Professional Documents

Culture Documents

Corrosion

Uploaded by

Shuvanjan DahalOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Corrosion

Uploaded by

Shuvanjan DahalCopyright:

Available Formats

Corrosion

Any process of deterioration (or destruction) and consequent loss of a solid metallic material, through an unwanted (or unintentional) chemical or electrochemical attack by its environment, starting at its surface is called corrosion.

Cause of Corrosion:

Most metals exist in nature in their combined form. They are reduced to metallic states from their ores, during their extraction processes. Since considerable amount of energy is required during extraction, the isolated pure metals can be regarded in excited state (a higher energy state) than their corresponding ores, and they have a natural tendency to revert back to combined state (or low energy state). Hence, when metals are exposed to environment, they begin to decay more or less rapidly. Examples: a. rusting of iron b. formation of green film of basic carbonate [CuCO3 + Cu(OH)2] on the surface of copper

Electrochemical Mechanism of Corrosion (Rusting of Iron)

Electrochemical Corrosion involves: a. The formation of anodic or cathodic areas in contact with each other b. Presence of a conducting medium c. Corrosion of anodic areas only d. Formation of corrosion product somewhere between anodic and cathodic areas For rusting of iron, we have to consider the following three electrodes: a. Fe

++

+ 2e Fe

-

E = -0.44 V E = -0.42 at pH=7 E = +0.40V

b. 2H2O + 2e H2 + 2OH c. O2 +2H2O + 4e 4OH

-

Combination of electrodes a and b: a=anode, b=cathode Rate of reaction is less since reduction reaction potentials are nearly equal. Combination of electrodes a and c: The rate of redox reaction is very fast.

Hence, oxygen in the presence of water can easily oxidize iron.

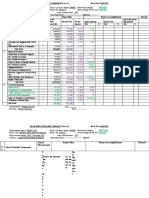

Dry or Chemical Corrosion

It occurs due to direct chemical action of environment/atmospheric gases such as oxygen, halogen, H2S, SO2, nitrogen, etc. with metal surfaces in immediate proximity. Electrochemical Corrosion i. It takes place under wet conditions presence i. of aqueous solution, or electrolyte. ii. It takes place through the formation of a series ii. of galvanic cells. iii. Corrosion products accumulate at cathode iii. whereas corrosion occurs at anode. It takes place by direct chemical attack of environment on metals. Corrosion products accumulate at the same spot where corrosion has occurred. Chemical Corrosion It takes place in dry conditions.

Other types of Corrosion

1. Galvanic (or Bimetallic Corrosion)

When two dissimilar metals (e.g. zinc and copper) are electrically connected and exposed to an electrolyte, the metal higher in electrochemical series undergoes corrosion. This type of corrosion is called galvanic corrosion. Here, zinc forms the anode and is attacked and gets dissolved whereas copper acts as cathode. The use of pipelines in conjunction with iron popes in water distribution systems has been the cau of cause galvanic corrosion.

2. Crevice/Contact Corrosion

Contact corrosion is produced at the region of contact of metals with metals or non non-metals e.g. crevices of different metallic objects such as bolts, rivets, nuts, etc. When these crevices come in contact with the liquids, they become anodic region where corrosion occurs due to restricted supply of oxygen. The exposed surface acts as cathode.

3. Pitting Corrosion

It is a localized corrosion, resulting in the formation of pits. Pitting usually takes place du to the cracking of due the protective film on metal surface. An anode is formed where the film has broken. The formation of small anodic region and large cathodic region results in severe anodic corrosion.

4. Intergranular Corrosion

This type of corrosion is due to the fact that grain boundaries contain material, which shows electrode potential more anodic than that of the grain centre. Alloys are generally more susceptible to Intergranular corrosion. E.g. during welding of stainless steel (Fe, C, Cr), chromium carbide is precipitated at grain chromium boundaries, thereby, making the regions adjacent to grain boundaries more anodic.

5. Stress Corrosion

It takes place due to the combined effect of static tensile stresses and corrosive environment on a metal. This type of corrosion is common in fabricated articles of some alloys such as zinc and nickel brasses caused by heavy working like rolling, drawing or insufficient annealing.

6. Microbiological Corrosion

It is the deterioration of materials caused directly or indirectly like microbes. Aerobic bacteria decrease the concentration of oxygen in the medium in contact with a metal surface as a result of which the exposed metal parts corrode due to differential aeration. Anaerobic bacteria cause corrosion of iron and steel.

