Professional Documents

Culture Documents

Design of RCC Slab

Uploaded by

anbugobiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of RCC Slab

Uploaded by

anbugobiCopyright:

Available Formats

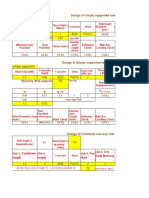

SECTION (MM) PI (constant) LONG SPAN SHORT SPAN COVER MATERIAL: GRADE OF CONCRETE GRADE OF STEEL - MAIN GRADE

OF STEEL - SECONDARY LOADS (Kn/m2) : LIVE LOAD FF LOAD PARTITION LOAD MISCELLANEOUS LOAD SAFETY FACTOR: FORCES CONDITION: R 3

ASSUME OVERALL THICKNESS OF SLAB EFFECTIVE DEPTH AS PER DESIGN ADOPT EFFECTIVE DEPTH AS OVERALL DEPTH REINFORCEMENT: DIA OF MAIN REINFORCEMENT IN MM DIA OF DISTRIBUTION REINFORCEMENT IN MM DIA OF TORSION REINFORCEMENT IN MM

3.14159265 6700 4300 15 M15 Fe 415 Fe 415 3.00 0.60 0 0 1.50

125 mm 79.72 mm 105 mm 125 mm

10 8 8

Reinforcement in middle strip: Steel along short span: Dia of reinforcement Spacing of bars c/c PROVIDE SPACING OF BARS c/c Total area provided Area of tension steel Aty along long span: since required area is greater than minimum required area, hence o.k., provide area Dia of reinforcement Spacing of bars c/c PROVIDE SPACING OF BARS c/c Total area provided Reinforcement in edge strip: 754 10 104.16 100 mm2 mm mm mm

O.K.

2 785.4 mm

226.08 mm2

226.08 8 222.35 150

mm2 mm mm mm

O.K.

2 335.13 mm

Minimum reinforcement Dia of reinforcement Along short span : Spacing of bars c/c PROVIDE SPACING OF BARS c/c Total area provided Along short span : Spacing of bars c/c PROVIDE SPACING OF BARS c/c Total area provided Corner Reinforcement: Length of corner reinforcement Area of each layer of reinforcement Dia of reinforcement Spacing of bars c/c Check for shear at short edge: Nominal shear stress,v In slabs c'

2 150.00 mm 8 mm

335.13 mm 200 mm

2 251.35 mm

Revise O.K. O.K. O.K. O.K. O.K.

335.13 mm 300 mm

2 167.57 mm

876 566 8 83

mm mm2 mm mm

2 0.21 N/mm 2 0.321 N/mm

The Slab panel is SAFE in shear. Check for development length at short edge: Dia of bar used 8 mm 8.13 mm Dia of bar used is less than required one , hence o.k. Check for deflection: Allowable L/d = Actual L/d Deflection requirements are O.K.

44.8 41.95

DESIGN OF R.C.C. SLAB (IS456-1978)

DESIGN DATA : SECTION (MM):

LONG SPAN, Ly SHORT SPAN, Lx COVER MATERIAL: GRADE OF CONCRETE GRADE OF STEEL - MAIN GRADE OF STEEL - SECONDARY LOADS (Kn/m2) : LIVE LOAD FF LOAD PARTITION LOAD MISCELLANEOUS LOAD SAFETY FACTOR: FORCES CONDITION: RESTRAINED SLAB ONE LONG EDGE DISCONTINUOUS DESIGN: ck = y(main) = y (secondary) = N.A. factor = Ly / Lx = This is two-way slab. Assume overall thicness of slab, D Effective depth, d Effective spans will be lx = Lx + d ly = Ly + d ly / lx = Moments along short span Mx and along long span My are given by : Mx = x w lx My = y w lx Corresponding ly /lx, For positive moment at mid span x = y = For negative moment at continuous edge x = y =

2 15 N/mm 2 415 N/mm 2 415 N/mm 0.48 1.56

6700 4300 15 M15 Fe 415 Fe 415 3.00 0.60 0 0 1.50

125 mm 105 mm 4.405 m 6.805 m 1.5

0.0512 0.028 0.0672 0.037

DESIGNED & DEVELOPED BY IDCS BASTI, INDIA

contd. On next page

DESIGN OF R.C.C. SLAB (IS456-1978)

