Professional Documents

Culture Documents

PWHT Requirement Rev 3

Uploaded by

kategordCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PWHT Requirement Rev 3

Uploaded by

kategordCopyright:

Available Formats

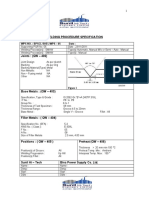

JG SUMMIT NAPHTHA CRACKER PROJECT

PIPING MATERIAL SPECIFICATION

JG Summit

Petrochemical Corporation

JOB NO. DOC.NO.

071061 JGSNCP-PI-ES-002

REV. NO. PAGE NO.

3 2/7

Appendix-B PIPING MATERIALS SERVICE INDEX

DESIGN TEMPERATURE RANGE ()

CLASS

RATING

PIPE MATERIAL

VALVE BODY TRIM

C.A (mm)

SERVICE

RT(%)

PWHT

A1A

150 RF

CS

CS 13 Cr/HF

1.6

-29 TO 427

ATMOSPHERIC VENT, BLOWDOWN, BOILER FEED WATER, CONTINUOUS BLOWDOWN, DECOKING AIR, DILUTION STEAM, FUEL GAS, LOW PRESSURE STEAM (SUPERHEATED), MEDIUM PRESSURE STEAM, NITROGEN, NON-CONTAMINATED DRAIN, PROCESS,PROCESS WATER SAFETY VALVE TO ATMOSPHERE, STEAM CONDENSATE, WASTE WATER CHEMICAL INJECTION, DILUTION STEAM, FUEL GAS, FLUX LIGHT OIL, FUEL OIL, HYDROGEN GAS, LOW PRESSURE STEAM (SUPERHEATED), METHANOL, NITROGEN, OILY DRAIN, OILY WATER DRAIN, PROCESS, PURGE OIL, PROCESS WATER, PLANT AIR AND PROCESS AIR, PYROLYSIS GASOLINE HYDROGENATION, UNIT DRAIN, QUENCH OIL, QUENCH WATER, SUPER HIGH PRESSURE STEAM, WASH OIL, WASTE WATER, WET LIQUID DRAIN PROCESS (SOUR SERVICE, NACE MR0103) HYDROGEN GAS

5%

>20mm

A1D

150 RF

CS

CS 13 Cr

1.6

-29 TO 427

5%

>20mm

A1DX

150 RF

CS

CS 13 Cr CS 13 Cr ALLOY 20 ALLOY 20 CS 13 Cr

1.6

-29 TO 427

5%

All

A1E

150 RF

CS

3.2

-29 TO 316 -29 TO 65 (Note 327) -29 TO 260

5%

>20mm

A1F

150 RF

CS

3.2

ACID PROCESS, WET FLARE, WET LIQUID DRAIN

5%

>20mm

A1K

150 RF

CS

3.2

5%

>20mm

* Note 327 : Sulfuric Acid lines to be insulated to maintain the surface temperature at below 50 from the solar heat as per NACE RP0391.

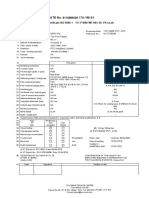

JG SUMMIT NAPHTHA CRACKER PROJECT

PIPING MATERIAL SPECIFICATION

JG Summit

Petrochemical Corporation

JOB NO. DOC.NO.

071061 JGSNCP-PI-ES-002

REV. NO. PAGE NO.

