Professional Documents

Culture Documents

ABB Transformers

Uploaded by

Roberto Cárdenas JiménezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ABB Transformers

Uploaded by

Roberto Cárdenas JiménezCopyright:

Available Formats

Transformers

Tr a

ns

fo

rm

er

Transformers

Description

Epoxy encapsulated coils up through 750VA Epoxy resin impregnated coils 1 kVA to 5 kVA Provides stepped down voltages for machine tool control devices and industrial control panels Laminations of high quality silicon steel Minimum core loss

Optimized performance Copper magnet wire providing the highest quality and efficient operation Molded-in terminals 80C rise, 130C insulation system 50/60 Hz UL File # E175311 CSA File #LR27533 IP 20 Touch safe covers available as an option

12

Low Voltage Products & Systems

12.1

a Tr

sf

m or

er

General information Catalog number explanation

X 4 100 PS F1 /C

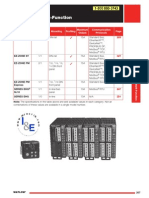

T - Industrial control transformer X - New generation industrial control transformer Primary voltage rating 1 4 - 460V, 230V & 208V 6 - 575V & 600V VA rating 045 = 45VA 050 = 50VA 075 = 75VA 100 = 100VA 150 = 150VA 200 = 200VA 250 = 250VA 300 = 300VA 350 = 350VA 500 = 500VA 750 = 750VA 1K = 1000VA 1.5K = 1500VA 2K = 2000VA 3K = 3000VA 5K = 5000VA Option 3 Add $15 to list price IP 20 Terminal covers Meets finger safe or touch safe requirements for IEC specification 529. Available 50VA thru 750VA Secondary voltage(s) 2 F = 24V 1 = 115V F1 = 115/24V dual secondary 2 Fuse blocks P = primary fuse block (2 pole Class CC, less fuses) S = secondary fuse clip (13/32" x 1 1/2", less fuse)

Example: T4100PSF1 ABB Industrial control transformer Primary voltage: 460V, 230V and 208V 100 VA rating Primary & secondary fuse blocks provided Secondary voltage 115/24V Optional IP 20 terminal covers

12

1 Consult factory for applications with different voltages. 2 Whenever both secondary voltages are to be used at the same time, remove the secondary fuse clip and use a separate mounted 2 pole fuse block. 3 Includes terminal and fuse covers.

12.2

Low Voltage Products & Systems

General information

Tr a

ns

fo

rm

er

Regulation

Selecting a transformer for industrial control circuit applications requires knowledge of the following terms: INRUSH VA is the product of load voltage (V) multiplied by the current (A) that is required during circuit start-up. It is calculated by adding the inrush VA requirements of all devices (contactors, timers, relays, pilot lights, solenoids, etc.), which will be energized together. Inrush VA requirements are best obtained from the component manufacturer. SEALED VA is the product of load voltage (V) multiplied by the current (A) that is required to operate the circuit after initial start-up or under normal operating conditions. It is calculated by adding the sealed VA requirements of all electrical components of the circuit that will be energized at any given time. Sealed VA requirements are best obtained from the component manufacturer. Sealed VA is also referred to as steady state VA. PRIMARY VOLTAGE is the voltage available from the electrical distribution system and its operational frequency, which is connected to the transformer supply voltage terminals. SECONDARY VOLTAGE is the voltage required for load operation which is connected to the transformer load voltage terminals. Once the circuit variables have been determined, transformer selection is a simple 5-step process as follows: 1. Determine the application inrush VA by using the following industry accepted formula: Application inrush VA = (INRUSH VA)2 + (SEALED VA)2

Transformer VA rating

Regulation Data Chart

Inrush VA at 20% power factor 95% secondary voltage 90% secondary voltage 85% secondary voltage

25 50 75 100 150 200 250 300 350 500 750 1000 1 1000 2 1500 2000 3000 5000

100 170 310 370 780 810 1400 1900 3100 4000 8300 15000 9000 10500 17000 24000 55000

130 200 410 540 930 1150 1900 2700 3650 5300 11000 21000 13000 15000 25500 36000 92500

150 240 540 730 1150 1450 2300 3850 4800 7000 14000 27000 18500 205000 34000 47500 115000

To comply with NEMA standards, which require all magnetic devices to operate successfully at 85% of rated voltage, the 90% secondary voltage column is most often used in selecting a transformer. NOTE For UL overcurrent protection, see page 12.11

2. Refer to the Regulation Data chart. If the primary voltage is basically stable and does not vary by more than 5% from nominal, the 90% secondary voltage column should be used. If the primary voltage varies between 5 and 10% of nominal, the 95% secondary voltage column should be used. 3. After determining the proper secondary voltage column, read down until a value equal to or greater than the application inrush VA is found. In no case should a figure less than the Application Inrush VA be used. 4. Read left to the Transformer VA rating column to determine the proper transformer for this application. As a final check, make sure that the Transformer VA rating is equal to or greater than the total sealed requirements. If not, select a transformer with a VA rating equal to or greater than the total sealed VA. 5. Refer to transformer selection pages to determine the proper catalog number based on the transformer VA, and primary and secondary voltage requirements.

12

Inrush

Industrial control circuits and motor control loads typically require more current when they are initially energized than under normal operating conditions. This period of high current demand, referred to as inrush, may be as great as ten times the current required under steady state (normal) operation conditions and can last up to 40 milliseconds. A transformer in a circuit subject to inrush will typically attempt to provide the load with the required current during the inrush period. However, it will be at the expense of the secondary voltage stability by allowing the voltage to the load to decrease as the current increases. This period of secondary voltage instability, resulting from increased current, can be of such a magnitude that the transformer is unable to supply sufficient voltage to energize the load. This transformer must therefore be designed and constructed to accommodate the high inrush current, while maintaining secondary voltage stability. According to NEMA standards, the secondary voltage should typically be at 85% of the rated voltage. Industrial Control Circuit Transformers by ABB Control Inc. are specifically designed and built to provide adequate voltage to the load while accommodating the high current levels present at inrush. These transformers deliver excellent secondary voltage regulation and meet or exceed the standards established by NEMA, ANSI, UL and CSA. Their hearty construction and excellent electrical characteristics assure reliable operation of electromagnetic devices and trouble-free performance.