7. Erosion Corrosion

It is the result of relative movement between a corrosive fluid and metal surface. All types of equipments exposed to moving fluids are subjected to erosion corrosion. E.g. ship propellers, hydraulic turbine

8. Soil Corrosion

Moisture and dissolved electrolytes present in soil promotes soil erosion. Caused due to: lved Acidity in the soil Moisture content of the soil

9. Concentrated Cell Corrosion

This type of corrosion is due to electrochemical attack on the metal surface, exposed to an electrolyte of varying concentrations or of varying aeration.

Factors Influencing Corrosion

Nature of Metal a. P HYSICAL STATE OF METAL: The smaller the grain-size of the metal or alloy, the greater will be its solubility and hence, greater will be its corrosion. Moreover, areas under stress, even in a pure metal, tend to be anodic and corrosion takes place at these areas. b. P URITY OF METAL: Impurities in a metal, generally, cause heterogeneity, and form minute electrochemical cells (at the exposed parts), and the anodic parts get corroded. c. NATURE OF THE SURFACE FILM: In aerated atmosphere, practically all metals get covered with a thin surface film of metal oxide. The ratio of the volumes of the metal oxide to the metal is known as a specific volume ratio. Greater the specific volume ration, lesser is the oxidation corrosion rate. d. RELATIVE AREAS OF THE ANODIC AND CATHODIC PARTS: Corrosion is more rapid and severe, and highly localized, if the anodic area is small, because the current density at a smaller anodic area is much greater. Nature of the Corroding Environment a. TEMPERATURE: With increase in temperature of environment, the reaction as well as diffusion rate increase, thereby corrosion rate is generally enhanced. b. HUMIDITY: Corrosion of a metal becomes faster in humid atmosphere since the gases (CO2, O2, etc.) and vapours, present in atmosphere furnish water to the electrolyte, essential for setting up an electrochemical cell. Critical humidity is defined as the relative humidity above which the atmospheric corrosion rate of metal increases sharply. c. P RESENCE OF IMPURITIES IN ATMOSPHERE: In presence of gases like CO2, H2S, SO2 and fumes of HCl, H2SO4, etc. the acidity of the liquid, adjacent to the metal surfaces, increases and its electrical conductivity also increases. This consequently, results in an increase of corrosion current flowing in the local electrochemical cells on the exposed metal surfaces. d. P RESENCE OF SUSPENDED PARTICLES IN ATMOSPHERE: If the suspended particles are chemically active in nature [like NaCl, (NH4)2SO4], they absorb moisture and act as strong electrolytes, thereby causing enhanced corrosion.

Prevention of Corrosion

a. The design of the materials should be such that corrosion, even if it occurs, is uniform and does not result in intense and localized corrosion. b. Pure metals having high corrosion-resistance should be used. Purification of metals like Al, Mg, etc. provides a coherent and impervious protective oxide film on their metal surfaces.

c. Corrosion-resistance of most metals can be increased by alloying them with suitable elements. d. SACRIFICIAL ANODIC PROTECTION METHOD: In this method, the metallic structure to be protected is connected by a wire to more anodic metal, so that all the corrosion is concentrated at this more active metal. Application: protection of buried pipelines, underground cables, water tanks, etc. e. APPLICATION OF PROTECTIVE COATINGS: A coating surface isolates the underlying metal from corroding environment. The coating applied must be chemically inert under particular conditions of temperature and pressure.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- NBC Update - Final Report-Building Code July 15 09Document170 pagesNBC Update - Final Report-Building Code July 15 09Nosheen Kashif KazmiNo ratings yet

- Impacts of Climate Change On EconomyDocument13 pagesImpacts of Climate Change On EconomyShuvanjan DahalNo ratings yet

- Theory of Vibrations: Assignment-1 (Solutions)Document13 pagesTheory of Vibrations: Assignment-1 (Solutions)Shuvanjan Dahal0% (1)

- Theory of Vibrations: Assignment-2 (Solutions)Document14 pagesTheory of Vibrations: Assignment-2 (Solutions)Shuvanjan Dahal100% (2)

- Bio EngineeringDocument1 pageBio EngineeringShuvanjan Dahal100% (1)

