Professional Documents

Culture Documents

Scrubber Design

Uploaded by

Amit RajmaneCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scrubber Design

Uploaded by

Amit RajmaneCopyright:

Available Formats

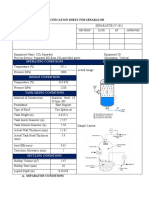

SCRUBBER DESIGN (PACKED COLUMN)

Prepared by : Checked by : Date :

Column Tag No. Job No. Client Project Stream = Intallox Saddles = 25 mm = PP = 15 mmWC / m packing height = 3.2 m (including all packed beds)

: : : : : HCL Vap.

Input Data Packing type Packing size Packing MOC Gas pr. Drop / m bed Total packing height

2 147.1 (N/m )/m

Gas / Vapour Properties Gas / Air flow rate = = Gas pressure at entry Gas temperature at entry Gas / Air mol weight = = =

1000 kg/h 0.2778 kg/s 1.0000 atm o 30.00 C 29

OR =

3 0 m /h 3 0 m /s

o 303.00 K

Component to be scrubbed Component Name = Component flow rate = % comp. in air/gas = Molecular weight of comp. =

HCL Vap 70 Kg/h 6 % (v/v) 36.5

(presumed) / (given by client) / (by process cal.)

Liquid / Scrubbing media Properties Scrubbing media = 20% NaOH Liquid flow rate, L = 77 kg/h = 0.0214 kg/s 3 Liquid Density, L = 1100 kg/m Liquid Viscosity, L Packing factor, Fp = 0.0035000 Ns/m =

-1 21 m 2

Conversion : 3.5 Cp =

2 0.00350000 Ns/m

Charac. Packing Factor,Cf = Conversion factor, J =

33 Ref. Table 6.3, Characterstics of Random packings 1.0 factor for adequate liquid distribution & irrigation across the bed

Sheet 1 of 11

Calculations TO CALCULATE COLUMN DIAMETER Since larger flow quantities are at the bottom for an absorber, the diameter will be chosen to accommodate the bottom conditions. To calculate Gas density Avg. molecular weight = If gas flow rate is given in kg/h Gas in = 0.009432183 Kmol/s kmol = mass / mol wt = (kmol/s) x T in kelvin x 1.0 atm x 22.4 273 pr. In atm 1 3 = 0.234499 m /s

29.45 Kg / Kmol If gas flow rate is given in m3/h Gas in = (m3/s) x 273 x pr. in atm x T in kelvin 1.0 atm 1 22.4

= =

0 Kmol/s 0 Kg/s mass = mol wt x kmol

Select vol. flow rate and mass flow rate from above, Selected mass flow rate = 0.277778 Kg/s 3 Selected vol. Flow rate = 0.234499 m /s Selected molar flow rate = 0.009432 Kmol/s Therefore, gas density =

3 1.1846 Kg/m

(mass flow rate / vol. Flow rate)

To find L', G' and Tower c/s area Assuming essentially complete absorbtion, Component removed = 0.0207 Kg/s Liquid leaving = 0.0420 Kg/s L' G' Using

G L 0.5

(molar flow rate x % comp. x mol. Wt.) (Inlet liquid flow rate + comp. Removed)

0.00497

0.00497

as ordinate, =

Refer fig.6.34 using a gas pressure drop of

147.1

(N/m2)/m

G' 2 Cf L0.1 J

G( L -G ) gc

0.04 (from graph)

Therefore, G'

0.04

G(

--

G)

gc

0.5

Cf L0.1 J = Tower c/s area Tower diameter = = = =

2 1.6665 Kg / m .s 2 0.1667 m

( c/s area = mass flow rate / G' ) = 460.7 mm

0.4607 m 500 mm

2 0.1963 m

Corresponding c/s area

Sheet 2 of 11

TO ESTIMATE POWER REQUIREMENT Efficiency of fan / blower = 60 % assumed / given

To calculate pressure drop Pressure drop for irrigated = packing For dry packing, O/L Gas flow rate, G' O/L Gas pressure Gas density, G