1 For units with class 105C insulation systems. 2 For units with class 180C insulation systems.

Low Voltage Products & Systems

12.3

a Tr

sf

m or

er

General information

IEC-742

The requirements for industrial control circuit transformers to be used in the European Common Market are identified by the International Electrotechnical Commission (IEC) and specified under IEC-742, Non-Short Circuit Proof Isolating Transformers, under the Low Voltage Directive 73/23/EEC. Manufacturers of control transformers indicate compliance with these requirements by placing a CE mark on the product. In addition to being able to handle the inrush requirements of industrial control circuits and motor loads, transformers built to the requirements of IEC-742 will exhibit several major construction differences from those manufactured in accordance with UL506. These construction differences will typically increase not only the physical size of the transformer when compared to those built only to UL requirements, but the inrush capability as well. The winding insulation thickness requirements, depending upon electrical currents, are comparable layer to layer for IEC-742 versus UL506. Winding to winding insulation requirements, however, may be twice that for IEC-742 compared to UL506. The electrical clearances between current carrying parts are one-third greater to comply with IEC-742 requirements for units up to 250VA with voltages up to 440 volts ac. The dielectric strength (hipot) test voltages are twice as long in duration to comply with IEC-742 compared to UL506 for all units and up to one-and-a-half times greater in magnitude on smaller VA sizes. Transformers manufactured to IEC-742 requirements will have a minimum of 10% higher overload capacity than those manufactured only to UL506 requirements. l IEC-742 requires that transformers in a failure mode under excessive current (10 times the unit rating) must not exhibit flame or molten material. There is no comparable requirement under UL506. While no requirement exists in IEC-742 for the electrical connections to be either finger safe or touch proof, the specification does state that IF a transformer is supplied with a cover to prevent incidental contact with current carrying parts, that cover must utilize two separate methods or places of securing it to the component, with neither being dependent upon the other. Additionally, one of these methods MUST require a tool to remove it.

CB Scheme

A CE mark indicates compliance to the applicable requirements of a particular product as outlined by the International Electrotechnical Commission (IEC) and by mutual agreement is recognized throughout the European Union. By itself, however, the CE mark may not necessarily be accepted as evidence of product compliance in countries outside of the European Union. Additionally, even countries within the European Union may require their own countrys approval mark in addition to the CE mark. To that end, a system of mutual recognition and reciprocal acceptance has been developed which would allow product acceptance outside of the European Union and the ability to obtain the approval mark of countries within it. The official title for this mutual acceptance agreement is The Scheme of the IECEE for Recognition of Results of Testing to Standards for Safety of Electrical Equipment (CB Scheme for short). The basis of the CB Scheme is a CB Test Certificate providing evidence that representative samples of a particular product have been tested to a particular IEC standard and successfully passed the required tests. Each country participating in the CB Scheme, currently over 50, including East and West Europe, the Middle and Far East, and the Pacific Rim, has a representative agency, referred to as a National Certification Body, in the IECEE. Each participant has agreed that they will accept the test results of other members if such results are based on a reasonably harmonized IEC standard. Thus, by utilizing the CB Scheme, a manufacturer of product carrying a CE mark may be able to have that product accepted throughout the world, or obtain additional listing marks, with no further product testing being required. To utilize the CB Scheme, a manufacturer must present the appropriate test reports, along with a CB Test Certificate prepared by the National Certification Body responsible for the original product listing, to the National Certification Body of the country to which the product is being supplied. At such time as the reports are accepted, the product manufacturer may place the certification mark of the country on the product without the need for additional testing.

12

IEC-529

The requirements for finger-safe or touch-proof electrical connections are identified by the International Electrotechnical Commission (IEC) under specification 529, Classification of Degrees of Protection Provided by Enclosures. These various degrees of protection are identified and differentiated by IP ratings. A variety of IP ratings are defined in IEC-529 ranging from IP00, which provides no protection from contact, to IP68, which identifies dust-proof and water-proof protection. Optionally, IP ratings may contain additional and supplementary designators. The IP specification which most closely approximates protection to a human finger is IP20. This IP rating would be the most common degree of touchproof connection for electrical components such as transformers. IEC-529 protection requirements would most commonly apply to products which fall under the requirements of the Machinery Directive 89/392/EEC, as opposed to the Low Voltage Directive 73/23/EEC, which covers components such as control transformers. Over time, however, users subject to the requirements of the Machinery Directive and/or IEC-529 have expanded their interpretation of finger-safe or touch-proof electrical connections to include the components of the equipment, such as transformers.

12.4

Low Voltage Products & Systems

Transformers

Tr a

ns

fo

rm

er

Primary voltage 460/230/208V, 480/240V, 440/220/200V Secondary voltage 115/24V 2, 120/25V, 110/23V

B E C

208V

208V

460V

230V

460V

230V

460V

230V

0V

0V

208V

H1 H2

H3 H4

H1 H2

H3 H4

H1 H2

H3 H4

0V

115V

X1

X3

24V

X2

X3

115V 24V

X1

X2 X3

Top View C Dimensions D mm 80 102 110 118 118 134 134 151 151 131 in 27/8 27/8 23/4 3 31/8 3 3 37/8 37/8 5.37 mm 72 72 71 76 81 76 76 98 98 136 in 21/2 21/2 23/4 31/8 31/8 33/4 33/4 43/8 43/8 43/8 E mm 64 64 71 80 80 95 95 111 111 111