3 3/7

Appendix-B PIPING MATERIALS SERVICE INDEX

DESIGN TEMPERATURE RANGE ()

CLASS

RATING

PIPE MATERIAL

VALVE BODY TRIM

C.A (mm)

SERVICE

RT(%)

PWHT

A1NR

150 RF

CS (STRESS RELIEVED)

CS MONEL

3.2

-29 TO 110

CAUSTIC, CHEMICAL DRAIN, OILY DRAIN, PROCESS, PROCESS WATER, WASTE WATER DILUTION STEAM, FUEL GAS, MEDIUM PRESSURE STEAM, PROCESS, QUENCH OIL PROCESS (SOUR SERVICE, NACE MR0103) PROCESS

5%

All

A1P

150 RF

CS

CS 13 Cr/HF CS 13 Cr/HF CS 13 Cr/HF

3.2

-29 TO 427

5%

>20mm

A1PX

150 RF

CS

3.2

-29 TO 427 -29 TO 427 (FULL VACUUM)

5%

All

A1PA

150 RF

CS

3.2

5%

>20mm

A2A

150 RF

L.T.C.S. (IMPACT TESTED) LINED C.S. (PVDF) 304 SS

L.T.C.S. 316 SS

1.6

-46 TO 260

PROCESS

5%

>20mm

A6A

150 RF

ALLOY 20 ALLOY 20 316 SS 316 SS

0.0

-29 TO 93

CHEMICAL INJECTION

5%

>20mm

A21A

150 RF

0.0

-29 TO 204

CAUSTIC, DEMINERALIZED WATER BIOCIDE SOLUTION, CORROSION INHIBITOR DISPERSANT, HYDROCARBON, PHOSPHATE HYDRAZINE LUBE AND SEAL OIL (HIGH AND LOW PRESS.) CRYOGENIC LIQUID DRAIN, DRY FLARE, PROCESS

5%

No

A21B

150 RF

304 SS

316 SS 316 SS

0.0

-29 TO 204

5%

No

A21C

150 RF

304 SS

316 SS 304 SS 316 SS 316 SS 316 SS 316 SS 316 SS 316 SS

0.0

-29 TO 204

5%

No

A21D

150 RF

304 SS 304 SS (IMPACT TESTED) 304 SS (IMPACT TESTED)

0.0

-29 TO 204

5%

No

A21K

150 RF

0.0

-101 TO 250

5%

No

A21KX

150 RF

0.0

-101 TO 250

PROCESS (SOUR SERVICE, NACE MR0103)

5%

No

JG SUMMIT NAPHTHA CRACKER PROJECT

PIPING MATERIAL SPECIFICATION

JG Summit

Petrochemical Corporation

JOB NO. DOC.NO.

071061 JGSNCP-PI-ES-002

REV. NO. PAGE NO.

3 4/7

Appendix-B PIPING MATERIALS SERVICE INDEX

DESIGN TEMPERATURE RANGE ()

CLASS

RATING

PIPE MATERIAL

VALVE BODY TRIM

C.A (mm)

SERVICE

RT(%)

PWHT

A21L

150 RF

304 SS (IMPACT TESTED)

316 SS 316 SS

0.0

-196 TO 204

CRYOGENIC LIQUID DRAIN, DRY FLARE, METHANOL, PROCESS, TERTIARY PEFPIGERANT HYDROCARBON, HYDROCARBON (HIGH TEMP.) ATMOSPHERIC VENT, BOILER FEED WATER, CONTINUOUS BLOWDOWN, COOLING WATER RETURN, COOLING WATER SUPPLY, INTERMEDIATE COOLING WATER, LOW PRESSURE STEAM (DESUPERHEATED), LOW PRESSURE STEAM (SUPERHEATED), MEDIUM PRESSURE STEAM, PROCESS WATER, SAFETY VALVE TO ATMOSPHERE, STEAM CONDENSATE BOILER FEED WATER, CHEMICAL INJECTION, COOLING WATER RETURN, COOLING WATER SUPPLY, CRYOGENIC LIQUID DRAIN, FLUX LIGHT OIL, FUEL OIL, HYDROGEN GAS, MEDIUM PRESSURE STEAM, METHANOL, NITROGEN, OILY DRAIN, PROCESS, PURGE OIL, PYROLY GASOLINE HYDROGENATION UNIT DRAIN, QUENCH OIL, QUENCH WATER, TERTIARY REFRIGERANT, WET LIQUID DRAIN PROCESS (SOUR SERVICE, NACE MR0103) HYDROGEN GAS, LOW PRESSURE STEAM (DESUPERHEATED), PROCESS, PLANT AIR AND PROCESS AIR, SAFETY VALVE TO ATMOSPHERE, STEAM CONDENSATE

