Professional Documents

Culture Documents

Layouts and Heat-Sinking (Classes A, AB, B, C, H) Layouts

Uploaded by

sarantapodarusa4009Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Layouts and Heat-Sinking (Classes A, AB, B, C, H) Layouts

Uploaded by

sarantapodarusa4009Copyright:

Available Formats

Layouts and heat-sinking (classes A, AB, B, C, H)

Layouts

To ease production costs amplifier cases usually consist

of a rectangular box, the internal layout of a common

domestic stereo amplifier looking similar to that below.

All those components inside handling power are then

dissipating heat in what amounts to a confined space.

Although ventilation holes and slots will be provided,

convection alone may not be sufficient and, as a

consequence, amplifiers can get hot. The situation can

be exacerbated when other 'components' such as

cassette decks, tuners, etc, are stacked on top. In tuner

amplifiers with more internal clutter and four or more

filament indicator lamps, internal heat generation when

quiescent can be that of a soldering iron.

The above arrangement, of a more sophisticated design,

can be useful if the bridge rectifiers and smoothers are

placed between the heat-sinks resulting in lowimpedance runs to the output devices via the amplifier's

PCB (an excellent way to reduce wiring, connectors and

associated problems).

Some designs will increase dissipation by exposing the

fins. However, exposed TO3 cans, for example, are

always a bad idea, given the added propensity for

'accidents'.

Sometimes a compact design ethic can introduce

problems that could be avoided with a larger enclosure.

For example, in the Mission Cyrus 1 heat-sinking was

limited (acknowledged in the instruction manual) with a

distinct lack of radiator fins, a commercial constraint

perhaps, an issue then addressed in the '2' with further

mods to increase output power and, invariably,

operating temperature.

Note the virtual absence of heatsinking and 'complex'

wiring of output stage in the Cambridge Audio P50 mkI

when the output device packages were specifically

intended for direct PCB mounting. The words 'baby' and

bathwater' come to mind.

The later mks redesigned the power amplifier

completely (including DC output coupling) and mounted

the output devices on aluminium extrusions to help

dissipation. The large supply electrolytics were however,

in the author's view, mounted too close to these.

Although some components can have comparatively

high operating temperature ranges, others will not.

Elevated temperatures will then reduce the operating

life of the equipment, possibly prompting a re-design,

but by then reputations can have been damaged. This

principle applies to most components, electrical and

even mechanical. For example, if the tungsten filament

temperature of a 150W general purpose light bulb is

reduced by some 300C by using half of it's rated

current, life expectancy can be increased by a factor of

a thousand, which can be useful for critical situations.

By using two 150W bulbs in series to give the light

output of one 100W bulb a newer dimension of

reliability is given to the function with a 25% reduction

in running costs. In contrast, assuming intermittent use,

a respectable brand of power tools, etc, designs all it's

motors for a total working full-load life of only ten

minutes.

Electronic components come in three grades commercial, industrial and military, each having a wider

operating temperature range than the former, for

example with semiconductors the following ranges may

be offered: commercial; 0C to +70C, industrial; -20C

to +85C and military; -55C to +200C. Choosing

industrial grade will increase reliability without

bankrupting.

A high-grade electrolytic capacitor might give typical

lives of say 1,000 hours (41 days) at 105C, 10,000

hours (13 months) at 85C and 160,000 hours (18

years) at 40C. The safe ripple current is also

temperature dependent, for example, the same

capacitor may quote 140% at 20C, 120% at 40C,

80% at 70C and only 40% at 85C.

Plotting these suggests a safe operating maximum

temperature of 50C and, operating below the

maximum ripple rating given, a life in excess of eleven

years.

A commercial 'audio' grade (and thus more expensive!)

capacitor, offering inferior performance, might offer only

2,000 hours at 85C. Allow ventilation around main

smoothers since reduced operating temperatures can

increase life dramatically.