Dead load of slab, wd = D x 25 Live load, wl Finish load, wf Partition Load, wp Miscellaneous load, w' Total load, w = wd+wl+wf+wp+w'

2 3.13 kN/m 2 3.00 kN/m 2 0.60 kN/m 2 0.00 kN/m 2 0.00 kN/m 2 6.73 kN/m

Factored load, wu = safety factor x w 10.09 Positive moment at mid span Mx = x w lx 10.024 My = y w lx 5.482 For negative moment at continuous edge Mx = x w lx 13.157 My = y w lx 7.244 The effective depth shall be designed for maximum of moment,i.e. 13.157 The effective depth d of the slab is given by 0.138ckbd2 d = 79.72 Adopt effective depth,d 105 Adopt overall depth,D 125 Along the long edge: Length 0f the middle strip 5.10 Length 0f the edge strip 0.851 Along the short edge: Length 0f the middle strip 3.304 Length 0f the edge strip 0.551 Minimum area of steel 0.12% Hence, Minimum area of steel Reinforcement in middle strip: Steel along short span: Atx = 0.36 ck b Xm / 0.87y Dia of reinforcement Area of bar Spacing of bars c/c Providing spacing of bars c/c Total area provided, Atxp Area of tension steel Aty along long span: d' = d - dia of bar a = 0.87 x y / ck x 1000 b = 0.87 x y x d' c = Mx Aty =( bb-4ac) / 2a

2

kN/m2 kNm/m kNm/m kNm/m kNm/m kNm/m

mm mm mm m m m m

2 150.00 mm

2 754 mm 10 mm 2 78.54 mm 104.16 mm 100 mm 2 785.4 mm

O.K. O.K.

95 mm 9.989 34299.750 7244000

2 226.08 mm

DESIGNED & DEVELOPED BY IDCS BASTI, INDIA

contd. On next page

DESIGN OF R.C.C. SLAB (IS456-1978)

since required area is greater than minimum required area, hence o.k., provide area Dia of reinforcement Area of bar Spacing of bars c/c Providing spacing of bars c/c Total area provided, Atyp

226.08

mm2 8 mm 2 50.27 mm 222.35 mm 150 mm 2 335.13 mm

O.K. O.K.

Curtail alternate bars at 1/10 th of effective span in each direction in accordance with clause C-2.1.1 of the Code. Provide 50% of the maximum positive steel at top near the supports to resist bending moment due to partial fixity. This steel is provided in length 0.1l from the face of supports.

Reinforcement in edge strip: Minimum reinforcement = Dia of reinforcement Area of bar Along short span : Spacing of bars c/c Providing spacing of bars c/c Total area provided, Atyp Along long span : Spacing of bars c/c Providing spacing of bars c/c Total area provided, Atyp Corner reinforcement: Length of corner reinforcement=0.2 lx Area of each layer of reinforcement= 75% 0f area required for maximum midspan moment Dia of reinforcement Area of bar no. of bars per rm Spacing of bars c/c Check for shear at short edge: Maximum SF, Vu = 0.5wLx Nominal shear stress,v= Vu/bd Percent tension steel = 100As / bd Shear strength of concrete,c =

2 150.00 mm 8 2 50.27 mm

335.13 mm 200 mm 2 251.35 mm 335.13 mm 300 mm 2 167.57 mm 876 mm

Revise O.K. O.K. O.K. O.K. O.K.

