henry Rodgers100% (1)

- Montgomery V Etreppid # 732 - 6/10 OSC Hearing TranscriptDocument226 pagesMontgomery V Etreppid # 732 - 6/10 OSC Hearing TranscriptJack RyanNo ratings yet

- JAMES SAVAGE, Et Al, Plaintiffs, v. NEWSMAX MEDIA, INC.Document7 pagesJAMES SAVAGE, Et Al, Plaintiffs, v. NEWSMAX MEDIA, INC.Kyle BeckerNo ratings yet

- House Bill 645 - Montana, Introduced by Rep. KmetzDocument4 pagesHouse Bill 645 - Montana, Introduced by Rep. Kmetzadan_infowarsNo ratings yet

- Motion To Limit Secret Service Cross ExaminationDocument6 pagesMotion To Limit Secret Service Cross ExaminationAmerican GreatnessNo ratings yet

- EC Report UkraineDocument12 pagesEC Report UkraineJames LynchNo ratings yet

- Rep Rosendale Letter To Atf and IrsDocument2 pagesRep Rosendale Letter To Atf and IrsZerohedge100% (1)

- Peter Strzok - DOJ Motion To Dismiss - 11.18.19Document151 pagesPeter Strzok - DOJ Motion To Dismiss - 11.18.19Victor I Nava100% (2)

- Open Source Evaluation of Power Transients Generated To Improve Performance Coefficient of Resistive Heating SystemsDocument16 pagesOpen Source Evaluation of Power Transients Generated To Improve Performance Coefficient of Resistive Heating Systemsfuzzytomcat50% (2)

- Arrington DoD LawsuitDocument9 pagesArrington DoD LawsuitABC News 4No ratings yet

- PA AffadavitDocument22 pagesPA AffadavitEdward Solomon67% (3)

- Judge VanDyke DissentDocument13 pagesJudge VanDyke DissentFox NewsNo ratings yet

- Case 1-92-cv-00449-SSDocument14 pagesCase 1-92-cv-00449-SSStephane BeladaciNo ratings yet

- DM FBI Search # 70 - Gov Docs Unsealed - D.nev. - 3-06-Cv-00263Document139 pagesDM FBI Search # 70 - Gov Docs Unsealed - D.nev. - 3-06-Cv-00263Jack RyanNo ratings yet

- Marinka Peschmann's First Amended Complaint - Defamation, Civil Conspiracy, Unjust Enrichment, Judge Paul G GardepheDocument75 pagesMarinka Peschmann's First Amended Complaint - Defamation, Civil Conspiracy, Unjust Enrichment, Judge Paul G GardepheBrowseDocsNo ratings yet

- ScribDocument3 pagesScribJamie WhiteNo ratings yet

- Florida First Freedom BOCC Final Report MachinesDocument7 pagesFlorida First Freedom BOCC Final Report MachinesChristopher GleasonNo ratings yet

- 2007 09 10 Dennis Montgomery Declaration (Montgomery V Etreppid)Document9 pages2007 09 10 Dennis Montgomery Declaration (Montgomery V Etreppid)Jack RyanNo ratings yet

- 0cc7a4b2-8e80-46f3-9c78-3ff36f7a08eeDocument14 pages0cc7a4b2-8e80-46f3-9c78-3ff36f7a08eeZerohedge JanitorNo ratings yet

- Comer LetterDocument3 pagesComer LetterThe Western JournalNo ratings yet

- Elementary Behaviors of Consecutive Totatives, Chapter 1: Edward SolomonDocument175 pagesElementary Behaviors of Consecutive Totatives, Chapter 1: Edward SolomonAnonymous apZaj5XRj50% (2)

- Fec Ballot Measure RulingDocument6 pagesFec Ballot Measure RulingJamie WhiteNo ratings yet

- GA Curling V Raffensperger Rulling 101120Document147 pagesGA Curling V Raffensperger Rulling 101120Jim HoftNo ratings yet

- Montgomery V Etreppid # 228 - Oct 30 2006 Montgomery DeclarationDocument23 pagesMontgomery V Etreppid # 228 - Oct 30 2006 Montgomery DeclarationJack RyanNo ratings yet

- 2023.07.13 - Goldman Referral To DOJDocument2 pages2023.07.13 - Goldman Referral To DOJFightWithKash100% (1)

- 2021-05-11 - Letter Re Violations of The Settlement AgreementDocument3 pages2021-05-11 - Letter Re Violations of The Settlement AgreementKTARNo ratings yet

- End COVID Tyranny ActDocument16 pagesEnd COVID Tyranny ActNew York PostNo ratings yet

- Deb ArtmentDocument6 pagesDeb ArtmentZerohedge JanitorNo ratings yet

- Fridman V Fusion GPS ComplaintDocument14 pagesFridman V Fusion GPS ComplaintSyndicated NewsNo ratings yet

- Gov Uscourts Nysd 590940 139 0Document33 pagesGov Uscourts Nysd 590940 139 0Zerohedge JanitorNo ratings yet

- OmniMeter Universal Smart Meter User Manual EKM MeteringDocument3 pagesOmniMeter Universal Smart Meter User Manual EKM MeteringAdam BrouwerNo ratings yet

- EKM Omnimeter Pulse v.4 Spec SheetDocument4 pagesEKM Omnimeter Pulse v.4 Spec SheetAdam BrouwerNo ratings yet