5%

No

A54A

150 RF

1 Cr

1 Cr 13 Cr/HF

1.6

-29 TO 538

5%

>13mm

B1A

300 RF

CS

CS 13 Cr/HF

1.6

-29 TO 427

5%

>20mm

B1D

300 RF

CS

CS 13 Cr

1.6

-29 TO 427

5%

>20mm

B1DX

300 RF

CS

CS 13 Cr

1.6

-29 TO 427

5%

All

B1E

300 RF

CS

CS 13 Cr

3.2

-29 TO 427

5%

>20mm

JG SUMMIT NAPHTHA CRACKER PROJECT

PIPING MATERIAL SPECIFICATION

JG Summit

Petrochemical Corporation

JOB NO. DOC.NO.

071061 JGSNCP-PI-ES-002

REV. NO. PAGE NO.

3 5/7

Appendix-B PIPING MATERIALS SERVICE INDEX

DESIGN TEMPERATURE RANGE ()

CLASS

RATING

PIPE MATERIAL

VALVE BODY TRIM

C.A (mm)

SERVICE

RT(%)

PWHT

B1NR

300 RF

CS (STRESS RELIEVED) L.T.C.S. (IMPACT TESTED)

CS MONEL

3.2

-29 TO 120

CAUSTIC

5%

All

B2A

300 RF

L.T.C.S. 316 SS

1.6

-46 TO 316

CRYOGENIC LIQUID DRAIN, METHANOL PROCESS, TERTIARY REFRIGERANT CAUSTIC, LUBE OIL, SEAL OIL CRYOGENIC LIQUID DRAIN, HYDROGEN GAS, LOW PRESSURE STEAM (DESUPERHEATED), PROCESS, TERTIARY REFRIGERANT

5%

>20mm

B21D

300 RF

304 SS

316 SS 316 SS

0.0

-29 TO 204

5%

No

B21K

300 RF

304 SS (IMPACT TESTED)

316 SS 316 SS

0.0

-101 TO 300

5%

No

B21KX

300 RF

304 SS (IMPACT TESTED) 304 SS (IMPACT TESTED)

316 SS 316 SS

0.0

-101 TO 300

PROCESS (SOUR SERVICE, NACE MR0103) CRYOGENIC LIQUID DRAIN, PROCESS, TERTIARY REFRIGERANT

5%

No

B21L

300 RF

316 SS 316 SS

0.0

-196 TO 204

5%

No

B54F

300 RF

1 Cr

1 Cr 13 Cr/HF CS 13 Cr/HF CS 13 CR CS 13 CR L.T.C.S. 316 SS 316 SS 316 SS

3.2

-29 TO 538

PROCESS BOILER FEED WATER, HIGH PRESSURE STEAM, HIGH PRESSURE CONDENSATE PROCESS

10%

>13mm

D1A

600 RF

CS

1.6

-29 TO 427

10%

>20mm

D1D

600 RF

CS

1.6

-29 TO 427

10%

>20mm

D1E

600 RF

CS L.T.C.S. (IMPACT TESTED) 304 SS

3.2

-29 TO 204

HYDROGEN

10%

>20mm

D2A

600 RF

1.6

-46 TO 316

PROCESS

10%

>20mm

D21D

600 RF

0.0

-29 TO 204

LUBE OIL, SEAL OIL

10%

No

JG SUMMIT NAPHTHA CRACKER PROJECT

PIPING MATERIAL SPECIFICATION

JG Summit

Petrochemical Corporation

JOB NO. DOC.NO.

071061 JGSNCP-PI-ES-002

REV. NO. PAGE NO.

