Professional Documents

Culture Documents

ACI Mix-Design Group Problem 2

Uploaded by

Shoyeeb AhmedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACI Mix-Design Group Problem 2

Uploaded by

Shoyeeb AhmedCopyright:

Available Formats

CIVL 1112

ACI Mix Design - Group Example #2

ACI Mix Design Example

1/3

ACI Mix Design Example

The 28-day compressive strength should be 7,000

lb/in2. The slump should be between 3 and 4 in. and the

maximum aggregate size should not exceed in.

The properties of the materials are as follows:

Step 1. Required material information (already given).

Step 2. Choice of slump. The slump is given, consistent

with Table 1.

Cement : Type I, specific gravity = 3.15

Coarse Aggregate: Bulk specific gravity (SSD) = 2.65;

absorption capacity = 0.5%; dry-rodded unit weight = 100

lb/ft3; surface moisture = 1%

Fine Aggregate: Bulk specific gravity (SSD) = 2.60; absorption

capacity = 1.1%; fineness modulus = 2.70; surface moisture = 3%

Step 3. Maximum aggregate size. Given: inches

ACI Mix Design Example

ACI Mix Design Example

Step 4. Estimation of mixing water and air content.

From Table 2, the recommended air content is 2%; the

water requirement is 340 lb/yd3.

Step 5. Water/cement ratio. From Table3, the

estimate for required w/c ratio to give a 28-day

strength of 7,000 lb/in2 is 0.33.

28-day Compressive Non-AE

Maximum aggregate size (in)

AE

S

Strength

h ((psi)

i)

Slump(in)

0.375

0.5

0.75

1.5

1 to 2

350

335

315

300

275

260

220

190

2,000

0.82

0.74

325

300

285

245

210

3,000

0.68

0.59

4,000

0.57

0.48

5,000

0.48

0.40

6,000

0.41

0.32

7,000

0.33

0.33

---

3 to 4

385

365

340

340

6 to 7

410

385

360

340

315

300

270

Air Content

3.0%

2.5%

2.0%

2.0%

1.5%

1.0%

0.5%

0.3%

0.2%

ACI Mix Design Example

Step 6. Calculation of cement content. Based on steps 4

and 5, the required cement content is:

weight of cement

340lb / yd 3

1,030lb / yd 3

0.33

ACI Mix Design Example

Step 7. Estimation of coarse aggregate content.

Interpolating Table 4 for the fineness modulus of the

fine aggregate of 2.70

Fineness Modulus

Max Aggregate (in)

2.4

2.5

2.6

2.7

2.8

2.9

0.375

0.50

0.49

0.48

0.47

0.46

0.45

0.44

0.500

0.59

0.58

0.57

0.56

0.55

0.54

0.53

0.750

0.66

0.65

0.64

0.63

0.62

0.61

0.60

1.000

0.71

0.70

0.69

0.68

0.67

0.66

0.65

1.500

0.75

0.74

0.73

0.72

0.71

0.70

0.69

2.000

0.78

0.77

0.76

0.75

0.74

0.73

0.72

3.000

0.82

0.81

0.80

0.79

0.78

0.77

0.76

6.000

0.87

0.86

0.85

0.84

0.83

0.82

0.81

CIVL 1112

ACI Mix Design - Group Example #2

ACI Mix Design Example

The coarse aggregate will occupy:

3

0.63 27ft

yd

17.01 ft

yd

Value from

T bl 4

Table

The OD weight of the coarse aggregate

17.01ft

yd 3

100 lb

ft 3

1,701 lb

yd 3

ACI Mix Design Example

Therefore, the fine aggregate must occupy a volume of:

27 ft 3 21.52 ft 3 5.48 ft 3

The SSD weight of the fine aggregate is:

5.48 ft 2.60 62.4lb

Specific Gravity

of Fine Aggregate

ft 3

889 lb

Unit Weight

of Water

Class ACI Mix Design Example

Step 9. Compute stockpile weight based on moisture

content

Fine aggregate required from the stockpile is:

889 lb (1 + 0.041) = 925 lb/yd3

Moisture Content 4.1%

ACI Mix Design Example

Step 8. Estimation of fine aggregate content by the

absolute volume method.

