Professional Documents

Culture Documents

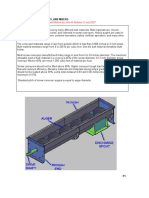

Belt Conveyors With Shaft Sizing

Uploaded by

Arun ChopraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Belt Conveyors With Shaft Sizing

Uploaded by

Arun ChopraCopyright:

Available Formats

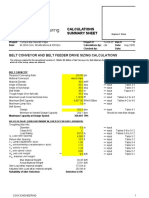

CALCULATIONS SUMMARY SHEET

Engineer's Stamp

Project: Item:

Project #: Calculations by: cdk Checked by:

Rev.#: Date: Date:

BELT CONVEYOR AND BELT FEEDER DRIVE SIZING CALCULATIONS

The reference material for this spreadsheet consists of CEMA's 4th Edition of Belt Conveyors for Bulk Materials from which all of the lookup values are obtained. CEMA 4th Edition Table or Figure or Page

BELT CAPACITY Required Conveying Rate: Material Conveyed: Material Density: Angle of Repose: Angle of Surcharge: Belt Width: Trough Angle (0 for flat belt): Maximum Load Cross Sectional Area: Maximum Belt Capacity: Maximum Lump Size: Belt Speed: Design: Minimum to Handle Design Capacity: Maximum Capacity at Design Speed:

24.00 Sand 30.0 45.0 30.0 36.0 0.0 1.1420 6,857.00 0.2

tph lb/ft deg deg in deg ft2 ft3/hr/100fpm in

3

<< input << input << input << input << input << input << input << input << input << input

Table 3-3 Table 3-3 Table 3-3 Table 3-1 Figure 4-1 Tables 4-2 to 4-5 Tables 4-2 to 4-5

25.0 fpm 23.3 fpm 25.714 TPH

<< input Table 4-1 Should be less than design

IDLER DESIGN (Only Belt Weight Wb req'd for Pan Belt Conveyors) Troughing Idler Info: Diameter 4.0 in Class (A-E) C Load Rating 837.0 lb Si, Load Idler Spacing: 4.000 ft Return Idler Spacing: 10.0 ft K1, Lump Adjustment Factor: 1.00 K2, Environmental & Maintenance Factor: 1.15 K3, Service Factor: 1.20 K4, Belt Speed Factor: 0.85 W b, Belt Unit Weight: ** 9.0 lb/ft W m, Material Unit Weight: Max Material Weight 34.26 lb/ft Actual Material Weight 32.00 lb/ft Idler Load (Max material weight): 173.04 lb Adjusted Idler Load (Max material weight): 202.98 lb Suitability of Idler Selection: Selection is OK

<< input << input << input << input << input << input << input << input << input << input

Tables 5-8 to 5-12 Tables 5-8 to 5-12 Table 5-2 Table 5-2 Table 5-4 Table 5-5 Table 5-6 Table 5-7 Table 6-1

COOK ENGINEERING

Te, EFFECTIVE TENSION Conveyor is Pan Type (Y or N): Coefficient of Dynamic Friction: # of Plows: # of Belt Cleaners (Scraper Type): L, Length of Conveyor (3000 ft maximum): H, Lift of Conveyor (Negative for Declining): # of Tight Side Non-Driving Pulleys: # of Slack Side Non-Driving Pulleys: Belt Material (Fabric or Steel): Approximate Tight Side Tension (Iterate): Approximate Slack Side Tension (Iterate): Number of drive pulleys: Lb, Length of Skirtboards (1 Side): Kt, Temperature Factor: Ai: Kx: Ky: Material velocity component in direction of belt travel as it is fed onto conveyor: Cs, Skirtboard Friction Factor: Hopper used to regulate flow of material (Y or N)? w, Width of Hopper Outlet: l, Length of Hopper Outlet: Tp, Tension From Non-Driving Pulleys: Tam, Tension from Acceleration: Tsb, Skirtboard Tension: Ttr, Tripper Tension: Tpl, Plow Tension: Tbc, Belt Cleaner Tension: Tension required to extract material from hopper (normal operation): Tension from belt on slide (Pan Conveyor Only): Te, Effective Tension (Required for Operation):

