Professional Documents

Culture Documents

AGP P07-ET19 - PC Hi Tech Technical Requirements - V1

Uploaded by

Frank RivasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AGP P07-ET19 - PC Hi Tech Technical Requirements - V1

Uploaded by

Frank RivasCopyright:

Available Formats

PC HI TECH

Product Technical Requirements

CDIGO

VERSIN

PGE

AGP P07-ET19

1 of 3

1. Dimensional Tolerances

1.1

Thickness

Thickness

Designation (mm)

2.5

3.0

4.5

1.2

Thickness Range

mm

min

2.40

2.85

4.30

in

max

2.60

3.15

4.70

min

0.095

0.112

0.169

max

0.102

0.124

0.185

Sheet Dimension

Length Sheet tolerance: 2800 mm 100mm

Width sheet tolerance: 1900 mm 100mm

2. Allowable defects Size and Distribution

2.1

Point Blemish1

Blemish size

D < 0.25mm

0.25mm < D < 0.50mm

0.50mm < D < 1.00mm

1.00mm < D < 1.50mm

D 1.50mm

Max Number of defects 1 sqm

allowed2

Allowed

13 units

3 units

1 unit

0 unit

Minimal separation

150 mm

150 mm

150 mm

None Allowed

None Allowed

Any visual defect less than 0.25 mm diameter shall be accepted provided they are not closely grouped

together (cluster) which make them easily detectable at 500 mm.

Coating defects like orange peel and milky effect are considered unacceptable.

The sheet must have > 90% utilization.

Defects like scratches are none allowed.

1

Point blemish: Coating defects, brilliant points, dirt, inclusions, color points without distortion and other

similar imperfections.

2

Dimension test sample: 100cm x 100 cm

PC HI TECH

Product Technical Requirements

CDIGO

VERSIN

PGE

AGP P07-ET19

2 of 3

3. Properties

3.1

Physical Properties

Property

Test Method

Units

Requirement

Density

ASTM D 792

g/cm3

1.2

Water absorption

ASTM D 570

0.40

3.2

Optical Properties

Property

Test Method

Units

Requirement

Light Transmission

ASTM D 1003

87.0

Taber Abraser C510F,

500g 500 cycles

Distortion

ASTM D 1044

4.00

DIN 52305 A-AZ

Dioptrie

0.06

ASTM D 3359 Test B

% Area removed

Rating

0.0

5B

Test Method

Units

Requirement

Tensile Strength, Yield

ASTM D 638

MPa

60 5

Tensile Modulus

ASTM D 638

MPa

2350 10

Elongation, Break

ASTM D 638

100

Flexural strength

ASTM D 790

MPa

90 5

Flexural Modulus

ASTM D 790

MPa

2300 50

Izod Impact strength

ASTM D 256

Ft-lb/inch

14 2

Scribe Adhesion

3.3

Mechanical Properties

Property

PC HI TECH

Product Technical Requirements

CDIGO

VERSIN

PGE

AGP P07-ET19

3 of 3

3.4

Performance Properties

Property

Test Method

Units

Requirement

Chemical Resistance

ANSI Z26 Test 19

N.A.

No change in the specimens

Impact Test

ANSI Z26 Test 29

N.A.

No delamination

Lamination Temperature

Internal Laboratory Data

105 130

Allowable radius

Internal Laboratory Data

mm

1000

4. Marking

Each package of polycarbonate shall bear a label with the following information:

Manufacturers name

Nominal thickness

Place of manufacture

ID/lot number

Product reference

Quantity of sheets per box

Production date.

The label will be visible on the outside of the box. In the same way, each sheet should have a label ID with at

least the Lot number, in order to be able to follow the internal use of the Polycarbonate.

5. Packaging

Defects in the masking like holes, scratch, wrinkles, gels, dirties or other contamination are not allowed.

