Professional Documents

Culture Documents

3

Uploaded by

mphil.rameshOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3

Uploaded by

mphil.rameshCopyright:

Available Formats

Meat Science 80 (2008) 13401344

Contents lists available at ScienceDirect

Meat Science

journal homepage: www.elsevier.com/locate/meatsci

The application of wheat bre and soy isolate impregnated with iodine salts to fortify processed meats

Katarzyna Waszkowiak *, Krystyna Szymandera-Buszka

Department of Food Service and Catering, University of Life Science in Poznan, ul. Wolska Polskiego 31, Poznan 60-624, Poland

a r t i c l e

i n f o

a b s t r a c t

The aim was to use wheat dietary bre and soy protein isolate as carriers of KI and KIO3 for fortication of processed meat with iodine. Products from minced pork were prepared with addition of iodised wheat bre and soy isolate, and iodised table salt for comparison and the effects of thermal processing and storage on changes in iodine content were determined. It was shown that both alternative carriers limited the iodine changes in meat products compared with iodised table salt. However, wheat bre was more effective in limiting iodine losses during thermal processing and soy protein during storage of the products. The greatest effect of the carriers was found in meat products fortied with the less stable KI. 2008 Elsevier Ltd. All rights reserved.

Article history: Received 18 March 2008 Received in revised form 12 June 2008 Accepted 17 June 2008

Keywords: Iodine carriers Wheat dietary bre Soy protein isolate Iodine retention Food fortication Meat product

1. Introduction Iodine deciency is a major public health problem in many countries (WHO., 2004). Iodine Deciency Disorders (Hetzel, 1983, 1989, 2000) are considered by WHO to constitute a group of social diseases of global importance (Burtland, 2004). Iodination of table salt, mainly with potassium iodate or iodide, is the most frequently adopted method to prevent iodine deciency. Despite its advantages (table salt is cheap and commonly consumed) this method also has some disadvantages. These include the instability of iodine compounds on this carrier during production and storage of fortied food (Szymandera-Buszka & Waszkowiak, 2007; Waszkowiak, Szymandera-Buszka, Janitz, & Grecka, 1999). It was found that the retention of iodine introduced to meat products with iodised salt depends on the thermal processing, i.e. higher iodine losses were observed for thermal processes using water as the thermal medium (Goindi, Karmarkar, Kapil, & Jagannathan, 1995). Moreover, there are the nutritional recommendations promoting reduced intake of salt (Serbranek et al., 1983). Thus, alternative carriers which would fortify foodstuffs with iodine are being sought for. Positive results have been recorded for connective tissue protein preparations (Waszkowiak & Szymandera-Buszka, 2005, 2007). Dietary bre and soy protein preparations due to their functional properties are extensively used in many branches of the food

industry, including the meat sector (Bilska, Krysztoak, Se k, & Uchman, 2002; Hoogenkamp, 2007; Jimnez-Colmenero, Ayo, & Carballo, 2005; Makaa & Olkiewicz, 2004; Pietrasik & Duda, 2000; Waszkowiak, Grecka, & Janitz, 2001). Utilization of them not only improves sensory attributes such as texture, but also supplements the diet with dietary bre or protein. As they are frequently used they may become carriers for different substances. Thus, the aim of this study was to assess the use of wheat dietary bre preparations and soy protein isolate as iodine salt carriers in the production of processed meats. The effect of thermal processing (steaming and roasting) and storage conditions on changes in the iodine content in meat products fortied with iodine using the above mentioned preparations and table salt was studied. The stability of two most popular iodine compounds used to fortify foodstuffs, i.e. potassium iodide (KI) and potassium iodate (KIO3) were also compared.

2. Methods 2.1. Iodine carriers Two preparations (Kulinaria S.A., Tychy, Poland) were used as iodine salt carriers, i.e. wheat bre Vitacel WF 400 (long-bre; composition: cellulose 73%, hemicellulose 26%, lignin <5%; water holding capacity 10.5 g water/1 g preparation) and a soy protein isolate (protein content 8991%; water holding capacity 6 g water/1 g preparation).

