Professional Documents

Culture Documents

Earthing Coil

Uploaded by

Abhishek DasCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Earthing Coil

Uploaded by

Abhishek DasCopyright:

Available Formats

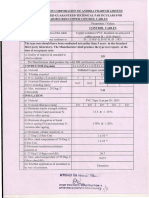

21.

0 EARTHING COIL

Earthing Coils shall be fabricated from soft GI Wire Hot Dip Galvanized. The Hot

Dip galvanized wire shall have clean surface and shall be free !"# paint enamel or an$

other poor conducting material. The coil shall be made as per !EC constructions

standard %&' (drawing enclosed). The Hot Dip galvanizing shall conform to I*+,-,.&'./01 I*+

,-22&'./- and I*+ 3/,-&'.4. with latest amendments. Galvanizing should be heavil$ coated

and should stand for the following tests.

,'.' Galvanizing Tests

i) #inimum #ass of 5inc

a) "6 GI Wire used ,/7 gm8m

,

b) 9fter Coiling : ,-- gm8m

,

. The certificate from recognized laborator$ shall

be submitted towards mass of zinc.

ii) Dip Test

*hall stand 2 dips of ' minute and one dip of ; minute before coiling and 32 dips of '

minute after coiling as per I*+3/,-&'.4..

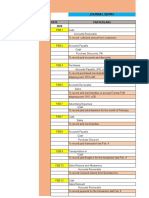

,'., THE DI#E6*I"69< !E=>I!E#E6T *H9<< ?E 9* "<<"W*

a) 6ominal dia of GI Wire 3 mm (Tolerance @ ,.0A)

b) #inimum no. of turns : ''0 6os.

c) EBternal dia of Coil (#in) : 07 mm

d) <ength of Coil (#in) : 3-7 mm

e) ree length of GI Wire at one end coil (#in.) : ,077 mm

The turns should be closel$ bound. Weight of one finished Earthing Coils (min.) : './07

Cg. 9dhesion test : 9s per I*+ 3/,- : '.4..

You might also like

- Welding Q6Document14 pagesWelding Q6Ahmed HaridiNo ratings yet

- Global Marketing For Tube & Pipe: JIS C8305 Rigid Steel ConduitsDocument7 pagesGlobal Marketing For Tube & Pipe: JIS C8305 Rigid Steel ConduitsHoangNo ratings yet

- Specification of Steel Tubular Poles 4009Document2 pagesSpecification of Steel Tubular Poles 4009Akshay DharNo ratings yet

- Acsr Zebra ConductorDocument17 pagesAcsr Zebra ConductorRam Dhani YadavNo ratings yet

- 6 +acsr+zebra+conductorDocument17 pages6 +acsr+zebra+conductorBagusIrawanSaputraNo ratings yet

- Is 280 - Gi Wire Technical SpecificationDocument5 pagesIs 280 - Gi Wire Technical SpecificationBhavesh Keralia100% (1)

- CSWIP 3.1 PracticeDocument6 pagesCSWIP 3.1 PracticeVinai Vikram100% (1)

- G I Wire No. 8 & 10Document5 pagesG I Wire No. 8 & 10Dharmendra KumarNo ratings yet

- European Patent ApplicationDocument18 pagesEuropean Patent ApplicationJared ReigleNo ratings yet

- Technical SpecificationDocument7 pagesTechnical SpecificationrohitctppNo ratings yet

- Final Exam (Open) : Weld Reinf. 1/8" THKDocument7 pagesFinal Exam (Open) : Weld Reinf. 1/8" THKNuwan RanaweeraNo ratings yet

- RRVPNL - Latest SpecificationDocument6 pagesRRVPNL - Latest SpecificationNirmal WiresNo ratings yet

- HV Porcelain Bushing: IS2099 Galvanization: IS2633 Primary Terminals: IS 10601Document9 pagesHV Porcelain Bushing: IS2099 Galvanization: IS2633 Primary Terminals: IS 10601AnilNo ratings yet

- Technical Description of Galvanized Steel Earth Wire.: Page 4.1.6A - 1Document24 pagesTechnical Description of Galvanized Steel Earth Wire.: Page 4.1.6A - 1DipeshNo ratings yet

- TS For 4Cx10 SQ - MM Armoured CableDocument8 pagesTS For 4Cx10 SQ - MM Armoured CableAshish bhattNo ratings yet

- O o o oDocument2 pagesO o o oJeyakandan MarudiahNo ratings yet

- api 510 اسئلة متنوعة لكل الكورسDocument42 pagesapi 510 اسئلة متنوعة لكل الكورسhussam ghiathNo ratings yet

- On DWG:: Plumbing Contractor CopiesDocument7 pagesOn DWG:: Plumbing Contractor CopiesyashirupNo ratings yet

