Professional Documents

Culture Documents

QW-466.1 Test Jig Dimensions: 2010 Section Ix

Uploaded by

esamhamadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QW-466.1 Test Jig Dimensions: 2010 Section Ix

Uploaded by

esamhamadCopyright:

Available Formats

2010 SECTION IX

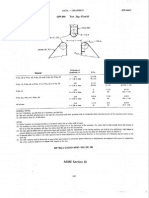

QW-466.1 TEST JIG DIMENSIONS

Tapped hole to suit testing machine As required

3/ 4

Hardened rollers 11/2 in. (38 mm) may be substituted for jig shoulders As required in. (19 mm)

Shoulders hardened and greased

3/ 4

1/ in. (13 mm) 2 11/8 in. (29 mm)

in. (19 mm) 11/8

1/ 4

in. (29 mm)

3 in. min. (75 mm) 2 in. min. (50 mm)

in. (6 mm)

3/ 4

in. R

1/ 8

(19 mm)

in. (3 mm)

Plunger

3/ 4

B R

in. (19 mm)

3/ 4

in. (19 mm)

2 in. (50 mm) Yoke 3 7/8 in. (97 mm)

Customary Units Material P-No. 23 to P-No. 21 through P-No 25; P-No. 21 through P-No. 25 with F-No. 23; P-No. 35; any P-No. metal with F-No. 33, 36, or 37 P-No. 11; P-No. 25 to P-No. 21 or P-No. 22 or P-No. 25 P-No. 51; P-No. 49

1

D R C 71/2 in. (190 mm) 9 in. (225 mm)

Thickness of Specimen, in. 8 t p 18 or less

A, in.

2116 1612t

B, in.

1132 814t

C, in.

238 1812t + 116

6 3/4 in. (170 mm)

3/ 4

in. (19 mm)

D, in.

1316 914t + 132

8 t p 38 or less

3

212 623t 3 8t 334 10t 112 4t 3278t max.

114 313t 112 4t 178 5t

3

338 823t + 18 378 10t + 18 458 12t + 18 238 6t + 18

11116 413t + 116 11516 5t + 116 2516 6t + 116 1316 3t + 116

1

8 t p 38 or less

3

P-No. 52; P-No. 53; P-No. 61; P-No. 62

8 t p 38 or less

3

All others with greater than or equal to 20% elongation Materials with 3% to less than 20% elongation

8 t p 38 or less

4 2t 16716t max.

t p [see Note (b)]

A + 2t + 116 max.

2C + 132 max.

187

2010 SECTION IX

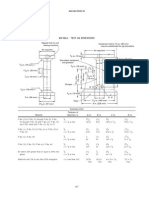

QW-466.1 TEST JIG DIMENSIONS (CONTD)

SI Units Material P-No. 23 to P-No. 21 through P-No. 25; P-No. 21 through P-No. 25 with F-No. 23; P-No. 35; any P-No. metal with F-No. 33, 36, or 37 P-No. 11; P-No.25 to P-No. 21 or P-No. 22 or P-No. 25 P-No. 51; P-No. 49 Thickness of Specimen, mm 3 t p 3 or less

A, mm

52.4 1612t

B, mm

26.2 814t

C, mm

60.4 1812t + 1.6

D, mm

30.2 914t + 0.8

10 t p 10 or less 10 t p 10 or less 10 t p 10 or less 10 t p 10 or less

63.5 623t 76.2 8t 95.2 10t 38.1 4t 3278t max.

31.8 313t 38.1 4t 47.6 5t 19.0 2t 16716t max.

85.8 823t + 3.2 98.4 10t + 3.2 117.5 12t + 3.2 60.4 6t + 3.2

42.9 413t + 1.6 49.2 5t + 1.6 58.7 6t + 1.6 30.2 3t + 1.6

1

P-No. 52; P-No. 53; P-No. 61; P-No. 62

All others with greater than or equal to 20% elongation Materials with 3% to less than 20% elongation

t p [see Note (b)]

A + 2t + 1.6 max.

2C + 0.8 max.

