Professional Documents

Culture Documents

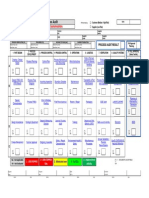

Production KPI

Uploaded by

Cucak RowoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Production KPI

Uploaded by

Cucak RowoCopyright:

Available Formats

SevenCommonKPIs

forProductionMonitoring

Using Visual Management to Drive Productivity

White Paper

SevenCommonKPIs

forProductionMonitoring

Using Visual Management to Drive Productivity

Table of Contents

Introduction.......................................................................................................................3

WhatareKeyPerformanceIndicators(KPIs)?.....................................................................3

WhatisVisualManagement?.............................................................................................3

SevenCommonProductionKPIs.........................................................................................4

1.Count(GoodorBad).....................................................................................................................4

2.RejectRatio...................................................................................................................................4

3.Rate...............................................................................................................................................4

4.Target............................................................................................................................................4

5.TaktTime......................................................................................................................................4

6.OverallEquipmentEffectiveness(OEE)........................................................................................5

7.Downtime.....................................................................................................................................5

ImplementingVisualManagement.....................................................................................5

DrivingProductivity............................................................................................................5

UsingVisualManagementforKPIMonitoring....................................................................6

TheRedLionAdvantage.....................................................................................................6

SevenCommonKPIs

forProductionMonitoring

Using Visual Management to Drive Productivity

Introduction

Strategic philosophies or practices such as Kaizen, Lean Manufacturing, Six Sigma, Total Quality

ManagementandContinuousImprovementareusedbymanyorganizationstohelpimproveprocesses,

driveproductivityandmaintainacompetitiveedgeintodayseverincreasingglobaleconomy.Despite

varying concepts, each practice uses Key Performance Indicators (KPIs) to assess, analyze and track

manufacturing processes. Even if an organization does not employ formal continuous improvement

initiatives, efficiency gains can still be realized by borrowing lessons learned through the visual

management techniques of those processes. This white paper discusses how visual management can

drive productivity by leveraging seven common Key Performance Indicators (KPIs) for production line

monitoring.

What are Key Performance Indicators (KPIs)?

KPIsareassortedvariablesthatorganizationsusetoassess,analyzeandtrackmanufacturingprocesses.

These performance measurements are commonly used to evaluate success in relation to goals and

objectives.

What is Visual Management?

VisualmanagementistheprocessofdisplayingcriticalinformationsuchasKPIsthatrelatespecificallyto

productionoutput,efficiencyandquality.Bydisplayingthisdataonthefactoryfloor,employeeshavea

better sense of production levels and tend to strive for higher performance. Visual management also

providesactionableinformationthatallowssupervisorstobettermonitorperformanceanddetermine,

in realtime, areas that may need improvement. The overall result helps to drive productivity

throughouttheorganizationbyincreasingefficiency,qualityanduptime.Moreinformationonthistopic

isoutlinedinRedLionsThreeVisualManagementSolutionswhitepaper.

Seven Common Production KPIs

KPIstendtovarybyorganization.Alistofsevencommon

productionKPIsusedonautomatedplantfloorsfollow:

. Count (Good or Bad)

Anessentialfactoryfloormetricrelatestotheamountof

product produced. The count (good or bad) typically

referstoeithertheamountofproductproducedsincethe

last machine changeover or the production sum for the

entire shift or week. Many companies will compare

individualworkerandshiftoutputtoinvokeacompetitive

spiritamongemployees.

. Reject Ratio

Productionprocessesoccasionallyproducescrap,whichis

measuredintermsofrejectratio.Minimizingscraphelps

organizationsmeetprofitabilitygoalssoitisimportantto

trackwhetherornottheamountbeingproducediswithin

tolerablelimits.

. Rate

Machinesandprocessesproducegoodsatvariablerates.

Whenspeedsdiffer,slowratestypicallyresultindropped

profits while faster speeds affect quality control. This is

why it is important for operating speeds to remain

consistent.

. Target

Manyorganizationsdisplaytargetvaluesforoutput,rate

and quality. This KPI helps motivate employees to meet

specificperformancetargets.

. Takt Time

Takt time is the amount of time, or cycle time, for the

completion of a task. This could be the time it takes to

produceaproduct,butitmorelikelyrelatestothecycle

time of specific operations. By displaying this KPI, manufacturers can quickly determine where the

constraintsorbottlenecksarewithinaprocess.

. Overall Equipment Effectiveness (OEE)

OEEisametricthatmultipliesavailabilitybyperformanceandqualitytodetermineresourceutilization.