N 0.45 0.0 1.0 40.0 ft 15.0 ft 0.0 0.0 Fabric 29,040.0 lbs 15,840.0 lbs 1.0 8.0 ft 1.0 1.8 0.48 lb/ft 0.028 300.0 0.0095 N 0.0 0.0 0.0 fpm

<< input << input Pan Conveyor Only << input << input << input << input << input << input << input << input from below << input from below << input << input << input << input << input << input << input << input << input << input Fig 6-1 Page 76 Tables 6-2, 6-3 Calculate Table 6-7

in in lb

-1.9 lb 49.0 lb 0.0 lb 0.0 lb 180.0 lb 0.0 lb 0.0 lb 777.2 lb << input Page 84

**** Manual entry for this conveyor ***

BELT SELECTION Angle of Wrap, Drive Pulley: Wrap Factor Cw: (Lagged) T2, Slack-Side Tension Required to Prevent Slip with Dry Belt (higher for wet conditions): Allowable percent sag of belt: T0, Required Belt Tension to Reduce Sag: T1, Operating Maximum Belt Tension: Maximum Belt Tension per inch (operating): Maximum Allowable Starting Tension:

180.0 deg 1.20 932.6 lb 2.00 % 1,033.2 lb 1,709.8 lb 47.5 lb/in 330.0 lb/in

<< input << input

Table 6-8

<< input << input << input

Table 6-10 Calc's p. 102-110 Manufacturer

COOK ENGINEERING

MOTOR SELECTION Operating Shaft Power Required from Te: Drive pulley friction loss horsepower: Speed Reduction Efficiency: Motor and Power Supply Efficiency: Operating Motor Power Required: Effective Tension Required for Starts: Percentage Full Load Torque req'd for Starts: Breakaway Torque Required for Starting: Selected Motor Horsepower: Selected Motor RPM: Motor Locked Rotor Torque (percentage of rated full load torque. Use 140% max for VFD applications, check with manufacturer): Motor Pull Up Torque (percentage of rated full load torque, check with manufacturer): Motor Rated Full Load Torque: Breakaway Torque Available for Starting: Minimum Pull Up Torque Available: Breakaway Torque Sufficient for Starting: Pull Up Torque Sufficient for Acceleration: Selected Motor and Drive O.K.: Reduced Torque Starting Required: YES YES YES YES

0.6 0.13 98.5 99.0 0.7

hp hp % % hp

<< input << input

Manufacturer

1,074.4 lbs 138.2 % 3.1 ft-lbs 10.0 hp 1,750.0 rpm << input << input

250.0 % 175.0 30.0 75.0 52.5 % ft-lbs ft-lbs ft-lbs

<< input << input

Table 13-1 Table 13-5

Notes and Comments:

1. This design method does not cover conveyors of over 3000 feet length, horizontally curved conveyors, head and tail driven conveyors, high lift conveyors, large decline with braking requirements or conveyors with undulating geometrics. 2. This design method uses actual expected belt loading. It is worthwhile checking the horsepower requirements for a fully loaded belt in case of future higher capacity requirements. 3. Motor starting torque characteristics and conveyor acceleration should be checked in depth to ensure compatibility between motor and conveyor.

Page 16

Page 119

PULLEY SELECTION (Based on Dodge PT-Components Engineering Catalog:) Selected Motor Horsepower: 10.0 hp Pulley Face Width: 38 Inches Design Bearing Center to Center: 51.00 Inches BCMF: 13.00 Te (Effective Tension): 13,200.0 lbs Drive Factor: (1.2 for bare manual, 0.8 for lagged) 1.2 T2 (Slack Side Tension): 15,840.0 lbs T1 (Tight Side Tension): 29,040.0 lbs Design PIW (Drive Side): 806.7 lbs per inch Design PIW (Slack Side): 440.0 lbs per inch Arc of Contact: 180.0 degrees Tail Pulley Diameter: (Ext'g., Bare) 20.0 Inches Drive Pulley Diameter: (Lagged, 1/4") 24.5 Inches Check on Tail Pulley to Belt Tension 275 lbs per inch Check on Drive Pulley to Belt Tension 345 lbs per inch Selected Tail Pulley Size O.K.: NO Selected Drive Pulley Size O.K.: NO SHAFT SELECTION (Based on Dodge PT-Components Engineering Catalog:) Resultant Pulley Load (Tail): 28,321.8 lbs COOK ENGINEERING Resultant Pulley Load (Drive): 40,122.6 lbs Design Drive Pulley Shaft Size: 2.9375 Inches

