Professional Documents

Culture Documents

Steel Foam Material Processing, Properties, and Potential Structural Applications

Uploaded by

bluecrete0 ratings0% found this document useful (0 votes)

17 views7 pagesSteel foam can now be produced at the laboratory scale using a variety of different processes. Structural designers have not explored the potential benefits of using steel foam in structural applications. This paper reviews some of the methods available for processing steel foams.

Original Description:

Original Title

steelfoam-cmmi-2011

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSteel foam can now be produced at the laboratory scale using a variety of different processes. Structural designers have not explored the potential benefits of using steel foam in structural applications. This paper reviews some of the methods available for processing steel foams.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views7 pagesSteel Foam Material Processing, Properties, and Potential Structural Applications

Uploaded by

bluecreteSteel foam can now be produced at the laboratory scale using a variety of different processes. Structural designers have not explored the potential benefits of using steel foam in structural applications. This paper reviews some of the methods available for processing steel foams.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

Proceedings of 2011 NSF Engineering Research and Innovation Conference, Atlanta, Georgia Grant #1000334

Steel foam material processing, properties, and potential structural

applications

Sanjay R. Arwade

University of Massachusetts, Amherst

Jerome F. Hajjar

Northeastern University

Benjamin W. Schafer

Johns Hopkins University

Mohammadreza Moradi

University of Massacusetts, Amherst

Brooks H. Smith

University of Massachusetts, Amherst

Stefan Szyniszewski

Johns Hopkins University

Abstract: Steel foam is a material that can now be

produced at the laboratory scale using a variety of

different processes that create materials with a variety

of different morphologies. Steel foam has not,

however, been adopted in structural applications. In

this paper we review some of the methods available for

processing steel foams and the material properties that

result from those processes, and demonstrate a possible

application of steel foam in mitigating instability in

structural members susceptible to local instability.

1. Introduction: Foam and cellular materials have

been produced from base materials that include

polymers, ceramics, and metals such as titanium,

aluminum, and copper, and such foams have been

applied to solve engineering problems primarily in the

aerospace, automotive, and process control domains.

Steel is one of the most widely used engineering

materials, yet today no foam using steel as the base

material is commercially available. Perhaps because of

the lack of commercial availability of steel foam, no

applications have been developed or widely

implemented.

Research conducted over approximately the

last 10-15 years has shown that it is possible to

fabricate steel foams at the laboratory scale and that

these foams can be made to have potentially desirable

mechanical properties. Despite these substantial

advances in the materials science of steel foams, a

commercially available product remains elusive, and

therefore structural designers have not begun to explore

the potential benefits of using steel foam in civil

structural applications. To date, the only experimental

investigations of the potential use of steel foam in

structural applications, as opposed to material

characterization tests, have been to test some one foot

long steel foam filled tubes [9] and some 40mm long

steel foam beams [4] to failure.

The dual purposes of our research project are:

(1) to experimentally characterize steel foams with

respect to their cyclic, tensile, and shear response,

properties that are critical to structural performance but

are essentially unknown for steel foams; (2) to develop

and computationally test candidate applications of steel

foam that will improve the performance of civil

structures by, for example, improving energy

dissipation or mitigating local structural instabilities.

In this paper, which represents the first six

months of progress in the project, we first present a

brief review of the current state-of-the art with respect

to steel foam manufacturing and processing. Next, a

review of the mechanical properties of steel foams

produced by each of the processing methods. Finally,

preliminary results that indicate that deploying steel

foam in thin-walled structural members has the

NSF GRANT # 1000334

NSF PROGRAM NAME: Structural Materials and Mechanics

Proceedings of 2011 NSF Engineering Research and Innovation Conference, Atlanta, Georgia Grant #1000334

potential to significantly improve resistance to local

instability or buckling.

2. Steel foam manufacturing processes: Table 1 lists

the manufacturing processes that have been

demonstrated to date for making steel foams. All of the

materials listed have been produced only in small

batched under laboratory, rather than commercial,

conditions. As can been seen from the included images,

a wide range of cell morphologies is possible using the

different processing methods, and foams with either

open or closed cells are possible. Investigators have

succeeded in fabricating steel foams with relative

Table 1: Steel foam fabrication processes, material design variables, relative densities, and cell morphology.

Process Typical Image Primary Variables

Min

Density

Max

Density

Open/Closed

Cells

References

Powder metallurgical

Granular foaming

agents (e.g. MgCO

3

,

CaCO

3

, SrCO

3

), cooling

patterns

0.04 0.65 Closed

[12]

Injection molding with

glass balls

Types of glass (e.g.