* Corresponding author. Fax: +48 618487431. E-mail address: kwaszkow@au.poznan.pl (K. Waszkowiak). 0309-1740/$ - see front matter 2008 Elsevier Ltd. All rights reserved. doi:10.1016/j.meatsci.2008.06.011

K. Waszkowiak, K. Szymandera-Buszka / Meat Science 80 (2008) 13401344

1341

For the purpose of comparison a traditional iodine salt carrier, i.e. evaporated table salt (Salt Mine Solino, Inowrocaw, Poland) was also used. 2.2. Carrier iodination Parameters of carrier iodination (concentrations of KI and KIO3 solutions) were selected so that the iodine content on the carriers met the guidelines of the Polish government (Dziennik Ustaw, 2003) concerning table salt iodination, i.e. 23 mg I kg1 carrier (which is equivalent to 30 mg KI kg1 or 39 mg KIO3 kg1, respectively). The iodination (impregnation) process in case of bre and protein preparations (according to Waszkowiak & Szymandera-Buszka, 2007) consists of soaking in iodine salt solutions, potassium iodide or iodate, respectively, at a 1:4 ratio (m/v). Soaking was for approximately 30 min at room temperature with limited access to light. Preparations were then freeze-dried for 24 h. Solutions of iodine compounds were applied at a concentration of 7.5 mg KI l1 or 9.75 mg KIO3. l1. Table salt was iodinated with potassium iodide or iodate by spray mixing (Diosady, Alberti, Mannar, & Stone, 1997). A total of 10 ml solution at a concentration of 3 g KI l1 or 3.9 g KIO3 l1, respectively, was sprayed per 1 kg table salt while it was constantly mixed in a homogenizer (Homogenizer 2094, Fos Tecator, Sweden). The iodised salt was freeze-dried. 2.3. Meat products preparation and storage The above carriers were used in the production of meatballs from ground pork. Pork (best end of neck) was ground in a meat grinder (mesh size 3 mm) and mixed with ingredients specied by the formulation of Waszkowiak et al. (2001). The meat batter was divided into three portions and the following additives (% of meat batter) were blended in (1) Iodised table salt (2%). (2) Impregnated wheat bre (2%) and non-iodised table salt (2%). (3) Impregnated soy isolate (2%) and non-iodised table salt (2%). Preparations impregnated with KI or KIO3 were added to the batter in the hydrated form (wheat bre at 1:6 ratios, soy isolate at 1:3). The hydration rate of carriers was chosen from the results ska & Szymanof sensory analysis of the products (Je drusek-Golin dera-Buszka, 2007) and was related with their water holding capacity. After thorough mixing of the additives (approximately 10 min) using a Homogenizer 2094 (Foss Tecator, Sweden) meatballs were formed. To maintain uniform conditions during thermal processing, the formed meat products had similar weights (approximately 50 g) and shapes (spherical). Thermal processing was conducted using a convection oven (CCC series, Rational, Germany). Meatballs were steamed for 16 min at 100 C or roasted for 16 min at 230 C. Steamed meatballs and roasted meatballs (burgers) were chilled (3 days, 4 C) or frozen (5 months, 18 C). 2.4. Determination of iodine contents The determination of iodine contents in meat products with KI involved combustion of 1 g sample in an alkali environment followed by the measurement of iodine content using the catalytic method of Moxon and Dixon (1980), based on the catalytic destruction of thiocyanate by nitrite in the presence of iodide. In case of products containing potassium iodate the above method was modied according to Khne, Wirth, and Wagner

(1993), by reduction of KIO3 to KI using 1% ascorbic acid solution immediately before the iodine content was determined. Iodine contents were determined in the raw meat batter and in meatballs after thermal processing and at intervals during storage. Two samples (two meatballs) of each product were taken for each analysis and all samples were analysed in quadruplet. 2.5. Statistical analysis Statistical analyses of data were performed with STATISTICA Version 7.0 (StatSoft). To compare mean values analysis of variance (ANOVA) was applied. The means were compared by the Tukeys multiple range test (P = 0.05). For analyses of iodine changes during storage the correlations between variables were investigated by regression analysis (Pike, 1986). To compare rates of change, the half-life t1/2 was determined, i.e. the time in which the initial iodine content decreased by half. 3. Results 3.1. Changes in iodine content during thermal processing From Table 1, it can be seen that the effect of thermal processing on iodine losses was dependent on the compound (KI or KIO3) used for product fortication. In case of products fortied with KI no signicant differences were found between iodine content in raw batter and roasted products (burgers), irrespective of the carrier. Steaming signicantly reduced iodine contents only in the case of product with iodised table salt (retention 93%). A stronger effect of thermal processing on iodine content was observed for products with KIO3 than for those fortied with KI. In those in which iodised table salt or soy isolates were used as KIO3 carriers, signicantly higher losses were recorded during steaming than roasting and in meatballs containing these substances iodine retention was 84% and 79%, respectively, while in roasted products it was 89% and 95%, respectively. In products containing wheat bre impregnated with KIO3 thermal processing method had no signicant effect on iodine losses, as they amounted to 94% for the roasted product and 92% for the steamed one.