3

Side View Mounting slots in /16 x 7/16 3 /16 x 7/16 3 /16 x 7/16 3 /16 x 7/16 3 /16 x 7/16 3 /16 x 7/16 3 /16 x 7/16 5 /16 x 11/16 5 /16 x 11/16 5 /16 x 11/16 mm 5 x 12 5 x 12 5 x 12 5 x 12 5 x 12 5 x 12 5 x 12 8 x 27 8 x 27 8 x 27

A X4045SF1 VA Rating 45 50 75 100 150 200 250 300 350 500 Catalog number X4045SF1 X4050PSF1 X4075PSF1 X4100PSF1 X4150PSF1 X4200PSF1 X4250PSF1 X4300PSF1 X4350PSF1 X4500PSF1 List Price $ 72.70 83.88 93.20 102.52 109.98 130.48 145.39 158.44 171.49 229.27

Output Amps 24/115

B mm 115 115 114 115 128 111 120 155 155 181 in 3 3 33/8 33/4 33/4 41/2 41/2 51/4 51/4 51/4 mm 76 76 86 95 95 114 114 133 133 133 in 31/8 4 4 3 /8 45/8 45/8 51/4 51/4 6 6 51/8

in 41/2 41/2 41/2 41/2 5 43/8 43/4 61/8 61/8 71/8

1.90 / 0.39 2.08 / 0.44 3.13 / 0.65 4.17 / 0.87 6.25 / 1.30 8.33 / 1.74 10.42 / 2.17 12.50 / 2.61 14.58 / 3.04 20.84 / 4.35

Primary voltage 460/230/208V, 480/240V, 440/220/200V Secondary voltage 115V, 120V, 110V

B B E C C

12

208V

460V

230V

H1 H2

H3 H4

0V

115V

X4750PSF1

X1

X2

Top View

Top View View Side

Side View

A VA Rating 750 1000 1500 2000 3000 5000 Catalog Number X4750PS1 X41K1 X41.5K1 X42K1 X43K1 X45K1 List Price $ 270.28 298.24 428.72 521.92 736.28 1,230.24 Output Amps 6.52 8.70 13.04 17.39 26.09 43.48 in 75/8 71/8 71/2 81/4 89/16 101/2 mm 193 181 191 210 217 267 in 51/4 63/8 63/4 63/4 9 9

B mm 133 162 171 171 229 229

Dimensions C in 6 5 3 /8 511/16 511/16 7 1 /2 103/16 mm 151 137 144 144 191 259 in 53/4 41/2 47/16 51/4 53/4 61/2

D mm 146 114 113 133 147 165 in 43/8 55/16 61/16 61/16 71/2 61/2

E mm 111 135 154 154 191 165

5

Mounting slots in /16 x 11/16 5 /16 x 11/16 9 /32 x 9/16 9 /32 x 9/16 7 /16 x 3/4 7 /16 x 3/4 mm 8 x 27 8 x 17 7 x 14 7 x 14 11 x 19 11 x 19

T41K1

1 Primary & secondary fuse block provided as standard (750VA unit, only). 2 Whenever both secondary voltages are to be used at the same time, remove the secondary fuse clip and use a separate mounted 2 pole fuse block.

Low Voltage Products & Systems

Discount schedule AT

12.5

a Tr

sf

m or

er

Transformers

Primary voltage 600/575/550V Secondary voltage 120/115/110V

600V

B

H1

0V

H2

115V

X1

X2

Top View A B mm 76 76 89 86 102 102 111 121 133 137 178 in 3 3 3 33/8 33/4 41/2 41/2 41/2 41/2 51/4 51/4 mm 76 76 76 86 95 114 114 114 114 133 133 in 2 9/16 315/16 315/16 41/4 49/16 53/16 53/16 53/16 53/16 61/8 61/8 C Dimensions D mm 65 100 100 108 116 132 132 132 132 156 156 in 2 2 21/2 23/8 27/8 21/2 27/8 31/4 33/4 41/8 43/8 mm 51 51 64 60 73 64 73 83 95 105 146 in

Side View E mm 64 64 64 71 79 95 95 95 95 111 111

13

Mounting slots in /64 x 3/8 13 /64 x 3/8 13 /64 x 3/8 13 /64 x 3/8 13 /64 x 3/8 13 /64 x 3/8 13 /64 x 3/8 13 /64 x 3/8 13 /64 x 3/8 5 /16 x 11/16 5 /16 x 11/16 mm 5 x 10 5 x 10 5 x 10 5 x 10 5 x 10 5 x 10 5 x 10 5 x 10 5 x 10 8 x 17 8 x 17

T6045S1

Catalog VA Rating Number 45 T6045SF1 50 T6050PSF1 75 T6075PSF1 100 T6100PSF1 150 T6150PSF1 200 T6200PSF1 250 T6250PSF1 300 T6300PSF1 350 T6350PSF1 500 T6500PSF1 750 T6750PSF1

List Price $ 76.42 116.46 96.93 140.99 183.88 208.40 281.93 175.22 188.26 246.05 326.20

Output Amps 0.43 0.43 0.65 0.87 1.3 1.74 2.17 2.61 3.04 4.35 6.52

in 3 3 31/2 33/8 4 4 43/8 43/4 51/4 53/8 7

21/2 21/2 21/2 213/16 31/8 33/4 33/4 33/4 33/4 43/8 43/8

12

Primary voltage 575/460/230V Secondary voltage 115 - 95V

575V 460V 230V 0V

B E C

H1 H2

H3 H4

115V

T61K1

95V

X1

X2 X3

Top View

Side View

A VA Rating 1000 1500 2000 3000 5000 Catalog Number T61K1 T61.5K1 T62K1 T63K1 T65K1 List Output Price Amps $ 547.54 6.52 642.12 8.70 865.02 13.04 1,608.33 17.39 2,277.81 26.09 in 71/8 81/4 79/16 85/8 131/2 mm 184 210 192 219 343 in 63/8 63/4 9 9 9

B mm 162 171 229 229 229 in 53/8 511/16 79/16 79/16 103/16

C mm 137 144 192 192 259

Dimensions D in 41/2 51/4 43/16 51/4 81/4 mm 114 133 106 133 210 in 53/16 61/16 61/2 61/2 61/2

E mm 135 154 165 165 165

5 9

Mounting slots in /16 x11/16 /32 x 9/16 7 /16 x 3/4 7 /16 x 3/4 7 /16 x 3/4 mm 8 x 17 7 x 14 11 x 19 11 x 19 11 x 19

12.6

Discount schedule AT

Low Voltage Products & Systems

Technical data Transformer terminology and FAQs

What is a transformer?