2 470.72 N/m

(pressure drop per m packing x total ht. of packing)

2 1.3095 Kg / m .s (Gas inlet flow rate - Component removed) / c/s area 2 100854.3 N/m (subtracting pressure drop across packing) gas mol wt. x 273 x gas o/l pr. 22.41m3/Kmol T in kelvin 101330 3 = 1.1605 Kg/m

= = =

CD Delta P Z

= = CD =

96.7 G' 2

G

Ref. Table 6.3, Characterstics of Random packings

2 142.89 N/m

Pressure drop for packing = Pressure drop for internals = = Gas velocity Inlet expansion & outlet contraction losses

2 613.61 N/m

(irrigated packing + dry packing) (packing supports and liquid distributors)

25 mmWC 2 245.17 N/m

= 7.5 m/s = 1.5 x Velocity heads = 42.19 N m / Kg 2 = 49.97 N/m =

2 908.75 N/m

1.5 x (V2 / 2g) (divide by density)

Total pressure drop Fan power output

(packing + internals + losses)

2 = pressure drop,N/m x (gas in - component removed) Kg/s O/L gas density, Kg/m3 = 201.35 N .m / s = 0.20 kW

Power for fan motor

= =

0.34 kW 0.45 hp

(fan power output / motor efficiency)

Sheet 3 of 11

COLUMN DIAMETER / HYDRAULIC CHECK Liq.-Vap. Flow factor, FLV = (L / V) x ( = 0.0025

V

L)

Design for an initial pressure drop of From K4 v/s FLV, K4 K4 at flooding Trial % flooding = = 0.85 6.50

15

mm H2O /m packing

= ( (K4 / K4 at flooding) = 36.1620 = K4 .

V( L

) x 100

Gas mass flow rate, Vm

-L)

13.1 Fp (L / = Trial column c/s area (Trial As) = = Trial column dia., D =

V) 0.1

(1/2)

2 3.7763 kg/m .s

V / Vm

2 0.0736 m

0.3060 m

D = (4/pi) x Trial As

Round off 'D' to nearest standard size Therefore, D = 0.500 m

2 0.1963 m 2 As = (pi/4) x D

Column C/S area, As

% flooding

13.5472

% flooding = Trial % flooding x (Trial As / As)

Conclusion Generally packed towers are designed for 50% -- 85% flooding. If flooding is to be reduced, (i) Select larger packing size and repeat the above steps. OR (ii) Increase the column diameter and repeat the above steps.

Sheet 4 of 11

HETP PREDICTION Norton's Correlation : ln HETP = n - 0.187 ln + 0.213 ln Applicable when, liquid phase surface tension > 4 dyne/cm & < 36 dyne/cm liquid viscosity > 0.08 cP & < 0.83 cP Conversion : Input Data 0.018 N/m = 18 dyne/cm Liquid-phase Surface Tension, = 20 dyne/cm Norton's Correlation Applicable Liquid Viscosity n = = 3.5 cP 1.13080 Norton's Correlation NOT applicable

Calculation ln HETP HETP = = = 0.837437 2.310437 ft 0.704221 m

For separations, less than 15 theoritical stages, a 20% design safety factor can be applied. Considering 20% safety factor, HETP = 0.845065 m

For separations, requiring 15 to 25 theoritical stages, a 15% design safety factor can be applied. Considering 15% safety factor, HETP = 0.809854 m

Sheet 5 of 11

Table 6.2 Constant for HETP Correlation

Ref.:: Random Packings and Packed Towers ---- Strigle

Ref. : : Chemical Engineering, Volume-6 , COULSON & RICHARDSON'S

Ref. : : Mass Transfer Operation : : Treybal

You might also like

- HCL Scrubber DesignDocument5 pagesHCL Scrubber DesignManish0301198375% (4)

- Scrubber Design (Packed Column)Document10 pagesScrubber Design (Packed Column)alinaveed198367% (3)

