Professional Documents

Culture Documents

Corrosion Control Methods

Uploaded by

Navas AzeezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Corrosion Control Methods

Uploaded by

Navas AzeezCopyright:

Available Formats

Page 11

Corrosion Control

Explain the various methods involved in control of corrosion The different methods used for control of corrosion are:1 1. Proper design and selection of material 2. Modifying the environment 3. Cathodic and anodic protection 4. Protection coating-metallic and organic

1. Design and Selection of Materials

The important design and material selection principles are a) b) c) d) e) f) Avoid contact of dissimilar metals in the presence of corrosive solution For two dissimilar metals in contact use an anodic material of larger area and a cathodic material of smaller area Two dissimilar metals used should be as clos as possible in the electrochemical series Try to avoid crevises In joints instead of bolt and rivets where ever possible use welding and brazing Figure (a) shows the different types of joints Minimize sharp corners and edges, use smooth bends as far as possible Figure (b) shows the illustration. g) the component should be free from residual stresses as in cold worked parts`. h) Try to use pure metals without impurities wherever possible..

Page 11

2.Modifying the Environment The corrosive environment can be modified either by removing the harmful constituents or by adding certain substances to neutralize the corrosive constituents. The important modifications to prevent corrosion are as below

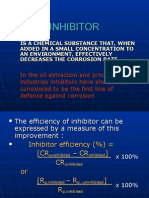

a) The de aeration and deactivations The presence of oxygen (air) at the cathodic area in the aqueous environment increases the rate of corrosion. Thus removal of oxygen helps prevention of corrosion. This is done by de aeration. This involves increasing the temp. By agitating the solution. This also brings down the CO2 content of water. Deactivation involves the addition of chemicals that combine readily with oxygen in the solution. Sodium Sulphate is added to form soluble Sodium Sulphate. Also Hydrazine hydrate ( NH2.NH2.H2O) can be used which produces hydrogen and water with oxygen. b) Dehumidification Presence of moisture has more effect on the corrosive phenomenon. Dehumidification is the process of reducing the moisture content of air so that corrosion can be prevented. c) Alkaline Neutralization Its the process of reducing the acidity of the SO2 at the corrosion area. The Alkaline Neutralizers are NH3,NaOH, Lime etc. These are used either in vapour or liquid forms and applied to the corroding parts d) Use of inhibitors

You might also like

- Corrosion PreventionDocument10 pagesCorrosion Preventionওয়াসিমNo ratings yet

- Ronak Mehta ContentDocument12 pagesRonak Mehta ContentDevashish JoshiNo ratings yet

- C51 PDFDocument29 pagesC51 PDFAbdulsalam MaaNo ratings yet

- Group topics water treatment air pollutants reducing pollutants fertilisersDocument2 pagesGroup topics water treatment air pollutants reducing pollutants fertilisersTysonNo ratings yet

- CorrosionDocument10 pagesCorrosionshivamNo ratings yet

- Corus CorrosionPrevention StructuralSteelworkDocument28 pagesCorus CorrosionPrevention StructuralSteelworkRabea Ala'gashNo ratings yet

- 9 Corrosion Prevention Design Material SelectDocument58 pages9 Corrosion Prevention Design Material SelectJesus De la RosaNo ratings yet

- The Prevention of Corrosion On Structural SteelworkDocument28 pagesThe Prevention of Corrosion On Structural Steelworkint8No ratings yet

- Corrosion EbbDocument3 pagesCorrosion EbbLim Xiu XianNo ratings yet

- Chemistry Project: Problems in Daily Life and Its SolutionDocument32 pagesChemistry Project: Problems in Daily Life and Its Solutionanurag prernaNo ratings yet

- DIsign Against CorrosionDocument72 pagesDIsign Against CorrosionAMAL MATHEWNo ratings yet

- Q & A BgasDocument33 pagesQ & A BgasAbdulRahman Mohamed Hanifa86% (7)

- Project On Corrosion Class 12Document16 pagesProject On Corrosion Class 12fizakouser1216No ratings yet

- FALLSEM2019-20 CHY1701 ETH VL2019201007055 Reference Material I 06-Sep-2019 Revised Module 4Document73 pagesFALLSEM2019-20 CHY1701 ETH VL2019201007055 Reference Material I 06-Sep-2019 Revised Module 4yuvanNo ratings yet

- Corrosion in Oil and Gas IndustryDocument25 pagesCorrosion in Oil and Gas IndustryAMINE0% (1)

- Option E Past Paper QuestionsDocument6 pagesOption E Past Paper QuestionsmafooooooooooNo ratings yet

- Corrosion Types Causes PreventionDocument51 pagesCorrosion Types Causes Preventionshartendu100% (2)

- Unit II CorrosionDocument3 pagesUnit II CorrosionavishekpatelNo ratings yet

- Black PassivationDocument12 pagesBlack PassivationZinebNo ratings yet

- Environmental Engineering SolutionsDocument22 pagesEnvironmental Engineering SolutionsZVS80% (10)