Rate resistors at twice their operating dissipation.

Normally a resistor is fitted close to the PCB, eg;

Those intended to carry high loads should be mounted

so that air-flow can occur around them, thus reducing

the possibility of hot spots and fire damage to the PCB

when a resistor incinerates. For best dissipation,

cylindrical types should be mounted horizontally. A

minimum distance between the PCB and adjacent

components can exceed the resistor's diameter, eg;

(2W5 emitter resistors for paralleled output devices,

class A)

Notwithstanding structural strength and circuit layout

issues, strategically placed large diameter holes through

the PCB will aid ventilation. If a low value, high power

resistor is not readily available, especially if a noninductive type is required, higher value, lower power

types can be paralleled. For example, if a 0R2, 5W is

needed then 10 2R, 0W6 MO types can be paralleled.

Anticipated uses of silicon bipolar power transistors have

been evaluated (1970s) by one manufacturer as

follows;

Silicon semiconductor junctions will fail at some 175C

(TO220) to 200C (TO3), although any plastic package

used will fail before this. The life expectancy of such

junctions is inversely proportional to temperature, and

typically at up to 150C the life expectancy of a TO220

type halves for every 10-15C increase. Between 150C

and 175C it halves for every 5-10C. To be safe,

assume that 100C is too hot. At the same time, it must

be borne in mind that whilst a transistor's maximum

power rating is quoted for 25C, at the maximum

temperature this must have been linearly derated to

zero.

Reducing chip operating temperature will not only

increase longevity but will increase safe power delivery

capacity. Thermal-cycling rating curves are usually

included in a transistor's datasheet. These can be useful

in predicting a maximum number of thermal cycles at a

given wattage versus temperature change. An

approximation for that for a 2N3055 pellet in a TO3 case

is given below and plots life expectancy versus thermal

stress, eg; if in excess of 100,000 operational cycles

involving a 50C temperature change are required, then

a maximum dissipation of some 30W or lower is

required. With a Tc of 75C this would be nearer 14W.

A sudden current surge, say from a short-circuited

speaker or associated wiring, can heat the chip to

catastrophic levels before the heat-sink can act. Lesser

heating events will have a cumulative effect on the chip,

in the same way a car windscreen can store stresses

over time, and will reduce life expectancy.

Bipolar transistors have a negative temperature

coefficient, this means that as they heat up they pass

more current, thus getting hotter. An inadequate bias

arrangement can exacerbate this. V-FETs have a

positive temperature coefficient which means that the

current they pass reduces as they heat up. These

devices have an inherent safety feature built in. At the

same time, because of their construction, V-FETs do not

develop hot-spots, which bipolar types are prone to. By

increasing the number of output devices, whether

bipolar or FET, this heat can be spread, or dissipated,

over a larger area.

Some high-power designs require fans, or forced-air

cooling, otherwise the case design will become

cumbersome. Unfortunately, fans and/or their drive

circuits can fail and a secondary thermal cut-out is

usually included. One manufacturer made very compact

forced-air cooled power amplifiers on a modular basis,

which at first seemed like a good idea. Unfortunately,

the fans included usually failed leaving the power amps

to cook unnoticed until, of course, it was too late. A

complex design, with a higher component count,

inevitably has 'more to go wrong' than a simpler albeit

bulkier one.

(Modifications to allow micropower sampling techniques

for low power systems).

Some professional designs with E-I laminated mains

transformers mounted these externally with the heatsinks. Excellent from a cooling point of view, and

helping to reduce hum pickup. The Technics SE-9060, a

compact but punchy and reliable favourite, is a good

example.

Two of these, each in bridge mode, drove multiple 18"

400W fundamental bass units as part of a highly mobile

system some described as 'awesome'. With this, it was

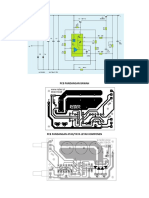

hard to disagree. An excellent example of PCB design,

typical of the Japanese, that considerably reduces

wiring, a similar layout appearing in the later SU-V6.