A transformer is a passive electrical device which is designed to change one voltage to another by magnetic induction.

Tr a

ns

fo

rm

er

What is temperature rise?

Temperature rise is the difference between the average temperature of the transformer windings and the ambient temperature.

What is an isolation transformer?

An isolation transformer, also referred to as an insulating transformer, is one where the primary and secondary windings are separate, as opposed to an autotransformer where the primary and secondary share a common winding.

What is hot spot?

The hot spot is an allowance selected to approximate the difference between the highest temperature inside the transformer coil and the average temperature of the transformer coil.

What is a control transformer?

A control transformer is an isolation transformer designed to provide a high degree of secondary voltage stability (regulation) during a short period overload condition typically referred to as inrush. Control transformers are also referred to as Industrial Control Transformers, Machine Tool Transformers or Control Power Transformers (CPTs).

Is one insulation system better than another?

One insulation system is not necessarily better than another. Each will typically provide a comparable life expectancy. The choice of an insulation system depends upon application, performance and cost considerations.

Why is a control transformer needed?

A control transformer is required to supply voltage to a load which requires significantly more current when initially energized than under normal steady state operating conditions. A control transformer is designed to provide secondary voltage stability under a short period of specific overload referred to as inrush.

Can a control transformer be reversed connected?

A control transformer can be reverse connected. However, the output voltage will be less than nameplate due to the compensation factor of the windings.

Can a single phase transformer be used with a three phase source?

A single phase transformer can be used with a three phase source by connecting the primary leads to any two wires of the three phase system. The transformer output will be single phase.

Are control transformers current limiting?

A control transformer is not current limiting and will allow as much current to pass through as is demanded by the load. As such, a secondary overcurrent device should be utilized.

Will a control transformer regulate output voltage?

Control transformers are not voltage regulating. Because voltage changes are a function of the transformers turns ratio, variations in input voltage will be proportionally reflected to the output.

Can a transformer be used at higher frequencies?

A transformer designed for 50/60HZ operation can be utilized at frequencies up to 400 HZ. However, at 400 HZ, the inrush capability will be reduced.

What is regulation?

Regulation is the change in output voltage when the load is reduced from rated value (full load) to zero (no load) with input voltage remaining constant.

What is duty cycle?

Duty cycle is the period and duration when a transformer will be loaded. The transformer is designed to run continuously at full load without exceeding the temperature limits. Transformers may also be operated for short time duty. Depending upon the time and cycle of the maximum load, the transformer VA size may be smaller than for continuous duty.

12

Can transformers be used at ambients other than 40C?

Transformers may be used at ambients less than 40C at full nameplate capacity. For ambients above 40C, they must be derated as follows: Max. ambient temperature 40C 50C 60C Max. percent of load 180C Units 100% 90% 79% 105C Units 100% 78% 50%

What is the value of encapsulation in control transformers?

Encapsulating the coils of a control transformer will help to protect the unit from moisture, dust, dirt and industrial contaminants. Encapsulation helps provide maximum protection in hostile environments while allowing the unit to run cooler than a non-encapsulated unit.

What is the effect of altitude on a transformer?

A transformer may be used at full nameplate capacity up to 3300 feet (1000 meters). Above that altitude, the capacity of the transformer should be derated by 0.3% for each 300 feet of elevation above 3300 feet.

What effect does a control transformer have on electrical disturbances found on the line?

Because a control transformer has isolated primary and secondary windings, it will provide some degree of clean-up with regard to electrical noise, spikes, surges and transients. It will not, however, provide the same degree of power conditioning found in products designed for that purpose.

What is the effect of load on a control transformer?

A control transformer is designed to provide rated output voltage at full VA. As the load decreases, the output voltage will go up. Conversely, increases in load will result in lower output voltages. Typically, the smaller the VA size of the unit, the greater difference there is between no-load and full-load voltage.

What is temperature class?

Temperature class is the rating of the transformer insulation system. It is determined by adding the ambient temperature, temperature rise and hottest spot temperature. The standard insulation system classification per UL506, are as follows: Ambient temperature 40c 40c 40c 40c Average winding temperature rise* 55C 80C 100C 120C Hot spot temperature 10C 10C 15C 20C Temperature class 105C 130C 155C 180C

*Measured by change-in-resistance method

Low Voltage Products & Systems

12.7

a Tr

sf

m or

er

Technical data UL Overcurrent protection Primary & secondary

Overcurrent protection on both the primary and secondary sides of transformers are specified in UL508 and the National Electrical Code. The maximum acceptable ratings are shown below. Due to the high inrush currents present when a transformer is initially energized, it is recommended that the primary fuse be time delay, to prevent nuisance trips during startup.