Production managers want OEE values to increase because this indicates more efficient utilization of

availablepersonnelandmachinery.

. Downtime

Whethertheresultofabreakdownorsimplyamachinechangeover,downtimeisconsideredoneofthe

most important KPI metrics to track. When machines are not operating, money isnt being made so

reducingdowntimeisaneasywaytoincreaseprofitability.Organizationsthattrackdowntimetypically

requireoperatorstoenterareasoncodeviakeypad,pushbuttonorbarcodescannersothatthemost

commonreasonscanbereviewedatalatertime.

Implementing Visual Management

To demonstrate how to implement visual management, lets consider a realworld example of how a

contract packaging company uses KPIs to drive productivity. This organization employs workers that

workinteamstoassemblepackagesanddeterminesquotesfornewjobsbaseduponpriortimestudies.

Considering the unique nature of every project, making a profit on a given job is dependent on the

teamsabilitytosetuptheproductionlineforanewrunwithintheshortestperiodoftime,aswellas

being able to maintain the assumed rate of production for the entirety of each job. To effectively

accomplish this, realtime information is required to confirm if assumptions made during the quoting

processarebeingmet.

ThepackagingcompanyinstalledlargeLEDdisplaysoneachlinetodisplayconveyorspeedsaswellas

theelapsedtimeduringchangeoverperiods.Byimplementingvisualmanagement,supervisorsarenow

able to take immediate action when changeovers take too long or workers fail to meet required

packaging rates. This deployment enabled the organization to substantially increase profitability and

driveproductivitywith1015percentfastercompletiontimes.

Driving Productivity

Managing productivity and profitability is a key role of plant managers and engineers in worldclass

manufacturing operations. The amount of increased productivity and profit an organization stands to

gaindependsquitelargelyonthecompanyanditsexistingprocesses.

Consider any given line or machine within a production facility, and estimate the financial impact if

outputcouldbeincreasedby1,5,10oreven20percent.Nowconsiderwhatthefinancialimpactmight

(

beifdowntimecouldbereducedbyasmuchas15percent.Eventheslightestimprovementcanresult

inattractivereturns.PlantswithtargetKPImetricsshouldtakethetimetoevaluatethenumbersand

examinehowvisualmanagementcoulddriveproductivityacrosstheorganization.

Since many visual management systems are low cost, there is little risk involved for potentially large

returnsinprocessimprovementsandprofitability.Whenevaluatingsavingspotential,itisimportantto

includeallcoststhatmayincurasaresultofdowntime.Forinstance,therearelaborandutilitycosts,

but what about scrap? Many continuous processes require machines run start to finish, so any

interruptionmeansscrapproduct.KPImonitoringhelpstotracksuchprocesses.

Using Visual Management for KPI Monitoring

RedLionControlsprovidesindustryleadingsolutionsforvisual

managementofawidevarietyofapplications.RedLionsvisual

managementproductsrangefromsimplelargeLEDdisplaysto

the powerful ProducTVity (PTV) Station. The PTV Station is a

readytodeploy plant floor visual management system that

seamlesslydisplaysrealtimeKPIdataandandonmessageson

large televisions to drive productivity. To learn more, please

visitwww.redlion.net/PTV.

The Red Lion Advantage

Astheglobalexpertsincommunication,monitoringandcontrolforindustrialautomation,RedLionhas

been delivering innovative solutions to customers for forty years. Our awardwinning technology

enables companies worldwide to gain realtime data visibility that drives productivity. Product brands

includeRedLion,SixnetandNTron.WithheadquartersinYork,Pennsylvania,thecompanyhasoffices

acrosstheAmericas,AsiaPacificandEurope.Formoreinformation,pleasevisitwww.redlion.netorcall

+1(717)7676511.RedLionisaSpectriscompany.

Willow Springs Circle

York, PA

USA

+ ( )

You might also like

- Manufacturing KPIs & Metrics - Explore The Best KPI ExamplesDocument24 pagesManufacturing KPIs & Metrics - Explore The Best KPI ExamplesGangadhar YerraguntlaNo ratings yet

- Maintenance KPIs Steel IndustryDocument10 pagesMaintenance KPIs Steel IndustryGuadagustinNo ratings yet

- Process AuditDocument15 pagesProcess Auditdesurkarb100% (2)

- Lean Scorecard 5Document4 pagesLean Scorecard 5EmmanuelLaresEmmyNo ratings yet

- Daily Work MGT Sheet & FormatsDocument5 pagesDaily Work MGT Sheet & FormatsKakara Surya NageswaraoNo ratings yet