The older and much larger SE-9600 used massive heatsinks down it's sides, whilst leaving the centrally

mounted mains transformer and smoothers exposed.

This design had regulators for the power stages and

consumed 960W whilst delivering 185W/4R or 110W/8R

with both channels.

The less complex, but eye-catching, class A Nakamichi

PA-7, which used 16 TO220 (14 output) devices per

channel used a similar form, whilst other manufacturers

used bridged configurations to help reduce enclosure

volumes, like those used in the Crown MicroTech 1000.

Some smaller cabinet designs, like those of the Quad

303 and the 405, made the front panel the heat-sink.

Although sometimes limited, this can be an excellent

idea when it is considered how the majority of domestic

hi-fi amplifiers and their peripherals are crammed into a

small space, with no air-flow around them. Lecson went

even further with a design that is still a subject of

discussion, and admiration. Always remember that a

heat-sink's given rating is that for operating in free air,

with no restrictions by cases, cabinets, wiring, etc, and

that the dissipation is distributed between all of the

devices fitted to it. For example, a 1.2C/W heat-sink

fitted with 4 output devices = 4.8C/W per transistor.

Removing the top panel from a contemporary power

amplifier might well reveal a similar layout to that

below. This arrangement has been used for fast

specialist designs of 50W or more and for professional

units delivering hundreds of watts. The two normally flat

side-panels are instead large area comb-type heatsinks

which, unrestricted in free air, do not require the use of

a fan. Deep comb heat-sinks with thermal resistances of

<1C/W are available. Heat from the output devices

entering the amplifier case then is much reduced.

Notwithstanding the heat generated by, say, an

amplifier rack, ambient temperatures may impose

restrictions on the maximum power it may be safe to

draw. Embarrassment can arise if a thermal cut-out

trips and a live performance then has to wait for it to

reset. Airflow into the case can be encouraged by

ventilating the bottom panel, especially if aesthetics or

function demand an undrilled top panel. Consideration

may have to be given to reinforcing the bottom panel

since it may be supporting a heavy component like the

mains transformer. Bracing and structural members may

be employed and care taken to avoid weakening the

case's structure. Ventilation holes may then be made in

less critical areas (shaded areas below). Assuming

convectional flow, exit slots can be placed along the top

of the rear panel allowing air to leave.

If components, like the smoothers, are stood off the

panels they are mounted on, airflow, however slight,

will be encouraged. In such a design the height of the

case will be determined by the height of the mains

transformer which will be mounted flush with it's

respective support panel. A gap between the

transformer and the upper panel will aid ventilation. If

aesthetics demand a slim design then two smaller

transformers can be used. To prevent long wiring runs

that could degrade performance, switches mounted at

the rear of the unit can be actuated by insulated rods

that then pass through the front panel.

The Armstrong 732 (only about 50 of which were built)

used this layout, the heat-sinks giving a reported rise

during heavy use of 10C. Some raised concerns over

limitations of the internal layout and the form of the

wiring.

The height of a high-power design will usually be

determined by the heat-sink's length. In such a

situation the electrolytics can be mounted vertically,

reducing case volume.

This configuration of case, using sheet steel, can be

assembled quickly. 2-3mm is recommended, although

thicker sheet can give an appealingly industrial

appearance when used with associated fasteners.

Portability is, however, reduced.

Heat-sinking

Heat-sinking is one parameter of which there usually

cannot be enough of, some designs appearing to offer

very little (take the Leak Delta 30/70). Consider the

operating conditions. For example, apart from being

hammered will a new design be used in a confined

space, in intense sunlight, next to a heater or be left on

for days? Unfortunately, a 100% duty-cycle is not

usually a commercial consideration.