GENERAL NOTES: (a) For P-Numbers, see QW/QB-422; for F-Numbers, see QW-432. (b) The dimensions of the test jig shall be such as to give the bend test specimen a calculated percent outer ber elongation equal to at least that of the base material with the lower minimum elongation as specied in the base material specication. 100t percent outer fiber elongation p A+t The following formula is provided for convenience in calculating the bend specimen thickness: thickness of specimen (t) p

A percent elongation [100 (percent elongation)]

(c) For guided-bend jig conguration, see QW-466.2, QW-466.3, and QW-466.4. (d) The weld and heat-affected zone, in the case of a transverse weld bend specimen, shall be completely within the bend portion of the specimen after testing. (e) For materials with less than 3% elongation, a macro-etch specimen shall be used in lieu of bend test at each bend test location. Acceptance criteria shall be in accordance with QW-183(a).

188

2010 SECTION IX

QW-466.2 GUIDED-BEND ROLLER JIG

A

Note (3)

B = 1/2 A

Notes (1), (2)

R min. = 3/4 in. (19 mm)

Notes (4), (5)

R min.

GENERAL NOTE: See QW-466.1 for jig dimensions and general notes. NOTES: (1) Either hardened and greased shoulders or hardened rollers free to rotate shall be used. (2) The shoulders or rollers shall have a minimum bearing surface of 2 in. (50 mm) for placement of the specimen. The rollers shall be high enough above the bottom of the jig so that the specimens will clear the rollers when the ram is in the low position. (3) The ram shall be fitted with an appropriate base and provision made for attachment to the testing machine, and shall be of a sufficiently rigid design to prevent deflection and misalignment while making the bend test. The body of the ram may be less than the dimensions shown in column A of QW-466.1. (4) If desired, either the rollers or the roller supports may be made adjustable in the horizontal direction so that specimens of t thickness may be tested on the same jig. (5) The roller supports shall be fitted with an appropriate base designed to safeguard against deflection and misalignment and equipped with means for maintaining the rollers centered midpoint and aligned with respect to the ram.

QW-466.3 GUIDED-BEND WRAP AROUND JIG

T

Roller

T + 1/16 in. (1.5 mm) max. A

B = 1/2 A

GENERAL NOTES: (a) See QW-466.1 for jig dimensions and other general notes. (b) Dimensions not shown are the option of the designer. The essential consideration is to have adequate rigidity so that the jig parts will not spring. (c) The specimen shall be firmly clamped on one end so that there is no sliding of the specimen during the bending operation. (d) Test specimens shall be removed from the jig when the outer roll has been removed 180 deg from the starting point.

189

You might also like

- ABS NDI - Guide Section 8 Acceptance Criteria For Hull Welds 5.Document3 pagesABS NDI - Guide Section 8 Acceptance Criteria For Hull Welds 5.Dagoberto AguilarNo ratings yet

- Wps PQR Aws d11 FormDocument2 pagesWps PQR Aws d11 Formflakosisas100% (1)

- The Heat Affected ZoneDocument24 pagesThe Heat Affected ZoneRatan PanditNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- WPS Steps of MakingDocument51 pagesWPS Steps of MakingSaut Maruli Tua Samosir100% (1)

- ASME 9 Multi Process Welding Procedures QW200Document2 pagesASME 9 Multi Process Welding Procedures QW200Teodor EzaruNo ratings yet

- WPS - Api 5L X52 - Codigo Api1104Document1 pageWPS - Api 5L X52 - Codigo Api1104Cristhian Camilo Quiroga WalterosNo ratings yet

- Welder Diameter Limitation ASME SEC IXDocument1 pageWelder Diameter Limitation ASME SEC IXkumarNo ratings yet

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- AsmeDocument11 pagesAsmeManoj BallaNo ratings yet

- Sample PQR Form (GTAW & SMAW - Page 1) Procedure Qualification Record (PQR)Document2 pagesSample PQR Form (GTAW & SMAW - Page 1) Procedure Qualification Record (PQR)Luis Carlos Clericci LimonNo ratings yet

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 pagesBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarNo ratings yet

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Document12 pagesPoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXNo ratings yet

- Sample API 1104 WpsDocument1 pageSample API 1104 Wpsippon_osoto100% (1)

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- ASME 9 Calculator Approval RangesDocument2 pagesASME 9 Calculator Approval RangesEmel Besir100% (1)