<< input

<< input

Table 2 pg.13-52

<< input << input << input << input

Table 1 pg.13-12 Table 1 pg.13-12 Manufacturer Manufacturer

3 << input Manufacturer

Design Tail Pulley Shaft Size: Check on Drive Shaft Load Rating: Check on Tail Shaft Load Rating: Design Steel Shafting Grade: (1045) Valve N Adrive (use Table 4 to choose correct A calc.) KB-drive (KB = 1.5 or KB = 2.5 for Overhung load) Check on Drive Pulley Shaft from Torque: Atail (use Table 4 to choose correct A calc.) KB-tail (KB = 1.5 or KB = 2.5 for Overhung load) Check on Tail Pulley Shaft from Torque: Selected Drive Pulley Shaft O.K. for Load: Selected Drive Pulley Shaft O.K. for Torque: Selected Tail Pulley Shaft O.K. for Load: Selected Tail Pulley Shaft O.K. for Torque:

2.1875 3200 1100 8,000 6.5 8.25

Inches lbs lbs psi Inches Inches

<< input << input << input << input << input << input << input << input

Manufacturer Table 3 PT13-13 Table 3 PT13-13 Manufacturer

2.50 6.5640 Inches 8.13 1.50 4.7896 Inches NO NO YES NO

BELT SELECTION Select a belt with a MOR 1/4" X 1/8", Grooved Pattern SELECTION: SCANDURA ROLYALON 3-330 BELT SPEED REDUCER SELECTION (Based on Dodge Gearing Catalogue:) Dodge TDT Series Convert FPM to RPM: 3.9 RPM Determine Service Factor: 1 Calculate Equivalent HP 10 HP Application Class II Select Unit Size & Ratio TDT425 Unit ratio 24.38 Ratio Therefore reuse existing 10 hp motor, new TDT425 reducer required

< Note: Manual add in lagging thickness << input Table 2 pg.2-7 << input << input << input

pg G1-21

BELT DRIVE SELECTION (Based on Dodge PT-Components Engineering Catalog:) Determine Service Factor: 1.5 Design HP: 15.0 Determine Overall Ratio Required: 448.99 Determine Belt Drive Ratio: 18.42 Selected nearest ratio 1.31 Driver Sheave OD 5.70 Inches Driven Sheave OD 7.50 Inches HP Per Belt 3VX series 15.64 Minimum Number of belts required: 1.0 Belt Selection 5VX-500 Belt Center to Center Distance 16.4 Note: Designer can also use Dodge PT-Components Engineering Catalog pg. PT7-1

<< input

table 2 pg PT7-43

Motor rpm/belt rpm Overall Ratio/reducer ratio << input Page B-168 << input Page B-168 << input Page B-168 << input Page B-168 << input << input

Page B-168

COOK ENGINEERING

-2 to 4-5 -2 to 4-5

n design

8 to 5-12 8 to 5-12

COOK ENGINEERING

You might also like

- Mobile Hydraulics Manual M-2990-ADocument192 pagesMobile Hydraulics Manual M-2990-AStevan Simić93% (29)

- Catalogo ParkerDocument116 pagesCatalogo ParkerSen Sei Gómez BonardoNo ratings yet

- 2014 HDD SupplementDocument60 pages2014 HDD Supplementcraptastic100% (1)

- Manual 1Document181 pagesManual 1AdrianNo ratings yet

- Design of ConveyorsDocument15 pagesDesign of ConveyorsRamachandran VenkateshNo ratings yet

- Rig Size CalculatorDocument28 pagesRig Size CalculatorHorafig75% (4)

- Drilling Plan Analysis for Palenque Norte 12 WellDocument32 pagesDrilling Plan Analysis for Palenque Norte 12 WellHorafigNo ratings yet

- Motor Selection CalculatorDocument5 pagesMotor Selection Calculatorjay100% (5)

- EASA Module 15Document655 pagesEASA Module 15Kushlan Sanka Fernando86% (7)

- HG Kawasaki K3VL Parts Catalog WebDocument17 pagesHG Kawasaki K3VL Parts Catalog WebPartagon PowNo ratings yet

