Professional Documents

Culture Documents

Plastic Identification Chart

Uploaded by

mohammadCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plastic Identification Chart

Uploaded by

mohammadCopyright:

Available Formats

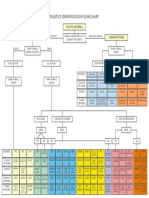

PLASTICS AND ELASTOMERS IDENTIFICATION CHART

PLASTIC MATERIALS ELASTOMERS

SOFTENS PRESS A SOLDERING IRON

THERMOPLASTICS OR A HOT ROD (500 F) THERMOSETS

AGAINST THE SAMPLE

Floats Sinks

Drop a small

BURN A SMALL CORNER OF THE SAMPLE sample in water

FLOATS DROP A SMALL SINKS

SAMPLE IN

WATER SELF-EXTINGUISHING CONTINUES TO BURN

TPV

TPO

MATERIAL MELAMINE PHENOL UREA

DAP FORMALDE- FORMALDE- FORMALDE- POLYESTER SILICONE EPOXY

OBSERVATIONS HYDE HYDE HYDE

PP, PE ALL OTHERS YELLOW YELLOW Self-Extinguishing

YELLOW Burn a small corner

COLOR OF FLAME YELLOW WITH WITH BRIGHT

WITH YELLOW

GREENISH BLUE YELLOW YELLOW of the sample

BLUE TIP BLUE EDGE EDGES

FAINT FISH SOUR PUNGENT

ODOR ODOR OF PHENOL FORMALDEHYDE NONE

LIKE CINNAMON AMINE TPV TPO

PHENOL Continues

BLACK to burn

OTHER SWELLS MAY OR MAY SWELLS SMOKE CONTINUES

BLACK BLACK Blue Base Blue with

MATERIAL SMOKE

AND NOT BE AND WITH TO

SMOKE

CHARACTERISTICS CRACKS SELF-EXTING. CRACKS BURN Large Yellow Yellow Tip Silicone

PE PP SOOT Tip

OBSERVATIONS

BLUE WITH BLUE WITH Burning Rubber Paraffin Wax Yellow

COLOR OF FLAME YELLOW YELLOW BURN A SMALL CORNER OF THE SAMPLE SELF-EXTINGUISHING

TIP TIP Sample

Glows

ACRID OR

ODOR PARAFFIN DIESEL NO FLAMES CONTINUES TO BURN Fast Slow

FUMES URETHANE

None

SPEED OF BURNING STYRENIC POLYESTER POLYAMIDE

ABS, ACRYLICS NYLON Black Smoke Melts & Drips POLYETHER POLYESTER

SLOW ≤ 3 INCHES FAST SLOW POLYCARBONATE

ACETALS Slow TYPE TYPE

FAST > 3 PER MIN. PPO

PTFE CELLULOSE ACETATE POLYSULFONE BLUE WHITE

MELTS CTFE CELLULOSE ACETATE BUTYRATE PVC YELLOW YELLOW

OTHER White YELLOW YELLOW SMALL YELLOW

& PVF CELLULOSE PROPIONATE ORANGE ORANGE

CHARACTERISTICS Smoke, TIP

DRIPS FEP CELLULOSE NITRATE Burned Part

POLYSTYRENE BURNT

Turns White FAINT BURNING

POLYURETHANE SWEET WOOL OR

APPLE RUBBER

POLYESTER HAIR

DRIPS

DRIPS DRIPS FAST SLOW FAST SLOW SLOW

YES NO YES NO YES NO

GRAY/BLACK SMOKE BLACK SOOTY

NO SMOKE

BUBBLES AND SPUTTERS SMOKE SMOKE

MATERIAL CELLULOSE

FEP CTFE PTFE PVF ABS ACETAL ACRYLICS CELLULOSE ACETATE CELLULOSE POLY- POLYESTER CELLULOSE POLY- NYLON POLY- POLY- PPO PPS PVC