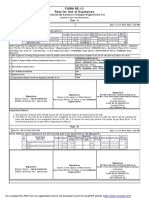

Table 1 Iodine content (lg 100 g1) in raw pork meatballs and after roasting or steaming Carrier Iodised table salt mean (SEM) Fortied with KI Raw Burgers (roasted) Meatballs (steamed) Fortied with KIO3 Raw Burgers (roasted) Meatballs (steamed) Impregnated wheat bre mean (SEM) 101.7 a (2.9) 106.0 a (2.1) 113.2 a (17.1) 101.2 a (0.8) 94.7 b (0.4) 93.2 b (0.8) Impregnated soy isolate mean (SEM) 106.0 a (2.9) 101.2 a (2.1) 107.6 a (10.7) 102.4 a (0.4) 97.5 b (0.8) 80.5 c (1.5)

141.5 a (4.2) 156.1 a (3.5) 132.0 b (1.9) 101.2 a (1.0) 89.8 b (1.0) 84.9 c (0.5)

Mean values (n = 8) with different letters in the same column are signicantly different (one-way ANOVA and Tukeys test, P < 0.05); standard error of mean (SEM).

1342

K. Waszkowiak, K. Szymandera-Buszka / Meat Science 80 (2008) 13401344

3.2. Changes in iodine content during cold storage Multifactor analysis of variance (ANOVA) showed a signicant inuence of thermal processing (P < 0.001) and iodine carrier (P < 0.05) on iodine loses during cold storage of meat iodised with both KI and KIO3. Cold storage had a signicant effect (P < 0.05) on the loss of iodine in steamed meatballs and burgers containing table salt iodised with KI (Table 2). After three-day storage steamed meatballs and burgers with iodised table salt iodine retained 69% and 73%, respectively. The use of alternative carriers, i.e. bre or soy isolate, signicantly reduced iodine losses during storage of dishes fortied with KI, irrespective of the type of the meat product. No signicant differences were found between iodine contents on the rst and third day of cold storage either in meatballs or burgers containing these carriers. For products iodised with KIO3 cold storage had a signicant effect (P < 0.05) on iodine loses, irrespective of the carrier. Smaller iodine losses were recorded during cold storage of products iodised with KIO3 compared to the products fortied with KI when table salt was used as a carrier. For meatballs and burgers containing table salt iodised with KIO3, retention after three-day cold storage was as much as 9495%. In case of products with fortied soy isolate iodine retention after cold storage was similar. With wheat bre observed iodine retention was slightly higher for burgers and lower for meatballs. However, it needs to be stressed that for all products iodine losses did not exceed 8%.

during storage were described well by exponential decay (correlation coefcient R2 was always higher than 0.92). Thus, it was decided to use half-life t for comparison of iodine changes. The highest rate of change in iodine content (i.e. the shortest half-life t Table 3), and thus, also the lowest iodine retention (i.e. approximately 30%) were recorded for both products with table salt iodised with KI. For products with wheat bre impregnated with KI nal retention was higher, i.e. 45% for burgers and 37% for meatballs. The lowest rate of change in iodine content (i.e. the longest half-life t) during storage was in products, to which KI was introduced using soy isolate. For the roasted product the calculated half-life t was two times longer than for products containing table salt iodised with KI, while for steamed products it was only 1.2 times. As a result, after 150-day storage burgers and meatballs with soy isolate had iodine retentions of 55% and 39%, respectively. During frozen storage of products fortied with table salt iodised with KIO3 (Table 3) smaller rates of changes in iodine content were recorded than in products containing table salt with KI, as

Table 3 Changes in iodine content (lg 100 g1) in fortied pork dishes during frozen storage Carrier Iodised table salt Content mean (SEM) Fortied with KI Burgers 1 day 156.1 a (3.5) 60 day 82.8 b (1.0) 105 day 63.8 c (0.6) 150 day 48.0 d (0.5) t1/2 (days) 89 Meatballs 1 day 60 day 105 day 150 day t1/2 (days) 132.0 a (1.9) 70.2 b (1.0) 52.1 c (0.6) 41.8 d (0.3) 90 Retention (%) Impregnated wheat bre Content mean (SEM) Retention (%) Impregnated soy isolate Content mean (SEM) Retention (%)

3.3. Changes in iodine content during frozen storage Signicant effects (P < 0.001) of thermal processing and iodine carrier on iodine contents during frozen storage were seen. Moreover, a signicant effect (P < 0.001) of time on the changes was observed, with both KI and KIO3. It was found that iodine changes

Table 2 Changes in iodine content (lg 100 g1) in fortied pork dishes during cold storage Carrier Iodised table salt Content mean (SEM) Fortied with KI Burgers 1 day 156.1 a (3.5) 3 day 108.3 b (2.1) Meatballs 1 day 132.0 a (1.9) 3 day 96.0 b (4.7) Retention (%) Impregnated wheat bre Content mean (SEM) Retention (%) Impregnated soy isolate Content mean (SEM) Retention (%)

