Professional Documents

Culture Documents

Company Profile Vke

Uploaded by

Bhadresh ShahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Company Profile Vke

Uploaded by

Bhadresh ShahCopyright:

Available Formats

V. K.

ENGINEERS

Company Profile

PATEL COMPOUND, Nr. 1, RAMDEV ESTATE, PH-IV, UMIYA DINNING HALL LANE, GIDC,

ATVA, AHMEDABAD -382445, GUJARAT, INDIA

PHONE: 91-79-25841211 MOBILE: 09426514026, 09426039618

E-MAIL: vksahd@gmail.com bhadreshah@gmail.com

1

Company Mission

V. K. Engineers will provide safe, innovative, state of the art products and

services:

VK is committed to being the "Supplier of Choice" through product and

service excellence. Our emphasis is on being a responsible, innovative

business partner providing value-added services to our customers and

suppliers.

Creating and maintaining an environment which encourages new

thinking and innovation on the part of all employees by encouraging

involvement, teamwork and the development of our people.

Assuring that all orders delivered to customers on time to provide

most value at the lowest total cost in the least amount of time.

Providing a safe, clean and pleasant work environment where

individual employees are challenged to contribute to the achievement

of team goals while growing professionally and personally.

Company Profile

V. K. Engineers is engaged in manufacturing parts of Material handling

equipment as per the customers design and supplying the same since 2007

We are experts in manufacturing mainly various parts of EOT Crane &

medium to Heavy fabrication as per customers design.

VK has a reputation for excellence in service, price and financial stability. We

take pride in our fair and ethical business practices, which has been a

significant factor in our years of success. Our employees are creative,

flexible, energetic, and our greatest resource.

Our workshop is equipped having 56 KW power and equipped with

conventional machinery along with CNC turning centers & VMC

We possess inspection facility for dimensional checking by gauges properly

calibrated at regular intervals. We have a full range of measuring

equipments.

2

Vision

Achieve a profitable, growth-oriented organization that satisfies its

employees, customers and community through continuous

improvement.

Quality Policy

V. K. Engineers is engaged in the business of Manufacture & Marketing of parts

of material handling equipments and project jobs as per customers requirements

Our Commitment is Total Customer Satisfaction. We shall achieve by,

Continually try to maintain and improve quality standard

Strictly adhering to the Quality Management System for our operation and

monitoring the same periodically for its effectiveness

Delivering right quality of products at right time

Continual Process improvement leading to less rejection and rework

Create a team of trained committed people

We ensure that our services meet the customer requirements and comply

with applicable statutory and regulatory requirements.

3

Values and Strategy

Fundamental to long-term leadership are these values:

SAFETY is the top most priority at VK.

TEAMWORK AND COOPERATION is necessary for our success. We expect

the participation and involvement of everyone.

COMMUNICATION: We require communication to be timely and thorough.

OPENNESS AND RESPECT is imperative. We must be straightforward with

each other and with our customers, suppliers and communities in order to

achieve long-term success.

CONTINUOUS LEARNING is required to meet challenges of the future. We

will provide learning opportunities and recognize the productive use of new

skills.

INDIVIDUAL CONTRIBUTION is a must. We expect individuals to strive for

excellence in job performance and seek new challenges.

CONTINUOUS IMPROVEMENT is everyone's responsibility. As an industry

leader, we must set new standards of excellence in everything we do.

ENTRUSTING authority and encouraging everyone to take responsibility as

if they are owners of V. K. ENGG will maximize our potential.

TIMELY ACTIONS performed consistently are critical to maintain our

leadership in a fast-paced industry.

Integrity We respect and value people by treating others, as we want to be

treated. We are honest by representing our intentions and ourselves

truthfully.

Innovation We learn and create by understanding that impatience with the

status quo drives business and personal growth.

4

People

Vyomesh Shah (BE Mech, ME Prod.)

The proprietor, Mr. Vyomesh Shah is BE (Mechanical), ME (Production); has

vast experience (35 years) in the engineering field. He was director in Mipa

Electronics & Engineers, Bombay; have induction furnace & machine &

testing shop for boiler feed pumps & process pumps till 1986, He was

director in Shah Controls & Valves P. Ltd., Vatva, Ahmedabad; making boiler

feed pumps till 1998. Since 1986, handling manufacturing of crane parts with

association with M/s. K. V. Engineers. He was director in Kunal Pumps P.Ltd.,

Vatva an ancillary of M/s. Kirloskar Brothers Ltd., manufacturing submersible

pumps for M/s KBL till 2006. He was advisor for M/s KBL in casting, M/s.