ACETATE BUTYRATE PROPIONATE STYRENE NITRATE URETHANE SULFONE CARBONATE

OBSERVATIONS

BLUE BLUE YELLOW YELLOW YELLOW

YELLOW PALE BLUE WITH ORANGE YELLOWISH YELLOW- WITH

COLOR OF FLAME WITH YELLOW BLUE WITH YELLOW WITH WITH BLUE YELLOW YELLOW WITH BLUE YELLOW YELLOW ORANGE OR

YELLOW ORANGE ORANGE GREEN

EDGES TIP SPARKS TIP EDGES TIP YELLOW EDGES

BURNT

BURNT ACETIC BURNT FORMALDE- FRUITY/ RANCID BURNT ILLUMINATING BURNING FAINT WOOL ODOR FAINT HYDRO-

ODOR ACIDIC ACRID VINEGAR GAS OR CAMPHOR OF PHENOL PHENOL ROTTEN CHLORIC

HAIR ACID HAIR HYDE FLORAL BUTTER SUGAR RUBBER APPLE OR

MARIGOLD HAIR SULFUR EGGS ACID

SPEED OF BURNING

SLOW ≤ 3 INCHES SLOW SLOW FAST SLOW SLOW FAST FAST FAST FAST FAST SLOW FAST SLOW SLOW SLOW SLOW

FAST > 3 PER MIN.

BLACK FROTHS BLACK SOME SOME DENSE BLACK SAMPLE SLIGHT BLACK BLACK DIFFICULT METALLIC

OTHER NO SOUND WHITE

SMOKE AND SMOKE SMOKE BLACK SMOKE SMOKE BURNS BLACK FROTHS SMOKE SMOKE TO IGNITE

CHARACTERISTICS SMOKE WITH SOOT WITH SOOT COMPLETELY SMOKE WITH SOOT WITH SOOT SMOKE WHEN SMOKE

WITH SOOT CRACKLES WITH SOOT WITH SOOT SMOKE DROPPED

© Vishu Shah, Consultek, LLC, 460-D West Lambert Road, Brea, CA 92821, 714-674-1981

The Plastics identification technique is laid out in flowchart for eash step-by-step identification by process of elimination. This is shown in the

plastics Identification Chart. There are some basic guidelines one must follow in order to simplify the procedure. The first step is to determine

whether the material is thermoplastic or thermoset. This distinction is made by simply probing the sample with a soldering iron or a hot rod heated

to approximately 500°F. If the sample softens, the material is thermoplastic. If not, it is thermoset. The next step is to conduct a flame test. It is

desirable to use a colorless Bunsen burner. A matchstick can also be used in place of a Bunsen burner. However, care must be taken to distinguish

between the odor of the materials used in the match and the odor given off by burning plastic materials. Before commencing the burning test, it is

advisable to be prepared to write down the following observations:

1.Does the material burn? 2.color of flame 3.Odor 4.Does the material drip while burning 5.Nature of smoke and color of smoke.

6. The presence of soot in the air. 7. Self-extinguishes or continues to burn. 8. Speed of burning--fast or slow

To identify the material, compare the actual observations with the ones listed in the flowchart. The accuracy of the test can be greatly improved by

performing similar tests on a known sample. While performing the identification tests, one must not overlook safety factors. The drippings from

the burning plastic may be very hot and sticky. After extinguishing the flame, inhale the smoke very carefully. Certain plastics like acetals give off

a toxic formaldehyde gas that may cause a severe burning sensation in the nose and chest.

You might also like

- Aspen Hysys Plastic PyrolysisDocument6 pagesAspen Hysys Plastic PyrolysishanaNo ratings yet

- Exploration KerinciDocument6 pagesExploration KerinciNovia Pirma Yeni PirdausNo ratings yet

- Aspen Plus Simulation of Polyethylene GasificationDocument17 pagesAspen Plus Simulation of Polyethylene Gasificationkishna009No ratings yet

- Alternative Process of Glucose To Be SorbitolDocument3 pagesAlternative Process of Glucose To Be SorbitolNabilatun SholikhaNo ratings yet

- Jump Start To Crushing and Milling in AspenPlus v8 - DownLoadLy - IrDocument14 pagesJump Start To Crushing and Milling in AspenPlus v8 - DownLoadLy - IrMarcoiNo ratings yet

- Transport Phenomena Data CompanionDocument160 pagesTransport Phenomena Data CompanionAna Luisa Garnica SalgadoNo ratings yet