- Asme Viii - Mandatoryappendix 12 - UtDocument1 pageAsme Viii - Mandatoryappendix 12 - UtDjamelNo ratings yet

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- AWS Part BDocument32 pagesAWS Part Balefeli260% (2)

- Aws d1.5 PQRDocument2 pagesAws d1.5 PQRjacquesmayolNo ratings yet

- Astm A335 p91 PipeDocument1 pageAstm A335 p91 PipeBhagwati SteelageNo ratings yet

- WPS & PQR (E Co Cr-E)Document3 pagesWPS & PQR (E Co Cr-E)HossamSAshourNo ratings yet

- WPQ WELDER QUALIFICATION 16MM PLATE SMAWDocument1 pageWPQ WELDER QUALIFICATION 16MM PLATE SMAWniket0No ratings yet

- Pws Convention PresentationDocument93 pagesPws Convention Presentationbenj100% (1)

- OCS Engineering & Construction Visual Inspection ReportDocument1 pageOCS Engineering & Construction Visual Inspection ReportvinothNo ratings yet

- PQRDocument2 pagesPQRafqzfieNo ratings yet

- Welder Qualification Test RequestDocument1 pageWelder Qualification Test RequestgoguluNo ratings yet

- Song Hong Co., Ltd Welding Procedure SpecificationDocument5 pagesSong Hong Co., Ltd Welding Procedure SpecificationTrinh DungNo ratings yet

- PQR Sample PrintoutDocument2 pagesPQR Sample PrintoutDhewo Rachmad Yansyah100% (3)

- WELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELDocument4 pagesWELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELAldeline SungahidNo ratings yet

- WPS Ernicu 7 R1 3 6 PDFDocument4 pagesWPS Ernicu 7 R1 3 6 PDFandresNo ratings yet

- Nioec SP 90 02Document77 pagesNioec SP 90 02aminNo ratings yet

- Tech Manual MVP Series 2017.1 WIP 3Document73 pagesTech Manual MVP Series 2017.1 WIP 3Chav HoangNo ratings yet

- TWI CSWIP 3.1 Welding InspectorDocument81 pagesTWI CSWIP 3.1 Welding Inspectormahmoeng100% (2)

- AISE Anchor Bolt Details PDFDocument1 pageAISE Anchor Bolt Details PDFYash PaulNo ratings yet

- PHB 5 PDFDocument22 pagesPHB 5 PDFestephan82No ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- WPS List For Piping: (Asme Section Ix)Document2 pagesWPS List For Piping: (Asme Section Ix)Ali MoosaviNo ratings yet

- WPS Api 1104Document3 pagesWPS Api 1104miguelNo ratings yet

- Weld Matrix Format 1Document7 pagesWeld Matrix Format 1Arslan WaheedNo ratings yet

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1No ratings yet

- CSM-QR-02-2, Medical Gas BPS TablesDocument8 pagesCSM-QR-02-2, Medical Gas BPS TablesaadmaadmNo ratings yet

- Astm A 516 Gr.60n Plate SpecificationDocument3 pagesAstm A 516 Gr.60n Plate Specificationharishbabuek100% (1)

- Repair WpsDocument2 pagesRepair WpsyogacruiseNo ratings yet

- Qw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )Document2 pagesQw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )essnelsonNo ratings yet

- Galvanize Inspection ReportDocument1 pageGalvanize Inspection ReportMuhammad FajarNo ratings yet

- INSPECTION REPORT TITLEDocument7 pagesINSPECTION REPORT TITLEABEC Trombay siteNo ratings yet

- Welding Report For Tank 1Document1 pageWelding Report For Tank 1Rifki HasyaNo ratings yet

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityNo ratings yet

- Dep 30.10.60.32 - Welding of Metals, Based On Iso StandardsDocument76 pagesDep 30.10.60.32 - Welding of Metals, Based On Iso StandardsPablo PazNo ratings yet

- Submerged Arc Welding (Saw)Document5 pagesSubmerged Arc Welding (Saw)Nnaji Chukwuma SlamNo ratings yet

- Overlay (Required Tests)Document1 pageOverlay (Required Tests)laz_k100% (1)