IM30K, S60HS)

0.48 0.66 Closed

[18]

Oxide ceramic foam

precursor

Ceramic / cement

precursor materials

0.13 0.23 Open

[16,17]

Consolidation of hollow

spheres

Methods for sphere

manufacture (e.g.

powder-coated

styrofoam, gas

blowing), method of

connecting spheres (e.g.

sintering, glue, metal

filler)

0.04 0.21 Either

[5,10]

Working and sintering

of bimaterial rods

Types of working

before sintering (e.g.

compacted, rod length),

filler materials

0.05 0.95 Open

[14]

Composite PM / hollow

spheres

Matrix material used,

casting may be done

instead of PM

0.32 0.43 Closed

[15]

SlipReactionFoam

Sintering

Dispersant, bubbling

agent, and quantity of

dispersant and bubbling

agent used

0.12 0.41 Open

[2]

Polymer foam precursor Polymer material used 0.04 0.11 Open

[1]

Proceedings of 2011 NSF Engineering Research and Innovation Conference, Atlanta, Georgia Grant #1000334

densities (! = !

f

/!

s

) that range from 0.04 to 0.95 times

the density of solid steel. In the definition of relative

density !, !

f

is the mass density of the foam and !

s

is

the mass density of the base material. Metal foams

currently available that use aluminum, titanium, or

copper as a base metals have relative densities in the

range 0.05 to 0.20, and have typically been used in

applications in which very high ratios of the material

stiffness to weight or compressive energy absorption to

weight are desired. A feature of such low density

foams is that they have very low material strength

relative to the base metal, with yield stress as low as 1%

of the base material yield stress at !

= 0.08 [7]. In

structural applications we expect the maintenance of

reasonable material strength to be critical to the

satisfactory performance of the material, and therefore

call particular attention the ability to achieve foams

with relative density greater than 0.40 using the powder

metallurgy and composite hollow sphere methods.

Although high relative density is also achievable using

injection molding with glass balls, the use of expensive

and fragile glass balls in the fabrication process will

likely restrict the potential commercialization of that

particular material, at least for civil engineering

applications. The working and sintering of bimaterial

rods can also produce high relative densities, but

creates an open cell morphology which is likely to be

disadvantageous in terms of corrosion resistance.

Furthermore, that process creates materials with strong

anisotropies in the material properties, a feature that

structural engineers prefer to avoid. Finally, although

the sintering of hollow steel spheres can produce

materials with relative density only up to 0.20, it is the

most widely investigated fabrication procedure, and is

likely the closest to commercialization. We therefore

intend to focus our investigations on the application of

steel foam to civil structures on materials produced by

powder metallurgy, sintering of hollow steel spheres, or

composite powder metallurgy / hollow steel sphere

processes.

3. Mechanical properties of steel foam: Foam

materials have typically been employed in mechanical

or aerospace applications in which they were asked to

undergo large compressive deformations at relatively

low stress, or provide substantial stiffness at extremely

low weight. For that reason, characterization of steel

foam material properties has focused exclusively on

compression testing of small rectilinear prisms of

material providing the elastic modulus and compressive

yield stress of the material.

Table 2 summarizes the published literature on

the mechanical properties of steel foam fabricated by

the various processes described in Section 2 and Table

2. In all cases, the number of experiments reported is

small, usually in the single digits. This reflects the

substantial challenges and costs still associated with the

production of steel foam. Table 2 reports values of the

elastic modulus and compressive yield stress. Several

of the papers also report material hardness, which is of

little consequence for civil engineering design, and

there exists only one published report of the tensile

capacity of a steel foam, which states tensile yield

stresses on the order of 1-10 MPa. We could find no

published reports on the cyclic or shear response of

steel foams, and both cyclic and shear loading

commonly arise in civil structural applications. Steel

foams with low relative density have yield stresses on

the order or 1% of typical yield stress values for bulk

steel, whereas when the relative density is closer to

0.50, steel foam yield stress of up to roughly 50% of

steel yield stress are achievable. These findings

highlight the potentially critical role that high density

foams might play in civil engineering design. Steel

foam elastic moduli vary from less than 1% of the bulk

property to as much as 5% of the bulk property. The

are low material stiffnesses, and point out that

Table 2: Summary of experimental characterization of steel foam material properties

Proceedings of 2011 NSF Engineering Research and Innovation Conference, Atlanta, Georgia Grant #1000334

maintaining sufficient stiffness in structural

applications of steel foam will be a critical and

challenging objective. Table 2 clarifies the nearly

complete lack of material property characterization

beyond compressive properties, and provides strong

motivation for our efforts at cyclic, tensile, and shear

measurements.

Ashby [3] and Gibson & Ashby [6] have

provided mechanics-based expressions that purport to

predict the mechanical properties of cellular materials

as a function of the relative density and base material

properties. For example, the elastic modulus is related

to the relative density by

!

E

f

E

s

= A

Ec

0.5"

2

+ 0.3"

( )

(1)

for closed cell foams, and the yield stress by

!

"

f

"

s

= A

"c

0.5#

2/ 3

+ 0.3#

( )

(2)

or

!

"

f

"

s

= A

"c

#

3/ 2

(3)

for closed and open cell foams, respectively. In Eqs. 1,

2 and 3, A

Ec

and A

"c

are coefficients to be fit to

experimental data. Figures 1 and 2 show the mechanical

properties of Table 2 plotted against relative density

and compare those data to the predictions of Eqs. 1, 2

and 3plotted for a range of values for the coefficients

A

Ec

and A

"c

. The figures demonstrate that no single

choice of the coefficients A

Ec

and A

"c

can yield accurate

predictions of the material properties of steel foams

across all manufacturing processes, and that even

within a manufacturing process, the mechanical

properties appear to depend on more than the relative

density. These comparisons demonstrate that

substantial further research is required to develop

models that can predict the mechanical properties of

steel foam produced by any of the currently available

processes, and that any such models must incorporate

mechanics of deformation beyond a characterization of

the material relative density.