- Potential For Real-Time Monitoring and Control of Dissolved Oxygen in The Injection Water Treatment ProcessDocument8 pagesPotential For Real-Time Monitoring and Control of Dissolved Oxygen in The Injection Water Treatment ProcessMinhquang NgoNo ratings yet

- Corrosion Prevention by Use of InhibitorsDocument19 pagesCorrosion Prevention by Use of InhibitorsSai PradeepNo ratings yet

- The Composition of Clean, Dry Air As Being Approximately 78% Nitrogen, 21% Oxygen and The Remainder As Being A Mixture of Noble Gases and Carbon DioxideDocument11 pagesThe Composition of Clean, Dry Air As Being Approximately 78% Nitrogen, 21% Oxygen and The Remainder As Being A Mixture of Noble Gases and Carbon DioxideShunzi YanNo ratings yet

- Chemistry-II: Answer Any Five of Following: (15 Marks)Document18 pagesChemistry-II: Answer Any Five of Following: (15 Marks)Kenneth C.LinojNo ratings yet

- Corrosion Behavior of Carbon Steel in Oxygenated Sodium Sulphate Solution Under Different Operating ConditionsDocument11 pagesCorrosion Behavior of Carbon Steel in Oxygenated Sodium Sulphate Solution Under Different Operating ConditionsSEP-PublisherNo ratings yet

- Photoreduction of Carbon Dioxide in The Presence of H, H O and CH Over Tio and Zno PhotocatalystsDocument9 pagesPhotoreduction of Carbon Dioxide in The Presence of H, H O and CH Over Tio and Zno PhotocatalystsĐại HảiNo ratings yet

- Inhibitor CorrosionDocument21 pagesInhibitor CorrosionDiego Pabon100% (2)

- Research Proposal IsdbDocument19 pagesResearch Proposal IsdbBashir AhmadNo ratings yet

- 9841 - Tunji Ss3 2nd Term Chemistry E-Lesson NoteDocument26 pages9841 - Tunji Ss3 2nd Term Chemistry E-Lesson Notepalmer okiemuteNo ratings yet

- C) Neutralization With LimeDocument16 pagesC) Neutralization With LimeJameel Gorgees TomaNo ratings yet

- Material Science Chapter on Economic, Environmental and Social IssuesDocument5 pagesMaterial Science Chapter on Economic, Environmental and Social IssuesHamza NawazNo ratings yet

- 170425 بحث مجلة ديالى نضالDocument18 pages170425 بحث مجلة ديالى نضالShurooq TaibNo ratings yet

- Corrosion Control PDFDocument48 pagesCorrosion Control PDFAnkit SinghNo ratings yet

- 26 1 17petrol1334 4359 1 PBDocument9 pages26 1 17petrol1334 4359 1 PBHichem RGNo ratings yet

- Effect of Chloride Concentration On The Corrosion Rate in Carbon SteelDocument7 pagesEffect of Chloride Concentration On The Corrosion Rate in Carbon SteelAziz SaputraNo ratings yet

- W The Rate in Weight Gain or Loss (G/CM I Current DensityDocument12 pagesW The Rate in Weight Gain or Loss (G/CM I Current Densityهدوء السماءNo ratings yet

- Research and Reviews: Journal of Pure and Applied PhysicsDocument8 pagesResearch and Reviews: Journal of Pure and Applied PhysicsdeewNo ratings yet

- Unit 9 Atmospheric Corrosion - SolomonDocument45 pagesUnit 9 Atmospheric Corrosion - SolomonDESALEGN SHIBESHNo ratings yet

- Development of Hydrophobic Non-Fluorine Sol-Gel Coatings On Aluminium Using Long Chain Alkyl Silane PrecursorDocument8 pagesDevelopment of Hydrophobic Non-Fluorine Sol-Gel Coatings On Aluminium Using Long Chain Alkyl Silane PrecursorsaatehNo ratings yet

- Technical Bulletin: Pickling Methods For Duplex Stainless SteelDocument3 pagesTechnical Bulletin: Pickling Methods For Duplex Stainless SteelPhoenix KukuruyukNo ratings yet

- Corrosion 1Document29 pagesCorrosion 1shaileshpathakNo ratings yet

- Unit 6 Corrosion Control by Inhibition - TeferiDocument40 pagesUnit 6 Corrosion Control by Inhibition - TeferiDESALEGN SHIBESHNo ratings yet

- Corrosion InhibitorsDocument38 pagesCorrosion Inhibitors20pcha122 20pcha122No ratings yet

- emision control system pptDocument22 pagesemision control system pptMayur Madhukar MankarNo ratings yet