- Impact of Climate Change On WildfireDocument7 pagesImpact of Climate Change On WildfireShuvanjan DahalNo ratings yet

- The Importance of Ethics in The Engineering SectorDocument3 pagesThe Importance of Ethics in The Engineering SectorShuvanjan Dahal80% (5)

- Masonry Structures - Under Lateral LoadsDocument58 pagesMasonry Structures - Under Lateral LoadsShuvanjan Dahal80% (5)

- MDRiM SyllabusDocument19 pagesMDRiM SyllabusShuvanjan DahalNo ratings yet

- Assignment ValuationDocument19 pagesAssignment ValuationShuvanjan DahalNo ratings yet

- CM CH8 Time-CostDocument18 pagesCM CH8 Time-CostArok ANo ratings yet

- Project Management - NotesDocument31 pagesProject Management - NotesShuvanjan DahalNo ratings yet

- AASHTO Method of Flexible Pavement DesignDocument18 pagesAASHTO Method of Flexible Pavement DesignShuvanjan Dahal100% (3)

- Notes - Water Supply EngineeringDocument95 pagesNotes - Water Supply EngineeringShuvanjan Dahal85% (26)

- RCC Lab ReportDocument18 pagesRCC Lab ReportShuvanjan Dahal50% (4)

- EQTip 14Document2 pagesEQTip 14raj_ferrariNo ratings yet

- Masonry Structures - Under Lateral LoadsDocument58 pagesMasonry Structures - Under Lateral LoadsShuvanjan Dahal80% (5)

- Concrete DurabilityDocument3 pagesConcrete DurabilityShuvanjan Dahal100% (1)

- Reservoirs and Distribution SystemDocument10 pagesReservoirs and Distribution SystemShuvanjan Dahal100% (2)

- Introduction To Masonry StructuresDocument12 pagesIntroduction To Masonry StructuresShuvanjan Dahal93% (15)

- Quality of Water (Water Supply Engineering)Document11 pagesQuality of Water (Water Supply Engineering)Shuvanjan Dahal100% (2)

- Introduction To Water Supply EngineeringDocument4 pagesIntroduction To Water Supply EngineeringShuvanjan Dahal90% (39)

- Introdution To Concrete and Concrete Materials (Concrete Technology)Document25 pagesIntrodution To Concrete and Concrete Materials (Concrete Technology)Shuvanjan Dahal100% (1)

- Properties of Hardened ConcreteDocument14 pagesProperties of Hardened ConcreteShuvanjan Dahal100% (3)

- Mix Design of Concrete and Properties of Green ConcreteDocument32 pagesMix Design of Concrete and Properties of Green ConcreteShuvanjan Dahal100% (9)

- Sources of Water (Water Supply Engineering)Document9 pagesSources of Water (Water Supply Engineering)Shuvanjan Dahal86% (7)

- Quantity of Water (Water Supply Engineering)Document7 pagesQuantity of Water (Water Supply Engineering)Shuvanjan Dahal100% (7)

- Intakes (Water Supply Engineering)Document5 pagesIntakes (Water Supply Engineering)Shuvanjan Dahal88% (17)

- Water Treatment (Water Supply Engineering)Document40 pagesWater Treatment (Water Supply Engineering)Shuvanjan Dahal100% (11)

- Landslide: Parts of A Typical SlideDocument14 pagesLandslide: Parts of A Typical SlideShuvanjan Dahal100% (3)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 2 Effective Manufacturing ERP MESDocument17 pages2 Effective Manufacturing ERP MESm_trang2005100% (2)

- Science 9-Quarter 2-Module-3Document28 pagesScience 9-Quarter 2-Module-3Mon DyNo ratings yet

- Chan v. ChanDocument2 pagesChan v. ChanjdpajarilloNo ratings yet

- Toaz - Info Fermentation of Carrot Juice Wheat Flour Gram Flour Etc PRDocument17 pagesToaz - Info Fermentation of Carrot Juice Wheat Flour Gram Flour Etc PRBhumika SahuNo ratings yet

- Biology 2 Chapter 4Document61 pagesBiology 2 Chapter 4Malas Nak TaipNo ratings yet

- Understanding Senior Citizens Outlook of Death Sample FormatDocument14 pagesUnderstanding Senior Citizens Outlook of Death Sample FormatThea QuibuyenNo ratings yet