100 53 41 31

106.0 a (2.1) 82.5 b (0.9) 65.3 c (0.6) 47.8 d (0.4) 131 113.2 a (17.1) 64.9 b (0.6) 52.8 b (0.4) 42.2 b (0.6) 106

100 78 62 45

101.2 a (2.1) 84.2 b (0.7) 68.3 c (10.7) 56.0 d (0.2) 173 107.6 a (1.4) 67.1 b (0.7) 53.5 c (0.3) 42.1 d (0.3) 111

100 83 67 55

100 53 39 32

100 57 47 37

100 62 50 39

100 69

106.0 a (2.1) 103.9 a (2.7) 113.2 a (17.1) 92.3 a (2.5)

100 98

101.2 a (2.1) 98.0 a (3.3) 107.6 a (10.7) 105.6 a (1.1)

100 97

100 73

100 81

100 98

Fortied with KIO3 Burgers 1 day 89.8 a 100 (1.0) 3 day 84.8 b 94 (0.4) Meatballs 1 day 84.9 a (0.5) 3 day 80.9 a (1.7) 100 95

Fortied with KIO3 Burgers 1 day 89.8 a (1.0) 60 day 76.0 b (0.7) 105 day 67.6 c (0.7) 150 day 50.9 d (0.5) t1/2 (days) 189 Meatballs 1 day 60 day 105 day 84.9 a (0.5) 65.3 b (0.8) 54.4 c (0.5) 40.8 d (0.4) 144

100 85 75 57

94.7 a (0.4) 89.0 b (0.8) 66.9 c (0.5) 51.3 d (0.6) 164 93.2 a (0.8) 71.2 b (0.6) 54.7 c (0.8) 43.0 d (0.4) 132

100 94 71 54

97.5 a (0.8) 83.1 b (0.5) 68.3 c (0.5) 52.9 d (0.3) 170 80.5 a (1.5) 67.1 b (0.7) 53.5 c (0.3) 42.5 d (0.4) 161

100 85 70 54

94.7 a (0.4) 92.0 a (0.9) 93.2 a (0.8) 85.8 b (1.4)

100 97

97.5 a (0.8) 92.0 b (0.7) 80.5 a (1.5) 77.1 a (0.6)

100 94

100 77 64 48

100 76 59 46

100 83 66 53

100 92

100 150 day 96 t1/2 (days)

Mean values (n = 8) with different letters in the same column are signicantly different (one-way ANOVA and Tukeys test, P < 0.05); standard error of mean (SEM).

Mean values (n = 8) with different letters in the same column are signicantly different (one-way ANOVA and Tukeys test, P < 0.05); standard error of mean (SEM); t is time (in days) in which the initial iodine content decreases by half.

K. Waszkowiak, K. Szymandera-Buszka / Meat Science 80 (2008) 13401344

1343

found during cold storage. Thus, iodine losses after 150-day frozen storage of both products with table salt iodised with KIO3 were smaller than when table salt with KI was used. The losses for meatballs amounted to 48% and 57% for burgers. The use of alternative carriers for KIO3 in the production of burgers only slightly affected the rates of change in iodine content during frozen storage, and as a consequence iodine retention was similar to that observed for burgers with iodised table salt. In meatballs the highest iodine retention (53%) was when soy isolate was used as a KIO3 carrier rather than table salt or wheat bre (4648%). It needs to be stressed that for burgers and meatballs containing soy isolate impregnated with KIO3 losses of iodine were similar (Table 3) and were similar to those observed in burgers with soy isolate iodinated with KI (similar retention values were found after 150-day storage). This means that the use of soy isolate as a carrier eliminated both the effect of the type of iodine compound used for fortication and the inuence of the previous thermal history on the changes in iodine content during storage. However, with thermal processing it was found only during storage of products iodised with the more stable KIO3.