4 Example application of steel foam: Kremer et al. [8]

reported success in mitigating local buckling of a thin-

walled steel tube in bending by filling the maximum

moment section of the tube with a moderate density (!

= 0.40) steel foam. The composite tube exhibited

higher peak load and more ductility than the empty

tube. Because local buckling of structural members is

essentially a manifestation of plate buckling, we have

investigated the crushing and elastic critical loads of a

steel foam plate simply supported on four edges and

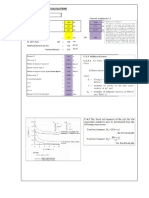

Figure 1: Comparison of predictive equations for

cellular material elastic modulus to experimental

measurements of elastic modulus for steel foams

produced by a variety of processing methods.

Experimental measurements for hollow sphere,

composite and powder metallurgy foams are shown, all

of which have closed cell morphology.

Figure 2: Comparison of predictive equations for

cellular material yield stress to experimental

measurements of compressive yield for steel foams

produced by a variety of processing methods.

loaded in pure compression. The main objective of this

preliminary study is to determine how varying the

relative density of the steel foam, while holding

constant the weight per unit area of the plate, affects the

elastic critical and crushing loads of the plate.

In order to hold the weight per unit length of the cross

section constant while reducing the relative density of

the walls (i.e. replacing the solid steel walls with steel

0 0.1 0.2 0.3 0.4 0.5 0.6

0

0.05

0.1

0.15

0.2

Youngs Modulus vs Relative Density

(with Gibson & Ashby closed!cell model)

Relative Density

N

o

r

m

a

l

i

z

e

d

Y

o

u

n

g

s

M

o

d

u

l

u

s

(

E

c

/

E

c

,

s

)

A

E

c

=1.0

A

E

c

=0.1

A

E

c

=0.55

Data

G&A max

G&A 1/2

G&A min

0 0.1 0.2 0.3 0.4 0.5 0.6

0

0.2

0.4

0.6

0.8

1

Compressive Yield Strength vs Relative Density

(with Gibson & Ashby open! and closed!cell models)

Relative Density

N

o

r

m

a

l

i

z

e

d

C

o

m

p

r

e

s

s

i

v

e

Y

i

e

l

d

S

t

r

e

n

g

t

h

(

!

c

/

!

c

,

s

)

A

!

c

=1.0

A

!

c

=0.1

A

!

c

=0.55

Composite HS

HS

Injection Mold

PM

Precursor

Closed G&A max

Closed G&A 1/2

Closed G&A min

Open G&A max

Open G&A 1/2

Open G&A min

Proceedings of 2011 NSF Engineering Research and Innovation Conference, Atlanta, Georgia Grant #1000334

foam walls), the thickness of the cross section has to be

increased.

The weight per unit area of a solid steel and

steel foam plate are

!

t

s

"

s

and

!

t

f

"

f

respectively, where

t

s

and t

s

are the solid steel and steel foam plate

thicknesses, and !

s

and !

f

are the solid steel and steel

foam densities. The constraint on the weight per unit

length of the member can then be expressed as,

!

t

f

=

t

s

"

(4)

which relates the thickness of the steel foam plate to the

thickness of the solid steel plate and the relative density

of the foam.

The material properties of the steel foam are

different from those of solid steel and depend on the

base metal properties and the relative density. Gibson

and Ashby [6] developed the expressions

!

E

f

= E

s

"

2

(5)

and

!

F

yf

= F

ys

"

3/ 2

(6)

that relate the elastic modulus and yield stress of the

foam to the relative density. Although we showed in

section 3 that equations such as these cannot predict the

mechanical properties of steel foams across a wide

variety of manufacturing processes, what will be shown

in the following calculations is that the exponent in the

expressions determines the interaction between steel

foam relative density and the crushing and elastic

critical load of the plate.

The plate we investigate has b = 92mm and

initial thickness t

s

= 1.73mm and the elastic modulus

and yield stress of the base steel are assumed to be 200

GPa and 345 MPa respectively. The material is

assumed to be perfectly plastic after yield.

The elastic critical load of the plate is

!

P

crf

=

4"

2

E

f

t

f

3

12 1#$

2

( )

b

(7)

By substituting the thickness and elastic modulus of

the steel foam plate (Eqs. 4 and 5) into Eq. 7 the elastic

critical load becomes

!

P

crf

=

4"

2

E

s

t

s

3

12 1#$

2

( )

b%

(8)

which depends inversely on the relative density, and

therefore increases when the relative density is

decreased since ! < 1 for a foam.

The crushing load of the plate is

!

P

yf

= F

yf

t

f

b (9)

which, by substitution of Eqs. 4 and 5, becomes

!

P

yf

= F

ys

t

s

b"

1/ 2

(10)

which depends on the square root of the relative density

and decreases when the relative density is decreased.

Thus, a steel foam plate would be expected to have a

higher buckling capacity and lower crushing capacity

than a solid steel plate with the same total mass,

geometry, and boundary conditions. Determining the

actual capacity of the plate requires analysis of the

postbuckling and inelastic buckling of the plate, both

topics of current investigation by the authors.