Maximum acceptable rating of primary overcurrent protection

Primary voltage 25 50 75 100 150 VA Rating 200 250 300 350 500 750

115 120 200 208 220 230 240 277 380 400 415

6/10 (1) 6/10 (1) 3/10 (6/10) 3/10 (6/10) 3/10 (1/2) 3/10 (1/2) 3/10 (1/2) 1/4 (4/10) 3/16 (3/10) 3/16 (3/10) 15/100 (3/10) 15/100 (1/4) 15/100 (1/4) 15/100 (1/4) 1/8 (2/10) 1/8 (2/10) 1/8 (2/10)

1-1/4 (2) 1-1/4 (2) 3/4 (1-1/4) 6/10 (1-1/8) 6/10 (1-1/8) 6/10 (1) 6/10 (1) 1/2 (8/10) 3/10 (6/10) 3/10 (6/10) 3/10 (6/10) 3/10 (1/2) 3/10 (1/2) 3/10 (1/2) 1/4 (4/10) 1/4 (4/10) 2/10 (4/10)

1-8/10 (3-2/10) 1-8/10 (3) 1-1/8 (1-8/10) 1 (1-8/10) 1 (1-6/10) 8/10 (1-6/10) 8/10 (1-1/2) 8/10 (1-1/4) 1/2 (8/10) 1/2 (8/10) 1/2 (8/10) 1/2 (8/10) 4/10 (8/10) 4/10 (3/4) 4/10 (6/10) 3/10 (6/10) 3/10 (6/10)

2-1/2 (4) 2-1/4 (4) 1-1/2 (2-1/2) 1-4/10 (2-1/4) 1-1/4 (2-1/4) 1-1/4 (2) 1-1/4 (2) 1 (1-8/10) 3/4 (1-1/4) 3/4 (1-1/4) 6/10 (1-1/8) 6/10 (1-1/8) 6/10 (1) 6/10 (1) 1/2 (8/10) 1/2 (8/10) 1/2 (8/10)

3-1/2 (6-1/4) 3-1/2 (6-1/4) 2-1/4 (3-1/2) 2 (3-1/2) 2 (3-2/10) 1-8/10 (3-2/10) 1-8/10 (3) 1-6/10 (2-1/2) 1-1/8 (1-8/10) 1-1/8 (1-8/10) 1 (1-8/10) 1 (1-6/10) 8/10 (1-6/10) 8/10 (1-1/2) 8/10 (1-1/4) 3/4 (1-1/4) 3/4 (1-1/4)

5 (8) 5 (8) 3 (5) 2-8/10 (4-1/2) 2-1/2 (4-1/2) 2-1/2 (4) 2-1/4 (4) 2 (3-1/2) 1-1/2 (2-1/2) 1-1/2 (2-1/2) 1-4/10 (2-1/4) 1-1/4 (2-1/4) 1-1/4 (2) 1-1/4 (2) 1 (1-8/10) 1 (1-6/10) 8/10 (1-6/10)

5 5 3-1/2 (6-1/4) 3-1/2 (6) 3-2/10 (5-6/10) 3-2/10 (5) 3 (5) 2-1/2 (4-1/2) 1-8/10 (3-2/10) 1-8/10 (3) 1-8/10 (3) 1-6/10 (2-8/10) 1-6/10 (2-1/2) 1-1/2 (2-1/2) 1-1/4 (2-1/4) 1-1/4 (2) 1-1/4 (2)

6-1/4 6-1/4 4-1/2 (7-1/2) 4 (7) 4 (6-1/4) 3-1/2 (6-1/4) 3-1/2 (6-1/4) 3-2/10 (5) 2-1/4 (3-1/2) 2-1/4 (3-1/2) 2 (3-1/2) 2 (3-2/10) 1-8/10 (3-2/10) 1-8/10 (3) 1-6/10 (2-1/2) 1-1/2 (2-1/2) 1-1/2 (2-1/2)

7-1/2 7 5 (8) 5 (8) 4-1/2 (7-1/2) 4-1/2 (7-1/2) 4 (7) 3-1/2 (6-1/4) 2-1/2 (4-1/2) 2-1/2 (4) 2-1/2 (4) 2-1/4 (3-1/2) 2-1/4 (3-1/2) 2 (3-1/2) 1-8/10 (3) 1-8/10 (3) 1-6/10 (2-8/10)

10 10 6-1/4 6 5-6/10 5 5 5 (9) 3-1/2 (6-1/4) 3-1/2 (6-1/4) 3-1/2 (6) 3-2/10 (5-6/10) 3-2/10 (5) 3 (5) 2-1/2 (4-1/2) 2-1/2 (4) 2-1/4 (4)

15 15 9 9 8 8 7-1/2 6-1/4 5-6/10 (9) 5-6/10 (9) 5 (9) 5 (8) 4-1/2 (8) 4-1/2 (7-1/2) 4 (6-1/4) 3-1/2 (6-1/4) 3-1/2 (6-1/4)

12

440 460 480 550 575 600

If the rated primary current is less than 2 amps, the maximum rating of the overcurrent device is 300% for power circuits, shown above, or 500% for control circuits, shown above in (brackets). If the rated primary current is 2 amps or more, the maximum rating of the overcurrent device is 250%. All figures assume secondary overcurrent protection per UL/NEC. Reference: NEC 430 - 72(c) exception #2, 450-3(b) 1 & 2, UL508 32.7, UL845 11.16 & 11.17.

Maximum acceptable rating of secondary overcurrent protection

Secondary voltage 25 50 75 100 150 VA Rating 200 250 300 350 500 750

23 24 25 90 95 100 110 115 120 220 230 240

1-8/10 1-6/10 1-6/10 4/10 4/10 4/10 3/10 3/10 3/10 15/100 15/100 15/100

3-1/2 3-2/10 3-2/10 8/10 8/10 8/10 3/4 6/10 6/10 3/10 3/10 3/10

5 5 5 1-1/4 1-1/4 1-1/4 1-1/8 1 1 1/2 1/2 1/2

7 6-1/4 6-1/4 1-8/10 1-6/10 1-6/10 1-1/2 1-4/10 1-1/4 3/4 6/10 6/10

10 10 10 2-1/2 2-1/2 2-1/2 2-1/4 2 2 1-1/8 1 1

12 12 12 3-1/2 3-1/2 3-2/10 3 2-8/10 2-1/2 1-1/2 1-4/10 1-1/4

15 15 15 4-1/2 4 4 3-1/2 3-1/2 3-2/10 1-8/10 1-8/10 1-6/10

20 20 15 5 5 5 4-1/2 4 4 2-1/4 2 2

20 20 20 6-1/4 6 5-6/10 5 5 4-1/2 2-1/2 2-1/2 2-1/4

30 30 25 9 8 8 7-1/2 7 6-1/4 3-1/2 3-1/2 3-2/10

45 40 40 12 12 12 10 10 10 5-6/10 5 5

If the rated secondary current is less than 9 amps, the maximum rating of the overcurrent device is 167%; 9 amps or more, the maximum rating of the overcurrent device is 125%. If 125% does not correspond to a standard fuse rating, the next highest standard rating may be used. Reference: NEC 430 - 72(c) exception #2, 450-3(b) 1 & 2, UL508 32.7, UL845 11.16 & 11.17.