- 1 BSC Iriigation Engineering 2018 19 Std1Document70 pages1 BSC Iriigation Engineering 2018 19 Std1Kwasi BempongNo ratings yet

- Quarterly Progress Report FormatDocument7 pagesQuarterly Progress Report FormatDegnesh AssefaNo ratings yet

- 13 Lombe Mumba Ramson 2017 Knowledge Attitude and Practice of Breast Self Examination For Early Detectoin of Breast Cancer Among Women in Roan Constituency in Luanshya Copperbelt Province ZambiaDocument9 pages13 Lombe Mumba Ramson 2017 Knowledge Attitude and Practice of Breast Self Examination For Early Detectoin of Breast Cancer Among Women in Roan Constituency in Luanshya Copperbelt Province ZambiaArick Frendi AndriyanNo ratings yet

- The Benefits of RunningDocument1 pageThe Benefits of Runningefendi odidNo ratings yet

- SRV SLB222 en - 05062020Document2 pagesSRV SLB222 en - 05062020Nguyen ThuongNo ratings yet

- Imagine Unit 1 P 10 11Document1 pageImagine Unit 1 P 10 11נויה לבדובNo ratings yet

- Tomography: Tomography Is Imaging by Sections or Sectioning Through The Use of AnyDocument6 pagesTomography: Tomography Is Imaging by Sections or Sectioning Through The Use of AnyJames FranklinNo ratings yet

- Hydrogen Production From The Air: Nature CommunicationsDocument9 pagesHydrogen Production From The Air: Nature CommunicationsdfdffNo ratings yet

- CL Analyzer: Coagulometric, Chromogenic and Immunological AssaysDocument2 pagesCL Analyzer: Coagulometric, Chromogenic and Immunological AssaysEdwinNo ratings yet

- Grounds of Divorce Under Hindu Religion or Hindu Law Unit-A: Chapter-IiDocument42 pagesGrounds of Divorce Under Hindu Religion or Hindu Law Unit-A: Chapter-IiSatyam PathakNo ratings yet

- Practical Cookery 14th Edition SAMPLEDocument16 pagesPractical Cookery 14th Edition SAMPLETendaiNo ratings yet

- UM-1D User ManualDocument30 pagesUM-1D User ManualAhmedBalaoutaNo ratings yet

- Distribución Del Mercurio Total en Pescados y Mariscos Del Mar ArgentinoDocument15 pagesDistribución Del Mercurio Total en Pescados y Mariscos Del Mar ArgentinoaldiNo ratings yet

- FINALE Final Chapter1 PhoebeKatesMDelicanaPR-IIeditedphoebe 1Document67 pagesFINALE Final Chapter1 PhoebeKatesMDelicanaPR-IIeditedphoebe 1Jane ParkNo ratings yet

- Installation Manual (DH84309201) - 07Document24 pagesInstallation Manual (DH84309201) - 07mquaiottiNo ratings yet

- Ifm Product Innovations PDFDocument109 pagesIfm Product Innovations PDFJC InquillayNo ratings yet

- Aliant Ommunications: VCL-2709, IEEE C37.94 To E1 ConverterDocument2 pagesAliant Ommunications: VCL-2709, IEEE C37.94 To E1 ConverterConstantin UdreaNo ratings yet

- OA Standard 050505Document75 pagesOA Standard 050505fido_dagemNo ratings yet

- Week 1 Seismic WavesDocument30 pagesWeek 1 Seismic WavesvriannaNo ratings yet

- Astm A712 PDFDocument3 pagesAstm A712 PDFCristian OtivoNo ratings yet

- Perioperative Care For CABG PatientsDocument32 pagesPerioperative Care For CABG PatientsAya EyadNo ratings yet

- Hasil Pemeriksaan Laboratorium: Laboratory Test ResultDocument1 pageHasil Pemeriksaan Laboratorium: Laboratory Test ResultsandraNo ratings yet

- Kebersihan, Fungsi Sanitasi Dan Drainase - BAHASA INGGRIS - VII - Semester IDocument5 pagesKebersihan, Fungsi Sanitasi Dan Drainase - BAHASA INGGRIS - VII - Semester IRiska AyuNo ratings yet

- Chapter 54 - Drugs Acting On The Upper Respiratory TractDocument13 pagesChapter 54 - Drugs Acting On The Upper Respiratory TractJonathonNo ratings yet