4. Discussion The study conrmed previous results (Waszkowiak, Szymandera-Buszka, & Janitz, 2000; Waszkowiak et al., 1999) that the method of thermal processing affects iodine losses in products fortied with iodised table salt. Cooking with water or steam increases iodine losses in comparison to e.g. roasting or frying (Goindi et al., 1995). This may be explained by the migration of water-soluble iodine compounds from products to the environment together with thermal drip (exudation of meat juices). In contrast, during roasting the surface of the product forms skin, limiting thermal drip and iodine losses (Szymandera-Buszka & Waszkowiak, 2007). The study also showed that storage (especially frozen storage for several months) enhances this effect, signicantly increasing losses in iodine content in steamed products in comparison to roasted products. At the same time a higher retention of iodine was recorded during cold and frozen storage in products containing table salt iodised with KIO3 than in those containing table salt iodised with KI, which may be connected with the high solubility of KI and its removal with water during defrosting and resulting drip. Moreover, differences in the stability of these compounds may be affected by their differing chemical properties (Diosady & Mannar, 2000). Potassium iodide is less stable than potassium iodate, as it is easily oxidized to iodine by oxygen or oxidizing agents, especially, in the presence of metal ions and moisture, which catalyze the reaction. However, potassium iodate is reduced to iodine by the action of reducing agents, such as ferrous ions. Moisture acts as the reaction medium for the decomposition of added iodate. The application of wheat bre or soy protein isolate as iodine carriers, instead of table salt, signicantly reduced iodine losses, both during thermal processing and storage. The positive effect of these alternative carriers was more marked during storage of products fortied with KI. Among the carriers, iodine compounds were more effectively stabilized during thermal processing by wheat bre. In turn, during storage the slowest losses of iodine were observed for products with soy isolate. Enhanced iodine retention by wheat bre during thermal processing most probably results from its high water holding capacity, which may limit iodine losses connected with thermal drip. This is conrmed by the smaller differences (or even their lack) between iodine losses taking place as a result of steaming and roasting of products containing wheat bre compared to those observed in products with other carriers. Similar observa-

tions on the relationship between high water holding capacity of carriers and iodine losses were reported previously (Waszkowiak & Szymandera-Buszka, 2005, 2007). However, the better stabilization of iodine compounds by soy protein isolate after thermal processing indicates that during storage other properties are more important for the stability of these compounds. Differences in the chemical structure of both alternative carriers need to be taken into consideration, i.e. soy isolate consists of isolated proteins and wheat bre contains mainly cellulose (a carbohydrate). During thermal processing soy proteins denature and it probably makes them able to protect iodine compounds and reduce losses. Generally, denaturation is essential for protein to form a gel (Chang & Hou, 2004). Upon heating soy proteins are dissociated into subunits and unfold to give extended chains of the polypeptides that subsequently associate and aggregate to form progels (Boye, Ma, & Harwalkar, 1997). This gel structure may protect iodine compounds against agents catalyzing their transformation to iodine. Thus, the application of soy protein isolate as a carrier makes it possible to eliminate differences in iodine retention and use iodine compounds with different stabilities (i.e. KI or KIO3). High stabilizing capacity was also reported for other protein preparations used as KI carriers, such as collagen (Waszkowiak & Szymandera-Buszka, 2007), where no signicant iodine losses were recorded in products prepared with their addition during sixmonth frozen storage. The higher iodine contents observed in some roasted or steamed meat products compared with the raw one (however, statistically signicant differences were not found Table 1) could be due to the formation of pockets with higher amounts of iodine after addition of iodised carriers.

5. Conclusions Is the use of wheat bre or soy protein isolate as alternative carriers for table salt justied in the production of processed meats? The 2% addition of iodine carrier to meat products (which contains 23 mg of iodine per kg) forties 100 g of product with 43 lg of iodine. It meets approximately 30% of the recommended daily allowance (150 lg I per day for adults). The application of both carriers limits iodine losses during thermal processing or storage, especially, in case of fortication with the less stable potassium iodide (KI). Their application may thus contribute to the reduction of iodine deciencies. However, further studies are required to determine which functional properties of the carriers (especially soy protein isolate) affect their stabilizing action in relation to iodine compounds, and the mechanisms involved. Previous work on sensory analysis of steamed meatballs and burgers fortied with iodised soy isolate and wheat bre (including colour, avour, aroma and overall acceptability) showed no signicant difference between meat products with and without the iodised carriers except a decrease in aroma intensity for products ska & Szymandera-Buszka, with wheat bre (Je drusek-Golin 2007). Moreover, in the fortied products (unpublished results) the iodine carriers (particularly soy isolate) increased the stability of thiamine during thermal processing and storage compared with products fortied with iodised table salt. Thus, the results indicate the proposed methods of processed meats fortication would be useful for enriching these products with iodine. Acknowledgements This research has been supported by the Ministry of Scientic Research and Information Technology (Ministerstwo Nauki i Informatyzacji - MNiI) in Poland under the Project No. N31202731/ 2058.