3 6/7

Appendix-B PIPING MATERIALS SERVICE INDEX

DESIGN TEMPERATURE RANGE ()

CLASS

RATING

PIPE MATERIAL

VALVE BODY TRIM

C.A (mm)

SERVICE

RT(%)

PWHT

D21K

600 RF

304 SS (IMPACT TESTED) 304 SS (IMPACT TESTED) 1 Cr

316 SS 316 SS 316 SS 316 SS 1 Cr 13 Cr/HF 1 Cr 13 Cr/HF L.T.C.S. 316 SS

0.0

-101 TO 204

TERTIARY REFRIGERANT

10%

No

D21L

600 RF

0.0

-196 TO 204

CRYOGENIC LIQUID DRAIN

10%

No

D54E

600 RF

3.2

-29 TO 538

HYDROGEN GAS HYDROGEN GAS (HYDROGEN SERVICE) LIQUID DRAIN , PROPYLENE REFRIGERANT, TERTIARY REFRIGERANT DRY FLARE, HYDROCARBON (LOW TEMP.), LIQUID DRAIN BOILER FEED WATER BLOWDOWN BOILER FEED WATER, CONTINUOUS BLOWDOWN, SUPER HIGH PRESSURE STEAM PHOSPHATE INJECTION

10%

>13mm

D54EH

600 RF

1 Cr L.T.C.S. (IMPACT TESTED) 304 SS (IMPACT TESTED) CS

3.2

-29 TO 538

100%

All

E2A

900 RTJ

1.6

-46 TO 316

10%

>20mm

E21K

900 RTJ

316 SS 316 SS CS 13 Cr/FHF

0.0

-101 TO 204

10%

No

F1A

1500 BW

1.6

-29 TO 427

100%

>20mm

F1AS

1500 BW

CS (ASME Sec. I)

CS 13 Cr/FHF

1.6

-29 TO 427

100%

19mm

F21B

1500 SW 1500 BW 2500 BW 2500 BW 2500 BW 2500 BW

304 SS

316 SS 316 SS 1 Cr 13 Cr/FHF 1 Cr 13 Cr/FHF 1 Cr 13 Cr/FHF 2 Cr-1 Mo Trim No.5/FHF 2 Cr-1 Mo Trim No.5/FHF

0.0

-29 TO 371

100%

No

F54AS

1 Cr (ASME Sec. I)

1.6

-29 TO 538

DESUPERHEATED STEAM

100%

13mm

G54A

1 Cr

1.6

-29 TO 550

SUPER HIGH PRESSURE STEAM

100%

>13mm

G54AS

1 CR (ASME Sec. I)

1.6

-29 TO 550

DESUPERHEATED STEAM

100%

13mm

G56A

2 Cr-1Mo

1.6

-29 TO 550

SUPER HIGH PRESSURE STEAM

100%

>13mm

G56AS

2 Cr-1 Mo (ASME Sec. I)

1.6

-29 TO 550

SUPER HIGH PRESSURE STEAM

100%

13mm

JG SUMMIT NAPHTHA CRACKER PROJECT

PIPING MATERIAL SPECIFICATION

JG Summit

Petrochemical Corporation

JOB NO. DOC.NO.

071061 JGSNCP-PI-ES-002

REV. NO. PAGE NO.

3 7/7

Appendix-B PIPING MATERIALS SERVICE INDEX

DESIGN TEMPERATURE RANGE ()

CLASS

RATING

PIPE MATERIAL

VALVE BODY TRIM

C.A (mm)

SERVICE

RT(%)