12.8

Low Voltage Products & Systems

You might also like

- VPR D Vacuum - Circuit - Breakers October2013 PDFDocument23 pagesVPR D Vacuum - Circuit - Breakers October2013 PDFtqbao4949No ratings yet

- Bus ProtectionDocument46 pagesBus ProtectionrdelgranadoNo ratings yet

- 3AG 3AF Outdoor Vacuum Circuit-Breakers Up To 40.5kV PDFDocument12 pages3AG 3AF Outdoor Vacuum Circuit-Breakers Up To 40.5kV PDFFranco David Chiarella TapiaNo ratings yet

- 0613CT0001 PDFDocument180 pages0613CT0001 PDFhimanshu yadavNo ratings yet

- Eti Fuses PDFDocument2 pagesEti Fuses PDFCaseyNo ratings yet

- Cables Aetna PDFDocument1 pageCables Aetna PDFRolando Henry Flores CamavilcaNo ratings yet

- SieyuanDocument4 pagesSieyuandanny maciasNo ratings yet

- Hvpak 18-02Document1 pageHvpak 18-02chengkkNo ratings yet

- C 407eb - GCHK 100 PDFDocument2 pagesC 407eb - GCHK 100 PDFHamilton GutierrezNo ratings yet

- Completely Self Protected Distribution (CSP) TransformersDocument11 pagesCompletely Self Protected Distribution (CSP) Transformersjobpei2No ratings yet

- Design of Transformers: A Step-by-Step GuideDocument21 pagesDesign of Transformers: A Step-by-Step GuideTahamee SHAIKHNo ratings yet

- Instruction Sheet D3208 MANUALDocument48 pagesInstruction Sheet D3208 MANUALscalariNo ratings yet

- Overhead Line ReclosesDocument14 pagesOverhead Line Reclosesalaa_saqNo ratings yet

- DCR Web PDFDocument4 pagesDCR Web PDFMahmoud AyadNo ratings yet

- Areva CT CCV CC English 72.5 20a 20765kVDocument4 pagesAreva CT CCV CC English 72.5 20a 20765kVnarinderNo ratings yet

- Manual DHP PDFDocument76 pagesManual DHP PDFJavier Salvador Fernandez FranciscoNo ratings yet

- PCS-931 MY Instruction Manual en General X R1.00 (En XLBH5104.0060.1101)Document229 pagesPCS-931 MY Instruction Manual en General X R1.00 (En XLBH5104.0060.1101)Mạc DavidNo ratings yet

- VRLA Instruction ManualDocument11 pagesVRLA Instruction Manualashja batteryNo ratings yet

- 1YHB00000002060 Voltage Indicator Cvd3 Il With CVD PC 3 3m Rated For Unigear Zs1 3kv 6kv 12kv OveDocument2 pages1YHB00000002060 Voltage Indicator Cvd3 Il With CVD PC 3 3m Rated For Unigear Zs1 3kv 6kv 12kv OvefrosverNo ratings yet

- 1250A Circuit Breaker and Disconnector Spec SheetDocument12 pages1250A Circuit Breaker and Disconnector Spec SheetPhước Khang NguyễnNo ratings yet

- 20 Chris Searles NERC PRC 005 02Document9 pages20 Chris Searles NERC PRC 005 02armandoa71565No ratings yet

- Siemens - Geafol Cast-Resin, Behavior in FireDocument4 pagesSiemens - Geafol Cast-Resin, Behavior in FirebookbumNo ratings yet

- Transformers Padmounted CompartmentalizedDocument2 pagesTransformers Padmounted CompartmentalizedRodel D DosanoNo ratings yet

- LC1D1210 Telemecanique LC1-D12-10 Contactor Replacement PDFDocument1 pageLC1D1210 Telemecanique LC1-D12-10 Contactor Replacement PDFredaNo ratings yet

- Man VLF Sinus 51 Eng 2Document33 pagesMan VLF Sinus 51 Eng 2Lê Nguyên TríNo ratings yet

- SalzerDocument37 pagesSalzerabu1882100% (1)

- Woodward Mca4 v2.0.h PTT User Manual EnuDocument6 pagesWoodward Mca4 v2.0.h PTT User Manual EnuRaúlEmirGutiérrezLópezNo ratings yet

- Siprotec 7sx800 Profile - enDocument2 pagesSiprotec 7sx800 Profile - enersanjeeb_456No ratings yet

- 4327 Corrosive Sulphur Flyer PDFDocument2 pages4327 Corrosive Sulphur Flyer PDFMichael Angelo VidalNo ratings yet

- Motor Datasheet 1500 HP 2300V PDFDocument8 pagesMotor Datasheet 1500 HP 2300V PDFGilberto MejiaNo ratings yet

- Aislador Estacion NPP20XG27SDocument1 pageAislador Estacion NPP20XG27SSaúl Gómez RobinsónNo ratings yet