- 1996 - Walford - Composition of Cane JuiceDocument2 pages1996 - Walford - Composition of Cane JuiceMartha GamalNo ratings yet

- E4 Batch Distillation 2016Document5 pagesE4 Batch Distillation 2016jayaprinaNo ratings yet

- Azbil Control Valve - CatalogueDocument10 pagesAzbil Control Valve - CataloguevallahanggaNo ratings yet

- PET flakes recycled into UV-curable resinsDocument10 pagesPET flakes recycled into UV-curable resinsR_M_M_No ratings yet

- K Untuk AmberlystDocument6 pagesK Untuk AmberlystcintyafitrianiNo ratings yet

- Mass Transfer Study and Modeling of Gas-Liquid Membrane ContactingDocument8 pagesMass Transfer Study and Modeling of Gas-Liquid Membrane Contactingpraveen100% (1)

- Plate Heat Exchanger SpecialistsDocument12 pagesPlate Heat Exchanger SpecialistsPKP MECHNo ratings yet

- Heat Capacity of Liquids - Critical Review and Recommended ValuesDocument404 pagesHeat Capacity of Liquids - Critical Review and Recommended ValuesDoris AngNo ratings yet

- B.Tech CH PDFDocument146 pagesB.Tech CH PDFAshutosh MishraNo ratings yet

- Shaftseal Chapter2 PDFDocument20 pagesShaftseal Chapter2 PDFImmanuel AutomatonNo ratings yet

- Preparation of 2,6-Diisopropylaniline PDFDocument2 pagesPreparation of 2,6-Diisopropylaniline PDFsam123potter100% (1)

- Cooling Towers Information PackageDocument25 pagesCooling Towers Information Packagemdawg467No ratings yet

- PFD PrintDocument1 pagePFD PrintAgung PrabowoNo ratings yet

- Thermodynamic model for vapor-liquid equilibria of the formaldehyde-water-methanol systemDocument7 pagesThermodynamic model for vapor-liquid equilibria of the formaldehyde-water-methanol systemsatishchemeng100% (1)

- 14 Chemical Recycling - Wim Hoenderdaal PDFDocument11 pages14 Chemical Recycling - Wim Hoenderdaal PDF7ferpac7No ratings yet

- Correlation of entrainment for annular flow in horizontal pipesDocument24 pagesCorrelation of entrainment for annular flow in horizontal pipesJohn Doe100% (1)

- Glycerol Tank Acetic Acid Tank Propyl Acetate Tank Triacetin Tank Recovery Acetid Acid TankDocument1 pageGlycerol Tank Acetic Acid Tank Propyl Acetate Tank Triacetin Tank Recovery Acetid Acid TankGusti Ayoe NurjanahNo ratings yet

- Membrane Gas-Solvent Contactor Trials of CO2 Absorption From SyngasDocument10 pagesMembrane Gas-Solvent Contactor Trials of CO2 Absorption From SyngascurlychemNo ratings yet

- DME-Review of TechnologiesDocument24 pagesDME-Review of TechnologiesSteven AlexanderNo ratings yet

- Amine Gas TreatingDocument3 pagesAmine Gas Treatinghmudassir_1No ratings yet

- AspenPolymersUnitOpsV8 - 4-Usr PDFDocument841 pagesAspenPolymersUnitOpsV8 - 4-Usr PDFValeria MolinaNo ratings yet

- The Effect of Particle Size Distributions On The Microstructural Evolution During SinteringDocument12 pagesThe Effect of Particle Size Distributions On The Microstructural Evolution During SinteringGusti EricsandraNo ratings yet

- Hydrocarbon Characterization for the Hydrocarbon Risk CalculatorDocument72 pagesHydrocarbon Characterization for the Hydrocarbon Risk CalculatorSteve MahoneyNo ratings yet

- Density, Thermal Expansivity, and Compressibility of Liquid Water From 0° To 150°CDocument9 pagesDensity, Thermal Expansivity, and Compressibility of Liquid Water From 0° To 150°CJuan Daniel Vallejo BernalNo ratings yet