1344

K. Waszkowiak, K. Szymandera-Buszka / Meat Science 80 (2008) 13401344 Makaa, H., & Olkiewicz, M. (2004). Role of selected wheat and oat cellulose preparations in binding water in nely comminuted model meat products. Acta Agrophysica, 4(1), 8596. Moxon, R. E. D., & Dixon, E. J. (1980). Semi-automatic method for the determination of total iodine in food. Analyst, 105, 344352. Pietrasik, Z., & Duda, Z. (2000). Effect of fat content and soy protein/carrageenan mix on the quality characteristics of comminuted scalded sausages. Meat Science, 56, 181188. Pike, D. J. (1986). A practical approach to regression. In J. R. Piggott (Ed.), Statistical procedures in food research (pp. 61100). London and New York: Elsevier Applied Science. Serbranek, J. G., Olson, D. G., Whiting, R. C., Benedict, R. C., Rust, R. E., Kraft, A. A., et al. (1983). Physiological role of dietary sodium in human health and implication of sodium reduction in muscle foods. Food Technology, 37, 5159. Szymandera-Buszka, K., & Waszkowiak, K. (2007). Stability of iodinated salts during roasting and storage of pork meatballs. Polish Journal of Food and Nutrition Sciences, 57(3), 335338. Waszkowiak, K., Grecka, D., & Janitz, W. (2001). Wpyw preparatu bonnika c sensoryczna pszennego na jakos potraw mie snych (Inuence of wheat _ dietary ber on the quality of meat dishes). Zywnos c, 28(3), 5361 [in Polish]. Waszkowiak, K., & Szymandera-Buszka, K. (2005). Utilization preparations of connective tissue proteins as carriers of potassium iodide studies of iodine retention during their storage. Polish Journal Human Nutrition and Metabolism, 32(Suppl. 1), 11301134. Waszkowiak, K., & Szymandera-Buszka, K. (2007). Effect of collagen preparations used as carriers of potassium iodide on retention of iodine and thiamine during cooking and storage of pork meatballs. Journal of Science and Food Agriculture, 87(8), 14731479. Waszkowiak, K., Szymandera-Buszka, K., & Janitz, W. (2000). Utilization of collagen isolate as a carrier of potassium iodide in production and storage of dishes from turkey meat. Electronic Journal of Polish Agricultural Universities, Series Food Science and Technology, 3, 18. Waszkowiak, K., Szymandera-Buszka, K., Janitz, W., & Grecka, D. (1999). Comparative evaluation of nutritive and sensory value of selected raw materials and dishes after thermal processing in a convection oven and with conventional methods. Electronic Journal of Polish Agricultural Universities, Series Food Science and Technology, 2, 110. WHO. (2004). Global database on iodine deciency. Iodine status worldwide. Geneva: WHO.

References

Bilska, A., Krysztoak, K., Se k, P., & Uchman, W. (2002). Inuence of the use of the Vitacel preparation on the quality of lunch meat sausages. Acta Scientarum Polonorum Technologia Alimentaria, 1(1), 4753. Boye, J. I., Ma, C. Y., & Harwalkar, V. R. (1997). Thermal denaturation and coagulation of proteins. In S. Damodaran & A. Parfan (Eds.), Food proteins and their application (pp. 2557). New York: Basil Marcel-Dekker Inc. Burtland, H. (2004). Sets out to eliminate iodine deciency disorder. WHO Reports. Chang, K. C., & Hou, H. J. (2004). Gelation of puried soy proteins. In Yiu H. Hui (Ed.). Hand book of vegetable preservation and processing, Part 8 (3(D), pp. 445446). Newyork: Basel Marcel Dekker, Inc.. Diosady, L.L., & Mannar, V.M.G. (2000). Stability of iodine in iodized salt. In R.M. Geertman (Ed.), 8th World Salt Symposium (Vol. 2, pp. 977982). The Hague: Elsevier. Diosady, L. L., Alberti, J. O., Mannar, M. G. V., & Stone, T. G. (1997). Stability of iodine in iodized salt used for correction of iodine-deciency disorders. Food and Nutrition Bulletin, 18(4), 388397. Dziennik Ustaw (2003). Regulation of health minister on fortifying substances added to food and conditions for their use. No. 27 poz. 237. Goindi, G., Karmarkar, M. G., Kapil, U., & Jagannathan, J. (1995). Estimation of losses of iodine during different cooking procedures. Asia Pacic Journal of Clinical Nutrition, 4(2), 225227. Hetzel, B. S. (1983). Iodine deciency disorders (IDD) and their eradication. Lancet, 2, 1261129. Hetzel, B. S. (1989). The iodine deciency disorders: Their nature and prevention. Annual Review of Nutrition, 9, 2138. Hetzel, B. S. (2000). Iodine and neuropsychological development. The Journal of Nutrition, 130, 493S495S. Hoogenkamp, H. (2007). The soy industrys love-hate relationship with meat. Meat International, 17(2), 811. ska, A., & Szymandera-Buszka, K. (2007). Consumer desirability of Je drusek-Golin pork meat products with an addition of preparations being carriers of iodine. Polish Journal of Human Nutrition and Metabolism, 34(1/2), 779782. Jimnez-Colmenero, F., Ayo, M. J., & Carballo, J. (2005). Physicochemical properties of low sodium frankfurter with added walnut: Effect of transglutaminase combined with caseinate, KCl and dietary bre as salt replacers. Meat Science, 69(4), 781788. Khne, D., Wirth, F., & Wagner, H. (1993). Jodbestimmung in jodierten eischerzeugnissen. Fleischwirtschaft, 73, 175178.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Increased Prediction Accuracy in The Game of Cricketusing Machine LearningDocument18 pagesIncreased Prediction Accuracy in The Game of Cricketusing Machine LearningLewis TorresNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Longitudinal Method KhooWestWuKwokDocument17 pagesLongitudinal Method KhooWestWuKwokmphil.rameshNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- CshaDocument42 pagesCshamphil.rameshNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Cricket Paper-1Document13 pagesCricket Paper-1mphil.rameshNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Cross Over DesignsDocument7 pagesCross Over Designsmphil.rameshNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- WanaparthyDocument12 pagesWanaparthymphil.rameshNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Review Robotics EducationDocument16 pagesReview Robotics EducationDiana CarolinaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Chapter 3: Central TendencyDocument26 pagesChapter 3: Central TendencyFatimaIjazNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Bayesian MultiparameterDocument15 pagesBayesian Multiparametermphil.rameshNo ratings yet