A class AB output transistor will, as the graphs show, be

under greater stress at a 'mid-band' voltage level

compared to the upper and lower limits. The greatest

stress occurs when the voltages across the load and

output device are equal.

Up to this point the output stage dissipates more energy

than the load, efficiency increasing as the voltage across

the device decreases. Given listening constraints,

headroom, etc, most use will be in the least efficient

area. Due to the dropout voltages across the output

devices (say 5V), notwithstanding power supply

considerations, a maximum of about 90% will be

achieved just before clipping.

Simply idling, a class A can consume some four or far

more times it's maximum usable output. Output stage

dissipation is drastically reduced with class D or G

configurations and these should be subjectively

evaluated if hardware considerations are excessive.

Looking at datasheets it can be seen that TO220

packages offer a typical operating temperature range of

-65C to +150C and thermal resistances of, say,

1.92C/W (TIP41), 2.5C/W, 3.125C/W and 4.17C/W.

Taking some older, well-known types as examples, the

TIP41, 150C - (say) 25C ambient = 125C operating

range.

TO3 packages (-65C to +200C) can offer from say

1.17C/W, 1.4C/W, 1.5C/W (2N3055) to 1.75C/W.

The 2N3055 gives 200C - 25C ambient = 175C. The

chips of these are usually <3mm square, higher rated

devices can nearly treble this.

Insulators will invariably be placed between the output

devices and the heat-sink, beryllium oxide, anodized

aluminium and mica can be used. Thermal compound on

mating surfaces will reduce thermal resistance to some

0.4C/W. Silicone-rubber washers offering 0.5C/W

without compound can be used, but should be replaced

when refitting a device. A safe margin to consider would

be 1C/W. However, TO220 devices might give 1.5C/W

with a 0.002" mica washer and 2C/W with 0.004" (with

Dow Corning 340 silicon grease). Larger mounting areas

will give a lower thermal resistance, although a hermetic

TO3 may not be a better choice than a plastic package

since some aluminium cases can fail after some 5,000

thermal cycles, allowing corrosion to occur.

For the TIP41, a maximum operating dissipation then

(with a 3C/W heat-sink) appears to be 1.92C/W +

1C/W + 3C/W = 5.92C/W , 125/5.92 = 21.1W,

considerably less than the 65W rated. With a larger

0.5C/W heat-sink; 1.92C/W + 1C/W + 0.5C/W =

3.42C/W , 125/3.42 = 36.5W.

For a 2N3055 with the same heat-sink this would be

1.5C/W + 1C/W + 3C/W = 5.5C/W, 150/5.5 =

27.3W, compared to the rated 117W. With a larger

0.5C/W heat-sink; 1.5C/W + 1C/W + 0.5C/W =

3C/W , 175/3 = 58W.

If 100C is considered an absolute maximum limit,

dissipation levels fall even further to 12W and 13W

respectively, for a 3C/W heat-sink, then 22W and 25W

for a 0.5C/W heat-sink. The same applies if the

ambient temperature is higher.

With a 6R load, a transistor will dissipate some 26Wmax

in an output pair running from a supply of 25V, some

38W with a supply of 30V and some 127W with 55V.

An averaged 'duty-cycle' of 50% can be assumed, but

may be meaningless considering signal content.

Similarly, a load's frequency dependent reactance can

impose conditions far in excess of an output device's

designed capabilities.

Given that the figure for a TO3 has an extra margin, it

can be seen that two, or even three, TO220 packages

will have a smaller PCB footprint than a single TO3 and

will be easier to mount. Paralleled devices can be

spaced quite closely together on a heat-sink since there

will be a distinct drop in chip operating temperature,

which is after all the object of the exercise.

Newer bipolar transistor designs, like the

MJL3281A/MJL1302A (TO-264) complementary pair, can

offer a vast improvement on older designs. Typical specs

for these devices include ratings of 200V, 200W, hFE 60175 (45min), fT 30MHz, Rjc 0.7C/W. Devices like these

should be considered for new builds and upgrades.