- Source Material PDFDocument2 pagesSource Material PDFsantisal11No ratings yet

- Chemcad Unifac GroupsDocument6 pagesChemcad Unifac Groupssnikt7863443No ratings yet

- Prico Process PDFDocument13 pagesPrico Process PDFcorkynhoNo ratings yet

- Firepel K133 Series Polyester ResinDocument3 pagesFirepel K133 Series Polyester ResinShahzaib KhanNo ratings yet

- 071 - 88 Ing.3Document18 pages071 - 88 Ing.3Leonardo SaggiomoNo ratings yet

- UOP77Document8 pagesUOP77arnautdusan100% (1)

- Refrigerated Butane SpecsDocument1 pageRefrigerated Butane SpecsMam Sok PagngnaNo ratings yet

- HSFCCDocument22 pagesHSFCCdonald55555100% (1)

- Curriculum Vitae of Assist Professor Farah Talib Jasim Al-SudaniDocument4 pagesCurriculum Vitae of Assist Professor Farah Talib Jasim Al-SudaniAlexandra ElenaNo ratings yet

- Random PackingDocument4 pagesRandom PackingAadam AryanNo ratings yet

- Mass Transfer TechnologyDocument32 pagesMass Transfer TechnologyVasu DevanNo ratings yet

- Simulation of GTL Process in Slurry Bubble Column ReactorDocument159 pagesSimulation of GTL Process in Slurry Bubble Column ReactorlumengentiunNo ratings yet

- Physical Property Methods and ModelsDocument436 pagesPhysical Property Methods and Modelstranhoangan100% (1)

- 4500MB Parr Stirred Reactors and Pressure Vessels Catalog v15 Literature 2Document178 pages4500MB Parr Stirred Reactors and Pressure Vessels Catalog v15 Literature 2asdasdNo ratings yet

- Catalysts Catafin HEDocument4 pagesCatalysts Catafin HEsashaNo ratings yet

- Distillation Columns Containing Structured Packings. A Comprehensive Model For Their Performance. 1. Hydraulic ModelsDocument11 pagesDistillation Columns Containing Structured Packings. A Comprehensive Model For Their Performance. 1. Hydraulic ModelsJohan Sebastian Moreno LaraNo ratings yet

- Extruder Times 1Document4 pagesExtruder Times 1skimmer05No ratings yet

- ALPEMA Standards Rev1Document8 pagesALPEMA Standards Rev1nattusharanNo ratings yet

- The Process Simulation Revolution: Thermophysical Property Needs and ConcernsDocument4 pagesThe Process Simulation Revolution: Thermophysical Property Needs and ConcernsbjsatolaNo ratings yet

- Toolbox TOP Handsaw WrenchDocument64 pagesToolbox TOP Handsaw WrenchMaydee GuarinNo ratings yet

- Module 14 Group 1 Concept MapDocument1 pageModule 14 Group 1 Concept MapAubrey GadorNo ratings yet

- Chemical Resistance GuideDocument35 pagesChemical Resistance GuideAGPNo ratings yet

- Plastics Identification Flow ChartDocument1 pagePlastics Identification Flow ChartchiralicNo ratings yet

- Legend:: Description Size Type 50mm.oDocument1 pageLegend:: Description Size Type 50mm.oDJNo ratings yet

- Lokmanya TilakDocument1 pageLokmanya TilakPradeep KumarNo ratings yet

- Rig Floor Structure: Air Drilling Associates Rig Up EquipmentDocument2 pagesRig Floor Structure: Air Drilling Associates Rig Up EquipmentAlger Danielle BallonNo ratings yet

- Disaster Risk Reduction Data for Schools in Tuburan I, Cebu ProvinceDocument1 pageDisaster Risk Reduction Data for Schools in Tuburan I, Cebu ProvinceBagamel YlananNo ratings yet

- Technical Specifications: Air CompressorsDocument1 pageTechnical Specifications: Air CompressorsSuprionoNo ratings yet

- JA Gas PFDocument2 pagesJA Gas PFsexy2714No ratings yet

- Atul LTD Risk AssessmentDocument108 pagesAtul LTD Risk AssessmentdevangNo ratings yet