PWHT

H1A20

150 RF

CS

CS 13 Cr/HF

1.6

-10 TO 121

COOLING WATER RETURN, COOLING WATER SUPPLY, DECOKING AIR, DESALINATED WATER, INTERMEDIATE COOLING WATER, PLANT AIR AND PROCESS AIR, SAFETY VALVE TO ATMOSPHERE, UTILITY WATER, WASTE WATER FIRE WATER(UPSTREAM OF DELUGE VALVE) (AG) FIRE WATER (UG) COOLING WATER RETURN (UG), COOLING WATER SUPPLY (UG), INTERMEDIATE COOLING WATER (UG) NON-CONTAMINATED-SEWER, OILY DRAIN/CASING DRAIN, OILY WATER DRAIN INSTRUMENT AIR, POTABLE WATER FIRE WATER(DOWNSTREAM OF DELUGE VALVE) (AG) CHEMICAL INJECTION, NEUTRALIZED WATER, PLANT AIR, PRESSURE AIR, SEA WATER RETURN, SEA WATER SUPPLY, WASTE SEA WATER, WASTE WATER CHEMICAL INJECTION (UG), NEUTRALIZED WATER (UG), PLANT AIR (UG), PRESSURE AIR (UG) , SEA WATER RETURN (UG), SEA WATER SUPPLY (UG), WASTE SEA WATER (UG), WASTE WATER (UG) FIRE WATER (UG), CHEMICAL DRAIN (UG) CO2 GAS, FM-200 GAS

No

>20mm

H1C20

150 RF

CS

CS 13 Cr/HF CS 13 Cr/HF

1.6

-10 TO 60

No

>20mm

H1CU20

150 RF

CS

1.6

-10 TO 60

No

>20mm

H1D20

150 RF

CS

CS 13 Cr/HF

1.6

-10 TO 121

No

>20mm

H3A20

150 RF

CS GALVANIZED CS GALVANIZED

CS 316 SS CS 13 Cr/HF

1.6

-10 TO 121

No

>20mm

H3B20

150 RF

1.6

-10 TO 60

No

>20mm

H61B

150 FF

RTRP

DUPLEX (S31803) DUPLEX (S31803)

0.0

-10 TO 65

No

No

H61BU

150 FF

RTRP

DUPLEX (S31803) DUPLEX (S31803)

0.0

-10 TO 65

No

No

H71B

150 FF

HDPE

BRONZE BRONZE CS 13 Cr/HF

0.0

0 TO 40

No

No

J1C20

300 RF

CS GALVANIZED

1.6

-10 TO 200

5%

>20mm

You might also like

- ASME B31.3-2016 Postweld Heat Treatment TableDocument1 pageASME B31.3-2016 Postweld Heat Treatment TableSumner TingNo ratings yet

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocument19 pagesJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeeNo ratings yet

- Hydro Aluminium - AlSi7Mg0.6Document2 pagesHydro Aluminium - AlSi7Mg0.6Raj PrasanthNo ratings yet

- Static Equipment in Oil and Gas IndustryDocument93 pagesStatic Equipment in Oil and Gas IndustryRaghavanNo ratings yet

- Data Sheet Material 2.4819Document3 pagesData Sheet Material 2.4819BoberNo ratings yet

- Asme PWHT PreheatDocument135 pagesAsme PWHT PreheatWaqas WaqasNo ratings yet

- Sandvik 25.22.2.Lmn: (Welding Wire)Document3 pagesSandvik 25.22.2.Lmn: (Welding Wire)Anonymous w6TIxI0G8lNo ratings yet

- Engineer's Resume for Static Equipment DesignDocument5 pagesEngineer's Resume for Static Equipment DesignAbdul RehmanNo ratings yet

- Thermanit 17-06 (Boehler)Document1 pageThermanit 17-06 (Boehler)queno1No ratings yet

- WELD DESIGN CHECK FOR ANCHOR SUPPORTDocument8 pagesWELD DESIGN CHECK FOR ANCHOR SUPPORTUmer AziqNo ratings yet

- WM PWHTDocument18 pagesWM PWHTFaiz IshakNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNo ratings yet

- Low Hydrogen Electrode BakingDocument1 pageLow Hydrogen Electrode BakingnksNo ratings yet