In order to further investigate the relationship

between plate properties and the crushing and elastic

critical loads, we allow the plate width and initial

thickness to vary and define a response surface P

cry

=

min(P

crf

,P

yf

), noting that this does not represent the

capacity of the plate since it does not consider

postbuckling or inelastic buckling behavior.

Figure 3 shows this response surface for the

case of variable plate width given by

!

P

cry

=

P

crf

=

3788838

b"

b < 80"

#3/ 4

P

yf

= 595b"

1/ 2

b $1.99"

#3/ 4

%

&

'

(

'

. (11)

One can observe that lowering the relative density

results in a transition from instability to crushing, and

that the value of ! at which this transition occurs

depends on the plate width.

Figure 4 shows P

cry

when the initial thickness

of the plate is allowed to vary. There is again a

transition between regimes in which the onset of elastic

stability and crushing initiate a departure from linear

response, and the curve delineating this transition

depends on the relative density. The value of the P

cry

is

given by

!

P

cry

=

P

crf

=

7986t

s

3

"

t

s

<1.99"

3/ 4

P

yf

= 31742t

s

"

1/ 2

t

s

#1.99"

3/ 4

$

%

&

'

&

(12)

Figure 3: Crushing and elastic critical response surface

for a simply supported plate loaded in pure compression

and made of steel foam with varying relative density

and width. Zones in which the response is governed by

elastic instability and crushing are indicated.

0.2

0.4

0.6

0.8

1

50

100

150

200

250

300

0

50

100

Plate Width (mm)

Relative Density

P

c

r

y

(

k

N

)

Buckling

Crushing

Proceedings of 2011 NSF Engineering Research and Innovation Conference, Atlanta, Georgia Grant #1000334

Figure 4: Crushing and elastic critical response surface

for a simply supported plate loaded in pure compression

and made of steel foam with varying relative density

and initial thickness. Zones in which the response is

governed by elastic instability and crushing are

indicated.

5 Conclusions: A review of the published literature on

processing and material properties of steel foams shows

that a variety of methods for fabricating steel foams

have been developed and implemented at the laboratory

scale over the past 10-15 years. Of these methods,

powder metallurgy, sintering of hollow spheres, and

composite powder metallurgy hollow sphere

processes appear to be the most promising for yielding

materials of potential use in civil structural applications

because of their relatively simple manufacturing

processes, simple cell morphology, and potential to

deliver high relative densities. Steel foams with a very

wide range of material properties have been

demonstrated, and these properties do not appear to

correlate well with predictive equations that treat only

the relative density as the material parameter. Finally,

we have evaluated the loads at which a simply

supported plate loaded in compression will crush and

suffer elastic instability when made of steel foam, and

have evaluated the dependence of those loads on the

plate thickness and width, and relative density of the

steel foam. We have found that a steel foam plate will

tend to experience elastic instability at a higher load

and crushing at a lower load than a solid steel plate of

equivalent mass and subject to the same loading.

6 Acknowledgements: This work was supported by the

United States National Science Foundation through

grant #1000334.

7. References:

[1] Adler J, Standke G, and Stephani G (2004).

Sintered open-celled metal foams made by replication

method - manufacturing and properties on example of

316L stainless steel foams. Proceedings of the

Symposium on Cellular Metals and Polymers (CMaP).

Deutsche Forschungsgemeinschaft (DFG), 12-14

October 2004, Frth, Germany, p.89-92.

[3] Angel S, Bleck W, and Scholz P-F (2004).

SlipReactionFoamSintering (SRFS) - process:

production, parameters, characterisation. Proceedings

of the Symposium on Cellular Metals and Polymers

(CMaP). Deutsche Forschungsgemeinschaft (DFG), 12-

14 October 2004, Frth, Germany.

[3] Ashby M, Evans A, Fleck N, Gibson L, Hutchinson

J, Wadley H. (2000) Metal Foams: A Design Guide.

Butterworth-Heinemann.

[4] Brown JA, Vendra LJ, and Rabiei A (2010).

Bending properties of Al-steel and steel-steel

composite metal foams. Metallurgical and Materials

Transactions A. Online:1 July 2010.

[5] Friedl O, Motz C, Peterlik H, Puchegger S, Reger

N, and Pippan R (2007). Experimental investigation of

mechanical properties of metallic hollow sphere

structures. Metallurgical and Materials Transactions B.

39(1):135-146.

[6] Gibson L, Ashby M. (1999) Cellular solids:

Structure and properties-second edition. Cambridge

University Press.

[7] Gong L, Kyriakides S, Jang W-Y. (2005).

Compressive response of open-cell foams. Part I.

Morphology and elastic properties. International

Journal of Solids & Structures 42, 13551379.

[8] Kremer K, Liszkiewicz A, Adkins J. (2004)

Development of steel foam materials and structures.

Tech. rep., Fraunhofer USA Delaware Center for

Manufacturing and Advanced Materials, 9 Innovation

Way Newark, DE 19711, US.

[9] Muriel J, Sanchez Roa A, Barona Mercado W, and

Sanchez Sthepa H (2009). Steel and gray iron foam by

powder metallurgical synthesis. Suplemento de la

Revista Latinoamericana de Metalurgia y Materiales.

2009. S1(4):1435-1440.

[10] Neville BP and Rabiei A (2008). Composite

metal foams processed through powder metallurgy.