VERSIN

FECHA DE

REVISIN

15-Oct-2010

REVISADO POR

APROBADO POR

DESCRIPCIN DEL CAMBIO

Nancy Torres

Supervisor de Laboratorio

Vincenzo Mannino

Director Tcnico

ORIGINAL

You might also like

- Handbook On Radio AstronomyDocument164 pagesHandbook On Radio Astronomygenih44348No ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Reinforced Concrete Shear Design GuideDocument20 pagesReinforced Concrete Shear Design GuidePamela JezreelNo ratings yet

- Engineering Mechanics Statics Note in Si UnitsDocument20 pagesEngineering Mechanics Statics Note in Si UnitsMei Guan100% (1)

- TDC Tech Spec For PlateDocument3 pagesTDC Tech Spec For PlateBantoo RajamandiNo ratings yet

- Radition Safety NotesDocument11 pagesRadition Safety NotesKingston RivingtonNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- DIN 7060 Curcular Sight Glass PDFDocument14 pagesDIN 7060 Curcular Sight Glass PDFalathekoala100% (2)

- Indian Standard Steel SectionsDocument9 pagesIndian Standard Steel SectionsAmitava SilNo ratings yet

- Technical Specification For Vacuum SystemsDocument284 pagesTechnical Specification For Vacuum SystemsUday SuleNo ratings yet

- NFT 58-000Document10 pagesNFT 58-000arun123123100% (3)

- NFT-58-000 Tolerances Applicable To Moulded PlasticDocument10 pagesNFT-58-000 Tolerances Applicable To Moulded PlasticTrexa Gyreue0% (1)

- Feasibility Report 38MnVS6Document2 pagesFeasibility Report 38MnVS6Amit Kumar UkeNo ratings yet

- Concrete Paving Test ResultsDocument7 pagesConcrete Paving Test ResultsomerNo ratings yet

- Datasheets E FDMDocument5 pagesDatasheets E FDMAlireza YaghoubiNo ratings yet

- Ficha Mang Oxiacetileno BalflexDocument1 pageFicha Mang Oxiacetileno BalflexJUANPANIAGUANo ratings yet

- Laminat Revelation 832 - Tehnički List PDFDocument1 pageLaminat Revelation 832 - Tehnički List PDFparecproNo ratings yet

- 10mm Size Hollow Shaft Type: A Series of Compact and Long-Life Encoders With Unique Hollow Shaft DesignDocument3 pages10mm Size Hollow Shaft Type: A Series of Compact and Long-Life Encoders With Unique Hollow Shaft DesignshyhuNo ratings yet

- PDS-PITTWRAP CF Jacket-EnDocument9 pagesPDS-PITTWRAP CF Jacket-EnChristian DoriaNo ratings yet

- Ford - Wsk-m4d684-A2 Abs - PC ConsoleDocument5 pagesFord - Wsk-m4d684-A2 Abs - PC ConsoleCamila SanchesNo ratings yet

- Skysafe Profile - FinalDocument21 pagesSkysafe Profile - FinalHenry NguyenNo ratings yet

- Acceptence Criteria IMTEDocument12 pagesAcceptence Criteria IMTEdanaka007100% (1)

- Cold Rolled TDC - EDD Grade PDFDocument1 pageCold Rolled TDC - EDD Grade PDFsansagithNo ratings yet

- Kyocera Substrates) Electronic Fine CeramicsDocument17 pagesKyocera Substrates) Electronic Fine Ceramicsmanolo_superNo ratings yet

- DIMO 42H - Prehardened CrMnMo-alloyed Steel in Holderblock Quality For The Construction of Plastic MoldsDocument4 pagesDIMO 42H - Prehardened CrMnMo-alloyed Steel in Holderblock Quality For The Construction of Plastic MoldsFernando LaraNo ratings yet

- Kat-SL Enw PDFDocument34 pagesKat-SL Enw PDFAlanAvtoNo ratings yet

- Abs (Basf Terluran Gp22)Document1 pageAbs (Basf Terluran Gp22)hakangokceNo ratings yet

- Counter Top SpecsDocument12 pagesCounter Top Specsapi-3797031100% (3)

- 3SU12002PS101AA0 enDocument4 pages3SU12002PS101AA0 enaaaguilarmNo ratings yet

- Especificaciones Tecnicas Solmax Hdpe Metric EspanolDocument3 pagesEspecificaciones Tecnicas Solmax Hdpe Metric EspanolAlfredo OvandoNo ratings yet

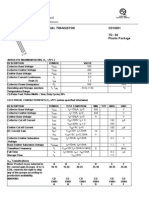

- TransistorDocument3 pagesTransistorAndres Vejar Cerda0% (1)

- DIMO 42M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsDocument4 pagesDIMO 42M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsFernando LaraNo ratings yet

- TDS Tape (White Kraft Tape) BackupDocument1 pageTDS Tape (White Kraft Tape) BackupTran Tuan anhNo ratings yet

- TDS Tape (White Kraft Tape)Document1 pageTDS Tape (White Kraft Tape)Tran Tuan anhNo ratings yet