Water:

340 lb/62.4 lb/ft3

= 5.45 ft3

Cement:

1 030 lb/(3

1,030

lb/(3.15

15 x 62

62.4

4

lb/ft3)

= 5.24

5 24 ft3

Coarse Aggregate:

1,701 lb/(2.65 x 62.4 lb/ft3)

= 10.29 ft3

Air:

2% x 27ft3/yd3

= 0.54 ft3

Total

Dry-Rodded

Unit Weight

2/3

Moisture Content 1.5%

Coarse aggregate required from the stockpile is:

1,701 lb (1 + 0.015) = 1,727 lb/yd3

21.52 ft3

Class ACI Mix Design Example

Step 9. Adjustment for moisture in the aggregate.

The weight of aggregate from the stock pile is:

WeightStock Pile WeightOD 1 MC

The change in the weight water due to the moisture of

the aggregate from the stock pile is:

WeightWater WeightOD SM

Adjusted WeightWater WeightWater WeightWater

Class ACI Mix Design Example

Step 9. Adjust the amount of water based on moisture

content

The required mixing water required is:

340 lb - 889 lb (0

(0.03)

03) fine aggregate

Surface moisture 3%

- 1,701 lb (0.01) coarse aggregate

= 296 lb/yd3

Surface moisture 1%

CIVL 1112

ACI Mix Design - Group Example #2

Class ACI Mix Design Example

Thus the estimated batch weights per yd3 are:

Water

= 296 lb

Cement

= 1,030

,

lb

Coarse aggregate (wet)

Fine aggregate (wet)

= 1,727 lb

= 925 lb

Total

= 3,978 lb/yd3

=

147.3 lb/ft3

3/3

End of ACI Mix Design

Questions?

You might also like

- ACI Mix-Design Group Problem 1Document3 pagesACI Mix-Design Group Problem 1Maksudur RahmanNo ratings yet

- ACI Mix Design Example #2 Class ACI Mix Design ExampleDocument3 pagesACI Mix Design Example #2 Class ACI Mix Design ExamplePhea SakNo ratings yet

- ACI Mix-Design Summary SheetDocument2 pagesACI Mix-Design Summary Sheetosama anterNo ratings yet

- ACI Concrete Design Mix ProcedureDocument4 pagesACI Concrete Design Mix ProcedureLan CorpuzNo ratings yet

- ACI Mix Design Example #1 Class ACI Mix Design ExampleDocument3 pagesACI Mix Design Example #1 Class ACI Mix Design ExamplePhea SakNo ratings yet

- Concrete Mix Design: Strength (Psi) 4000 Slump (In) : 3 To 4 Max. Aggregate (In) : 0.750 Cement: Coarse AggregateDocument2 pagesConcrete Mix Design: Strength (Psi) 4000 Slump (In) : 3 To 4 Max. Aggregate (In) : 0.750 Cement: Coarse AggregateAnonymous PeFQLw19No ratings yet

- Mix DesignDocument26 pagesMix Designhasan.edc20No ratings yet

- For Moment of Inertia For PSC GirderDocument6 pagesFor Moment of Inertia For PSC GirderAshutosh GuptaNo ratings yet

- OEL Final ReportDocument12 pagesOEL Final ReportAreeba GhulamNo ratings yet

- Mechanical Operations (CH31007 and CH21205) Assignment: InstructionsDocument5 pagesMechanical Operations (CH31007 and CH21205) Assignment: InstructionsHarsh GuptaNo ratings yet

- M40 Grade Concrete Mix Design As Per ACI MethodDocument7 pagesM40 Grade Concrete Mix Design As Per ACI Methodugrasen chaudharyNo ratings yet

- RESULT and DISCUSSIONDocument5 pagesRESULT and DISCUSSIONnisasoberiNo ratings yet

- Aggregate Properties and Testing (Part 4Document11 pagesAggregate Properties and Testing (Part 4Rohit VasudevaNo ratings yet

- Reserve Estimation Unit: Ooip Recov Oil (MMSTB) (MMSTB)Document8 pagesReserve Estimation Unit: Ooip Recov Oil (MMSTB) (MMSTB)FreddyCorredorNo ratings yet