- Geetha 20160826 WA0008Document961 pagesGeetha 20160826 WA0008mphil.rameshNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Systematic Review of Infant and Young Child Complementary Feeding Practices in South Asian Families The Pakistan PerspectiveDocument14 pagesSystematic Review of Infant and Young Child Complementary Feeding Practices in South Asian Families The Pakistan Perspectivemphil.rameshNo ratings yet

- Food BasedapproachDocument8 pagesFood Basedapproachmphil.rameshNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Review Robotics EducationDocument16 pagesReview Robotics EducationDiana CarolinaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- 4703 07 Notes ARMDocument4 pages4703 07 Notes ARMPhuong HoangNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Data PerentageDocument10 pagesData Perentagemphil.rameshNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grossman Statistical InferenceDocument483 pagesGrossman Statistical Inferencemphil.ramesh100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Journal of The American Statistical AssociationDocument11 pagesJournal of The American Statistical Associationmphil.rameshNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Normal DistributionDocument12 pagesNormal Distributionmphil.rameshNo ratings yet

- Fixed Effects Fixed Effects Fixed Effects Random Effects Random EffectsDocument2 pagesFixed Effects Fixed Effects Fixed Effects Random Effects Random Effectsmphil.rameshNo ratings yet

- Fail-Safe-N IDDDocument1 pageFail-Safe-N IDDmphil.rameshNo ratings yet

- 7.11.2 Vitamin A Deficiency PR MapDocument9 pages7.11.2 Vitamin A Deficiency PR MapRishav RajNo ratings yet

- Micronutrient Fortification of Food and Its Impact On Woman and Child Health: A Systematic ReviewDocument24 pagesMicronutrient Fortification of Food and Its Impact On Woman and Child Health: A Systematic Reviewmphil.rameshNo ratings yet

- The American StatisticianDocument10 pagesThe American Statisticianmphil.rameshNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Calculation of IDDDocument3 pagesCalculation of IDDmphil.rameshNo ratings yet

- 1742 5573 1 5Document19 pages1742 5573 1 5mphil.rameshNo ratings yet

- Quick Study For Computer Keyboard Short CutsDocument2 pagesQuick Study For Computer Keyboard Short Cutsmahazari100% (3)

- 1478 7547 11 18Document6 pages1478 7547 11 18mphil.rameshNo ratings yet

- 1471 2288 12 125Document15 pages1471 2288 12 125mphil.rameshNo ratings yet

- 124 - 2 197 202Document6 pages124 - 2 197 202mphil.rameshNo ratings yet

- 10Document4 pages10mphil.rameshNo ratings yet

- Additional Help With OSCOLA Style GuidelinesDocument26 pagesAdditional Help With OSCOLA Style GuidelinesThabooNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- DMDW Mod3@AzDOCUMENTS - inDocument56 pagesDMDW Mod3@AzDOCUMENTS - inRakesh JainNo ratings yet

- Audit Acq Pay Cycle & InventoryDocument39 pagesAudit Acq Pay Cycle & InventoryVianney Claire RabeNo ratings yet

- Inventory Control Review of LiteratureDocument8 pagesInventory Control Review of Literatureaehupavkg100% (1)

- DC Motor Dynamics Data Acquisition, Parameters Estimation and Implementation of Cascade ControlDocument5 pagesDC Motor Dynamics Data Acquisition, Parameters Estimation and Implementation of Cascade ControlAlisson Magalhães Silva MagalhãesNo ratings yet

- C6 RS6 Engine Wiring DiagramsDocument30 pagesC6 RS6 Engine Wiring DiagramsArtur Arturowski100% (3)