- EKM OmniMeter UL User Manual Spec Sheet SubmeterDocument3 pagesEKM OmniMeter UL User Manual Spec Sheet SubmeterAdam BrouwerNo ratings yet

- EKM Omnimeter Pulse UL v.4 Spec SheetDocument4 pagesEKM Omnimeter Pulse UL v.4 Spec SheetAdam BrouwerNo ratings yet

- EKM Omnimeter Pulse UL v4 Spec SheetDocument4 pagesEKM Omnimeter Pulse UL v4 Spec SheetAdam BrouwerNo ratings yet

- CHEM111-Week3-Atoms and The Periodic TableDocument21 pagesCHEM111-Week3-Atoms and The Periodic TableJr BalagtasNo ratings yet

- Nirma University Institute of Technology B.Tech. in Mechanical Engineering Semester IVDocument2 pagesNirma University Institute of Technology B.Tech. in Mechanical Engineering Semester IVKartik aminNo ratings yet

- ACP Intro 2020R1 WS05.1 Solid ModelDocument30 pagesACP Intro 2020R1 WS05.1 Solid ModelV CafNo ratings yet

- TO Engineering Mechanics: Cestat30 - Statics of Rigid BodiesDocument11 pagesTO Engineering Mechanics: Cestat30 - Statics of Rigid BodiesJeter Isaac SantiagoNo ratings yet

- ABB Seccionadores de Potencia HV: Caracteristicas Tecnicas y Aplicaciones EspecialesDocument52 pagesABB Seccionadores de Potencia HV: Caracteristicas Tecnicas y Aplicaciones EspecialesAndrea AtzeniNo ratings yet

- Mini FocusDocument52 pagesMini FocusLmn TrixNo ratings yet

- Pedrotti - Bab 6 - LASERDocument32 pagesPedrotti - Bab 6 - LASERTheresia AnggitaNo ratings yet

- Manual de Mantenimiento Precipitador ElectrostáticoDocument18 pagesManual de Mantenimiento Precipitador ElectrostáticoJorge Perez CorreaNo ratings yet

- Tia 607 B 2011Document72 pagesTia 607 B 2011Elizabeth P0% (1)

- Tan Delta Testing Reveals Cable Insulation QualityDocument6 pagesTan Delta Testing Reveals Cable Insulation QualitySean LudwickNo ratings yet

- Class 5 ScienceDocument38 pagesClass 5 ScienceQulb e Abbas100% (1)

- 2 Unit 35-61Document25 pages2 Unit 35-61806 Ansh gargNo ratings yet

- Graphene BatteriesDocument12 pagesGraphene BatteriesSarvesh KumarNo ratings yet

- 5 Techniques For Pressure Gauge Adjustment and Repair - Calibration AwarenessDocument9 pages5 Techniques For Pressure Gauge Adjustment and Repair - Calibration AwarenessTahan SibueaNo ratings yet

- The Loop RulesDocument12 pagesThe Loop RulesPoppyNo ratings yet

- Li2020 3DPrintingOfHydroxyapatiteTricDocument15 pagesLi2020 3DPrintingOfHydroxyapatiteTricspawnmeaddowNo ratings yet

- X-Ray Attenuation by VishnuDocument49 pagesX-Ray Attenuation by VishnuVishnu nNo ratings yet

- Horizontal Axis Wind Turbines Passive Flow Control Methods: A ReviewDocument18 pagesHorizontal Axis Wind Turbines Passive Flow Control Methods: A ReviewHavaldar, SanjayNo ratings yet

- Finite Element Analysis of Fluid and Solid Mechanics Problems Using AnsysDocument59 pagesFinite Element Analysis of Fluid and Solid Mechanics Problems Using AnsysRebeca CruzNo ratings yet

- CESA-clean PEA0420182-ZN - TDS - SriLanka - 03042017 PDFDocument2 pagesCESA-clean PEA0420182-ZN - TDS - SriLanka - 03042017 PDFASHANNo ratings yet

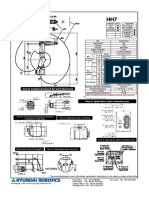

- Hh7 CatalogDocument1 pageHh7 Catalogjitender kumarNo ratings yet

- Thermal Modeling and Simulation of Distribution TransformersDocument4 pagesThermal Modeling and Simulation of Distribution Transformerssujit tiwariNo ratings yet

- Eng SS 108-40025 CDocument7 pagesEng SS 108-40025 CdeeppriyagovuNo ratings yet

- Heating Vent Lighting SE7542Document48 pagesHeating Vent Lighting SE7542sairajNo ratings yet

- KKS Code DescriptionDocument31 pagesKKS Code DescriptionAmal Chinthaka100% (3)

- Sofía López Ochoa Biology HLDocument7 pagesSofía López Ochoa Biology HLSofia lopezNo ratings yet

- Crystallography: Classification of Crystal Systems and DefectsDocument54 pagesCrystallography: Classification of Crystal Systems and DefectsSaad MohammedNo ratings yet

- Technical Data Sheet For GIS 18-2-2022Document14 pagesTechnical Data Sheet For GIS 18-2-2022sami ul haqNo ratings yet

- Malayalam Holy Qurbana Lent SeasonDocument76 pagesMalayalam Holy Qurbana Lent SeasonTojo AlexNo ratings yet

- Maintain Loader Scoop Type ManualDocument702 pagesMaintain Loader Scoop Type ManualJovanNo ratings yet