- Financial Modeling AssignmentDocument11 pagesFinancial Modeling AssignmentamerNo ratings yet

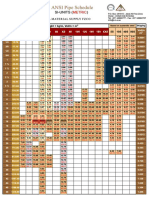

- NPS, Pipe Schedule Outside Diameter, KG / M Vol. / MDocument8 pagesNPS, Pipe Schedule Outside Diameter, KG / M Vol. / MnazimNo ratings yet

- Rep025 011Document11 pagesRep025 011Ilhame HarNo ratings yet

- DIRECT SHEAR TEST ANALYSISDocument23 pagesDIRECT SHEAR TEST ANALYSISDinar AliNo ratings yet

- Scatter Graph Showing Current Affecting Force On A Current Carrying WireDocument3 pagesScatter Graph Showing Current Affecting Force On A Current Carrying WirePatrick MuñozNo ratings yet

- Mechanical Analysis of SoilDocument8 pagesMechanical Analysis of Soilmp SinghNo ratings yet

- Bracing Calculations(3.3m Walls)Document34 pagesBracing Calculations(3.3m Walls)Rajeshwari NarayanamoorthyNo ratings yet

- Calculate composite cross-section propertiesDocument1 pageCalculate composite cross-section propertiesVivek KumarNo ratings yet

- Fluid Rock Interactions Relative Permeability CompressibilityDocument2 pagesFluid Rock Interactions Relative Permeability CompressibilityTripoli ManoNo ratings yet

- Worksheet For Protein Conc Determination - May 2022Document2 pagesWorksheet For Protein Conc Determination - May 2022Joseph John Patrick KabigtingNo ratings yet

- Esterification of EthanolDocument15 pagesEsterification of EthanolSadia HasanNo ratings yet

- Enzyme concentration, substrate concentration, and pH effect on absorbanceDocument3 pagesEnzyme concentration, substrate concentration, and pH effect on absorbanceinshirahizhamNo ratings yet

- Waterdrive Layered Fractional Flow Model Report: Input DataDocument13 pagesWaterdrive Layered Fractional Flow Model Report: Input DataCarlita SuntaxiNo ratings yet

- Bom BoqDocument4 pagesBom BoqRenzel EstebanNo ratings yet

- Laporan Harian Asbuton 04 Agustus 2023 IIDocument22 pagesLaporan Harian Asbuton 04 Agustus 2023 IItoshiba devedoNo ratings yet

- ANSI Pipe Schedule SI UNITS METRIC PDFDocument1 pageANSI Pipe Schedule SI UNITS METRIC PDFmm100% (4)

- 103EXP3 SpectrophotometerDocument5 pages103EXP3 SpectrophotometeralperlengerNo ratings yet

- Hari Ke.2 Hari Ke.3 Hari Ke.4 Hari Ke.5 Hari Ke.6: - Lab. AnalysisDocument17 pagesHari Ke.2 Hari Ke.3 Hari Ke.4 Hari Ke.5 Hari Ke.6: - Lab. AnalysisMus TakimNo ratings yet

- 1.000 0.950 0.900 0.850 0.800 0.750 0.700 0.650 0.600 0.550 0.500 0.450 0.400 0.350 (Cyclic Stress Level T) / (Tmax)Document11 pages1.000 0.950 0.900 0.850 0.800 0.750 0.700 0.650 0.600 0.550 0.500 0.450 0.400 0.350 (Cyclic Stress Level T) / (Tmax)Nadifa AuliaNo ratings yet

- Department of Chemical Engineering: Particle TechnologyDocument2 pagesDepartment of Chemical Engineering: Particle TechnologyKhan AaghaNo ratings yet

- Lab Analysis Soil ConsolidationDocument17 pagesLab Analysis Soil ConsolidationRandi SetiawanNo ratings yet

- Cewb1021 Exp - 1Document5 pagesCewb1021 Exp - 1alolqigoNo ratings yet

- Expansion Tank Selection CalculatorDocument17 pagesExpansion Tank Selection Calculator185412No ratings yet

- Particle Size Distribution Bs 1377-2-1990Document12 pagesParticle Size Distribution Bs 1377-2-1990Nzunzu BenNo ratings yet