- 1662 15Document117 pages1662 15RajamanikkamNo ratings yet

- Highlights On ASME Essential VariablesDocument8 pagesHighlights On ASME Essential VariableschowhkNo ratings yet

- WELDING PROCEDURE SPECIFICATION SHEET 2 OF 2Document2 pagesWELDING PROCEDURE SPECIFICATION SHEET 2 OF 2surya1960No ratings yet

- ITP For Drum Screen InspectionDocument1 pageITP For Drum Screen InspectionkapsarcNo ratings yet

- MTC Sample Dia 36 Inch Heat 639914 4130Document2 pagesMTC Sample Dia 36 Inch Heat 639914 4130emadabdelsattarNo ratings yet

- Welder Certificate ISO 9606-1 QualificationDocument1 pageWelder Certificate ISO 9606-1 QualificationDeepak Das100% (1)

- MBS-001, Rotor Shaft Specification - SemifinishedDocument4 pagesMBS-001, Rotor Shaft Specification - SemifinishedNirmit GandhiNo ratings yet

- Aotai Welding EquipmentDocument16 pagesAotai Welding EquipmentSutanAMariNo ratings yet

- PWHTDocument3 pagesPWHTharishcsharmaNo ratings yet

- Material Datea 2.4602Document3 pagesMaterial Datea 2.4602Charwin XiaoNo ratings yet

- Heat ExchangerDocument36 pagesHeat ExchangerUsman MansuriNo ratings yet

- ASTM A36 DatasheetDocument4 pagesASTM A36 DatasheetRene D. ArrietaNo ratings yet

- Data Sheet for 16.8.2 Welding Consumables for High Temperature 3XXH Stainless SteelsDocument5 pagesData Sheet for 16.8.2 Welding Consumables for High Temperature 3XXH Stainless Steelsprabu prasadNo ratings yet

- BohlerThyssen PDFDocument386 pagesBohlerThyssen PDFElMacheteDelHuesoNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- Fabrication of Components at Dillinger Huette Heavy FabricationDocument82 pagesFabrication of Components at Dillinger Huette Heavy Fabrication66apenlullenNo ratings yet

- Lunch & Learn: Structural Steel SelectionDocument17 pagesLunch & Learn: Structural Steel Selectionanuj SinghNo ratings yet

- Stainless Steel Welding Filler Metal Selection Chart PDFDocument1 pageStainless Steel Welding Filler Metal Selection Chart PDFrajeshmohanaNo ratings yet

- 338033-4604-45ES-0005-07 (Carbon Steel Vessels - Technical Specification) PDFDocument9 pages338033-4604-45ES-0005-07 (Carbon Steel Vessels - Technical Specification) PDFjdgh1986No ratings yet

- Ferrite Content ReportDocument2 pagesFerrite Content ReportJawad MunirNo ratings yet

- WPS FormatDocument7 pagesWPS FormatPradip SalunkheNo ratings yet

- Welding Rod For c5 & f5 - Er 80s-b6Document1 pageWelding Rod For c5 & f5 - Er 80s-b6SatyamEngNo ratings yet

- Preheat Calculation 2 PDFDocument3 pagesPreheat Calculation 2 PDFravi00098No ratings yet

- OCS Prel WPS 007Document2 pagesOCS Prel WPS 007vinothNo ratings yet

- Pressure Vessel Calculations ASME SectioDocument11 pagesPressure Vessel Calculations ASME Sectioivan chirinosNo ratings yet

- Wps Sp14 Reva PDFDocument9 pagesWps Sp14 Reva PDFravi00098No ratings yet

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- NPCIL Tube Fitting SpecificationsDocument22 pagesNPCIL Tube Fitting Specificationssumant.c.singh1694100% (1)

- Metrode P92 Consumables Jul2006Document28 pagesMetrode P92 Consumables Jul2006Claudia MmsNo ratings yet