- QW-466 Test Jigs (Couf D) : Data - GraphicsDocument1 pageQW-466 Test Jigs (Couf D) : Data - GraphicsMacielNatieleNo ratings yet

- Nondestructive Testing Methods and Qualification BlocksDocument9 pagesNondestructive Testing Methods and Qualification BlocksPradeepNo ratings yet

- Ut ProcedureDocument4 pagesUt Procedureأحمد صبحىNo ratings yet

- Brazing Procedure 1Document5 pagesBrazing Procedure 1Tina MillerNo ratings yet

- Guia de Salario Petroleo y Gas Hays - 920901Document36 pagesGuia de Salario Petroleo y Gas Hays - 920901Javier CastroNo ratings yet

- Optimizing Cleaning Heat ExchangersDocument9 pagesOptimizing Cleaning Heat ExchangersesamhamadNo ratings yet

- Welding DefectsDocument94 pagesWelding DefectsesamhamadNo ratings yet

- Decision Making Under Uncertain and Risky SituationsDocument22 pagesDecision Making Under Uncertain and Risky SituationsnastasjafilipovnaNo ratings yet

- Ejercicio de Soldadura AISC 2005Document11 pagesEjercicio de Soldadura AISC 2005APBNo ratings yet

- Training Engineers PDFDocument11 pagesTraining Engineers PDFamlatas100% (2)

- 2011 Hydro Test Master ManualDocument57 pages2011 Hydro Test Master ManualBoopathi RajuNo ratings yet

- Mechanical Integrity Risk-Based Inspection Program EssentialsDocument24 pagesMechanical Integrity Risk-Based Inspection Program Essentialsesamhamad100% (1)

- 1-Essential Elements of A Piping Reliability Program-Development and Management of Corrosion Systems and CircuitsDocument29 pages1-Essential Elements of A Piping Reliability Program-Development and Management of Corrosion Systems and CircuitsesamhamadNo ratings yet

- Brief 3 BDocument2 pagesBrief 3 BesamhamadNo ratings yet

- Brief 3 BDocument2 pagesBrief 3 BesamhamadNo ratings yet

- Financial TrainingDocument15 pagesFinancial TrainingGismon PereiraNo ratings yet

- Compass InstructionsDocument2 pagesCompass InstructionsesamhamadNo ratings yet

- Mumme BennyBackgroundHistorialReviewAPI1160Document7 pagesMumme BennyBackgroundHistorialReviewAPI1160esamhamadNo ratings yet

- Heatexchangers 140603082139 Phpapp01Document67 pagesHeatexchangers 140603082139 Phpapp01esamhamadNo ratings yet

- Heat Exchangers (Shell & Tube)Document29 pagesHeat Exchangers (Shell & Tube)babak mirNo ratings yet

- DrivingDocument36 pagesDrivingesamhamadNo ratings yet

- Https Inspector - ApiDocument4 pagesHttps Inspector - ApiesamhamadNo ratings yet

- Guided Bend Test Jig Dimension ASME 9Document3 pagesGuided Bend Test Jig Dimension ASME 9esamhamad50% (2)

- Water QualityDocument18 pagesWater QualityesamhamadNo ratings yet

- Fin For Non Fin NotesDocument47 pagesFin For Non Fin NotesGajo VankaNo ratings yet

- Skidder Inspection 5.24.131Document0 pagesSkidder Inspection 5.24.131esamhamadNo ratings yet

- CC Complaint Manual 0111Document82 pagesCC Complaint Manual 0111esamhamadNo ratings yet

- Guided Bend Test Jig Dimension ASME 9Document3 pagesGuided Bend Test Jig Dimension ASME 9esamhamad50% (2)

- A - Piping Joint HandbookDocument161 pagesA - Piping Joint HandbookCharles Tauk100% (30)

- API653 Training Application 170610 UpdateDocument4 pagesAPI653 Training Application 170610 UpdateesamhamadNo ratings yet

- Pickling HandbookDocument20 pagesPickling HandbookRhona100% (1)

- API Standard 620 - Design and Construction of Large, Welded, Low-Pressure Storage TanksDocument28 pagesAPI Standard 620 - Design and Construction of Large, Welded, Low-Pressure Storage TanksMohammad ElhedabyNo ratings yet