- Unit I Phase Iii Cost EstimateDocument11 pagesUnit I Phase Iii Cost EstimateBernadette SisonNo ratings yet

- ResultsDocument2 pagesResultsGanim ShedNo ratings yet

- Department of Civil Engineering - Materials Testing LaboratoryDocument24 pagesDepartment of Civil Engineering - Materials Testing LaboratoryChris JosephNo ratings yet

- Appendix - Final Report - KAMULIDocument26 pagesAppendix - Final Report - KAMULIOjullaIsaacNo ratings yet

- Test 1 PDFDocument5 pagesTest 1 PDFFibo ForexNo ratings yet

- Maragondon Bulk Water Supply ProjectDocument35 pagesMaragondon Bulk Water Supply ProjectAbel VirayNo ratings yet

- Entrance Region Length and Mass Transfer in Bubble ColumnsDocument20 pagesEntrance Region Length and Mass Transfer in Bubble Columnsmouhcine maouhoubNo ratings yet

- Kanthal ResistancesDocument2 pagesKanthal ResistancesJT MVNo ratings yet

- Vapor and Liquid Equilibrium of Ethanol-Water SystemDocument5 pagesVapor and Liquid Equilibrium of Ethanol-Water SystemAsilahNo ratings yet

- Acid Gas Removal and Amine Treatment ProcessDocument12 pagesAcid Gas Removal and Amine Treatment Processahmed sobhyNo ratings yet

- Pavement Materials: Highway and Transportation Engineering (Faculty of Engineering)Document38 pagesPavement Materials: Highway and Transportation Engineering (Faculty of Engineering)atharNo ratings yet

- Dimensi SaluranDocument23 pagesDimensi SaluranAde SetiawanNo ratings yet

- SEO-OPTIMIZED SUPPLEMENTARY TABLESDocument7 pagesSEO-OPTIMIZED SUPPLEMENTARY TABLESRAJESH SIMHADRINo ratings yet

- CHE 42 Problem Set on Phase EquilibriumDocument3 pagesCHE 42 Problem Set on Phase EquilibriumROMELIE GABALLO ALBIANo ratings yet

- Lab Sheet 7 Lab BeatingDocument39 pagesLab Sheet 7 Lab BeatingWan Aziz Wan Othman0% (1)

- Retaining WallDocument8 pagesRetaining WallethjetjetNo ratings yet

- Binary System Thermo DyncamixDocument19 pagesBinary System Thermo DyncamixJohn Fritz FestejoNo ratings yet

- Data Mentah PenelitianDocument6 pagesData Mentah PenelitianIrham KusumaNo ratings yet

- Lab Tubular ResultDocument1 pageLab Tubular ResultNur Amira JasminNo ratings yet

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesFrom EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesRating: 5 out of 5 stars5/5 (3)

- The JPEG 2000 SuiteFrom EverandThe JPEG 2000 SuitePeter SchelkensNo ratings yet

- Aer Concrete Mix DesignDocument256 pagesAer Concrete Mix DesignleimrabottNo ratings yet

- 04 - (Beams) (6) Reinforced of Beams Using Moment of Resistance Method.Document63 pages04 - (Beams) (6) Reinforced of Beams Using Moment of Resistance Method.leimrabottNo ratings yet

- ACI Mix-Design Group Problem 2Document3 pagesACI Mix-Design Group Problem 2leimrabottNo ratings yet

- ACI Education Bulletin E1-99: Developed by Committee E-701, Materials For Concrete ConstructionDocument26 pagesACI Education Bulletin E1-99: Developed by Committee E-701, Materials For Concrete ConstructionFarhanjnNo ratings yet

- Aggregate TestDocument21 pagesAggregate Testleimrabott0% (1)

- Design of Beams 1: Act BCXDocument27 pagesDesign of Beams 1: Act BCXleimrabottNo ratings yet

- ccpc15 Supportive and Preventive WorkbookDocument30 pagesccpc15 Supportive and Preventive WorkbookJeremy HamptonNo ratings yet

- System Software Module 3: Machine-Dependent Assembler FeaturesDocument28 pagesSystem Software Module 3: Machine-Dependent Assembler Featuresvidhya_bineeshNo ratings yet