Materials and Design 29:388-396.

[11] Park C and Nutt SR (2000). PM synthesis and

properties of steel foams. Materials Science and

Engineering A. A288:111-118.

[12] Park C and Nutt SR (2001). Anisotropy and strain

localization in steel foam. Materials Science and

Engineering A. A299:68-74.

[13] Park C and Nutt SR (2002). Strain rate sensitivity

and defects in steel foam. Materials Science and

Engineering A. A323:358-366.

[14] Tuchinsky L (2005). Novel fabrication

technology for metal foams. Journal of Advanced

Materials. 37(3):60-65.

0.2

0.4

0.6

0.8

1

1

1.5

2

2.5

0

50

100

Plate Thickness (mm)

Relative Density

P

c

r

y

(

k

N

)

Buckling

Crushing

Proceedings of 2011 NSF Engineering Research and Innovation Conference, Atlanta, Georgia Grant #1000334

[15] Rabiei A and Vendra L J (2009). A comparison

of composite metal foam's properties and other

comparable metal foams. Materials Letters 63:533-

536.

[16] Verdooren A, Chan HM, Grenestedt JL, Harmer

MP, and Caram HS (2005). Fabrication of low density

ferrous metallic foams by reduction of ceramic foam

precursors. Journal of the Materials Science. 40:4333-

4339.

[17] Verdooren A, Chan HM, Grenestedt JL, Harmer

MP, and Caram HS (2005). Fabrication of low density

ferrous metallic foams by reduction of chemically

bonded ceramic foams. Journal of the American

Ceramic Society. 89(10):3101-3106.

[18] Weise J, Beltrame Derner Silva G, and Salk N

(2010). Production and properties of syntactic steel

and iron foams with micro glass bubbles. In

Proceedings of MetFoam 2009, Bratislava, Slovakia.

You might also like

- Modelling of Metal Perforated Sheet FacadeDocument41 pagesModelling of Metal Perforated Sheet FacadeMoța FlorinNo ratings yet

- Modular Construction Barge AnalysisDocument6 pagesModular Construction Barge AnalysisBoy FirdausNo ratings yet

- Pile Design Cal - Rev-1Document9 pagesPile Design Cal - Rev-1Nitin SakpalNo ratings yet

- Definition For SpringDocument18 pagesDefinition For SpringamanpurushothNo ratings yet

- Guide to Installing Solar PV Systems in SingaporeDocument64 pagesGuide to Installing Solar PV Systems in SingaporeFrancisco José Murias Dominguez100% (2)

- Design of Mat FoundationsDocument32 pagesDesign of Mat Foundationssalahaddinsharif100% (2)

- Plinth Beam Design CalculationDocument4 pagesPlinth Beam Design CalculationVinod NairNo ratings yet

- Gardner2005 TheuseofstainlesssteelinstructuresDocument39 pagesGardner2005 Theuseofstainlesssteelinstructuresherdi sutanto adigunaNo ratings yet

- Application of Stainless SteelDocument13 pagesApplication of Stainless Steelsweety1188No ratings yet

- ASM-Powder Metallurgy Stainless Steels - Processing, Microstructures, and PropertiesDocument227 pagesASM-Powder Metallurgy Stainless Steels - Processing, Microstructures, and PropertiesAldin Bubic100% (2)

- Wear Analysis of Chromium Carbide Coating On A516 WCB Steel by Plasma Spraying TechniqueDocument12 pagesWear Analysis of Chromium Carbide Coating On A516 WCB Steel by Plasma Spraying TechniqueIJRASETPublicationsNo ratings yet

- Sandwich PanelsDocument25 pagesSandwich PanelsGajaraj GajapathiNo ratings yet

- An Introduction To Failure Analysis For Metallurgical EngineersDocument20 pagesAn Introduction To Failure Analysis For Metallurgical EngineersbluecreteNo ratings yet

- THIEL, A. (2013) ULS and SLS Design of CLT and Its Implementation in The CLTdesignerDocument39 pagesTHIEL, A. (2013) ULS and SLS Design of CLT and Its Implementation in The CLTdesignerRamon Vilela100% (1)

- Modern High Strength Niobium Microallyed Structural SteelsDocument26 pagesModern High Strength Niobium Microallyed Structural SteelsimetallurgyNo ratings yet

- SM12 2014 PDFDocument60 pagesSM12 2014 PDFm_irfaanbuttNo ratings yet

- Report 4 Group 4 Steel SlagDocument11 pagesReport 4 Group 4 Steel SlagAshwini SanapNo ratings yet

- Gardner2005 TheuseofstainlesssteelinstructuresDocument39 pagesGardner2005 TheuseofstainlesssteelinstructuresthisaintwapNo ratings yet

- The Use of Stainless Steel in Structures: Progress in Structural Engineering and Materials April 2005Document39 pagesThe Use of Stainless Steel in Structures: Progress in Structural Engineering and Materials April 2005RatanRatuNo ratings yet

- Ductile Iron Research PapersDocument8 pagesDuctile Iron Research Papersxkcwaaqlg100% (1)

- CE032 FINAL ReformattedDocument11 pagesCE032 FINAL ReformattedElakkiya KarthicNo ratings yet