- IGCSE Chemistry - Oxygen, Hydrogen and Carbon DioxideDocument15 pagesIGCSE Chemistry - Oxygen, Hydrogen and Carbon DioxideChemistryKlipz75% (4)

- Flame StabilityDocument11 pagesFlame StabilityMir Reza Negahban100% (1)

- Is Steam Power in Your Future - by Skip Goebel PDFDocument6 pagesIs Steam Power in Your Future - by Skip Goebel PDFJ ENo ratings yet

- 0791a9 AppDocument12 pages0791a9 AppJosé Luís100% (1)

- Low Volatile Doosan BabcockDocument22 pagesLow Volatile Doosan BabcockKUNALJAY100% (1)

- Micro 171 PDFDocument8 pagesMicro 171 PDFTuyen NguyenNo ratings yet

- Bunsen Burner LabDocument3 pagesBunsen Burner LabSteven CaceresNo ratings yet

- CombustionDocument46 pagesCombustionIrene Kaye AceroNo ratings yet

- A. Beccantini, A. Malczynski and E. Studer - Comparison of TNT-Equivalence Approach, TNO Multi-Energy Approach and A CFD Approach in Investigating Hemispheric Hydrogen-Air Vapor Cloud ExplosionsDocument18 pagesA. Beccantini, A. Malczynski and E. Studer - Comparison of TNT-Equivalence Approach, TNO Multi-Energy Approach and A CFD Approach in Investigating Hemispheric Hydrogen-Air Vapor Cloud ExplosionsSodaMoussezNo ratings yet

- Flus 06 Uv / Fls 09 Uv: User ManualDocument24 pagesFlus 06 Uv / Fls 09 Uv: User ManualDuyNo ratings yet

- Chemical Vs Physical ChangeDocument5 pagesChemical Vs Physical ChangeFathia HonoreNo ratings yet

- Fire Behaviour Review of Factors Affecting Wood BurningDocument49 pagesFire Behaviour Review of Factors Affecting Wood BurningMuhammad MalikNo ratings yet

- Troubleshoot AAS issuesDocument10 pagesTroubleshoot AAS issueseko budinugroho100% (1)

- Safe Scan-IiDocument1 pageSafe Scan-IiRajeevAgrawalNo ratings yet

- Laminar Premixed FlamesDocument84 pagesLaminar Premixed FlamesKoharudin SyahNo ratings yet

- Fire Protection and Arson InvestigationDocument16 pagesFire Protection and Arson Investigationrodne rufinoNo ratings yet

- Fire Explosion HazardsDocument91 pagesFire Explosion HazardsJoao Santos100% (2)

- 12Document16 pages12Anonymous kBjvdERRQNo ratings yet

- Fire Science, Fire Behaviour & Fire Growth Curve - OptimizeDocument193 pagesFire Science, Fire Behaviour & Fire Growth Curve - OptimizeHSE CRECNo ratings yet

- Base of Body Repair: Group 9Document50 pagesBase of Body Repair: Group 9Toponari MedveNo ratings yet

- Chemical Reactions and Reaction StoichiometryDocument38 pagesChemical Reactions and Reaction StoichiometryJames Loyed TabasanNo ratings yet

- IJRHS 2015 Vol03 Issue 04 06Document4 pagesIJRHS 2015 Vol03 Issue 04 06aqsa imranNo ratings yet

- Boost TheoryDocument98 pagesBoost TheoryGigi KomatsuNo ratings yet

- Secondary Air Damper ControlDocument3 pagesSecondary Air Damper ControlRajesh Kumar MohantyNo ratings yet

- GeneDocument3 pagesGeneMarj BaniasNo ratings yet

- HSE Pipelines Accidents PDFDocument128 pagesHSE Pipelines Accidents PDFRene Arancibia MuñozNo ratings yet

- In Context: Subject Area: Organic Chemistry Level: 14-16 Years (Foundation) Topic: Alcohols Source: RSC - Li/3NtocpmDocument5 pagesIn Context: Subject Area: Organic Chemistry Level: 14-16 Years (Foundation) Topic: Alcohols Source: RSC - Li/3NtocpmCarlton GrantNo ratings yet

- Jul 97Document35 pagesJul 97c_nghiaNo ratings yet