- PACKED COLUMN DESIGN FOR HCL SCRUBBERDocument11 pagesPACKED COLUMN DESIGN FOR HCL SCRUBBERsoreksatuNo ratings yet

- Ventury Scrubber Design MethodDocument3 pagesVentury Scrubber Design MethodPukhraj DagaNo ratings yet

- Pompa Transfer Fungsi Untuk MemoDocument5 pagesPompa Transfer Fungsi Untuk MemoDavid LambertNo ratings yet

- CO2 Plant DesignDocument12 pagesCO2 Plant DesignOmprakaash MokideNo ratings yet

- Packed Column DesignDocument6 pagesPacked Column Designyamen-691904No ratings yet

- Heatcalc: A Natural Gas Heat of Combustion CalculatorDocument7 pagesHeatcalc: A Natural Gas Heat of Combustion CalculatorMuzzamilNo ratings yet

- Venturi Scrubber Theory & ExperimentDocument6 pagesVenturi Scrubber Theory & ExperimentTian Fung Wang100% (1)

- Vapor Line Sizing-Mpp6Document10 pagesVapor Line Sizing-Mpp6Nitin KurupNo ratings yet

- Absorber DesignDocument2 pagesAbsorber DesignDhrumil Gandhi100% (1)

- Ammonia Design 2520of 2520equipmentsDocument32 pagesAmmonia Design 2520of 2520equipmentsapi-3714811100% (1)

- EIND 3184 15 Liquid Flash Vessel SizingDocument20 pagesEIND 3184 15 Liquid Flash Vessel SizingzamijakaNo ratings yet

- Boiling Up Rate For Batch DistillationDocument4 pagesBoiling Up Rate For Batch DistillationKanhaiyalal PatilNo ratings yet

- 2-Phase Vertical SeparatorDocument9 pages2-Phase Vertical SeparatorTolstoy LeoNo ratings yet

- Evap DesignDocument16 pagesEvap DesignAhmed Ali100% (3)

- Ammonia Wet Scrubber System (17-7-2018)Document12 pagesAmmonia Wet Scrubber System (17-7-2018)addin wokatuba100% (1)

- ATFD Feed CalculationDocument11 pagesATFD Feed Calculationnarayana reddy100% (1)

- Chap3-2e SO2 Absorption ExampleDocument8 pagesChap3-2e SO2 Absorption Exampledarkelf_riderNo ratings yet

- Tripple Effect Evaporator Design CalculationDocument6 pagesTripple Effect Evaporator Design CalculationCathal McKeownNo ratings yet

- Final Ventury Working For Wet Alkaline ScrubberDocument11 pagesFinal Ventury Working For Wet Alkaline ScrubberNanasaheb JagtapNo ratings yet

- Wet Air Properties Calculation Sheet: at Low PressureDocument2 pagesWet Air Properties Calculation Sheet: at Low Pressurezsmith0% (1)

- Evaporator (D-1) Design ExcelDocument7 pagesEvaporator (D-1) Design ExceldiRkdARyLNo ratings yet

- 8 Absorber DesignDocument16 pages8 Absorber DesignilhamriswandaaNo ratings yet

- Claus Process CalculationDocument105 pagesClaus Process CalculationDaniel SetyadiNo ratings yet

- Cooling Tower-CalculatorDocument7 pagesCooling Tower-CalculatorparykoochakNo ratings yet

- PLN CNG Process CalculationDocument14 pagesPLN CNG Process CalculationViqiNo ratings yet

- AtfdDocument4 pagesAtfdDarshan PatelNo ratings yet

- Cyclone SeparatorDocument1 pageCyclone SeparatorDan ToaderNo ratings yet

- Design Stripper Column ProcessDocument10 pagesDesign Stripper Column ProcessAhmed HassanNo ratings yet

- Batch Time Calculation For Isothermal Cooling in Internal Coil Vessel With AgitationDocument2 pagesBatch Time Calculation For Isothermal Cooling in Internal Coil Vessel With Agitationdhavalesh1No ratings yet

