Professional Documents

Culture Documents

HP Boiler Blowdown Hex - OPERATING

Uploaded by

MuthuKumar ArunachalamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HP Boiler Blowdown Hex - OPERATING

Uploaded by

MuthuKumar ArunachalamCopyright:

Available Formats

1

2

3

4

5

6 600 / 6000 mm Type BEM 1 1

7 m2 1

8

9

10

11

12

13

14

15

16 C

17 C

18 / / / /

19 / / / /

20

21

22 / / / /

23 / / / /

24

25

26

27

28 Ao based

29 C

30

31

32

33 kgf/cm2 / / / /

34 C

35

36 mm

37 In mm 1 / /

38 1 / /

39 Nominal / /

40 OD 19.05 1.65 mm Length mm mm

41

42 ID OD mm

43 Carbon Steel

44 Carbon Steel

45 -

46 Single segmental H mm

47 mm

48

49

50

51 1 2

52 Flat Metal Jacket Fibe Tube Side Flat Metal Jacket Fibe

53 -

54 R - refinery service

55 kg

56

57

58

0.598

kg/h

kg/h

kcal/kg

kcal/(kg*C)

kcal/(h*m*C)

Hor

Shell Side

0

kg/h

cp

kg/m3

kg/h

6353

1.0154

0.593

Tube Side

10529

0 0

10529

DM water

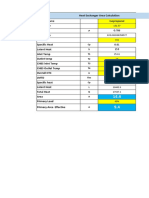

PERFORMANCE OF ONE UNIT

6353

0

blowdown water

0.04

0.265

Bundle

kg/(m*s2) Bundle exit

620

41.41 Cut(%d)

Exp.

Inlet

590 Spacing: c/c

Expansion joint

Tubesheet-stationary

Floating head cover

Remarks

Filled with water

Code requirements ASME Code Sec VIII Div 1 TEMA class

Weight/Shell 2418.1

892.48

Type

Carbon Steel Type Baffle-crossing

Intermediate

1

-

3.18

-

38.1

31.75

Baffle-long

Supports-tube U-bend

Seal type -

Connections

Channel or bonnet

Tube No.

Carbon Steel 600

38.1

Fluid allocation

Fluid name

Fluid quantity, Total 6353 10529

0

Specific heat

Thermal conductivity

Latent heat

Vapor (In/Out)

Liquid

Noncondensable

Temperature (In/Out)

Density (Vap / Liq)

Viscosity

Molecular wt, Vap

Dew / Bubble point

Molecular wt, NC

0

0.27

Connected in

Surf/shell (eff.) Shells/unit Surf/unit(eff.)

Size series

m2 181.2

Heat Exchanger Specification Sheet

HP BOILER BLOW DOWN HEAT EXCHANGER-OPERATING CONDITION

parallel

181.2

154 45 40 106

954.27 994.53

0.6534 0.191

1

992.7

6000

-

Plain

512

30 Tube type

Shell

Tks-

Carbon Steel Material

Avg

Bypass seal Tube-tubesheet joint

3609.5 5076.2

RhoV2-Inlet nozzle

Gaskets - Shell side

Floating head

-

1977 Bundle entrance

Type

-

Channel cover -

None Impingement protection

Tubesheet-floating

Tube pattern

Pitch 23.81

Shell cover

7

0.539

Size/rating

218 Clean 262

- Out

CONSTRUCTION OF ONE SHELL

Shell Side Tube Side

Transfer rate, Service

Heat exchanged

kgf/cm2

Design/Vac/Test pressure

Pressure

Velocity

m2*h*C/kcal

kgf/cm2

5.3

m/s

Design temperature

Pressure drop, allow./calc.