- Nanofil Manual PDFDocument5 pagesNanofil Manual PDFJuliana FreimanNo ratings yet

- EVS XT2+ Tech Ref Software Manual v10.03 PDFDocument80 pagesEVS XT2+ Tech Ref Software Manual v10.03 PDFgibonulNo ratings yet

- Footprints 080311 For All Basic IcsDocument18 pagesFootprints 080311 For All Basic IcsAmit PujarNo ratings yet

- Introduction To The Philosophy of The Human Person Quarter I - Module 2Document26 pagesIntroduction To The Philosophy of The Human Person Quarter I - Module 2Katrina TulaliNo ratings yet

- PrognosisDocument7 pagesPrognosisprabadayoeNo ratings yet

- Accounting Students' Attitude Towads AccountingDocument29 pagesAccounting Students' Attitude Towads AccountingSham Salonga Pascual50% (2)

- BC Planning EvenDocument5 pagesBC Planning EvenRuth KeziaNo ratings yet

- Chime Primary School Brochure TemplateDocument1 pageChime Primary School Brochure TemplateNita HanifahNo ratings yet

- OB HandoutsDocument16 pagesOB HandoutsericNo ratings yet

- Linear Programming Models: Graphical and Computer MethodsDocument91 pagesLinear Programming Models: Graphical and Computer MethodsFaith Reyna TanNo ratings yet

- LTC2410 Datasheet and Product Info - Analog DevicesDocument6 pagesLTC2410 Datasheet and Product Info - Analog DevicesdonatoNo ratings yet

- WP1019 CharterDocument5 pagesWP1019 CharternocnexNo ratings yet

- 4MB0 02R Que 20160609 PDFDocument32 pages4MB0 02R Que 20160609 PDFakashNo ratings yet

- Picco Tac 1095 N Hydrocarbon ResinDocument2 pagesPicco Tac 1095 N Hydrocarbon ResindevanandamqaNo ratings yet

- Balajit Nath Pandita-Specific Principles of Kashmir Saivism-Munshiram Manoharlal Publishers (1998) PDFDocument228 pagesBalajit Nath Pandita-Specific Principles of Kashmir Saivism-Munshiram Manoharlal Publishers (1998) PDFvramaniitkNo ratings yet

- Broom Manufacture Machine: StartDocument62 pagesBroom Manufacture Machine: StartHaziq PazliNo ratings yet

- Absolute Value - WikipediaDocument10 pagesAbsolute Value - WikipediaVenu GopalNo ratings yet

- Solution Manual For Contemporary Project Management 4th EditionDocument15 pagesSolution Manual For Contemporary Project Management 4th EditionDanaAllendzcfa100% (77)

- Thank you for purchasing your remap from HDI Tuning LtdDocument2 pagesThank you for purchasing your remap from HDI Tuning LtdMaks LebanNo ratings yet

- CELTA Pre-Interview Grammar, Vocabulary and Pronunciation ExercisesDocument4 pagesCELTA Pre-Interview Grammar, Vocabulary and Pronunciation ExercisesMichelJorge100% (2)

- Physics MCQ Solid State PhysicsDocument15 pagesPhysics MCQ Solid State PhysicsRams Chander88% (25)

- 60Hz Axial-Fan Centrifugal-Fan AC EN (2009) PDFDocument136 pages60Hz Axial-Fan Centrifugal-Fan AC EN (2009) PDFRodrigo GonçalvesNo ratings yet

- British and American Culture Marking RubricDocument5 pagesBritish and American Culture Marking RubricAn Ho LongNo ratings yet

- Appraisal Sample PDFDocument22 pagesAppraisal Sample PDFkiruthikaNo ratings yet

- Rock ClimbingDocument11 pagesRock ClimbingDaria TurdalievaNo ratings yet

- Laboratory SafetyDocument4 pagesLaboratory SafetyLey DoydoraNo ratings yet

- Literature Revisited: Understanding Key Concepts and Applying Analytical SkillsDocument31 pagesLiterature Revisited: Understanding Key Concepts and Applying Analytical SkillsMuhammad Furqan Aslam Awan100% (2)

- Assignment No.7Document2 pagesAssignment No.7queen estevesNo ratings yet