- Chain Conveyor ExampleDocument4 pagesChain Conveyor ExampledeeptidhaNo ratings yet

- AMCA Publication 203 R2007Document148 pagesAMCA Publication 203 R2007lethanhvan18680% (5)

- Vertical Roller Mill-DatasheetDocument6 pagesVertical Roller Mill-DatasheetAdnan Nawaz100% (2)

- PC30 35MR 3 PDFDocument20 pagesPC30 35MR 3 PDFSabahNo ratings yet

- Screw ConveyorDocument5 pagesScrew ConveyorEDUARDO100% (3)

- Reference Data: Terex Trucks Product LineDocument8 pagesReference Data: Terex Trucks Product LineSaid Touhami100% (1)

- Belt Conveyor Drive Sizing CalculationsDocument3 pagesBelt Conveyor Drive Sizing Calculationsmishra_1982No ratings yet

- Belt Conveyor Capacity CalculatorDocument5 pagesBelt Conveyor Capacity CalculatorramsaiNo ratings yet

- Belt Selection CalculationDocument29 pagesBelt Selection CalculationElwathig BakhietNo ratings yet

- Design (Metric) 6.25Document8 pagesDesign (Metric) 6.25Salih Has100% (2)

- HAND BOOK OF THERMOPLASTIC ROAD MARKINGDocument13 pagesHAND BOOK OF THERMOPLASTIC ROAD MARKINGArun ChopraNo ratings yet

- Conveyor CalculationDocument32 pagesConveyor CalculationsutanuprojectsNo ratings yet

- Belt Feeder Calculation CEMADocument7 pagesBelt Feeder Calculation CEMANAITIK100% (4)

- Conveyor Design CalcDocument6 pagesConveyor Design CalcGregory Nick Toledo VelizNo ratings yet

- Conveyor Tension and Trajectory CalculationDocument8 pagesConveyor Tension and Trajectory CalculationGregory Nick Toledo Veliz50% (2)

- Conveyor Design DraftDocument25 pagesConveyor Design DraftDxFxNo ratings yet

- CONVEYOR CALCULATION SHEET DraftDocument24 pagesCONVEYOR CALCULATION SHEET DraftRaghava0% (1)

- Training Notes Arrius 2F 1999-11 PDFDocument542 pagesTraining Notes Arrius 2F 1999-11 PDFAndrés60% (5)

- CEMA8 5pgDocument5 pagesCEMA8 5pgkmats100% (2)

- Shaftless Screw ConveyorsDocument2 pagesShaftless Screw Conveyorshenker21No ratings yet

- CHAIN PULL AND POWER CALCULATION FOR HORIZONTAL AND INCLINED CONVEYORDocument2 pagesCHAIN PULL AND POWER CALCULATION FOR HORIZONTAL AND INCLINED CONVEYORdeddy ariyanto100% (1)

- Belt Conveyors With Shaft SizingDocument5 pagesBelt Conveyors With Shaft SizingRakhi Mor100% (2)

- Project: Vijayawada Thermal Power Station, Stage-IV Unit#7 (500 MW) Subject: Conveyor Design Calculation As Per 5th Edition of CEMADocument7 pagesProject: Vijayawada Thermal Power Station, Stage-IV Unit#7 (500 MW) Subject: Conveyor Design Calculation As Per 5th Edition of CEMASara Lopez100% (8)

- BELT FEEDER Preliminary Dimension IngDocument29 pagesBELT FEEDER Preliminary Dimension Ingshani5573100% (1)

- Belt Feeder Calc. Pns Line 1Document4 pagesBelt Feeder Calc. Pns Line 1Waris La Joi Wakatobi67% (3)

- Apron FeederDocument2 pagesApron FeederRaji Suri100% (1)

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Conveyor CalculationDocument46 pagesConveyor CalculationBuditama Chandranegara100% (1)

- Konveyör Hesabı 7.24Document9 pagesKonveyör Hesabı 7.24Salih HasNo ratings yet

- Belt Conveyor CalcsDocument3 pagesBelt Conveyor Calcspandu_chemengNo ratings yet

- Conveyor Design-DraftDocument42 pagesConveyor Design-Draftmkchy1295% (21)

- Bucket Elevator Calculation - Rev. 1Document8 pagesBucket Elevator Calculation - Rev. 1Jose David Jurado100% (4)