- Design Calculation of Outbreathing Flowrates and Valve Sizing for an Expansion TankDocument24 pagesDesign Calculation of Outbreathing Flowrates and Valve Sizing for an Expansion Tankvenkatesh801No ratings yet

- Process Design: Vessel Sizing (Liquid & Vapour Separators)Document36 pagesProcess Design: Vessel Sizing (Liquid & Vapour Separators)Krishanu SahaNo ratings yet

- Specification Sheet For Separator: Operating Conditions SketchDocument12 pagesSpecification Sheet For Separator: Operating Conditions SketchAngelikaOdimer100% (1)

- Stacks: Ammonia Injection: A Route To CleanDocument8 pagesStacks: Ammonia Injection: A Route To CleanZEN MA100% (1)

- CEB 2063 Evaporation Process Design and AnalysisDocument28 pagesCEB 2063 Evaporation Process Design and AnalysisScorpion RoyalNo ratings yet

- Briefs - Emergency Chlorine ScrubberDocument8 pagesBriefs - Emergency Chlorine ScrubberSher MuhammadNo ratings yet

- Venturi Scrubber Design Equations Formulas CalculatorDocument2 pagesVenturi Scrubber Design Equations Formulas Calculatorblueboy33% (3)

- EjectorDocument6 pagesEjectorbadelitamarius100% (1)

- Drum Flaker Introduction Guide by FUJI KOKI CO.,LTDDocument20 pagesDrum Flaker Introduction Guide by FUJI KOKI CO.,LTDAna Quintana100% (2)

- Scrubber Design SheetDocument11 pagesScrubber Design Sheetganeshdhage100% (1)

- Scrubber DesignDocument11 pagesScrubber Designsaji kumar0% (1)

- Design of Distillation Column EquipmentDocument41 pagesDesign of Distillation Column EquipmentHardik Gandhi100% (1)

- Scrubber Design (Packed Column)Document10 pagesScrubber Design (Packed Column)Aris StarsNo ratings yet

- Burner CalculationDocument6 pagesBurner CalculationAnonymous 3ESYcrKP100% (4)

- Air Stripping Design ReportDocument17 pagesAir Stripping Design ReportShawn MauldinNo ratings yet

- Scrubber Design (Packed Column)Document11 pagesScrubber Design (Packed Column)Peddy NesaNo ratings yet

- Sample Problem StatementDocument2 pagesSample Problem Statementsunildubey02No ratings yet

- Design A Distillation Column With A Total Condenser and Partial Re Boiler For The Following SeparationDocument41 pagesDesign A Distillation Column With A Total Condenser and Partial Re Boiler For The Following SeparationSihanu Subasingha100% (1)

- Design of Strippe1Document10 pagesDesign of Strippe1Iqra MaqsoodNo ratings yet

- Monoethanolamine Design 2520of 2520equipmentsDocument54 pagesMonoethanolamine Design 2520of 2520equipmentsbhaskar5377No ratings yet

- PPE AssignmentDocument16 pagesPPE AssignmentlibbissujessyNo ratings yet

- Nukiyama & Tanasawa Correlation: Liquid Mean Droplet Size or Sauter Mean DiameterDocument2 pagesNukiyama & Tanasawa Correlation: Liquid Mean Droplet Size or Sauter Mean Diametersreekanth reddyNo ratings yet

- Components Molar Flowrate (Kmole/hr) Mass Flowrate (KG/HR) : Composition of The Incoming GasDocument12 pagesComponents Molar Flowrate (Kmole/hr) Mass Flowrate (KG/HR) : Composition of The Incoming GasIsmail JamaluddinNo ratings yet

- Heat Exchanger Project FinalDocument16 pagesHeat Exchanger Project FinalChristopher CameronNo ratings yet

- Lecture 6 1Document24 pagesLecture 6 1Dany LoboNo ratings yet

- Absorption NotesDocument79 pagesAbsorption Noteshanisshi100% (2)

- Rotary Drier DesignDocument29 pagesRotary Drier DesignDharamvir Singh80% (5)

- Distillation DesignDocument18 pagesDistillation DesignViswanath KapavarapuNo ratings yet