1

0.00035 0.00035

190 145

kcal/h

6.118

MTD corrected 695159

Sketch

0.00042

-

Fouling resist. (min)

- - 50.8

Number passes per shell

Corrosion allowance

8.158

200.8

19.1

3.18

Dirty kcal/(h*m2*C)

1

913.05

1

0.586

1.0028

0.03

0.51 0.023

6.977

0.534

1.0002

0.026

5.274

T1

S1

S2

T2

You might also like

- Steam CondenserDocument2 pagesSteam CondenserAlphaEcc EngineeringTeamNo ratings yet

- Heat Exchanger Specification Sheet: Shell Side Tube Side Performance of One UnitDocument2 pagesHeat Exchanger Specification Sheet: Shell Side Tube Side Performance of One UnitMuthuKumar ArunachalamNo ratings yet

- Cvts - Tag No. Mpt-tv-4161Document2 pagesCvts - Tag No. Mpt-tv-4161biswasdipankar05No ratings yet

- Heat HXerDocument2 pagesHeat HXerGade JyNo ratings yet

- Condenser & EvaporatorDocument21 pagesCondenser & EvaporatorfitratulqadriNo ratings yet

- Natural Gas Processing Separator TechniquesDocument37 pagesNatural Gas Processing Separator TechniquestahaNo ratings yet

- Process Data Sheet for Rupture DiskDocument2 pagesProcess Data Sheet for Rupture DisksafaldNo ratings yet

- Packed Towers: 12.1 Device TypeDocument10 pagesPacked Towers: 12.1 Device TypeSagar BhavsarNo ratings yet

- Cooling Tower ComparisonDocument4 pagesCooling Tower ComparisonKiran DasNo ratings yet

- 2.0 AasasDocument41 pages2.0 AasasMinimac Pune - HONo ratings yet

- Plate Type Wet ScrubberDocument6 pagesPlate Type Wet ScrubberRoger IsidoreNo ratings yet

- Separator SizingDocument3 pagesSeparator SizingMaryJane Ayisha Sado-ObahNo ratings yet

- 2 3 Phase Separation SystemDocument14 pages2 3 Phase Separation SystemDodiya Nikunj100% (1)

- Observations Water in DF Out DF Oil DF Flow Ml/s Flow ft3/hrDocument2 pagesObservations Water in DF Out DF Oil DF Flow Ml/s Flow ft3/hrUmair FareedNo ratings yet

- BBS-10-W8-DS-003 - C - TEG Reflux Condenser DS PDFDocument1 pageBBS-10-W8-DS-003 - C - TEG Reflux Condenser DS PDFAdianto RahmanNo ratings yet

- Equilibrium Vapor-Liquid CalculationsDocument8 pagesEquilibrium Vapor-Liquid Calculationsdhea novitaNo ratings yet

- Heat Exchanger Area & Boilup Rate CalculationDocument19 pagesHeat Exchanger Area & Boilup Rate CalculationNitin KurupNo ratings yet

- Horizontal Three Phase Separator Sizing CalculationDocument3 pagesHorizontal Three Phase Separator Sizing CalculationDazzy 265No ratings yet

- HP Dosing - AgecDocument12 pagesHP Dosing - AgecShameer MajeedNo ratings yet

- Glycol Dehydration Unit English LetterDocument4 pagesGlycol Dehydration Unit English LetterRaulCamachoNo ratings yet

- Condenser Design: Calculation of LMTD: Hot Fluid (Cold Fluid (Difference (Document5 pagesCondenser Design: Calculation of LMTD: Hot Fluid (Cold Fluid (Difference (Lokesh EmandiNo ratings yet

- Drier Bed SizingDocument14 pagesDrier Bed SizingvkumaranNo ratings yet

- Filters FbaDocument1 pageFilters FbaSpoonful BurnsideNo ratings yet

- Vessel Weight CheckDocument11 pagesVessel Weight CheckneelNo ratings yet

- DearatorDocument3 pagesDearatorEDUARDONo ratings yet

- Distillation Tower Design PresentationDocument2 pagesDistillation Tower Design PresentationAlmotsemNo ratings yet

- Boiler Combustion & EmissionDocument15 pagesBoiler Combustion & EmissionMustafa HusainNo ratings yet

- Coal Gasifier ProcessesDocument28 pagesCoal Gasifier ProcessesH Janardan PrabhuNo ratings yet

- Ammonium 2520sulphate Material 2520balance.Document9 pagesAmmonium 2520sulphate Material 2520balance.AgadmatorNo ratings yet

- Specify Three-Phase SeparatorsDocument12 pagesSpecify Three-Phase SeparatorsRobert MontoyaNo ratings yet