- Tech Note 26Document6 pagesTech Note 26Srinivas PentapatiNo ratings yet

- CABAWinDocument80 pagesCABAWinHoang AnhNo ratings yet

- Trihal - Up To 3 150 kVA: Cast Resin TransformersDocument8 pagesTrihal - Up To 3 150 kVA: Cast Resin TransformersReyaz Basha100% (1)

- 1 - IGARD GCHK-100 Mining Relay Instruction ManualDocument21 pages1 - IGARD GCHK-100 Mining Relay Instruction ManualJhann Oliva GalvezNo ratings yet

- 5.2 Dm1-A - LPCT - 081114Document11 pages5.2 Dm1-A - LPCT - 081114cachiletNo ratings yet

- Busbar trunking system project detailsDocument2 pagesBusbar trunking system project detailsAndes PutraNo ratings yet

- MX Spark Detector FUX 4000 UEWA PDFDocument2 pagesMX Spark Detector FUX 4000 UEWA PDFNarendra Reddy BhumaNo ratings yet

- SQ-300®i Automatic Voltage Control: Proven Electrostatic Precipitator SolutionsDocument2 pagesSQ-300®i Automatic Voltage Control: Proven Electrostatic Precipitator SolutionsRafael Paiva100% (1)

- 3ap1 DTC: - Dead Tank CompactDocument18 pages3ap1 DTC: - Dead Tank CompactFidel AgüeroNo ratings yet

- Euromold CatalogoDocument24 pagesEuromold CatalogoPablo RodaNo ratings yet

- Nxair enDocument28 pagesNxair endmglennonNo ratings yet

- Solutions: Power ProtectionDocument47 pagesSolutions: Power Protectionkamil arnous100% (1)

- Product Catalogue: Power CablesDocument54 pagesProduct Catalogue: Power CablesBrion Bara IndonesiaNo ratings yet

- Catalog Megger Mto210 PDFDocument2 pagesCatalog Megger Mto210 PDFleha_pc3No ratings yet

- Protecciones de Tierra de TransformadoresDocument9 pagesProtecciones de Tierra de Transformadoresmaidenheavy1No ratings yet

- Short Circuit Calculations With SIMARIS DesignDocument0 pagesShort Circuit Calculations With SIMARIS Designsuljo1234No ratings yet

- Grupos de ConexionDocument13 pagesGrupos de ConexionPedro SanchezNo ratings yet

- StacoAVR2 PDFDocument20 pagesStacoAVR2 PDFmaungNo ratings yet

- Reconectador GVRDocument16 pagesReconectador GVRjuanete29100% (1)

- Raychem - RSTI InstalaciónDocument6 pagesRaychem - RSTI Instalaciónfredy telloNo ratings yet

- Power QualityDocument9 pagesPower QualityJuhi PatilNo ratings yet

- E214 64 PDFDocument1 pageE214 64 PDFJosue Espinoza YachachinNo ratings yet

- Air Circuit Breakers Technical SpecsDocument28 pagesAir Circuit Breakers Technical SpecsDerargh100% (1)

- Manual 3UG4625Document5 pagesManual 3UG4625Saulo VieiraNo ratings yet

- Catalog Medicale en PDFDocument196 pagesCatalog Medicale en PDFLiviu PetreusNo ratings yet

- MX Interactive Analogue Addressable Detectors PDFDocument2 pagesMX Interactive Analogue Addressable Detectors PDFNarendra Reddy BhumaNo ratings yet

- Catalogue-Simoprime en PDFDocument16 pagesCatalogue-Simoprime en PDFhizbi7No ratings yet

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsFrom EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsNo ratings yet

- Transformers optimize performanceDocument4 pagesTransformers optimize performanceBanupriya BalasubramanianNo ratings yet

- Watlow SERV-RITE WireDocument40 pagesWatlow SERV-RITE WireEliasNo ratings yet

- Watlow Heater Selection MatrixDocument4 pagesWatlow Heater Selection MatrixEliasNo ratings yet

- Watlow Resistance Temperature SensorsDocument21 pagesWatlow Resistance Temperature SensorsEliasNo ratings yet

- Watlow AccessoriesDocument30 pagesWatlow AccessoriesEliasNo ratings yet

- Watlow Circulation HeatersDocument54 pagesWatlow Circulation HeatersEliasNo ratings yet

- Watlow Reference DataDocument19 pagesWatlow Reference DataEliasNo ratings yet

- Watlow Strip Clamp On HeatersDocument15 pagesWatlow Strip Clamp On HeatersEliasNo ratings yet

- Watlow Cartridge HeatersDocument49 pagesWatlow Cartridge HeatersEliasNo ratings yet

- Watlow Mineral InsulatedDocument13 pagesWatlow Mineral InsulatedEliasNo ratings yet

- Watlow Tubular HeatersDocument55 pagesWatlow Tubular HeatersEliasNo ratings yet

- Watlow Thermocouple SDocument62 pagesWatlow Thermocouple SEliasNo ratings yet

- Watlow Immersion HeatersDocument163 pagesWatlow Immersion HeatersEliasNo ratings yet

- Watlow Fluid Delivery HeatersDocument5 pagesWatlow Fluid Delivery HeatersEliasNo ratings yet

- Watlow Radiant HeatersDocument16 pagesWatlow Radiant HeatersEliasNo ratings yet

- Watlow High Temperature HeatersDocument33 pagesWatlow High Temperature HeatersEliasNo ratings yet

- Watlow Flexible HeatersDocument46 pagesWatlow Flexible HeatersEliasNo ratings yet

- Waltlow Specialty HeatersDocument17 pagesWaltlow Specialty HeatersEliasNo ratings yet

- Watlow Air HeatersDocument32 pagesWatlow Air HeatersEliasNo ratings yet

- Watlow Thermostats and AccessoriesDocument10 pagesWatlow Thermostats and AccessoriesEliasNo ratings yet

- Watlow Band Barrel HeatersDocument13 pagesWatlow Band Barrel HeatersEliasNo ratings yet