566 8 50.27 12 83

mm2 mm mm2 mm

21.69 kN/m 2 0.21 N/mm 0.11 %

DESIGNED & DEVELOPED BY IDCS BASTI, INDIA

contd. On next page

DESIGN OF R.C.C. SLAB (IS456-1978)

= 0.8 ck / 6.89 Pt > 1.0 c = 0.85/6 0.80ck ((1+5) -1) 15.833

2 0.247 N/mm

In slabs c' = k c 0.321 The Slab panel is SAFE in shear. Check for development length at short edge: d' = 96 Moment of resistance, M1 = 0.87y At(d'-(y At / ck b)) 5527464.11 Vu = 21.69 Anchorage value of bars,Lo =60+ 8 124 Development length, Ld = 56 Ld 1.3 M1/Vu + Lo 56 1.3 M1/Vu + Lo 455.29 8.13 Dia of bar used is less than required one , hence o.k. Check for deflection: Percent tension steel at midspan = 100As / bd 0.32 = 1.4 = 1 = 1 = 32 Allowable L/d = 44.8 Actual L/d = 41.95 Deflection requirements are O.K.

O.K.

mm Nmm kN mm

mm mm

You might also like

- RCC Design SheetsDocument69 pagesRCC Design SheetsFahim H bepari100% (1)

- Flat Slab ExcelDocument50 pagesFlat Slab ExcelJEFFY JACOB100% (1)

- Design of Slab (One Way)Document9 pagesDesign of Slab (One Way)anumned100% (1)

- Strap FootingDocument30 pagesStrap Footinganon_140586866No ratings yet

- RCC Slab Design and Reinforcement DetailsDocument79 pagesRCC Slab Design and Reinforcement Detailssurendra_panga100% (2)

- Slab Design ExcelDocument6 pagesSlab Design ExcelsahmeduNo ratings yet

- RCC - Design Excel SheetDocument10 pagesRCC - Design Excel SheetYashas KatugamNo ratings yet

- Beam Design by SP 16Document1 pageBeam Design by SP 16Arnab Deb67% (3)

- Slab Design ExcelDocument30 pagesSlab Design Excelwajid ahmadNo ratings yet

- RCC Doubly Reinforced Beam by Is 456: 2000 (LSM)Document26 pagesRCC Doubly Reinforced Beam by Is 456: 2000 (LSM)mafiapumba67% (3)

- Continuous One Way Sunk Slab Design ProgrammeDocument24 pagesContinuous One Way Sunk Slab Design ProgrammeNikhilNo ratings yet

- All Footing DesignDocument16 pagesAll Footing Designer.praveenraj30No ratings yet

- SLAB DESIGN CALCULATIONSDocument6 pagesSLAB DESIGN CALCULATIONSsharathkn50% (2)

- Design of WingwallDocument29 pagesDesign of WingwallMar MartillanoNo ratings yet

- Stair Case Design Single FlightDocument3 pagesStair Case Design Single Flightrahul100% (1)

- 11.staircase Design Spreadsheet As Per IS 800Document4 pages11.staircase Design Spreadsheet As Per IS 800Mahadev D. Bhandare0% (1)

- Two Way Slab Design Excel SheetDocument11 pagesTwo Way Slab Design Excel SheetZevanyaRolandTualakaNo ratings yet

- Strap Footing Design As Per Is 456Document4 pagesStrap Footing Design As Per Is 456Sanjay Rokka75% (4)

- StaircaseDocument2 pagesStaircaseMAGED MOHMMED AHMED QASEMNo ratings yet

- RCDC Plinth BeamsDocument25 pagesRCDC Plinth BeamsEr Suresh Kumar50% (2)

- R.C.C. Column DesignDocument5 pagesR.C.C. Column Designgufran khan60% (5)

- Design of Isolated FootingDocument1 pageDesign of Isolated FootingchanakyaNo ratings yet

- Design BookDocument53 pagesDesign BookmollikaminNo ratings yet

- DESIGN OPTIMIZEDDocument5 pagesDESIGN OPTIMIZEDJitendra Kumar100% (1)

- JEC+Prog+ +Combined+Rectangular+FootingDocument6 pagesJEC+Prog+ +Combined+Rectangular+FootingLaura HernandezNo ratings yet

- Design of Columns As Per IS 456-2000Document68 pagesDesign of Columns As Per IS 456-2000S Praveenkumar87% (93)

- Corbel Excel Sheet WorksDocument5 pagesCorbel Excel Sheet WorksIbrahim A.LNo ratings yet

- 1.0 Beam DesignDocument8 pages1.0 Beam Designklynchelle100% (1)