- Total Preventive (Productive) Maintenance, Volume 2.Document50 pagesTotal Preventive (Productive) Maintenance, Volume 2.Fernando MaltempoNo ratings yet

- Kpis Maintenace PDFDocument8 pagesKpis Maintenace PDFCristian GarciaNo ratings yet

- My HR SuzlonDocument105 pagesMy HR Suzlonkaushik makwana100% (2)

- Manufacturing Process Audit Checklist: Reference DocumentsDocument4 pagesManufacturing Process Audit Checklist: Reference DocumentsAri Rosyadi100% (1)

- Production Department KPIsDocument76 pagesProduction Department KPIssuraj rawatNo ratings yet

- Template - Lean Six Sigma Charter (EDocFind (1) (1) .Com)Document6 pagesTemplate - Lean Six Sigma Charter (EDocFind (1) (1) .Com)Dipika PandaNo ratings yet

- Process Audit Check ListDocument47 pagesProcess Audit Check ListAnas NazriNo ratings yet

- Quality Management KpiDocument8 pagesQuality Management Kpiselinasimpson2801No ratings yet

- Maximise Project KPI PerformanceDocument2 pagesMaximise Project KPI PerformanceKashi PatelNo ratings yet

- 8D Report SummaryDocument9 pages8D Report SummaryLukas LukasNo ratings yet

- Manual 5-Office TPMDocument8 pagesManual 5-Office TPMsaravanan_mvs8989100% (1)

- Process Audit ChecklistDocument15 pagesProcess Audit Checklistmulachu100% (1)

- Skill ChartDocument89 pagesSkill ChartVasudev Bhanaji67% (3)

- MSA Bias & GRRDocument2 pagesMSA Bias & GRRRamchandrarao DeshpandeNo ratings yet

- RASIC Chart SampleDocument2 pagesRASIC Chart SamplejibharatNo ratings yet

- Operator Skill MATRIXDocument11 pagesOperator Skill MATRIXsrinivasprem93No ratings yet

- 4M Change Summary Sheet - PRFDocument4 pages4M Change Summary Sheet - PRFkumar QANo ratings yet

- Why analysis root cause manufacturing defectsDocument4 pagesWhy analysis root cause manufacturing defectsmaulikgadaraNo ratings yet

- Master List of Lab DocumentsDocument4 pagesMaster List of Lab DocumentsSherry100% (1)

- Presentation Guidelines: Case Study - Zero Defect Drive by Laxmikant MishraDocument28 pagesPresentation Guidelines: Case Study - Zero Defect Drive by Laxmikant MishrapiyushNo ratings yet

- Blank Turtle DiagramDocument1 pageBlank Turtle Diagrammrtelephone1100% (2)

- Process Sheet: Express Luck Egypt Company Express Luck Egypt CompanyDocument8 pagesProcess Sheet: Express Luck Egypt Company Express Luck Egypt Companymohamed abdullahNo ratings yet

- Business Accounts Manager's Resume CV TemplateDocument2 pagesBusiness Accounts Manager's Resume CV TemplateMike KelleyNo ratings yet

- Iso 9001:2008 Quality Management System Implementation Plan: PlanningDocument1 pageIso 9001:2008 Quality Management System Implementation Plan: PlanningKhirullah Abdul HamidNo ratings yet

- METHODOLOGY FOR Vendor Rating SystemDocument5 pagesMETHODOLOGY FOR Vendor Rating SystemRangaNo ratings yet

- European Air Traffic KPI Monitoring GuideDocument35 pagesEuropean Air Traffic KPI Monitoring GuidemdavangeNo ratings yet

- 5S Implementation Plan at Work PlaceDocument18 pages5S Implementation Plan at Work PlacemanishlmehtaNo ratings yet

- LEAN Execution OEEDocument11 pagesLEAN Execution OEEVergence Business Associates100% (7)

- Daily Operation Management ReportDocument1 pageDaily Operation Management ReportRebekah SchmidtNo ratings yet

- 02 SD - Performance Measures MFG GuidelinesDocument41 pages02 SD - Performance Measures MFG GuidelinesTrần Hướng ĐôngNo ratings yet

- TianJin DeHua Petroleum Quality ManualDocument46 pagesTianJin DeHua Petroleum Quality ManualIjabi100% (1)

- MMD Honda QAV1 Audit Observation - 31.07.2019 To 02.08.2019 R2Document13 pagesMMD Honda QAV1 Audit Observation - 31.07.2019 To 02.08.2019 R2Rohit SoniNo ratings yet