Torrent Pharma Ltd., Vatva for pumping solutions, M/s. Sukan equipments

P.Ltd., Vatva for technical consultancy & M/s Alta Plast, Bapunagar,

Ahmedabad for technical & BIS consultancy. Maximum of his tenure is spent

as director, production.

Bhadresh Shah (BE Plastic Tech)

The Marketing & Purchase executive has vast experience in the defined field. Started his

carier with Indomax Machinery P.Ltd., Chhatral & then with The Supreme Industries Ltd.,

Somshiva Impex Ltd., subsidiary of Sintex Industries Ltd., & New Age Company L.L.C,

Abudhabi.

Company Details:

Company Type: Proprietorship Firm

Proprietor: Mr. Vyomesh Shah (BE (Mech), ME (Prod))

Contact No: 09426514026 E-Mail: vksahd@gmail.com

Marketing: Mr. Bhadresh Shah (BE (PT))

Contact No: 09426039618 E-Mail: bhadreshah@gmail.com

No. of workers: 12

D & B Credit rating agency reg. No. (D-U-N-S No): 91-545-3501

ISO: ISC: 9001-2008

5

List of Products

Wheel Assembly with L-Block consists of:

Forged or FLP (PHBr) Wheel

Driving Axle (Shaft)

Trailing (Non driving) Axle (Shaft)

L-Block (Bearing Housing)

Key L-block (Wheel Centre Distance Pad)

Bearing Cover

Spacer (Sleeve)

Open Reduction type Wheel Assembly consists of:

Forged or FLP (Ph Br/Al Bronze or Gun metal) Teethed & non

teethed wheel

Axle

Sleeve

End carriage pad

Gear Pinion

Bearing Cover

Brake Drum Coupling

Gear Couplings

GR PR Wheels

Coil winder Assembly

Conveyors

Fabrication / Fabricated Assembly

Engineering parts as per clients design & MOC

6

List of Machinery

Sr.

No.