- CorrosionDocument20 pagesCorrosionndesigngmailNo ratings yet

- Yin 2009Document7 pagesYin 2009Imam Saja DechNo ratings yet

- The Use of Corrosion Inhibitors in Oil and GasDocument7 pagesThe Use of Corrosion Inhibitors in Oil and Gasdodofan2000No ratings yet

- Corriosion 1Document9 pagesCorriosion 1Dima Al KibbiNo ratings yet

- Protection of Metals From CorrosionDocument18 pagesProtection of Metals From CorrosionNicole PalomaresNo ratings yet

- Applied Chemistry-Ii (May-2018 Solution) : Power AlcoholDocument18 pagesApplied Chemistry-Ii (May-2018 Solution) : Power AlcoholKenneth C.LinojNo ratings yet

- Corrosion Prevention and ControlDocument22 pagesCorrosion Prevention and ControlMobile LegendsNo ratings yet

- HaaaaysDocument11 pagesHaaaaysPsalm Bethaniel MaalaNo ratings yet

- Acid Deposition and its EffectsDocument14 pagesAcid Deposition and its EffectsTae-Yeol [Tyler] BeakNo ratings yet

- Corrosion in the Petroleum IndustryDocument12 pagesCorrosion in the Petroleum IndustryAnurag Borah0% (1)

- Env UNIT 4 QBDocument7 pagesEnv UNIT 4 QBVenkatram PrabhuNo ratings yet

- Week 1b IntroductionDocument44 pagesWeek 1b IntroductionAraasu EgambaramNo ratings yet

- Deniss ProjectDocument24 pagesDeniss Projectreuben simiyuNo ratings yet

- Unit VI Corrosion Science: Course Instructor-Dr. Shailesh DhokeDocument58 pagesUnit VI Corrosion Science: Course Instructor-Dr. Shailesh DhokeLadliNo ratings yet

- BGAS 2 Questions-1 PDFDocument33 pagesBGAS 2 Questions-1 PDFShyam Sundar Gayen100% (1)

- Corrosion: Corrosion ControlFrom EverandCorrosion: Corrosion ControlL L ShreirRating: 5 out of 5 stars5/5 (1)

- Skid ControlDocument16 pagesSkid Controlsangeethsreeni100% (3)

- Evolvable Hardware Applied To NanotechnologyDocument7 pagesEvolvable Hardware Applied To NanotechnologyNavas AzeezNo ratings yet

- Central Railway Railway Recruitment Cell P D'Mello Road, Wadi Bunder, Mumbai - 400010Document15 pagesCentral Railway Railway Recruitment Cell P D'Mello Road, Wadi Bunder, Mumbai - 400010Navas AzeezNo ratings yet

- Vbe 13Document1 pageVbe 13Navas AzeezNo ratings yet

- Vbe 9Document1 pageVbe 9Navas AzeezNo ratings yet

- RR EnglishDocument3 pagesRR EnglishNavas AzeezNo ratings yet

- KR PrepaidgDocument2 pagesKR PrepaidgNavas AzeezNo ratings yet

- VBE 12bDocument1 pageVBE 12bNavas AzeezNo ratings yet

- 4 AcknowledgementDocument6 pages4 AcknowledgementNavas AzeezNo ratings yet

- A Seminar Report Challenges in The Migration To 4GDocument34 pagesA Seminar Report Challenges in The Migration To 4GSowmya_Reddy_5407No ratings yet

- VBE 12aDocument1 pageVBE 12aNavas AzeezNo ratings yet

- Vbe 8Document1 pageVbe 8Navas AzeezNo ratings yet

- Rollover Simulation of Bus StructureDocument13 pagesRollover Simulation of Bus StructureNavas AzeezNo ratings yet

- Automobile & Mechanical Engineering ProjectsDocument2 pagesAutomobile & Mechanical Engineering ProjectsNavas AzeezNo ratings yet

- Mechanical Multipoint Port Fuel Injection System (Bosch K-Jetronic System)Document1 pageMechanical Multipoint Port Fuel Injection System (Bosch K-Jetronic System)Navas AzeezNo ratings yet

- R IntroDocument103 pagesR Introtajjj9No ratings yet

- Ergonomics Part 1Document2 pagesErgonomics Part 1Navas AzeezNo ratings yet

- Fabrication of Turbo Charger in Two WheelerDocument2 pagesFabrication of Turbo Charger in Two WheelerNavas AzeezNo ratings yet

- Vbe 13Document1 pageVbe 13Navas AzeezNo ratings yet

- Fabrication of Reverse Gear in Two WheelerDocument2 pagesFabrication of Reverse Gear in Two WheelerNavas AzeezNo ratings yet

- Electric EcofloorDocument21 pagesElectric EcofloorNavas AzeezNo ratings yet

- Evolutionary Psychology Journal Critiques Darwin Exhibition ErrorsDocument18 pagesEvolutionary Psychology Journal Critiques Darwin Exhibition ErrorsNavas AzeezNo ratings yet

- R IntroDocument103 pagesR Introtajjj9No ratings yet