A rough rule of thumb balancing cost versus

performance appears to recommend the use of output

devices whose maximum ratings total about five times

the amplifier's output power.

With 6 V-FETs, say, each with a maximum rating of

125W, totalling 750W, a reasonable maximum output of

between 125W and 187W seems feasible. Assuming an

AB output and an averaged 60% efficiency, heat output

can be expected to be between 83W and 124W. Heatsinking should then be rated at 0.8C/W in free air, or

less. This can be derated in proportion to a reduction in

supply voltage/output power, eg: 1.6C/W for 50-75W

and 3.2C/W for 30W output. For stereo use, another

rough rule of thumb gives 2.5C/W for a 100VA

transformer, 5 for 50VA and 1.2 for a 200VA, etc.

Ideally, and where feasible, design for a continuous DC

output.

A similar hardware layout can be used for PWM

implementations involving paralleled output pairs and/or

those utilising Paralleled Phase Shifted Carrier Pulse

Width Modulation, or PPSCPWM, which can potentially

offer higher output handling using smaller output

devices and a virtual absence of heat-sinking by

comparison.

Most good quality systems appear to give a sufficient

domestic output at 3W, or less, per channel and to

observe a ratio of 20:1 or more between the maximum

power handling available and that used to obtain a

satisfactory sound output, 50-75W appearing adequate.

However, smaller designs cannot be underestimated, if

built well.

A method to load limit a 2N3055 to 40W is given below

but is unsuitable as an audio output stage.

Output transistors are often mounted on an 'anglebracket' which is then bolted to a heat-sink. This can be

unavoidable with TO3 cases which are then soldered to

the PCB, but can concentrate heat around the output

devices, especially if the bracket is thin and/or has been

bent to a right-angle. This last may surprise but is

caused by the deformation of the metal's crystals

offering a higher thermal resistance. If resource

permits, this bracket should be as substantial as

possible and ideally be milled from copper, although

extruded aluminium is often used. Beryllium is not

recommended however, despite it's use in electronics as

a heat transfer medium.

A common arrangement is for the heat-sink to be

attached to the back panel, flat-pack style packaged

output devices can then be secured to this via screws

through the panel, see below (back panel omitted for

clarity).

An increased rate of dissipation can be achieved with

two heat-sinks, a more even 'spread' obtained with a

'pillow' between the output devices and heat-sinks. This

can be copper (5mm or more thick) and have a

mounting face similar in size, but smaller than a single

heat-sink's mounting face. An arrangement like this can

be used if a common heat-sink is used in a stereo

design, or if high-power handling is a priority, thus

aiding disspation along the heat-sink's entire length.

Apply thermal compound to all mating surfaces. With

comb-type heat-sinks in free air apply heat-flow

contrary, or perpendicular, to vane orientation, which

should be vertical, as shown.

From the above illustrations it can be seen that the

outermost output transistor's mounting screws are

obscured by an electrolytic capacitor. An axial type,

although having a greater PCB footprint, might be a

better choice than a radial one. When designing a PCB

bear these aspects in mind in order to avoid further

unnecessary disassembly when required. Similarly, even

a slight gap between the PCB and heat-sink will promote

air-flow around the output devices. The solution below,

though compact, does not represent the best dissipative

layout.

For example, all of the components on the PCB will be

subjected to the temperature rise emanating from the

output devices. During the design process, this will

probably not have been taken into account and, as a

consequence, the resulting failure rate can then be high

and/or instabilities can arise as commercial grade

components are run at or near their thermal limits.

Sometimes a heat-sink's physical design lends itself to,

or inspires, an innovative or eye-catching case. Highpower industrial types can be an example. Keeping

things simple, however, is often the key to a design

becoming reality. Water-cooling, for example (necessary

for some transmitters, X-ray machines and fashionable

for overclocked PCs), can introduce far more problems

than it solves.