- Latvia CivilEngineering2013Vol4PartI 53-59Document7 pagesLatvia CivilEngineering2013Vol4PartI 53-59boim1234No ratings yet

- CONBUILDMATDocument8 pagesCONBUILDMATsaeid59No ratings yet

- 8 P 4 R NZBCBMGDV Nobp 3 HJ QHNIQ8 XBpru WFX Myr 0 ZIDocument3 pages8 P 4 R NZBCBMGDV Nobp 3 HJ QHNIQ8 XBpru WFX Myr 0 ZImoonstarNo ratings yet

- Material Properties and Compressive Local BucklingDocument37 pagesMaterial Properties and Compressive Local BucklingvardhangargNo ratings yet

- Research Paper On SteelDocument4 pagesResearch Paper On Steelfvf66j19No ratings yet

- 2.aluminium Metal Foam Production Methods, Properties andDocument7 pages2.aluminium Metal Foam Production Methods, Properties andShinchan NoharaNo ratings yet

- A Review On Prodution of Aluminium Metal Foams PDFDocument13 pagesA Review On Prodution of Aluminium Metal Foams PDFSaliq ShahNo ratings yet

- Thesis On Steel Fibre Reinforced ConcreteDocument8 pagesThesis On Steel Fibre Reinforced Concretedenisemillerdesmoines100% (2)

- Friction Stir Welding of Structural Steel S235 and S355Document7 pagesFriction Stir Welding of Structural Steel S235 and S355Ramona SzaboNo ratings yet

- Steelfoam Review JCSR 14Document31 pagesSteelfoam Review JCSR 14Samuel ArelianoNo ratings yet

- Experimental and Analytical Study of Cold Formed Steel SectionsDocument44 pagesExperimental and Analytical Study of Cold Formed Steel SectionsAmit SonavaneNo ratings yet

- Microstructure and Mechanical Properties of Powder Metallurgy 2024 Aluminum Alloy During Cold RollingDocument12 pagesMicrostructure and Mechanical Properties of Powder Metallurgy 2024 Aluminum Alloy During Cold Rollingjesus herazoNo ratings yet

- Mechanical Properties of Reinforcing Steel Bar (Deformed/Ribbed) With Different Degree of CorrosionDocument32 pagesMechanical Properties of Reinforcing Steel Bar (Deformed/Ribbed) With Different Degree of CorrosioncholoNo ratings yet

- Investigation Into The Strength Characteristics of Reinforcement Steel Rods in Sokoto Market, Sokoto State NigeriaDocument4 pagesInvestigation Into The Strength Characteristics of Reinforcement Steel Rods in Sokoto Market, Sokoto State NigeriaInternational Journal of Latest Research in Engineering and TechnologyNo ratings yet

- 1ME512-0825Pre Strain CorNDocument16 pages1ME512-0825Pre Strain CorNEduardo PazNo ratings yet

- Accepted Manuscript: ApsuscDocument35 pagesAccepted Manuscript: ApsuscXtem AlbNo ratings yet

- Aluminum ThesisDocument8 pagesAluminum Thesisalyssaschultecolumbia100% (2)

- Mechanical_properties_and_reinforced_mechanism_of_Document9 pagesMechanical_properties_and_reinforced_mechanism_of_nguyentbilienNo ratings yet

- 3.design and Weight Optimization of Lift Base PlateDocument40 pages3.design and Weight Optimization of Lift Base Plateumesh KudalkarNo ratings yet

- ASTM Paper Material Science and ManagementDocument19 pagesASTM Paper Material Science and ManagementMerviNo ratings yet

- Review Article: Review On Cold-Formed Steel ConnectionsDocument12 pagesReview Article: Review On Cold-Formed Steel ConnectionsRakeshNo ratings yet

- Farayibi2020 Article HardCladdingBySupersolidusLiquDocument19 pagesFarayibi2020 Article HardCladdingBySupersolidusLiqugau3koNo ratings yet

- Ballistic Impact Behavior of Alloys Against Armor Piercing ProjectilesDocument8 pagesBallistic Impact Behavior of Alloys Against Armor Piercing Projectilesibrahim sugarNo ratings yet

- Perforation of AA5083-H116 Aluminium PlatesDocument18 pagesPerforation of AA5083-H116 Aluminium PlatesLev LevinNo ratings yet

- Abaqus AnalysisDocument12 pagesAbaqus AnalysisMohan BhalmeNo ratings yet

- Materials: Ffect of Welding Speed and Post Quenching On TheDocument16 pagesMaterials: Ffect of Welding Speed and Post Quenching On TheZamZamNo ratings yet

- Structural Performance of Additive Manufactured MeDocument53 pagesStructural Performance of Additive Manufactured MebobNo ratings yet

- Journals For Springs ProjectsDocument6 pagesJournals For Springs ProjectsSathya ThyaguNo ratings yet

- Axial and Flexural Performance of Adhesive Connection On Cold-Formed Steel StructuresDocument10 pagesAxial and Flexural Performance of Adhesive Connection On Cold-Formed Steel Structurespiscesas45No ratings yet

- Fadhilah AIP 1.5011493Document7 pagesFadhilah AIP 1.5011493Ehsan WasimNo ratings yet

- Physical Metallurgy of Modern High Strenght Steel Sheets PDFDocument13 pagesPhysical Metallurgy of Modern High Strenght Steel Sheets PDFJose Merced Martinez VazquezNo ratings yet