- Trikling FiltersDocument16 pagesTrikling Filtersmosaad khadrNo ratings yet

- Clarifier Gear Drive Torque ValuesDocument4 pagesClarifier Gear Drive Torque ValuesDavid Lambert100% (4)

- Cyclone DesignDocument1 pageCyclone DesignDavid LambertNo ratings yet

- Pekerjaan Plumbing Main Equipment: Bill No 3 Project: Coca-Cola Bulan Baru, Surabaya Services: PlumbingDocument34 pagesPekerjaan Plumbing Main Equipment: Bill No 3 Project: Coca-Cola Bulan Baru, Surabaya Services: PlumbingDavid LambertNo ratings yet

- Venting DesignDocument1 pageVenting DesignDavid LambertNo ratings yet

- Commissioning Procedure Air Pre HeaterDocument15 pagesCommissioning Procedure Air Pre HeaterDavid LambertNo ratings yet

- DAFDocument1 pageDAFDavid LambertNo ratings yet

- Booster Pump RequiredDocument6 pagesBooster Pump RequiredDavid LambertNo ratings yet

- Pekerjaan Plumbing Main Equipment: Bill No 3 Project: Coca-Cola Bulan Baru, Surabaya Services: PlumbingDocument34 pagesPekerjaan Plumbing Main Equipment: Bill No 3 Project: Coca-Cola Bulan Baru, Surabaya Services: PlumbingDavid LambertNo ratings yet

- Process Produksi WOOD PELLLETDocument3 pagesProcess Produksi WOOD PELLLETDavid LambertNo ratings yet

- Pressure Drop CalculationDocument8 pagesPressure Drop CalculationDavid Lambert100% (1)

- Grease Trap SizingDocument9 pagesGrease Trap SizingEngFaisal Alrai100% (2)

- PyrolysisDocument1 pagePyrolysisDavid LambertNo ratings yet

- DAFDocument1 pageDAFDavid LambertNo ratings yet

- Selecting of Booster Pump For BuildingDocument7 pagesSelecting of Booster Pump For BuildingDavid LambertNo ratings yet

- Booster Pump RequiredDocument6 pagesBooster Pump RequiredDavid LambertNo ratings yet

- Gambar ProsesDocument1 pageGambar ProsesDavid LambertNo ratings yet

- Load FactorDocument4 pagesLoad FactorDavid LambertNo ratings yet

- Matchday Hari IniDocument2 pagesMatchday Hari IniDavid LambertNo ratings yet

- Price List With Breakdown & Unit PriceDocument1 pagePrice List With Breakdown & Unit PriceDavid LambertNo ratings yet

- Konversi Besi Tulangan Ke Wire MeshDocument1 pageKonversi Besi Tulangan Ke Wire MeshDavid LambertNo ratings yet

- Load FactorDocument4 pagesLoad FactorDavid LambertNo ratings yet

- PFD WTP PDFDocument1 pagePFD WTP PDFDavid LambertNo ratings yet

- Perhitungan Natural DraftDocument2 pagesPerhitungan Natural DraftDavid LambertNo ratings yet

- Sizing ScrubberDocument62 pagesSizing ScrubberindahazhrNo ratings yet

- Layout Line Checking Part (Front View) Revisi-1Document1 pageLayout Line Checking Part (Front View) Revisi-1David LambertNo ratings yet

- Bleaching Tank PT. Gurita Mandala No. Deskripsi KeteranganDocument1 pageBleaching Tank PT. Gurita Mandala No. Deskripsi KeteranganDavid LambertNo ratings yet

- Local Control Panel Sheet-5Document1 pageLocal Control Panel Sheet-5David LambertNo ratings yet

- MBBR OM Manual-250Document42 pagesMBBR OM Manual-250senthil2002100% (3)

- Wiring Diagram DC IIDocument2 pagesWiring Diagram DC IIDavid LambertNo ratings yet

- Technical Form WWTPDocument35 pagesTechnical Form WWTPDavid LambertNo ratings yet