In a similar vein, two Class A designs used heavy-duty

radiators in layouts like those shown below.

In each case, 6 off Redpoint NV115-1 type heat-sinks

offering 0.5W/C were used. This profile, in larger form,

was intended for flanged 200A+ thyristors (which had

leads fitted and were used on milk floats, fork-lifts, etc)

and not for T03 packages. In these amplifiers a

considerable proportion of the fins are encased and/or

obscured by the enclosure, reducing the airflow and

efficacy of the heat-sinking by a considerable margin

thus negating much of the reasoning behind choosing

these types. The output devices (and regulators in one

case) then have to be connected to their respective

PCBs by long lengths of wiring, a 'warm' invitation to

instability problems, RF pick-up, etc.

It is assumed that these types were adopted for their

low thermal resistance, although an element of overkill

was evident in one design, the input capacitor being

rated at 630VDC(!) whilst those components that

followed were of a much more modest 'normal' scale. At

the same time, in both designs, considerations relating

to mains filtering and soft-starting for the large-value

capacitor banks were completely absent. Given that one

of these amplifiers is required per speaker, with a usable

output of 60W in one case and perhaps a quarter of that

from the other with everything running flat out, the

author would adopt the form shown earlier not only for

the reservations stated, but also on grounds of reduced

cost and bulk.

By contrast, a layout used for another amplifier, using

machined plates and rectangular section tube

aluminium, presents a more efficient, and pleasing

aspect.

Nevertheless, a perhaps faulty assumption is made that

simply because the mode of operation is class A,

everything must run hot.

Many amplifiers assume the general shape of A below

which doesn't always have to be the case.

Sony experimented with cylindrical radios and made

some smaller integrated amps having the form of B in

the sixties, which, in use (bookshelf), made greater

ergonomic sense. Notwithstanding the limitations set by

cooling requirements (for example, in B the sides can

now present a large possible heat-sinking area), this in

itself can be an area of study, eg;

A very efficient and substantial radiator from the '70s

(cast aluminium, Crimson Electrik) used 'fingers' instead

of fins.

Class D amplifiers

Power Supplies | Protection | Distortion | Dimensioning

a design | Setting up an audio amplifier

Contact me at paulkemble@hotmail.com

especially if you want additional content to this page

or if you find any links that don't work. Don't forget

to add the page title or URL. Take care!

Back to index, sound, tips or home.

Sponsored by

You might also like

- Zilano 2Document22 pagesZilano 2blargbl100% (4)

- All About The Design of HeatsinksDocument40 pagesAll About The Design of Heatsinks조용규No ratings yet

- The Heat Sink Guide-Information About HeatsinksDocument6 pagesThe Heat Sink Guide-Information About HeatsinksTahseen Al-Sumayda'yNo ratings yet

- Stan Curtis, System A AmplifierDocument3 pagesStan Curtis, System A AmplifierGrahamNo ratings yet

- Designing Inherently Short-Circuit-Proof, Potted Safety Transformers Up To 10VA With Rale Design System, in Accordance With IEC 61558Document15 pagesDesigning Inherently Short-Circuit-Proof, Potted Safety Transformers Up To 10VA With Rale Design System, in Accordance With IEC 61558PredragPeđaMarkovićNo ratings yet

- Heat SinkDocument15 pagesHeat Sinknitin chauhanNo ratings yet

- GoedhartVCI P 2012 en Version1 IDocument24 pagesGoedhartVCI P 2012 en Version1 IRodrigo GonçalvesNo ratings yet

- Electric Furnace SteelmakingDocument136 pagesElectric Furnace SteelmakingIsrael Damian Silva Rosado100% (2)

- Comparing Plate-Fin and Coil-Wound Heat ExchangersDocument16 pagesComparing Plate-Fin and Coil-Wound Heat Exchangerscapricorno4694No ratings yet