- Belt Conveyor CalcsDocument3 pagesBelt Conveyor Calcsjnmanivannan100% (4)

- Bulk material chain conveyors design and maintenanceDocument11 pagesBulk material chain conveyors design and maintenancesgupta_61579683% (6)

- Bulk Material Conveyor Design Guide - Belt Selection, Idlers, Pulleys, Curves & MoreDocument56 pagesBulk Material Conveyor Design Guide - Belt Selection, Idlers, Pulleys, Curves & MoresigisyahNo ratings yet

- Belt Conveyor Take Up DesignDocument4 pagesBelt Conveyor Take Up DesignKroya HunNo ratings yet

- Belt ConveyorDocument11 pagesBelt Conveyormishra_1982No ratings yet

- Screw Conveyor Excel CalculationDocument8 pagesScrew Conveyor Excel Calculationhardik033No ratings yet

- Design and Analysis of Screw Conveyor at Inlet of Ash/Dust ConditionerDocument6 pagesDesign and Analysis of Screw Conveyor at Inlet of Ash/Dust ConditionerMohd HafizzNo ratings yet

- Line-by-line conveyor code for material handling parameters and calculationsDocument4 pagesLine-by-line conveyor code for material handling parameters and calculationskmats2No ratings yet

- Bucket Elevator Design StudyDocument24 pagesBucket Elevator Design StudyVeena100% (1)

- Technical Manual: TroubleshootingDocument6 pagesTechnical Manual: TroubleshootingMaulana SaputraNo ratings yet

- Calculate Bucket Elevator CapacityDocument2 pagesCalculate Bucket Elevator CapacityBùi Hắc HảiNo ratings yet

- Apron Feeder Power Calculations PDFDocument4 pagesApron Feeder Power Calculations PDFtuba25% (4)

- Bucket Elevator Calculation: Yellow Cell To Be FilledDocument2 pagesBucket Elevator Calculation: Yellow Cell To Be Filledm_verma21100% (2)

- Belt Conveyor CalculationDocument8 pagesBelt Conveyor CalculationFarrahxviiiNo ratings yet

- Bucket Elevator Excel Calculations Bucket Elevator ApplicationsDocument22 pagesBucket Elevator Excel Calculations Bucket Elevator ApplicationsThaigroup CementNo ratings yet

- Conveyor CalculatorDocument3 pagesConveyor CalculatorBayuNo ratings yet

- ICE All ExercisesDocument10 pagesICE All ExercisesB Ninh100% (1)

- Screw Conveyor DesignDocument8 pagesScrew Conveyor DesignPavan Kumar100% (1)

- Belt Conveyor Capacity - CalculatorDocument6 pagesBelt Conveyor Capacity - CalculatorRolando Daclan67% (3)

- TYPICAL MANUAL CALCULATIONDocument32 pagesTYPICAL MANUAL CALCULATIONSergio Diaz100% (1)

- Bucket ElevatorDocument2 pagesBucket ElevatorAndrés Lagos Méndez100% (5)

- Simple Belt Conveyor Calculation ExampleDocument3 pagesSimple Belt Conveyor Calculation ExampleBerk Koç100% (6)

- Belt Catalog #2 Bridge StoneDocument55 pagesBelt Catalog #2 Bridge Stonetinyfalse100% (3)

- Belt Conveyor PowerDocument10 pagesBelt Conveyor PowerRyukiNo ratings yet

- Apron Weigh FeederDocument4 pagesApron Weigh FeederRaji SuriNo ratings yet

- Perhitungan ConveyorDocument88 pagesPerhitungan ConveyorLukmanulHakimNo ratings yet

- RENOLD CHAIN DOUBLE PITCH SPROCKET DESIGN SPECIFICATIONSDocument1 pageRENOLD CHAIN DOUBLE PITCH SPROCKET DESIGN SPECIFICATIONSWaris La Joi Wakatobi0% (1)

- Air Slide Data SheetDocument2 pagesAir Slide Data SheetTECHCONS Consulting and Engineering Pvt LtdNo ratings yet

- Analisis Drag Scrapper Chain Feeder (FB01 & FB02) EPIDocument10 pagesAnalisis Drag Scrapper Chain Feeder (FB01 & FB02) EPIWaris La Joi WakatobiNo ratings yet