Machine Make Total

Machines

Workshop Machinery

1 Double Head CNC Lathe 1

2 450 Dia. CNC Turning Centre 1

3 250 Dia. CNC Turning Centre 1

4 600 x 450 x 400 4 Axis VMC 1

5 250 Dia X 800 CNC Turning Centre, 1

6 Heavy Duty 700 mm Lathe Machine 1

7 Lathe Machine 8 1

8 Lathe Machine 4 1

9 12 stroke Shaping machine 1

10 7 Hacksaw Machine 1

11 8 Hacksaw Machine 1

12 Radial Drill Machine 1 1

13 Drill Machine 1

14 100 ton Hydraulic Press 1

15 Bench Grinder 2800 RPM Make: Manu 1

16 Air Compressor 1

17 250 A Welding machine 1

18

1000 Dia. X 1150 mm CNC Turning Centre

1

19

KESUNBERG Welding Generator

1

20

Safex 1 Ton Crane

1

___________________________________________________________________________________________________________

ADDRESS:PATELCOMPOUND,Nr.RITESHEQUIPMENTS,PHIV,UMIYADINNINGHALL

LANE,GIDC,VATVA,AHMEDABAD382445,GUJARAT,INDIA

PHONE:917925841211 MOBILE:09426514026,09426039618

EMAIL:vksahd@gmail.com bhadreshah@gmail.com

7

Major Production Equipments- Details

Machine / Equipment Major Specification Quantity

Zenith Make Taurus TTC-4

CNC Turning Centre

Max. Turning :450mm

Max. Turn Length:400mm

Spindle nose: A8

Spindle Power:15KW

Spindle Spped:125-1200rpm

Tool Turret: BTP100

CNC System: Fanuc O i Mate TC

30 Slant Bed CNC Turning Centre with AC Servo Drives

01 No

Zenith Make Taurus TTC-2.5

CNC Turning Centre

Max. Turning :300mm

Max. Turn Length:410mm

Spindle nose: A6

Spindle Power:7.5KW

Spindle Spped:200-2000rpm

Tool Turret: BTP80

CNC System: Fanuc O i Mate TC

30 Slant Bed CNC Turning Centre with AC Servo Drives

01 No

Zenith Make Taurus TTC-2.5

x 2 CNC Turning Centre

Twin Head, Single Control

Max. Turning :300mm

Max. Turn Length:410mm

Spindle nose: A6

Spindle Power:7.5KW

Spindle Spped:200-2000rpm

Tool Turret: BTP80

CNC System: Fanuc O i Mate TC

Flat Bed CNC Turning Centre with AC Servo Drives

01 No

Zenith Make Taurus VMC

machine

AXES TRAVELS:X Axis mm 600

Y Axis mm 400

Z Axis mm 450

Spindle Nose ISO 40

Spindle Power KW 7 / 9

Spindle Speed rpm 200-2500

CNC System: Siemens 802-D

01 No

Zenith Make Taurus TTC-2.5

CNC Turning Centre

Max. Turning :300mm

Max. Turn Length:820mm

Spindle nose: A6

Spindle Power:7.5KW

Spindle Spped:200-2000rpm

Tool Turret: BTP80

CNC System: Siemens 802C

Flat Bed CNC Turning Centre with AC Servo Drives

01 No

Zenith Make Taurus TTC10

CNC Turning Centre

Max. Turning :1000mm

Max. Turn Length:1050mm

Spindle nose: Threaded

Spindle Power:15 KW

Spindle Spped:60-500rpm

Tool Turret: BTP100

CNC System: Fanuc O i Mate TC

Flat Bed CNC Turning Centre with AC Servo Drives

01 No

Batala make 8 Heavy Duty Conventional Lathe with Max. Turning : 900mm & Max 01 No

8

Lathe Turn Length between centre :1200mm, 5HP motor

Rajkot make 4 medium duty

Lathe

Conventional lathe 01 No

Richa make Radial Drill 1 02 No

Butbhavani make Compressor 3HP 02 No

Hack saw machines 7 & 8 02 No

Tool & cutter grinder 01 No

Shaping machine 12 01 No

CMT 6 Heavy duty lathe Conventional Lathe 02 No

Drill Jig & Fixture For bearing cover & L-block As require

MAJOR TESTING & INSPECTION EQUIPMENT

Machine / Equipment Major Specification

Quantity

Forbes make outside micro meter 0-25 (L.C-0.01)

25-50 (L.C.-0.01)

50-75 (L.C.-0.01)

75-100 (L.C-0.01)

100-125 (L.C-0.01)

125-150 (L.C-0.01)

150-175 (L.C-0.01)

175-200 (L.C-0.01)

200-300 (L.C-0.01)

01 No

02 No

01 No

01 No

01 No

01 No

01 No

01 No

01 No

Forbes Make Bore Gauge

Mitutoyo Make

Mitutoyo Make

Precision Make

Precision Make

Forbes Make

18-35

0-3 (dial indicator type)

50-150

0-10 (dial indicator type)

50-150

0-10 (dial indicator type)

160-250

0-3 (dial indicator type)

0-300

01 No each

Forbes Make Vernier Calipers 0-180

0-300

0-600

01 No

06 No

01 No

Forbes Make deep Gauge 0-180 01 No

Degree Protector 01 No

Radius Gauge 02 No

Thread Gauge 01 No

Snap Gauges (k6)

with Machine & finish size ref.

35, 40 , 45, 50, 70, 80, 90

01 No Each

V.K.ENGINEERS

PATELCOMPOUND,NR.1,RAMDEVESTATE,PHIV,UMIYADINNINGHALLLANE,GIDC,VATVA,

AHMEDABAD382445,GUJARAT,INDIA

Mob:09426039618/09426514026

EMAIL:bhadreshah@gmail.com vksahd@gmail.com

9

SOME OF OUR VALUED CLEINTS

SAFEX INDUSTRIES LTD.

SAFEX ELECTROMECH P. LTD.

SAFEX ENERGY P.LT D.

DHIMAN INDUSTRIES AND FABRICATORS P .LTD,

BRADY & MORISS LTD.,

VISHWA INDUSTRIES

KRISHNA TECH REVOL P. LTD.

DNP INFRASTRUCTURES P. LTD.

SUKAN EQUIPMENTS P. LTD.

JAIKVIN ENTERPRISE

MANU DRIVES & CONTROLS P. LTD.