- Manufacturing Head Types for Pressure Vessels and TanksDocument6 pagesManufacturing Head Types for Pressure Vessels and TanksJohn MaldonadoNo ratings yet

- Duplex Ss Welding PDF FreeDocument8 pagesDuplex Ss Welding PDF Freeel_sharkawy2011No ratings yet

- AWS specifications for selecting electrodes for welding various material gradesDocument1 pageAWS specifications for selecting electrodes for welding various material gradesmohammedetaNo ratings yet

- Afcons Infrastructure Limited: Procedure Qualification Record (PQR)Document21 pagesAfcons Infrastructure Limited: Procedure Qualification Record (PQR)GaapchuNo ratings yet

- CV Mechanical Engineer with Extensive Experience in Oil & Gas ProjectsDocument3 pagesCV Mechanical Engineer with Extensive Experience in Oil & Gas Projectshamza brahmiNo ratings yet

- Astm A179 PDFDocument1 pageAstm A179 PDFgaminNo ratings yet

- Weld Map Pressure VesselDocument32 pagesWeld Map Pressure Vesselarun yNo ratings yet

- WPS PQR-05Document10 pagesWPS PQR-05Ranjan KumarNo ratings yet

- FCAW Electrode DesignationDocument3 pagesFCAW Electrode DesignationthedreampowerNo ratings yet

- ISO 9692 joint preparation guideDocument46 pagesISO 9692 joint preparation guidebiancogallazziNo ratings yet

- GMAWDocument12 pagesGMAWsushant47No ratings yet

- WPS for Urea Reclaimer Butt Joint WeldingDocument1 pageWPS for Urea Reclaimer Butt Joint Weldingasirul_meNo ratings yet

- 1 SS PP 005Document18 pages1 SS PP 005sanketNo ratings yet

- P1 A C LHDocument2 pagesP1 A C LHMohamed Reda HusseinNo ratings yet

- Rationalise List Welding ConsumablesDocument19 pagesRationalise List Welding ConsumablesMayank SadaniNo ratings yet

- Volume3A MechDocument321 pagesVolume3A MechAdeel JamilNo ratings yet

- Flyer Rotar FMR Rev3Document2 pagesFlyer Rotar FMR Rev3Catarino FloresNo ratings yet

- Structure Calculation Sheet For SiloDocument174 pagesStructure Calculation Sheet For Silojohn12345No ratings yet

- Steel Grating Catalogue 2010 SpreadsDocument19 pagesSteel Grating Catalogue 2010 SpreadsOliver SanvictoresNo ratings yet

- Vertical Silo Costs and Dimensions for Dairy Cattle FeedingTITLE Horizontal Silo and Ag Bag Cost Analysis for Dairy OperationsDocument10 pagesVertical Silo Costs and Dimensions for Dairy Cattle FeedingTITLE Horizontal Silo and Ag Bag Cost Analysis for Dairy OperationsOliver SanvictoresNo ratings yet

- Silo CapDocument5 pagesSilo CapOliver SanvictoresNo ratings yet

- Piping Interview Question Part 4Document2 pagesPiping Interview Question Part 4mithunjobs80% (5)

- Maria PRL 412Document33 pagesMaria PRL 412Oliver SanvictoresNo ratings yet

- Refresher 3 PipeDocument11 pagesRefresher 3 PipeKira YagamiNo ratings yet

- 1-CHA 3-PROPERTIES OF PURE SUBSTANCES LECTURE Revision PDFDocument33 pages1-CHA 3-PROPERTIES OF PURE SUBSTANCES LECTURE Revision PDFWilliam SalazarNo ratings yet

- Chapter Three: Steam Generators 3.1 DefinitionDocument43 pagesChapter Three: Steam Generators 3.1 DefinitionHeber Farid Fabrica Quispe100% (1)

- CFX12 Multiphase Nuclear 05 TOC Real Gas and IAPWSDocument13 pagesCFX12 Multiphase Nuclear 05 TOC Real Gas and IAPWSSoumyajyoti MukherjeeNo ratings yet