- Dewatering Well PointsDocument4 pagesDewatering Well Pointssalloum3No ratings yet

- ADL MATRIX STRATEGY FOR BPCL'S GROWTHDocument17 pagesADL MATRIX STRATEGY FOR BPCL'S GROWTHSachin Nagar100% (1)

- Test Unit 7 m.2Document6 pagesTest Unit 7 m.2Petchara SridakunNo ratings yet

- Effect of Social Media On The Academic PerformanceDocument55 pagesEffect of Social Media On The Academic PerformanceFJ Asufra100% (2)

- Admission:Discharge Criteria in Speech-Language Pathology - ASHADocument16 pagesAdmission:Discharge Criteria in Speech-Language Pathology - ASHANádia MarquesNo ratings yet

- Spectro Xepos Brochure 2016Document8 pagesSpectro Xepos Brochure 2016Mary100% (1)

- Develop Network Monitoring System IP Subnet CalculatorDocument23 pagesDevelop Network Monitoring System IP Subnet CalculatorabiramanNo ratings yet

- Timeline of Internet in The PhilippinesDocument29 pagesTimeline of Internet in The PhilippinesJhayson Joeshua Rubio100% (1)

- Catalogue: Product Offering 51Document56 pagesCatalogue: Product Offering 51Bruno MartinsNo ratings yet

- Action Plan On GadDocument1 pageAction Plan On GadCherish Devora ArtatesNo ratings yet

- An Introduction To Community DevelopmentDocument21 pagesAn Introduction To Community DevelopmentThuyAnh NgnNo ratings yet

- Chemistry 101 - The Complete Notes - Joliet Junior College (PDFDrive)Document226 pagesChemistry 101 - The Complete Notes - Joliet Junior College (PDFDrive)Kabwela MwapeNo ratings yet

- MST 2 ReviewerDocument4 pagesMST 2 ReviewerAizha NarioNo ratings yet

- Whirlpool FL 5064 (ET)Document8 pagesWhirlpool FL 5064 (ET)long_kongo100% (1)

- Tithi PRAVESHADocument38 pagesTithi PRAVESHAdbbircs100% (1)

- CEILING BOARDING GUIDEDocument5 pagesCEILING BOARDING GUIDEahahNo ratings yet

- Republic of The Philippines Iba, Zambales: President Ramon Magsaysay State UniversityDocument3 pagesRepublic of The Philippines Iba, Zambales: President Ramon Magsaysay State UniversityErika Joy EscobarNo ratings yet

- Daftar PustakaDocument3 pagesDaftar PustakaNurha ZizahNo ratings yet

- Water Sampling and Borehole Inspection FormsDocument2 pagesWater Sampling and Borehole Inspection FormsSibanda MqondisiNo ratings yet

- CTM Catalogue 2015-2016Document100 pagesCTM Catalogue 2015-2016Anonymous dXcoknUNo ratings yet

- Sinavy Pem Fuel CellDocument12 pagesSinavy Pem Fuel CellArielDanieli100% (1)

- Naaqs 2009Document2 pagesNaaqs 2009sreenNo ratings yet

- MAPEH 6- WEEK 1 ActivitiesDocument4 pagesMAPEH 6- WEEK 1 ActivitiesCatherine Renante100% (2)

- TSR Cyl Tilt Cab LD 110Document2 pagesTSR Cyl Tilt Cab LD 110Ferry AndisNo ratings yet

- Influence of Oxygen in Copper - 2010Document1 pageInfluence of Oxygen in Copper - 2010brunoNo ratings yet

- Laser Module 5Document25 pagesLaser Module 5Luis Enrique B GNo ratings yet

- Prelims in NSTPDocument2 pagesPrelims in NSTPJanine Alexis TividadNo ratings yet

- Sulzer MC EquipmentDocument12 pagesSulzer MC EquipmentsnthmlgtNo ratings yet

- MA4850 Supply Chain & Logistics ManagementDocument21 pagesMA4850 Supply Chain & Logistics ManagementQy LeeNo ratings yet

- Column and Thin Layer ChromatographyDocument5 pagesColumn and Thin Layer Chromatographymarilujane80% (5)