- LT Power Cable - Data SheetDocument9 pagesLT Power Cable - Data SheetAnagha DebNo ratings yet

- LC0406FC3.3C LC0406FC36C: ApplicationsDocument6 pagesLC0406FC3.3C LC0406FC36C: ApplicationsselocaNo ratings yet

- Specification ZWPF Itu-T g.652.d OptomagicDocument2 pagesSpecification ZWPF Itu-T g.652.d OptomagicJuan Pablo GNo ratings yet

- Encoder S Short FormDocument2 pagesEncoder S Short FormelecompinnNo ratings yet

- ABS EDGEBANDS Technical SpecificationsDocument3 pagesABS EDGEBANDS Technical SpecificationsBurak KececiNo ratings yet

- Altera MT2000 Modified, Medical Grade, Polyolefin, Heat - Shrinkable TubingDocument2 pagesAltera MT2000 Modified, Medical Grade, Polyolefin, Heat - Shrinkable TubingkpNo ratings yet

- DIMO 30M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsDocument4 pagesDIMO 30M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsFernando LaraNo ratings yet

- Catalogue PoralDocument10 pagesCatalogue Poralashish2783No ratings yet

- TDS Tape (Masking Tape W Crepe)Document1 pageTDS Tape (Masking Tape W Crepe)Tran Tuan anhNo ratings yet

- CD13001 TRANSISTOR Datasheet PDFDocument3 pagesCD13001 TRANSISTOR Datasheet PDFmikcomiNo ratings yet

- EC18A 18mm Insulated Shaft EncoderDocument4 pagesEC18A 18mm Insulated Shaft EncodershyhuNo ratings yet

- Lacqare Technical DataDocument3 pagesLacqare Technical DataMahmoud MassadNo ratings yet

- Af-200 Universal AngDocument4 pagesAf-200 Universal AngGeorgi KalchevNo ratings yet

- Continental Device India Limited: NPN Silicon Planar Epitaxial Transistor CD13001 TO - 92 Plastic PackageDocument3 pagesContinental Device India Limited: NPN Silicon Planar Epitaxial Transistor CD13001 TO - 92 Plastic PackageRaj SharmaNo ratings yet

- Fabric Technical Specifications: AppendixDocument4 pagesFabric Technical Specifications: AppendixAani MazharNo ratings yet

- CD13001 TO-92 Data SheetDocument3 pagesCD13001 TO-92 Data SheethuvillamilNo ratings yet

- Hot Strip Mill Product TolerancesDocument9 pagesHot Strip Mill Product TolerancesAyman Al AnsaryNo ratings yet

- Insulated Shaft Rotary EncodersDocument3 pagesInsulated Shaft Rotary EncodersshyhuNo ratings yet

- TDS Tape (NKHQ 60.50) BackupDocument1 pageTDS Tape (NKHQ 60.50) BackupTran Tuan anhNo ratings yet

- TML Flat CableDocument2 pagesTML Flat CableMahmoud Al-SherbinyNo ratings yet

- Cable Size ChartDocument5 pagesCable Size ChartGarry BoagNo ratings yet

- Tabela Completa Fusiveis PDFDocument57 pagesTabela Completa Fusiveis PDFJose Miguel MarquesNo ratings yet

- HDPE Smooth Geomembrane Technical Data SheetDocument1 pageHDPE Smooth Geomembrane Technical Data SheetAgun GunawanNo ratings yet

- Machine Performance ReportDocument22 pagesMachine Performance ReportProduction HeicoNo ratings yet

- HDPE Geomembrane Specification SheetDocument1 pageHDPE Geomembrane Specification SheetAzfar Aizat ZawawiNo ratings yet

- 44 - Ing - 1319115187 5199Document1 page44 - Ing - 1319115187 5199Luis Matamala MoNo ratings yet

- Tds Bopa 15 STDDocument1 pageTds Bopa 15 STDHemant Kumar PathakNo ratings yet

- Gmd9505yb 3V2700Document4 pagesGmd9505yb 3V2700fjcortes2021No ratings yet

- PO Ceramic Book 2021Document227 pagesPO Ceramic Book 2021Frank RivasNo ratings yet

- AutoCAD Shortcuts 11x8.5 MECH-REV PDFDocument11 pagesAutoCAD Shortcuts 11x8.5 MECH-REV PDFKristijan BorasNo ratings yet

- Past Simple: I. Watch This Video and Answer The Six Questions. (6points)Document2 pagesPast Simple: I. Watch This Video and Answer The Six Questions. (6points)Frank RivasNo ratings yet