- Operational Excellence HandbookDocument17 pagesOperational Excellence Handbookcherry100% (4)

- Office TPM ConceptsDocument9 pagesOffice TPM ConceptsNivedh Vijayakrishnan100% (1)

- Simple Oee SpreadsheetDocument2 pagesSimple Oee SpreadsheetadeNo ratings yet

- Audit Checklist For ManufacturingDocument2 pagesAudit Checklist For ManufacturingRenganathan IyengarNo ratings yet

- Drill Deep Root Cause Analysis WorksheetDocument1 pageDrill Deep Root Cause Analysis WorksheetLipecaNo ratings yet

- CEO Time 15 Must-Have Dashboards For 2021Document21 pagesCEO Time 15 Must-Have Dashboards For 2021ssabdullssNo ratings yet

- Process Management for Quality AssuranceDocument22 pagesProcess Management for Quality AssuranceVikas0% (1)

- Plant Lean Assessment Reveals Opportunities for 5S Workplace OrganizationDocument19 pagesPlant Lean Assessment Reveals Opportunities for 5S Workplace OrganizationLeontin LeonNo ratings yet

- Six Sigma ToolsDocument56 pagesSix Sigma Toolslandersjc100% (1)

- APQP Fundamentals PDFDocument105 pagesAPQP Fundamentals PDFRajesh Sahasrabuddhe100% (3)

- 8DDocument117 pages8DLokesh NarasimhaiahNo ratings yet

- Process Control PlanDocument1 pageProcess Control PlanAbhi ChowdhuryNo ratings yet

- PPAP Assessment Process Flow DiagramDocument15 pagesPPAP Assessment Process Flow Diagramffppxxzz100% (1)

- IMDS Create MDS Tips - ComponentDocument64 pagesIMDS Create MDS Tips - ComponentmonicaramonaNo ratings yet

- Sample BSC ScorecardDocument4 pagesSample BSC Scorecardfcleong69No ratings yet

- System Audit RequirementDocument37 pagesSystem Audit Requirementavinashbatra171% (7)

- Office (Eng)Document31 pagesOffice (Eng)kingathur26681No ratings yet

- Cci Kpi Report 2004Document22 pagesCci Kpi Report 2004Daniel Pratama100% (1)

- MIT Fayoum Faculty KPIs Production AutomationDocument17 pagesMIT Fayoum Faculty KPIs Production AutomationAmer Abd EL-hkimNo ratings yet

- Script ReportDocument3 pagesScript ReportCosinas, Lairah Chen B.No ratings yet

- ByD DemoScript GEN ManagementAccountingHighlights en USDocument33 pagesByD DemoScript GEN ManagementAccountingHighlights en USNguyen HaiNo ratings yet

- 10 Step Process Improvement Initiative GuideDocument316 pages10 Step Process Improvement Initiative GuideHemal KamdarNo ratings yet

- Lean System Edited Lyst7490Document23 pagesLean System Edited Lyst7490AbhilashNo ratings yet

- Chapter 5 Flow Rate and Capacity 1-16-10Document27 pagesChapter 5 Flow Rate and Capacity 1-16-10Cucak RowoNo ratings yet

- Pivot StepDocument9 pagesPivot StepCucak RowoNo ratings yet

- Beatrice Cristina Pacea 1Document6 pagesBeatrice Cristina Pacea 1Cucak RowoNo ratings yet

- Capacity AnalysisDocument1 pageCapacity AnalysisCucak RowoNo ratings yet

- 20 Ways To Improve Productivity in Garment Production and Planning CapacityDocument8 pages20 Ways To Improve Productivity in Garment Production and Planning CapacityCucak RowoNo ratings yet

- Line Balancing PresentationDocument42 pagesLine Balancing PresentationGlenn RebelloNo ratings yet

- Northwest CornerDocument6 pagesNorthwest CornerCucak RowoNo ratings yet

- 3021 - 07 Predetermined Time SystemsDocument37 pages3021 - 07 Predetermined Time Systemssunilkjain6105100% (1)

- Operator Name: A, B, C Divisi: UC Work Sampling FormDocument7 pagesOperator Name: A, B, C Divisi: UC Work Sampling FormCucak RowoNo ratings yet

- Six Sigma Belt RolesDocument1 pageSix Sigma Belt RolesCucak RowoNo ratings yet

- Re - New List of Solution ManualDocument4 pagesRe - New List of Solution ManualCucak RowoNo ratings yet