JAPS PROJECTS

VINAY CRANES P LTD. (HYDRABAD)

JYOTI LTD (VADODARA)

LAXCON STEELS LTD.,

V.K.ENGINEERS

PATELCOMPOUND,NR.1,RAMDEVESTATE,PHIV,UMIYADINNINGHALLLANE,GIDC,VATVA,

AHMEDABAD382445,GUJARAT,INDIA

Mob:09426039618/09426514026

EMAIL:bhadreshah@gmail.com vksahd@gmail.com

10

11

12

13

14

15

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Pipe Wall Thickness Under External PressureDocument1 pagePipe Wall Thickness Under External PressureAnonymous DJrec2No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- ORGANIZING NURSING SERVICES FOR PATIENT CAREDocument28 pagesORGANIZING NURSING SERVICES FOR PATIENT CAREAnusha VergheseNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Crane Design Basics Webpage Provides IntroductionDocument13 pagesCrane Design Basics Webpage Provides IntroductionAnandh PsNo ratings yet

- Risk Governance Checklist v1.0 2aug16Document4 pagesRisk Governance Checklist v1.0 2aug16Mohammed OsmanNo ratings yet

- Hoist Design Procedure For EOT Crane - Tech ExpertDocument40 pagesHoist Design Procedure For EOT Crane - Tech ExpertBhadresh Shah100% (1)

- Curves in Relation To Wheel BaseDocument16 pagesCurves in Relation To Wheel BaseBhadresh ShahNo ratings yet

- Crane Girder Design ProcedureDocument18 pagesCrane Girder Design ProcedureBhadresh Shah0% (1)

- EOT CraneDocument84 pagesEOT CraneSambhav Poddar80% (5)

- Comparison of GradesDocument4 pagesComparison of GradesSourav RobinNo ratings yet

- PMP Simulation Exam Prep: Key Steps for Handling Project IssuesDocument25 pagesPMP Simulation Exam Prep: Key Steps for Handling Project IssuesJocelyn TaguibaoNo ratings yet

- Guidelines On Water ProofingDocument88 pagesGuidelines On Water Proofingkishor150688No ratings yet

- Trends and Issues Educational LeadersDocument5 pagesTrends and Issues Educational LeadersNathaniel LepasanaNo ratings yet

- Spherical Roller Bearing SKF CatlougeDocument72 pagesSpherical Roller Bearing SKF Catlougemrkadu_61No ratings yet

- Press Fit Pressure CalculatorDocument4 pagesPress Fit Pressure CalculatorBhadresh ShahNo ratings yet

- Projet Fin D'etudeDocument142 pagesProjet Fin D'etudeMerdas ChamseddineNo ratings yet

- Map For The Hotel Paris and Its HR Score CardDocument4 pagesMap For The Hotel Paris and Its HR Score Cardnick john caminadeNo ratings yet

- Materials 13 04018Document20 pagesMaterials 13 04018Bhadresh ShahNo ratings yet

- Carbon Steel Billets, Blooms, Slabs and Bars For ForgingsDocument9 pagesCarbon Steel Billets, Blooms, Slabs and Bars For ForgingsHizkia Yarden SinagaNo ratings yet

- Case1328021324 PDFDocument145 pagesCase1328021324 PDFChrista Epifani SebayangNo ratings yet

- Ms Pipes Tubes PDFDocument2 pagesMs Pipes Tubes PDFBhadresh ShahNo ratings yet

- V. K. Engineers: Company ProfileDocument6 pagesV. K. Engineers: Company ProfileBhadresh ShahNo ratings yet

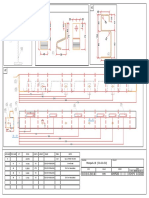

- Stair Assembly 20160809-3Document1 pageStair Assembly 20160809-3Bhadresh ShahNo ratings yet

- Crane TipsDocument10 pagesCrane TipskhayagskiNo ratings yet

- SHP20 - Deck Side Profiles 1Document1 pageSHP20 - Deck Side Profiles 1Bhadresh ShahNo ratings yet

- Developmentnearoverheadlines PDFDocument28 pagesDevelopmentnearoverheadlines PDFbhavsargaurang21510No ratings yet

- BronzeAB2AluminiumBronze PDFDocument1 pageBronzeAB2AluminiumBronze PDFANILNo ratings yet

- Bearing Load CalculationDocument16 pagesBearing Load CalculationmhsalihNo ratings yet

- DOCUMENT Sample Vessel CalculationsDocument10 pagesDOCUMENT Sample Vessel CalculationsCristian Camilo Zapata PardoNo ratings yet