- SL - No Description Refrence 1 Beam Design - B1 1.1 INPUTDocument2 pagesSL - No Description Refrence 1 Beam Design - B1 1.1 INPUTkushaljp8989No ratings yet

- Design of Steel STAADDocument61 pagesDesign of Steel STAADPrashant Sunagar100% (1)

- Design of Two Way Slab by IS 456Document8 pagesDesign of Two Way Slab by IS 456Mohmmedhusain Fruitwala50% (2)

- Design of Staircase - 04Document8 pagesDesign of Staircase - 04Engr SwapanNo ratings yet

- 8.0 Slab Design (Aci)Document4 pages8.0 Slab Design (Aci)klynchelleNo ratings yet

- One Way Slab DesignDocument10 pagesOne Way Slab DesignBijendra PradhanNo ratings yet

- Analysis and Design of Cantilever SlabDocument9 pagesAnalysis and Design of Cantilever SlabOscarKonzultNo ratings yet

- Beam Design With RCCDocument24 pagesBeam Design With RCCOsarieme Osakue100% (1)

- Staircase Design IS456-2000Document2 pagesStaircase Design IS456-2000Nitesh SinghNo ratings yet

- Design RCC 2 Storey BuildingDocument37 pagesDesign RCC 2 Storey BuildingNeetesh Sharma91% (44)

- Cantilever Slab DesignDocument18 pagesCantilever Slab DesignSarah Huff67% (9)

- Design of Cantilever Chajja SlabDocument4 pagesDesign of Cantilever Chajja SlabMaheshNo ratings yet

- Design of combined footing and strap beamDocument4 pagesDesign of combined footing and strap beamSakar ShresthaNo ratings yet

- Combined Strap FootingDocument8 pagesCombined Strap FootingNoman Khan100% (2)

- L Shaped Reatining WAll With HORZONTAL Bach FillDocument29 pagesL Shaped Reatining WAll With HORZONTAL Bach Fillsarveshfdk48100% (2)

- Slab Design As Per IS 456Document7 pagesSlab Design As Per IS 456RitaBiswas100% (1)

- Design of Simply Supported One Way SlabDocument15 pagesDesign of Simply Supported One Way SlabNikhil100% (2)

- Slab Design SpreadsheetDocument16 pagesSlab Design SpreadsheetmuraliNo ratings yet

- Strip Footing DesignDocument4 pagesStrip Footing Designkm_ananth100% (1)

- Design of Combined FootingDocument12 pagesDesign of Combined FootingAhmmed Muhsee100% (2)

- Slab Design Calculation: f (5* f A /8 A βDocument1 pageSlab Design Calculation: f (5* f A /8 A βchannajayamangala100% (1)

- Design of Continuos Beam As Per IS 456-2000 1) Design Data: Eff CK 2 2Document5 pagesDesign of Continuos Beam As Per IS 456-2000 1) Design Data: Eff CK 2 2khaniskhan03No ratings yet

- StariDocument28 pagesStariBikal BastakotiNo ratings yet

- S4 - Roof DeckDocument2 pagesS4 - Roof DeckJoemarie MartinezNo ratings yet

- SRB DesignDocument3 pagesSRB DesignRam LangheNo ratings yet

- Escaltor Cantilever Beam: Load CalculationDocument6 pagesEscaltor Cantilever Beam: Load CalculationJAYASHREEBHUVANANo ratings yet

- Slab design calculations for two-storey residential projectDocument6 pagesSlab design calculations for two-storey residential projectZulkiflee TaugNo ratings yet

- Hetauda Raft DesignDocument92 pagesHetauda Raft DesignSurendra MaharjanNo ratings yet

- Base Plate DesignDocument21 pagesBase Plate Designtitir bagchi100% (1)

- DEEP BEAM DesignDocument2 pagesDEEP BEAM DesignmangeshNo ratings yet

- Beam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesDocument13 pagesBeam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesVenkatesha Hebbar100% (1)

- Expt 2 - Two Way SlabDocument4 pagesExpt 2 - Two Way Slabganesh rajaNo ratings yet

- Grade 10 Illustration Q3 Week3Document6 pagesGrade 10 Illustration Q3 Week3NetsuNo ratings yet