- Re BoilersDocument42 pagesRe BoilersShashi MashalNo ratings yet

- MODEL: PFTA 1500-4: Ratings & Performance DataDocument4 pagesMODEL: PFTA 1500-4: Ratings & Performance DataAnonymous izGbhcNo ratings yet

- Design 2 ReboilerDocument5 pagesDesign 2 ReboilerAbdulrazzaqAL-MalikyNo ratings yet

- We Need A Mist Eliminator in That Knockout Drum!: AmacsDocument5 pagesWe Need A Mist Eliminator in That Knockout Drum!: AmacsmanuNo ratings yet

- Sodium Bicarbonate For Flue Gas TreatmentDocument12 pagesSodium Bicarbonate For Flue Gas Treatmentblabla21No ratings yet

- Chap 34 PDFDocument16 pagesChap 34 PDFnelson escuderoNo ratings yet

- Thermophysical PropertiesDocument14 pagesThermophysical PropertiesKalinga BalNo ratings yet

- Sparger Calc MotDocument5 pagesSparger Calc MotRajesh NareNo ratings yet

- Pipe DimensionDocument7 pagesPipe DimensionLily NurdianaNo ratings yet

- Vapor Liquid Equilibrium of Water + Ethanol + GlycerolDocument8 pagesVapor Liquid Equilibrium of Water + Ethanol + GlycerolcsandrasNo ratings yet

- BP RP26-1HeatExchangeEquipment PDFDocument40 pagesBP RP26-1HeatExchangeEquipment PDFMohd KhairulNo ratings yet

- Glutaraldehyde Bulk HandlingDocument4 pagesGlutaraldehyde Bulk HandlingnubblerNo ratings yet

- Engineering Sheet: Heat Exchanger Capacity Calculation For High-Temperature WaterDocument4 pagesEngineering Sheet: Heat Exchanger Capacity Calculation For High-Temperature WaterTrishul Nath PallayNo ratings yet

- Monoethanolamine Design 2520of 2520equipmentsDocument54 pagesMonoethanolamine Design 2520of 2520equipmentsbhaskar5377No ratings yet

- Prediction of HETP For Randomly Packed Towers Operation:integration of Aqueous and Non-Aqueous Mass Transfercharacteristics Into One Consistent CorrelationDocument18 pagesPrediction of HETP For Randomly Packed Towers Operation:integration of Aqueous and Non-Aqueous Mass Transfercharacteristics Into One Consistent Correlationcamilo_ortiz_6No ratings yet

- Volumes 2Document1 pageVolumes 2Rafael ReyesNo ratings yet

- Coulson Richardson's Chemical Engineering Vol.6 Chemical Engineering Design 4th EditionDocument2 pagesCoulson Richardson's Chemical Engineering Vol.6 Chemical Engineering Design 4th EditionClaChristinaNo ratings yet

- Gas Chiller Datasheet PDFDocument2 pagesGas Chiller Datasheet PDFidilfitriNo ratings yet

- 882design of Helical Baffle in Shell and Tube Heat Exchanger and Comparing With Segmental Baffle Using Kern Method PDFDocument6 pages882design of Helical Baffle in Shell and Tube Heat Exchanger and Comparing With Segmental Baffle Using Kern Method PDFDavid Alemán Sánchez100% (1)

- KIRK Sep-Calc SoftwareDocument4 pagesKIRK Sep-Calc Softwaredhl_tuNo ratings yet

- 09 SpargerDocument17 pages09 SpargerWeb LogueandoNo ratings yet

- ChE450 TBWS15.28Document6 pagesChE450 TBWS15.28HaematomaNo ratings yet

- Preparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsFrom EverandPreparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsNo ratings yet

- Heat Exchanger Specification Sheet SI UnitsDocument2 pagesHeat Exchanger Specification Sheet SI UnitssalamrefighNo ratings yet

- Heat Exchanger Rating Data SheetDocument1 pageHeat Exchanger Rating Data SheetagusnnnNo ratings yet

- Heat Exchanger Specification SheetDocument1 pageHeat Exchanger Specification SheetTrần Quang ThắngNo ratings yet

- Heat Exchanger Specification Sheet: MM M? M? Performance of One UnitDocument9 pagesHeat Exchanger Specification Sheet: MM M? M? Performance of One UnitGladys ZiSing LeeNo ratings yet

