Professional Documents

Culture Documents

PIC Design Training Issue 3 - Gear Setup PDF

Uploaded by

Vladimir AgeevOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PIC Design Training Issue 3 - Gear Setup PDF

Uploaded by

Vladimir AgeevCopyright:

Available Formats

Training: Issue 3, Gear Setup

While PIC Design can provide a set of gears for most high precision applications, there are a few considerations to take when using the parts to achieve the best performance. Proper setup will ensure the gear mesh will be both durable and accurate. There is an ideal distance between two meshing gears. At this ideal, tooth contact would be continuous and perfectly smooth. Since this perfect center is impossible to achieve due to manufacturing tolerances in all parts of the assembly, we have to understand what happens when we are close to it.

Center Distance The size of two meshing gears dictates how far apart they should be. It is governed by a simple equation:

Remember, meshing gears must have the same pitch!

Understanding Backlash When the center distance is smaller than ideal, the gears can become too close together. This interference results in jamming or excessive friction and wear. When the center distance is larger than ideal, the result is backlash, or clearance between the teeth. Backlash is preferable over interference, however the following must be considered: o Changes to input speed and direction will need to take up backlash before affecting output. o Excessive backlash will disrupt the smooth engagement of the teeth. o Clearance from backlash can be advantageous for lubricants and thermal expansion Eliminating Backlash For low load, high accuracy applications like sensor drives, Anti-Backlash gears are available. What looks like one gear is actually two gears stacked. Springs tie the two gears together and load them in opposite directions. The effect is an expanding tooth. Backlash clearance will be taken up until the spring force is overcome.

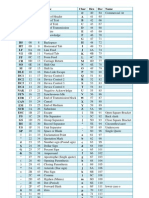

You might also like

- Connecting Downloading Uploading PDFDocument9 pagesConnecting Downloading Uploading PDFVladimir AgeevNo ratings yet

- Guide to TCP/IP Connections Between PCs and PLCsDocument11 pagesGuide to TCP/IP Connections Between PCs and PLCsCamilo BlanquivNo ratings yet

- Using Ladder Logic For Gray Code Conversion PDFDocument3 pagesUsing Ladder Logic For Gray Code Conversion PDFVladimir AgeevNo ratings yet

- Festo Hydraulics Workbook Basic Level TP501 204Document204 pagesFesto Hydraulics Workbook Basic Level TP501 204Avtomatika Kole NehteninNo ratings yet

- HA466357Document50 pagesHA466357Hayden Lovett100% (2)

- How Do You Backup - Restore With A Windows-Based Panel PDFDocument10 pagesHow Do You Backup - Restore With A Windows-Based Panel PDFVladimir AgeevNo ratings yet

- Supp01 e PDFDocument30 pagesSupp01 e PDFVladimir AgeevNo ratings yet

- 1352 PDFDocument1 page1352 PDFVladimir AgeevNo ratings yet

- Festo PLC Basic Level TP301-218Document218 pagesFesto PLC Basic Level TP301-218Marcos Aldana Villalda0% (1)

- RtethernetDocument18 pagesRtethernetCyril WalloisNo ratings yet

- BOOK 2, CHAPTER 8 - Directional Control Valves PDFDocument37 pagesBOOK 2, CHAPTER 8 - Directional Control Valves PDFVladimir Ageev0% (1)

- ASCII Table PDFDocument2 pagesASCII Table PDFVladimir AgeevNo ratings yet

- Electric Current EverywhereDocument30 pagesElectric Current EverywherePreetham VenkkyNo ratings yet

- PIC Design Training Issue 6 - Worm Gearing PDFDocument1 pagePIC Design Training Issue 6 - Worm Gearing PDFVladimir AgeevNo ratings yet

- Modbus Over Serial LineDocument44 pagesModbus Over Serial Linearindammanna123No ratings yet

- Adventures of Huckleberry Finn by Mark TwainDocument190 pagesAdventures of Huckleberry Finn by Mark TwainChandan SahaNo ratings yet

- Tuning ServomotorsDocument6 pagesTuning ServomotorsRodriguez JohannNo ratings yet

- PIC Design Training Issue 2 - Spur Gears PDFDocument1 pagePIC Design Training Issue 2 - Spur Gears PDFVladimir AgeevNo ratings yet

- Hmi Ibn 072010 76Document3 pagesHmi Ibn 072010 76Vladimir AgeevNo ratings yet

- Programming in List On A Mitsubishi PLC - Part 1 PDFDocument8 pagesProgramming in List On A Mitsubishi PLC - Part 1 PDFVladimir AgeevNo ratings yet

- Programming in List On A Mitsubishi PLC - Part 2 PDFDocument27 pagesProgramming in List On A Mitsubishi PLC - Part 2 PDFVladimir AgeevNo ratings yet

- Introduction To FX Positioning Control SystemsDocument80 pagesIntroduction To FX Positioning Control SystemsVladimir AgeevNo ratings yet

- THB 416Document510 pagesTHB 416Vladimir AgeevNo ratings yet

- 10 Phrasal Verbs Very UsefulDocument28 pages10 Phrasal Verbs Very UsefulManuel PacavitaNo ratings yet

- SSM4 V 07Document6 pagesSSM4 V 07Vladimir AgeevNo ratings yet

- Grammar RulesDocument251 pagesGrammar Ruless0mu@yahoo.comNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)