- Harmonic HPF Series SpecsheetDocument4 pagesHarmonic HPF Series SpecsheetElectromateNo ratings yet

- C3048 PNJ CAL B 0002 B Conveyor 11 CV 01Document30 pagesC3048 PNJ CAL B 0002 B Conveyor 11 CV 01Joel MooreNo ratings yet

- Sign On Roads Gov. IndiaDocument15 pagesSign On Roads Gov. IndiaArun ChopraNo ratings yet

- Garam Masala - 1 KGDocument1 pageGaram Masala - 1 KGArun ChopraNo ratings yet

- Industrial Employment (Standing Order) Act, 1946Document11 pagesIndustrial Employment (Standing Order) Act, 1946Pradyumna Kumar AtriNo ratings yet

- The Factories Act, 1948 INDIADocument71 pagesThe Factories Act, 1948 INDIAArun KumarNo ratings yet

- Msds Litium BatteriesDocument5 pagesMsds Litium BatteriesArun ChopraNo ratings yet

- Iso 31000 Risk Analysis GuidelinesDocument11 pagesIso 31000 Risk Analysis GuidelinesArun Chopra100% (1)

- 5 Ways To Prevent Bearing FailuresDocument5 pages5 Ways To Prevent Bearing FailuresArun ChopraNo ratings yet

- 5 Ways To Prevent Bearing FailuresDocument5 pages5 Ways To Prevent Bearing FailuresArun ChopraNo ratings yet

- MaintenanceDocument75 pagesMaintenancesharif339100% (1)

- Gita SarDocument17 pagesGita Sarkushal jaitwaniNo ratings yet

- Scientific American Supplement, No. 492, June 6, 1885 by VariousDocument76 pagesScientific American Supplement, No. 492, June 6, 1885 by VariousGutenberg.orgNo ratings yet

- Product News: Cat C12 ACERT™ Marine Propulsion EngineDocument6 pagesProduct News: Cat C12 ACERT™ Marine Propulsion EnginericardoNo ratings yet

- 2000 Mitsubishi Fuso FH SpecsDocument2 pages2000 Mitsubishi Fuso FH SpecsRiyad GamilNo ratings yet

- SPESIFIKASI12Document6 pagesSPESIFIKASI12Ahmad NasirNo ratings yet

- DX225LCA Spec SheetDocument51 pagesDX225LCA Spec SheetMoises Garcia DuranNo ratings yet

- Cat 312EDocument36 pagesCat 312Ekomatsu2562No ratings yet

- Chelsea Power Take Offs Quick Reference Guide 2018Document28 pagesChelsea Power Take Offs Quick Reference Guide 2018Mateus ViníciusNo ratings yet

- Dynamics 2 - HandoutsDocument7 pagesDynamics 2 - HandoutsRomeoNo ratings yet

- Ficha Tecnica JLG - G9-43aDocument2 pagesFicha Tecnica JLG - G9-43aGRUAS FENIXNo ratings yet

- SectionK MáquinaDocument12 pagesSectionK MáquinaRoberto Zanati PereiraNo ratings yet

- Balakrishna Engineering: Quality Is Our MottoDocument12 pagesBalakrishna Engineering: Quality Is Our MottoMahendhiranNo ratings yet

- Season 4Document6 pagesSeason 4Jeline LunaNo ratings yet

- JCB 540 - 170 Stabilizers ComparisonDocument16 pagesJCB 540 - 170 Stabilizers ComparisonDarrenNo ratings yet

- BreezewayDocument47 pagesBreezewaypascualNo ratings yet

- BENCH TEST PROCEDURE FOR THE PERFORMANCE OF POWER STEERING PUMPDocument13 pagesBENCH TEST PROCEDURE FOR THE PERFORMANCE OF POWER STEERING PUMPm.srinivasanNo ratings yet

- LE COUPLINGS FOR MACHINERYDocument4 pagesLE COUPLINGS FOR MACHINERYSatNo ratings yet

- R-69 Rig Data SheetDocument1 pageR-69 Rig Data SheetBaurzhanNo ratings yet

- VI. 07. Synchronous Machine PDFDocument16 pagesVI. 07. Synchronous Machine PDFDesi HertianiNo ratings yet