- 220kv 132kv Unarmoured CablesDocument3 pages220kv 132kv Unarmoured CablesArif AhmedNo ratings yet

- 510 Practice Exam 5 OB QuestionsDocument0 pages510 Practice Exam 5 OB QuestionsGireesh Hegde100% (1)

- UntitledDocument258 pagesUntitledapi-155035535No ratings yet

- 8044 3 Technical Specification of HT AB Cable 11KVDocument9 pages8044 3 Technical Specification of HT AB Cable 11KVdkshtdkNo ratings yet

- Fencing SpecificationDocument6 pagesFencing Specificationkanji yamashitaNo ratings yet

- Technical Specification of Steel Tubular Pole.......... Dtd. 29.12.2014Document7 pagesTechnical Specification of Steel Tubular Pole.......... Dtd. 29.12.2014Jhoinner OsorioNo ratings yet

- Chapter - E12: Requirements of Auxiliary Items Aluminium Tubular ConductorDocument10 pagesChapter - E12: Requirements of Auxiliary Items Aluminium Tubular ConductorvenkateshbitraNo ratings yet

- Specifications of T, 40,20081347Document5 pagesSpecifications of T, 40,20081347Ardalan KhoshnawNo ratings yet

- Amendment No. 2 April 2022 To Is 7098 (Part 2) : 2011 Crosslinked Polyethylene Insulated Thermoplastic Sheathed Cables - SpecificationDocument11 pagesAmendment No. 2 April 2022 To Is 7098 (Part 2) : 2011 Crosslinked Polyethylene Insulated Thermoplastic Sheathed Cables - SpecificationVatsalNo ratings yet

- CSC-XII 1 C Is 7098 Part 2Document8 pagesCSC-XII 1 C Is 7098 Part 2Ashish bhattNo ratings yet

- Welding QuestnDocument37 pagesWelding QuestnmehdiNo ratings yet

- Dry Gis and Transformer TerminationsDocument2 pagesDry Gis and Transformer TerminationssalvgranNo ratings yet

- Previous Years GATE Questions Sub: Production Technology (Welding)Document12 pagesPrevious Years GATE Questions Sub: Production Technology (Welding)KAUSTUB CHAUHANNo ratings yet

- Duties of Welding InspectorDocument11 pagesDuties of Welding Inspectormuhammadazhar50% (2)

- اسئلة واجوبة CSWIPDocument64 pagesاسئلة واجوبة CSWIPLaith SalmanNo ratings yet

- Is 277 - 2003Document8 pagesIs 277 - 2003chandrani_acsNo ratings yet

- 11kV CT & PTDocument6 pages11kV CT & PTSanjeev RajputNo ratings yet

- Stay Wire Specifications 7-2.5mmDocument5 pagesStay Wire Specifications 7-2.5mmVatsalNo ratings yet

- PHED SpecificationsDocument8 pagesPHED SpecificationssaxraviNo ratings yet

- API 653 PC Final OpenDocument7 pagesAPI 653 PC Final OpenMuhammad Nozar100% (1)

- Fluid MechnicsDocument258 pagesFluid MechnicsMathew RodriguezNo ratings yet

- Technical Specification For 7/3.66 EARTH WIRE: Rail Coach Factory, Rae BareliDocument8 pagesTechnical Specification For 7/3.66 EARTH WIRE: Rail Coach Factory, Rae BareliPrashant TrivediNo ratings yet

- Tech Specs for 11kV Aerial Bunched CablesDocument6 pagesTech Specs for 11kV Aerial Bunched CablesBilal AhmadNo ratings yet

- Api 510 - Book 6Document120 pagesApi 510 - Book 6Tauqeer SalimNo ratings yet

- Submerged Arc Welding (Saw)Document5 pagesSubmerged Arc Welding (Saw)Nnaji Chukwuma SlamNo ratings yet

- Acsr Panther ConductorDocument17 pagesAcsr Panther ConductorRam Dhani Yadav100% (1)

- Multi Choice Question Paper (MSR - WI - 3)Document6 pagesMulti Choice Question Paper (MSR - WI - 3)BudimanNo ratings yet

- General All SolvedDocument25 pagesGeneral All SolvedAndiappan Pillai100% (2)

- DGMS circulars on mining safety standardsDocument61 pagesDGMS circulars on mining safety standardsravimutyamNo ratings yet

- Dgms All Circular 2002 PDFDocument61 pagesDgms All Circular 2002 PDFravimutyamNo ratings yet

- Technical Specification of Lattice Steel PolesDocument9 pagesTechnical Specification of Lattice Steel PolesCalinB.ACNo ratings yet

- API-510 Questions & Answers Closed Book 1Document12 pagesAPI-510 Questions & Answers Closed Book 1Ravindra S. Jivani70% (10)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo ratings yet

- The Boy Mechanic: Volume 1 700 Things for Boys to DoFrom EverandThe Boy Mechanic: Volume 1 700 Things for Boys to DoNo ratings yet