- NGPDocument2 pagesNGPBhadresh ShahNo ratings yet

- BronzeAB2AluminiumBronze PDFDocument1 pageBronzeAB2AluminiumBronze PDFANILNo ratings yet

- Is - 2062.2011 PDFDocument17 pagesIs - 2062.2011 PDFN GANESAMOORTHYNo ratings yet

- DOCUMENT Sample Vessel CalculationsDocument10 pagesDOCUMENT Sample Vessel CalculationsCristian Camilo Zapata PardoNo ratings yet

- 3177Document62 pages3177krishnan_88No ratings yet

- Company Profile VkeDocument8 pagesCompany Profile VkeBhadresh ShahNo ratings yet

- Tentative Academic Calendar for Freshman StudentDocument2 pagesTentative Academic Calendar for Freshman StudentDAWIT FIKADUNo ratings yet

- Dubai Government Innovation FrameworkDocument103 pagesDubai Government Innovation FrameworkAshiq MaanNo ratings yet

- UNISA Graduate School MBL Program Welcome LetterDocument24 pagesUNISA Graduate School MBL Program Welcome Lettereugene123No ratings yet

- Personal and Academic DetailsDocument17 pagesPersonal and Academic DetailsWaqas AhmadNo ratings yet

- Reference Letter New ZealandDocument7 pagesReference Letter New Zealandnew0nikazuw3100% (1)

- Effective Supervision UnitDocument44 pagesEffective Supervision UnitlieutenantnickNo ratings yet

- Sample Questionnaire on Brand Positioning and PerceptionDocument14 pagesSample Questionnaire on Brand Positioning and PerceptionTimothy DaudaNo ratings yet

- Case StudyDocument17 pagesCase StudyDhanashree Chaudhari0% (1)

- Pinchhe Tole, Gwarko, Kathmandu: Kathmandu University School of ManagementDocument4 pagesPinchhe Tole, Gwarko, Kathmandu: Kathmandu University School of ManagementNeha Dahal100% (1)

- Allstate Insurance Diversity Index Motivates EmployeesDocument9 pagesAllstate Insurance Diversity Index Motivates Employees1nita123No ratings yet

- Bombardier. SaDocument17 pagesBombardier. SaPayel MukherjiNo ratings yet

- Engleza An III, Sem IDocument26 pagesEngleza An III, Sem IDenise BlackNo ratings yet

- Wk2 Building Managing TeamsDocument21 pagesWk2 Building Managing TeamsMuhammad GulfamNo ratings yet

- Pepsi Final EiditedDocument30 pagesPepsi Final EiditedumairNo ratings yet

- BUS160 Final ExamDocument23 pagesBUS160 Final ExamMaria NoedinsNo ratings yet

- Benefits of CommunityDocument3 pagesBenefits of CommunitySafiyyah NajwaNo ratings yet

- Nursing Leandership: Ely Gustina.S. Kep, NsDocument17 pagesNursing Leandership: Ely Gustina.S. Kep, NsAPRINo ratings yet

- Professional Brochure JDADocument2 pagesProfessional Brochure JDArei020282No ratings yet

- Professional Communications Skills in English: ENG 300 A ENG 300 B ENG 300 CDocument30 pagesProfessional Communications Skills in English: ENG 300 A ENG 300 B ENG 300 Cbaba fingoNo ratings yet

- Performance Appraisal Fairness, Leader Member Exchange and Motivation ToDocument13 pagesPerformance Appraisal Fairness, Leader Member Exchange and Motivation ToIcuk HertantoNo ratings yet

- Contoh Proposal - Data PrimerDocument91 pagesContoh Proposal - Data PrimerBagus Hamdan SyahputraNo ratings yet

- LGRC BrochureDocument2 pagesLGRC Brochureanon_741187102No ratings yet

- Human Resources: Cholida Imaysari Muhammad Iqbal Syaipuddin ZuhriDocument11 pagesHuman Resources: Cholida Imaysari Muhammad Iqbal Syaipuddin ZuhriMuhammad FikriansyahNo ratings yet

- Leadership Style in Banking Sector (Original)Document16 pagesLeadership Style in Banking Sector (Original)Akshay PariharNo ratings yet

- Chapter 18 Creating Competitive AdvantageDocument36 pagesChapter 18 Creating Competitive AdvantageShelveyElmoDiasNo ratings yet