- Relief SummaryDocument6 pagesRelief SummaryMuthuKumar ArunachalamNo ratings yet

- Air SupplyDocument1 pageAir SupplyMuthuKumar ArunachalamNo ratings yet

- Close or Deactivate Your Zerodha Account FormDocument1 pageClose or Deactivate Your Zerodha Account FormMuthuKumar Arunachalam100% (1)

- Nozzle MomentumDocument4 pagesNozzle MomentumMuthuKumar ArunachalamNo ratings yet

- Weir Type Bs 5156: SizesDocument2 pagesWeir Type Bs 5156: SizesMuthuKumar ArunachalamNo ratings yet

- Korf Hydraulic ReportDocument10 pagesKorf Hydraulic ReportMuthuKumar ArunachalamNo ratings yet

- Process Block Flow DiagramDocument2 pagesProcess Block Flow DiagramMuthuKumar ArunachalamNo ratings yet

- Pump Sizing Calculation - Twopump RunningDocument2 pagesPump Sizing Calculation - Twopump RunningMuthuKumar ArunachalamNo ratings yet

- HMBDocument5 pagesHMBMuthuKumar ArunachalamNo ratings yet

- Korf Hydraulic ReportDocument10 pagesKorf Hydraulic ReportMuthuKumar ArunachalamNo ratings yet

- Lâminas Simulação de Processos (ENG)Document82 pagesLâminas Simulação de Processos (ENG)Thiago André WeschenfelderNo ratings yet

- Trees To Be Planted Around HouseDocument6 pagesTrees To Be Planted Around HouseMuthuKumar ArunachalamNo ratings yet

- Clear Water PumpDocument1 pageClear Water PumpMuthuKumar ArunachalamNo ratings yet

- Pipe Sizing for Optimal Steam FlowDocument6 pagesPipe Sizing for Optimal Steam Flowferdie14No ratings yet

- Political History of South IndiaDocument53 pagesPolitical History of South IndiaSaminathan MunisamyNo ratings yet

- Korf Hydraulic ReportDocument10 pagesKorf Hydraulic ReportMuthuKumar ArunachalamNo ratings yet

- Line Sizing TrialDocument5 pagesLine Sizing TrialMuthuKumar ArunachalamNo ratings yet

- TRVDocument1 pageTRVMuthuKumar ArunachalamNo ratings yet

- Pump SizingDocument4 pagesPump SizingNikunj100% (5)

- Steam DP CalcDocument10 pagesSteam DP CalcMuthuKumar ArunachalamNo ratings yet

- Calculation of Q, V Using Manning Formula For Sewer Line (More Than Half Full Flow Condition)Document2 pagesCalculation of Q, V Using Manning Formula For Sewer Line (More Than Half Full Flow Condition)MuthuKumar ArunachalamNo ratings yet

- OWS Sump Volume CalculationsDocument1 pageOWS Sump Volume CalculationsMuthuKumar ArunachalamNo ratings yet

- Pressure Drop CalculationDocument6 pagesPressure Drop CalculationMuthuKumar ArunachalamNo ratings yet

- Can A Water Pump ExplodeDocument1 pageCan A Water Pump ExplodeHimanshu ChichraNo ratings yet

- BF3 Scrubber Column DiameterDocument21 pagesBF3 Scrubber Column DiameterMuthuKumar Arunachalam0% (1)

- Pump Power CalculationDocument1 pagePump Power CalculationMuthuKumar ArunachalamNo ratings yet

- Feasibility StudyDocument7 pagesFeasibility StudyMuthuKumar ArunachalamNo ratings yet

- Name Arunachalam Muthukumar Department Process Engineering Purpose of Travel Domestic Travel Start Date DepartureDocument3 pagesName Arunachalam Muthukumar Department Process Engineering Purpose of Travel Domestic Travel Start Date DepartureMuthuKumar ArunachalamNo ratings yet

- Heat Exchanger Heat Accumulation 63545.31kcal/hrDocument4 pagesHeat Exchanger Heat Accumulation 63545.31kcal/hrMuthuKumar ArunachalamNo ratings yet

- Design PrintsDocument1 pageDesign PrintsMuthuKumar ArunachalamNo ratings yet