- Polyolefin Fiber-Reinforced Concrete Enhanced With Steel-Hooked FibersDocument10 pagesPolyolefin Fiber-Reinforced Concrete Enhanced With Steel-Hooked FibersCuriosoNo ratings yet

- A Comprehensive Review On Pre and Post-Forming Evaluation of Aluminum To Steel BlanksDocument22 pagesA Comprehensive Review On Pre and Post-Forming Evaluation of Aluminum To Steel Blanksjose ramirez cruzNo ratings yet

- Investigation of Weld Defects in Friction-Stir Welding and Fusion Welding of Aluminium AlloysDocument10 pagesInvestigation of Weld Defects in Friction-Stir Welding and Fusion Welding of Aluminium AlloysV.v. TaguisNo ratings yet

- 1.metallic StructureDocument34 pages1.metallic StructureSaid Mansour MohamedNo ratings yet

- Cold Work EmbrittlementDocument2 pagesCold Work EmbrittlementAgustine SetiawanNo ratings yet

- Cladding of Low-Carbon Steel To Austenitic Stainless Steel by Hot-Roll Bonding: Microstructure and Mechanical Properties..Document13 pagesCladding of Low-Carbon Steel To Austenitic Stainless Steel by Hot-Roll Bonding: Microstructure and Mechanical Properties..Rami GhorbelNo ratings yet

- Rolling Contact Fatigue Resistance of Hard Coatings On Bearing SteelsDocument24 pagesRolling Contact Fatigue Resistance of Hard Coatings On Bearing Steelsmans2014No ratings yet

- Innovation in Composite ConstructionDocument6 pagesInnovation in Composite ConstructionnicholasNo ratings yet

- Mousavi 2017Document21 pagesMousavi 2017PennarasiNo ratings yet

- Chapter Five Materials and Fabrication SelectionDocument11 pagesChapter Five Materials and Fabrication SelectionKom MieNo ratings yet

- Steels in Additive Manufacturing: A Review of Their Microstructure and PropertiesDocument54 pagesSteels in Additive Manufacturing: A Review of Their Microstructure and PropertiesAdéliaSouzaNo ratings yet

- Repair and Reinforcement of Historic Timber Structures With Stainless Steel-A ReviewDocument23 pagesRepair and Reinforcement of Historic Timber Structures With Stainless Steel-A ReviewAtluri PrasannaNo ratings yet

- Advantages and Disadvantages of Structural Steel StructuresDocument13 pagesAdvantages and Disadvantages of Structural Steel StructuresMangoTangoNo ratings yet

- Abstract Exp1Document5 pagesAbstract Exp1wan nur mursyidahNo ratings yet

- Variability of Chemical in BarDocument12 pagesVariability of Chemical in BarManish AryalNo ratings yet

- Investigation of Mechanical Properties of Ribbed Reinforcement Steel Bars: A Case Study On Ethiopian Construction IndustryDocument12 pagesInvestigation of Mechanical Properties of Ribbed Reinforcement Steel Bars: A Case Study On Ethiopian Construction IndustrymichaelNo ratings yet

- AMP Vol 171 - N°09 - September 2013Document89 pagesAMP Vol 171 - N°09 - September 2013bluecreteNo ratings yet

- Engineering Failure Analysis: E. Mohammadi Zahrani, A. Saatchi, A. AlfantaziDocument8 pagesEngineering Failure Analysis: E. Mohammadi Zahrani, A. Saatchi, A. AlfantazibluecreteNo ratings yet

- AMP Vol 172 - N°06 - June 2014Document69 pagesAMP Vol 172 - N°06 - June 2014bluecreteNo ratings yet

- AMP Vol 171 - N°09 - September 2013Document89 pagesAMP Vol 171 - N°09 - September 2013bluecreteNo ratings yet

- Concurso ASM Metalografia 2014Document5 pagesConcurso ASM Metalografia 2014bluecreteNo ratings yet

- Identified, Risks - 2009 - Scientific Committee On Emerging and Newly Identified Health Risks SCENIHR Risk Assessment of Products of NanDocument71 pagesIdentified, Risks - 2009 - Scientific Committee On Emerging and Newly Identified Health Risks SCENIHR Risk Assessment of Products of NanRenato SchmidtNo ratings yet

- Metkon Sample PreparationDocument83 pagesMetkon Sample PreparationbluecreteNo ratings yet

- AMP Vol 171 - N°08 - August 2013Document69 pagesAMP Vol 171 - N°08 - August 2013bluecreteNo ratings yet

- AMP Vol 174 - N°07 - Jul-Aug 2016Document66 pagesAMP Vol 174 - N°07 - Jul-Aug 2016bluecreteNo ratings yet

- IrisDocument5 pagesIrisbluecreteNo ratings yet

- Team Eds HelpDocument493 pagesTeam Eds HelpbluecreteNo ratings yet

- Introduction To Fundamentals of Modeling For Metals ProcessingDocument4 pagesIntroduction To Fundamentals of Modeling For Metals ProcessingbluecreteNo ratings yet

- Manual SemDocument224 pagesManual Sembluecrete100% (1)

- Advance Your Career in MetallographyDocument3 pagesAdvance Your Career in MetallographybluecreteNo ratings yet