- S03.s1 ExercisesDocument1 pageS03.s1 ExercisesFrank RivasNo ratings yet

- Veneer Clean Extras PDFDocument1 pageVeneer Clean Extras PDFFrank RivasNo ratings yet

- Greek Entire BookDocument256 pagesGreek Entire Bookapi-374834889% (9)

- COLOMBO Dimensional SamplesDocument2 pagesCOLOMBO Dimensional SamplesFrank RivasNo ratings yet

- Plantilla para Cortar La Sim Card A Nanosim o Microsim PDFDocument1 pagePlantilla para Cortar La Sim Card A Nanosim o Microsim PDFJuniorBasquezNo ratings yet

- Turbulent Flows and Modelling: S.Vengadesan Department of Applied Mechanics, IIT MadrasDocument35 pagesTurbulent Flows and Modelling: S.Vengadesan Department of Applied Mechanics, IIT MadrasVXNo ratings yet

- CV Highlights Mechanical EngineerDocument7 pagesCV Highlights Mechanical EngineerE.s. BinbillahNo ratings yet

- Gaurav Burhade's Mechanics Problems and SolutionsDocument14 pagesGaurav Burhade's Mechanics Problems and SolutionsmansikakaniNo ratings yet

- Elements of Earthquake SeismologyDocument8 pagesElements of Earthquake SeismologylevyaiiNo ratings yet

- Sylvania BKD Dual BeamKat HID Floodlight Spec Sheet 1-87Document4 pagesSylvania BKD Dual BeamKat HID Floodlight Spec Sheet 1-87Alan MastersNo ratings yet

- Gate Aerospace 2016 SolutionDocument27 pagesGate Aerospace 2016 SolutionJackobNo ratings yet

- Chemical Engineering Calculations for Gases and VaporsDocument2 pagesChemical Engineering Calculations for Gases and VaporsKhristel PenoliarNo ratings yet

- 9.1 Multiple-Choice and Bimodal QuestionsDocument18 pages9.1 Multiple-Choice and Bimodal QuestionsQuốc Thắng NguyễnNo ratings yet

- Forces and The Laws of Motion: G9-AthsDocument25 pagesForces and The Laws of Motion: G9-AthsSalma 7assanNo ratings yet

- Temperature Control & VentilationDocument30 pagesTemperature Control & VentilationAssasia HydeNo ratings yet

- CR - Installation and Operating InstructionsDocument48 pagesCR - Installation and Operating InstructionsHusniNo ratings yet

- JEE Advanced Syllabus 2023 - Detailed Syllabus With Free PDFDocument26 pagesJEE Advanced Syllabus 2023 - Detailed Syllabus With Free PDFkarangaleshivdasarunNo ratings yet

- Chapt2 PDFDocument4 pagesChapt2 PDFDrjasmeet KaurNo ratings yet

- Problem Set 1Document2 pagesProblem Set 1JiiiNo ratings yet

- Mechanical Properties of MaterialsDocument45 pagesMechanical Properties of MaterialsRonan SeeNo ratings yet

- Characterization of Nanoparticles Using EDAXDocument11 pagesCharacterization of Nanoparticles Using EDAXRohit MaliNo ratings yet

- DME Objective QuestionsDocument103 pagesDME Objective QuestionsaruchellamNo ratings yet

- Autonomous HVAC CFD - IntroductionDocument31 pagesAutonomous HVAC CFD - IntroductionPraveen Kumar RNo ratings yet

- Duaso Test YourselfDocument42 pagesDuaso Test YourselfSharmaine Cruzat Austria100% (1)

- Preparation and standardization of sulphuric acid solutionsDocument1 pagePreparation and standardization of sulphuric acid solutionsswapon kumar shillNo ratings yet

- Overall Heat Transfer CoefficientDocument8 pagesOverall Heat Transfer CoefficientSarthak DandareNo ratings yet

- High-performance industrial gear oilsDocument5 pagesHigh-performance industrial gear oilsKeshab ShresthaNo ratings yet

- Model Exam - 1Document6 pagesModel Exam - 1Bipul Poudel100% (2)

- MP Assignment-III (Questions)Document1 pageMP Assignment-III (Questions)Raja HarisNo ratings yet

- Unsteady Heat Transfer Experiment ResultsDocument16 pagesUnsteady Heat Transfer Experiment ResultssukhmaniNo ratings yet