- Watson McDaniel Product Catalog-2013Document336 pagesWatson McDaniel Product Catalog-2013sas999333100% (1)

- Chapter 11Document12 pagesChapter 11Den Lester CabilesNo ratings yet

- Vacuum EjectorDocument6 pagesVacuum EjectorAmol KadamNo ratings yet

- IB SERIES Inverted Bucket Steam TrapDocument6 pagesIB SERIES Inverted Bucket Steam TrapThanh ThuNo ratings yet

- Steam Tables Practice ExamplesDocument1 pageSteam Tables Practice Examplesumairsaleem_8867% (3)

- Steam Table Englishhvv PDFDocument9 pagesSteam Table Englishhvv PDFSam CunananNo ratings yet

- Module 3 Thermo - ECEADocument219 pagesModule 3 Thermo - ECEARaja DuduluNo ratings yet

- IEK 101-Chemical Process Calculations (Penghitungan Proses KimialDocument11 pagesIEK 101-Chemical Process Calculations (Penghitungan Proses KimialFranko KapoorNo ratings yet

- Fundamentals of Thermodynamics Solutions ch05Document190 pagesFundamentals of Thermodynamics Solutions ch05Cierré No'Middlename Jones100% (10)

- Mechanical Engineering Elements Module 1 Energy ResourcesDocument55 pagesMechanical Engineering Elements Module 1 Energy ResourcesYuga ChandrashekarNo ratings yet

- Boiler CalculationsDocument16 pagesBoiler CalculationsBilly Moerdani100% (1)

- Ee Oral QB-1Document26 pagesEe Oral QB-1Atharva RodgeNo ratings yet

- Waste Heat Recovery SystemDocument32 pagesWaste Heat Recovery SystemOprea IulianNo ratings yet

- Baze University, Abuja Faculty of Engineering Department of Mechanical EngineeringDocument20 pagesBaze University, Abuja Faculty of Engineering Department of Mechanical EngineeringAudu SanusiNo ratings yet

- Gasification Based Topsoe WSA Process PrinciplesDocument4 pagesGasification Based Topsoe WSA Process PrinciplesGopiNo ratings yet

- Thermodynamics 2: Precious Arlene Villaroza-MelendrezDocument54 pagesThermodynamics 2: Precious Arlene Villaroza-MelendrezAlvin RazoNo ratings yet

- 3 Properties of Refrigerants On P-H DiagramDocument7 pages3 Properties of Refrigerants On P-H DiagramJustin MercadoNo ratings yet

- Domestic Refrigerator and Water Cooler ProjectDocument25 pagesDomestic Refrigerator and Water Cooler ProjectAniket Kalore88% (8)

- Formation and Properties of Steam: Lecture-6Document17 pagesFormation and Properties of Steam: Lecture-6Amanullah TomalNo ratings yet

- Project ReportDocument103 pagesProject ReportSeth CamachoNo ratings yet

- Chapter 3 - PROPERTIES OF PURE SUBSTANCESDocument40 pagesChapter 3 - PROPERTIES OF PURE SUBSTANCESMohammed Al-OdatNo ratings yet

- Danfoss Refrigeration Basics - ESSENTIALDocument24 pagesDanfoss Refrigeration Basics - ESSENTIALGeorge Mavromatidis100% (1)

- Heat Engines Vol 2 Chapter 3 PDFDocument23 pagesHeat Engines Vol 2 Chapter 3 PDFtarunNo ratings yet

- Water-tube Boilers: Types, Advantages & Combined Heat Power SystemsDocument8 pagesWater-tube Boilers: Types, Advantages & Combined Heat Power Systemshafidhrahadiyan2No ratings yet

- Boiler Report PDFDocument34 pagesBoiler Report PDFAditya Aggarwal83% (52)

- CalorimetryDocument5 pagesCalorimetryJason PaquibulanNo ratings yet