- 1 s2.0 S1350630713003658 MainDocument26 pages1 s2.0 S1350630713003658 MainbluecreteNo ratings yet

- Corrosion Study of Metallic Biomaterials in Simulated Body FluidDocument10 pagesCorrosion Study of Metallic Biomaterials in Simulated Body FluidbluecreteNo ratings yet

- Thermal Applications of Open Cell Metal FoamsDocument25 pagesThermal Applications of Open Cell Metal FoamsSri Ram VikasNo ratings yet

- Noise Sponge - Dr. Ajay K. AgrawalDocument2 pagesNoise Sponge - Dr. Ajay K. AgrawalbluecreteNo ratings yet

- Corrosion Cost JapanDocument35 pagesCorrosion Cost JapanSudhir SharmaNo ratings yet

- Gift From The Aluminum GodDocument38 pagesGift From The Aluminum GodStephane CaronNo ratings yet

- Crystal-Plasticity Fundamentals: Henry R. Piehler, Carnegie Mellon UniversityDocument7 pagesCrystal-Plasticity Fundamentals: Henry R. Piehler, Carnegie Mellon UniversitybluecreteNo ratings yet

- MSDS - Galvanized SteelDocument6 pagesMSDS - Galvanized SteelbluecreteNo ratings yet

- Corrosion High Temp Alloys - ReportDocument19 pagesCorrosion High Temp Alloys - ReportbluecreteNo ratings yet

- The Bay Phenomenon in Steels With Reasonably Strong Carbide FormersDocument12 pagesThe Bay Phenomenon in Steels With Reasonably Strong Carbide FormersbluecreteNo ratings yet

- Shot PeeningDocument3 pagesShot PeeningbluecreteNo ratings yet

- S-51-63-Eng 061101Document8 pagesS-51-63-Eng 061101bluecreteNo ratings yet

- Shot PeeningDocument3 pagesShot PeeningbluecreteNo ratings yet

- Typical Uses of MPC PDFDocument14 pagesTypical Uses of MPC PDFManoj KumarNo ratings yet

- Innate™ Precision Packaging ResinsDocument5 pagesInnate™ Precision Packaging ResinsalfredoNo ratings yet

- Analysis and Design of RCC Bridge and Box CulvertDocument114 pagesAnalysis and Design of RCC Bridge and Box CulvertimamtaNo ratings yet

- EME Important QuestionsDocument4 pagesEME Important QuestionsChaitanya YengeNo ratings yet

- Strength of Material Formulas Short NoteDocument19 pagesStrength of Material Formulas Short NotePankaj pacharNo ratings yet

- KellyandCalabrese v3 CMJDocument100 pagesKellyandCalabrese v3 CMJdakar84No ratings yet

- Finite-Element Plasticity and Metalforming AnalysisDocument323 pagesFinite-Element Plasticity and Metalforming AnalysisHassan DM100% (1)

- PDFDocument25 pagesPDFMuddu AlaparthiNo ratings yet

- Implant Materials - Wrought 18 - Chromiickel - 2.5 - Molybdenum Stainless Steel.5 - Molybdenum Stainless SteelDocument32 pagesImplant Materials - Wrought 18 - Chromiickel - 2.5 - Molybdenum Stainless Steel.5 - Molybdenum Stainless SteelGagan BajpaiNo ratings yet

- Release Notes Sap 2000 V 1911Document10 pagesRelease Notes Sap 2000 V 1911TarmanNo ratings yet

- Parametric Study On Underpass RCC BridgeDocument7 pagesParametric Study On Underpass RCC BridgePramod SinghNo ratings yet

- Efficient FE Model ConnectionsDocument24 pagesEfficient FE Model Connectionsjejep4No ratings yet

- AASHTO LRFD 2012 BridgeDesignSpecifications 6th Ed (US)Document33 pagesAASHTO LRFD 2012 BridgeDesignSpecifications 6th Ed (US)Joel H A VargasNo ratings yet

- Mom LabDocument8 pagesMom LabTahseen QashouNo ratings yet

- Astm d3044 PDFDocument3 pagesAstm d3044 PDFJose Manuel GaliciaNo ratings yet

- T 321-07 2011Document11 pagesT 321-07 2011susanaleNo ratings yet

- Mechanical Vibration 2 Marks QuestionsDocument5 pagesMechanical Vibration 2 Marks Questionsakvssakthivel100% (1)

- Mechanical Properties and DefintionDocument29 pagesMechanical Properties and DefintionSiva SundaramNo ratings yet

- Basics of Multi-Degree Freedom SystemsDocument5 pagesBasics of Multi-Degree Freedom SystemsKarnalPreethNo ratings yet

- S2-Finite Element Analysis For Geomechanics (516) .Text - MarkedDocument2 pagesS2-Finite Element Analysis For Geomechanics (516) .Text - MarkedHari RamNo ratings yet

- TTU Faculty of Engineering Torsion Test ReportDocument6 pagesTTU Faculty of Engineering Torsion Test ReportG. Dancer GhNo ratings yet

- Mechanical Properties of Materials: Definition, Testing and ApplicationDocument11 pagesMechanical Properties of Materials: Definition, Testing and ApplicationWint Thu HtunNo ratings yet