- Pom Final On Rice MillDocument21 pagesPom Final On Rice MillKashif AliNo ratings yet

- Music 7: Music of Lowlands of LuzonDocument14 pagesMusic 7: Music of Lowlands of LuzonGhia Cressida HernandezNo ratings yet

- LM1011 Global ReverseLogDocument4 pagesLM1011 Global ReverseLogJustinus HerdianNo ratings yet

- Reflection Homophone 2Document3 pagesReflection Homophone 2api-356065858No ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 08 Sepam - Understand Sepam Control LogicDocument20 pages08 Sepam - Understand Sepam Control LogicThức Võ100% (1)

- New Education Policy 2019Document55 pagesNew Education Policy 2019Aakarshanam VenturesNo ratings yet

- Towards A Human Resource Development Ontology Combining Competence Management and Technology-Enhanced Workplace LearningDocument21 pagesTowards A Human Resource Development Ontology Combining Competence Management and Technology-Enhanced Workplace LearningTommy SiddiqNo ratings yet

- Last Clean ExceptionDocument24 pagesLast Clean Exceptionbeom choiNo ratings yet

- AFNOR IPTDS BrochureDocument1 pageAFNOR IPTDS Brochurebdiaconu20048672No ratings yet

- Column Array Loudspeaker: Product HighlightsDocument2 pagesColumn Array Loudspeaker: Product HighlightsTricolor GameplayNo ratings yet

- International Certificate in WealthDocument388 pagesInternational Certificate in Wealthabhishek210585100% (2)

- STAT100 Fall19 Test 2 ANSWERS Practice Problems PDFDocument23 pagesSTAT100 Fall19 Test 2 ANSWERS Practice Problems PDFabutiNo ratings yet

- Water Jet CuttingDocument15 pagesWater Jet CuttingDevendar YadavNo ratings yet

- DELcraFT Works CleanEra ProjectDocument31 pagesDELcraFT Works CleanEra Projectenrico_britaiNo ratings yet

- PESO Online Explosives-Returns SystemDocument1 pagePESO Online Explosives-Returns Systemgirinandini0% (1)

- Philippine Coastal Management Guidebook Series No. 8Document182 pagesPhilippine Coastal Management Guidebook Series No. 8Carl100% (1)

- Built - in BeamsDocument23 pagesBuilt - in BeamsMalingha SamuelNo ratings yet

- Interpretation of Arterial Blood Gases (ABGs)Document6 pagesInterpretation of Arterial Blood Gases (ABGs)afalfitraNo ratings yet

- GlastonburyDocument4 pagesGlastonburyfatimazahrarahmani02No ratings yet

- Chennai Metro Rail BoQ for Tunnel WorksDocument6 pagesChennai Metro Rail BoQ for Tunnel WorksDEBASIS BARMANNo ratings yet

- Take This LoveDocument2 pagesTake This LoveRicardo Saul LaRosaNo ratings yet

- Acne Treatment Strategies and TherapiesDocument32 pagesAcne Treatment Strategies and TherapiesdokterasadNo ratings yet

- Site Visit Risk Assessment FormDocument3 pagesSite Visit Risk Assessment FormAmanuelGirmaNo ratings yet

- Portfolio Artifact Entry Form - Ostp Standard 3Document1 pagePortfolio Artifact Entry Form - Ostp Standard 3api-253007574No ratings yet

- The Dude Diet: Clean(ish) Food for People Who Like to Eat DirtyFrom EverandThe Dude Diet: Clean(ish) Food for People Who Like to Eat DirtyRating: 3.5 out of 5 stars3.5/5 (10)

- The Obesity Code: Unlocking the Secrets of Weight LossFrom EverandThe Obesity Code: Unlocking the Secrets of Weight LossRating: 5 out of 5 stars5/5 (3)

- Pasta, Pretty Please: A Vibrant Approach to Handmade NoodlesFrom EverandPasta, Pretty Please: A Vibrant Approach to Handmade NoodlesNo ratings yet

- Plant Based Main Dishes Recipes: Beginner’s Cookbook to Healthy Plant-Based EatingFrom EverandPlant Based Main Dishes Recipes: Beginner’s Cookbook to Healthy Plant-Based EatingRating: 4.5 out of 5 stars4.5/5 (15)

- Not That Fancy: Simple Lessons on Living, Loving, Eating, and Dusting Off Your BootsFrom EverandNot That Fancy: Simple Lessons on Living, Loving, Eating, and Dusting Off Your BootsNo ratings yet

- Saved By Soup: More Than 100 Delicious Low-Fat Soups To Eat And Enjoy Every DayFrom EverandSaved By Soup: More Than 100 Delicious Low-Fat Soups To Eat And Enjoy Every DayRating: 4 out of 5 stars4/5 (10)