- Watlow Agency Heaters CertificationsDocument6 pagesWatlow Agency Heaters CertificationsEliasNo ratings yet

- Watlow Nozzle HeatersDocument5 pagesWatlow Nozzle HeatersEliasNo ratings yet

- Watlow Operator InterfacesDocument11 pagesWatlow Operator InterfacesEliasNo ratings yet

- Watlow Integrated Multi-FunctionDocument45 pagesWatlow Integrated Multi-FunctionEliasNo ratings yet

- Watlow Temperature and ProcessDocument24 pagesWatlow Temperature and ProcessEliasNo ratings yet

- Watlow Data LoggersDocument10 pagesWatlow Data LoggersEliasNo ratings yet

- Watlow Controller AccessoriesDocument12 pagesWatlow Controller AccessoriesEliasNo ratings yet

- Watlow Power Switching DevicesDocument38 pagesWatlow Power Switching DevicesEliasNo ratings yet

- Watlow SoftwareDocument10 pagesWatlow SoftwareEliasNo ratings yet

- Watlow Limits ScannersDocument24 pagesWatlow Limits ScannersEliasNo ratings yet

- Phase and Group VelocityDocument3 pagesPhase and Group VelocityKeshav ChhapoliaNo ratings yet

- Fabrication of Segmented-Channel MOSFETs for SCE ReductionDocument2 pagesFabrication of Segmented-Channel MOSFETs for SCE ReductioncreativityyNo ratings yet

- Summer Training Report: Sarvjeet Mor EEE (Roll No. 4350, 7 Sem)Document48 pagesSummer Training Report: Sarvjeet Mor EEE (Roll No. 4350, 7 Sem)Saransh DeswalNo ratings yet

- 8F/-Electrical Installation: Block - D Superstructure 08Document46 pages8F/-Electrical Installation: Block - D Superstructure 08Sajeewa Lakmal90% (10)

- Log Periodic V Array-Quad ArrayDocument5 pagesLog Periodic V Array-Quad ArrayRobert TurnerNo ratings yet

- Atomic Structure RulesDocument3 pagesAtomic Structure RulesMd Abdus SaburNo ratings yet

- Licensing Electrical Cables JointersDocument17 pagesLicensing Electrical Cables Jointersraedkaissi5096100% (2)

- Electromagnetic Compatibility: Unit-1: Introduction To EmcDocument28 pagesElectromagnetic Compatibility: Unit-1: Introduction To EmcShiva Prasad M100% (1)

- (DPR1000) Modbus Map Tech Data en 201909Document2 pages(DPR1000) Modbus Map Tech Data en 201909Duẩn Nguyễn VănNo ratings yet

- Popular Electronics Electronic Hobbyists Handbook 1989Document171 pagesPopular Electronics Electronic Hobbyists Handbook 1989tpapre90% (20)

- Transmission Materials Standard Specification for Current TransformersDocument0 pagesTransmission Materials Standard Specification for Current Transformersrenjithas2005No ratings yet

- Introduction To AC CircuitsDocument11 pagesIntroduction To AC CircuitsRyan A. RamosNo ratings yet

- Full Mock - 1 Paper-4Document7 pagesFull Mock - 1 Paper-4Dewan Olin ChotepadaeNo ratings yet

- ACS800 CatalogueDocument40 pagesACS800 CatalogueDeepak JainNo ratings yet

- Line Differential Protection Red670Document8 pagesLine Differential Protection Red670igorsfaceNo ratings yet

- True VisionDocument9 pagesTrue Visionmanoj DocsNo ratings yet

- InductorsDocument37 pagesInductorsAlexander Robles Caicedo100% (1)

- Electronic Device and Circuit Theory 11t-Halaman-1,5,852-856Document7 pagesElectronic Device and Circuit Theory 11t-Halaman-1,5,852-856Be guNo ratings yet

- Testing Industrial Resistance Thermometers: Standard Test Methods ForDocument21 pagesTesting Industrial Resistance Thermometers: Standard Test Methods ForFrancisco ArizagaNo ratings yet

- LG 32lh30fr-Ma Chassis Lp91aDocument30 pagesLG 32lh30fr-Ma Chassis Lp91aJohn TrejoNo ratings yet

- Overtone, IR Spectroscopy, Raman SpectrosDocument12 pagesOvertone, IR Spectroscopy, Raman SpectrosMahmood Mohammed AliNo ratings yet

- Quiz 20 Reflection and AbsorptionDocument1 pageQuiz 20 Reflection and AbsorptionAnonymous L4VPBZNo ratings yet

- Wireless Radioline Data Sheet RAD 2400 Phoenix Contact PDFDocument12 pagesWireless Radioline Data Sheet RAD 2400 Phoenix Contact PDFMuhammad Fajar ArmanNo ratings yet

- Microwave Engineering-Chapter 11-SampleDocument60 pagesMicrowave Engineering-Chapter 11-SampleVamshi KrishnaNo ratings yet

- 1.5KE6.8 to 440V transient voltage suppressor datasheetDocument3 pages1.5KE6.8 to 440V transient voltage suppressor datasheettuecamphu1No ratings yet

- Low Cost, Precision 2.5 V IC References AD1403/AD1403ADocument4 pagesLow Cost, Precision 2.5 V IC References AD1403/AD1403AaseelNo ratings yet

- NERC Standardized Component Model ManualDocument19 pagesNERC Standardized Component Model ManualNagy AbedNo ratings yet

- Full Wave Bridge Rectifier AdvantagesDocument4 pagesFull Wave Bridge Rectifier AdvantagesNoor HassanNo ratings yet

- Technical Specification For Termonorte 93MW DFPPDocument23 pagesTechnical Specification For Termonorte 93MW DFPPandersonNo ratings yet

- Prototype CNC Machine Design Article Analyzes Modular SystemDocument6 pagesPrototype CNC Machine Design Article Analyzes Modular SystemTheng ChanntholNo ratings yet