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Rating: 5 out of 5 stars5/5 (1)

- Ceramic Materials for Energy Applications VIFrom EverandCeramic Materials for Energy Applications VIHua-Tay LinNo ratings yet

- E-Governance Challenges and Prospects in IndiaDocument13 pagesE-Governance Challenges and Prospects in Indiaakhil negiNo ratings yet

- RBI DataDocument86 pagesRBI DatarumiNo ratings yet

- Nct-Rex Inspired ThemeDocument11 pagesNct-Rex Inspired ThemeFania SafitriNo ratings yet

- Pre-Feasibility Report for Kempegowda International Airport ExpansionDocument103 pagesPre-Feasibility Report for Kempegowda International Airport Expansionprerana anuNo ratings yet

- Ascension EIS Fund Tax Efficient ReviewDocument16 pagesAscension EIS Fund Tax Efficient Reviewsky22blueNo ratings yet

- Comprehensive Problem - (Merchandising Concern)Document19 pagesComprehensive Problem - (Merchandising Concern)Hannah Pearl Flores VillarNo ratings yet

- IPCR Performance ReviewDocument32 pagesIPCR Performance ReviewDILG DipaculaoNo ratings yet

- Advanced Process Control - Sustaining Benefits and CostsDocument20 pagesAdvanced Process Control - Sustaining Benefits and CostsHarshit SharmaNo ratings yet

- Islamic Banks and Investment FinancingDocument29 pagesIslamic Banks and Investment FinancingAhmad FananiNo ratings yet

- ABNT NBR 6330 2020 - General Purpose Carbon Steel Wire RodDocument12 pagesABNT NBR 6330 2020 - General Purpose Carbon Steel Wire RodElton Felipe Gularte dos SantosNo ratings yet

- DataHack Summit 2023 AgendaDocument1 pageDataHack Summit 2023 AgendaRishi rao KulakarniNo ratings yet

- Hkustiems Huang Why Did The Peer To Peer Lending Market Fail in China tlb61Document4 pagesHkustiems Huang Why Did The Peer To Peer Lending Market Fail in China tlb61wjh20061126No ratings yet

- Principles of AccountingDocument70 pagesPrinciples of AccountingCassandra UmaliNo ratings yet

- NCDC Business Listing for Sept 7Document96 pagesNCDC Business Listing for Sept 7AjayNo ratings yet

- Desktop 10 QA Exam Prep Guide PDFDocument16 pagesDesktop 10 QA Exam Prep Guide PDFSAPPA NARESHNo ratings yet

- DevOps Project 101: Complete Source Code and DeploymentDocument22 pagesDevOps Project 101: Complete Source Code and Deploymentvivek reddyNo ratings yet

- Meiser IndustryDocument36 pagesMeiser IndustryAleksiey PellicciaNo ratings yet

- Natural Resources of BangladeshDocument22 pagesNatural Resources of BangladeshDibakar Das0% (1)

- Understanding Plants Abroad Functionality in SAP PDFDocument3 pagesUnderstanding Plants Abroad Functionality in SAP PDFAnoop Rathod50% (2)

- Civil Case MemorialDocument15 pagesCivil Case Memorialkajalpatil80% (5)

- An Appraisal On The Impact of Financial Planning and Control in The Profitability of An OrganizationDocument156 pagesAn Appraisal On The Impact of Financial Planning and Control in The Profitability of An OrganizationJamesNo ratings yet

- TCL Case StudyDocument8 pagesTCL Case StudyParag_Ghatpand_8912No ratings yet

- Modern Data Strategy 1664949335Document39 pagesModern Data Strategy 1664949335Dao NguyenNo ratings yet

- DIY Oxygen Absorber For Caching Food StorageDocument7 pagesDIY Oxygen Absorber For Caching Food StorageMHammondNo ratings yet

- Chapter 7Document10 pagesChapter 7Eki OmallaoNo ratings yet

- Naamm Stair Manual FinalDocument126 pagesNaamm Stair Manual FinalAhmed BdairNo ratings yet

- CARP Outline For ClassmatesDocument3 pagesCARP Outline For ClassmatesAudreyNo ratings yet

- Shrimp Turtle CaseDocument11 pagesShrimp Turtle Casepoet36No ratings yet

- Effectiveness of The Public Financial Management Assessment Tool or (PFMAT) in Strengthening The Financial Capability of Local Government Unit in Talavera, Nueva EcijaDocument10 pagesEffectiveness of The Public Financial Management Assessment Tool or (PFMAT) in Strengthening The Financial Capability of Local Government Unit in Talavera, Nueva EcijaKomal sharmaNo ratings yet

- Participation of SMEs in Tourism ClustersDocument11 pagesParticipation of SMEs in Tourism ClustersDaniel GardanNo ratings yet