- Paper 2 Answer SPMDocument12 pagesPaper 2 Answer SPMSylarkNo ratings yet

- ACI-439.3R-91 Mechanical Connections of Reinforcing BarsDocument16 pagesACI-439.3R-91 Mechanical Connections of Reinforcing BarsMichi AGNo ratings yet

- L1Document7 pagesL1Francisco Roberto Trujillo LeonNo ratings yet

- Manual de Diagnostico D3E PDFDocument72 pagesManual de Diagnostico D3E PDFJosé Luis Contreras Calderón100% (3)

- Laboratory Activity No. 01 - Properties of LiquidDocument2 pagesLaboratory Activity No. 01 - Properties of LiquidCzarina Relleve0% (1)

- Chapter 3Document12 pagesChapter 3Raymond LeoNo ratings yet

- Magazine 55 EnglishPartDocument50 pagesMagazine 55 EnglishPartAli AwamiNo ratings yet

- Hydraulic System Trainer AS-10Document13 pagesHydraulic System Trainer AS-10Tanlets Gery100% (1)

- Volume 5 Issue 1Document625 pagesVolume 5 Issue 1IJAET Journal0% (1)

- Nordson EFD Ultimus I II Operating ManualDocument32 pagesNordson EFD Ultimus I II Operating ManualFernando KrauchukNo ratings yet

- E02-E02 Rev 3 Jun 2017 Selection of Elec Equip in Hazardous AreaDocument6 pagesE02-E02 Rev 3 Jun 2017 Selection of Elec Equip in Hazardous AreaSALMANNo ratings yet

- PandoraFMS Alerts WhatsappDocument6 pagesPandoraFMS Alerts Whatsapppacolo89No ratings yet

- Automatic Helmet DetectDocument4 pagesAutomatic Helmet Detectvasanth100% (1)

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolssierroNo ratings yet

- Unit 30 WorkDocument2 pagesUnit 30 WorkThanh HàNo ratings yet

- UniSim Heat Exchangers User Guide PDFDocument22 pagesUniSim Heat Exchangers User Guide PDFzhangyiliNo ratings yet

- George B Dantzig PDFDocument19 pagesGeorge B Dantzig PDFKeith BoltonNo ratings yet

- ADC MethodDocument16 pagesADC MethodPhilip K MathewNo ratings yet

- Kent Lawrence LORDAN Grade-1Document1 pageKent Lawrence LORDAN Grade-1Kent Lawrence LordanNo ratings yet

- 3 - Big Data CharacteristicsDocument32 pages3 - Big Data CharacteristicsWong pi wenNo ratings yet

- Ese 570 Mos Inverters Static Characteristics: Kenneth R. Laker, University of Pennsylvania, Updated 13feb12 1Document44 pagesEse 570 Mos Inverters Static Characteristics: Kenneth R. Laker, University of Pennsylvania, Updated 13feb12 1het shahNo ratings yet

- C ProgDocument29 pagesC ProgaishwaryaNo ratings yet

- VUCG Guia de Instalacion y Comisionamiento en Ingles 1ZSC000562-AAY en Rev 1 - LowDocument56 pagesVUCG Guia de Instalacion y Comisionamiento en Ingles 1ZSC000562-AAY en Rev 1 - Lowarmandoa71565No ratings yet

- Cathodic Disbonding TesterDocument1 pageCathodic Disbonding TesterfelavinNo ratings yet

- Grade 3 Unit 3 (English)Document1 pageGrade 3 Unit 3 (English)Basma KhedrNo ratings yet

- Module 1 SIMPLE INTERESTDocument15 pagesModule 1 SIMPLE INTERESTElle Villanueva VlogNo ratings yet

- A320 Flex CalculationDocument10 pagesA320 Flex CalculationMansour TaoualiNo ratings yet

- Educ 61 Module 5 ActivityDocument4 pagesEduc 61 Module 5 ActivityMitchille GetizoNo ratings yet

- ACL-PDC-01 - Rev01 (Procurement Document Control)Document3 pagesACL-PDC-01 - Rev01 (Procurement Document Control)Mo ZeroNo ratings yet