- Transformer Heating and CoolingDocument11 pagesTransformer Heating and CoolingAli FarooqNo ratings yet

- First Tests of Bi-Y T-FDocument8 pagesFirst Tests of Bi-Y T-FEBENo ratings yet

- Thermal Efficiency For Conduction Cooled MIL-Spec EnclosuresDocument2 pagesThermal Efficiency For Conduction Cooled MIL-Spec EnclosuresRodrigo Rivera CarrilloNo ratings yet

- LNG Applications of Diffusion Bonded HEXDocument9 pagesLNG Applications of Diffusion Bonded HEXrowanlimNo ratings yet

- Russell ALL Temp2BDocument8 pagesRussell ALL Temp2BErixon RamírezNo ratings yet

- AEM600 Lateral MOS-FET Audio Amplifier DesignDocument5 pagesAEM600 Lateral MOS-FET Audio Amplifier DesignCristi Mihalcea100% (1)

- Air Coolers LiteratureDocument11 pagesAir Coolers Literatureyinkaakins200133% (3)

- Introduction To Power AmplifiersDocument22 pagesIntroduction To Power AmplifiersGaneshVenkatachalamNo ratings yet

- What Is PCB Thermal ResistanceDocument11 pagesWhat Is PCB Thermal ResistancejackNo ratings yet

- Coil - Fundamentals Question & AnswerDocument12 pagesCoil - Fundamentals Question & AnsweroiramhoangNo ratings yet

- Cooling System of TransformerDocument6 pagesCooling System of TransformerFaiza RafliNo ratings yet

- Heat SinkDocument2 pagesHeat Sinkmartinroger100% (1)

- Coping With Very High Heat Loads in Electronic Telephone Systems of The Future R. Mckay Bell Communications Research, Morristown, J UsaDocument5 pagesCoping With Very High Heat Loads in Electronic Telephone Systems of The Future R. Mckay Bell Communications Research, Morristown, J UsakrrbanirudhNo ratings yet

- AH AV CatalogDocument16 pagesAH AV CatalognomurapreNo ratings yet

- Ohmite-What Is A Heatsink-StageDocument7 pagesOhmite-What Is A Heatsink-StagemilitiamonNo ratings yet

- Specialty HeatersDocument40 pagesSpecialty Heaterskvanps_kumarNo ratings yet

- 31.0 Thermal Considerations: 31.1 Computer Finite Element AnalysisDocument4 pages31.0 Thermal Considerations: 31.1 Computer Finite Element Analysisbuggy buggerNo ratings yet

- General Information On Air-Cooled Heat ExchangersDocument5 pagesGeneral Information On Air-Cooled Heat ExchangersSrinivas BobbyNo ratings yet

- B1+ GyratorDocument3 pagesB1+ GyratorbigpriapNo ratings yet

- History and Introduction PeltierDocument15 pagesHistory and Introduction PeltierZilhaq Putra Edy SanjayaNo ratings yet

- Convection Section CleaningDocument10 pagesConvection Section CleaningSuresh RamakrishnanNo ratings yet

- Thermoelectric Cooling For Industrial EnclosuresDocument6 pagesThermoelectric Cooling For Industrial EnclosuresErdinc KlimaNo ratings yet

- AgitatorsDocument5 pagesAgitatorsDon Aries EidosNo ratings yet

- Strip Heater Technical CatalogueDocument8 pagesStrip Heater Technical CataloguechikoopandaNo ratings yet

- Cooling Technology for ElectronicsDocument29 pagesCooling Technology for ElectronicsNikhil ShahNo ratings yet

- FCU McQUAYDocument12 pagesFCU McQUAYben_splNo ratings yet

- Build a powerful 1.4kW induction heaterDocument8 pagesBuild a powerful 1.4kW induction heaterArte Y MecatrónicaNo ratings yet

- CHEVRON Shell and Tube Exchanger Component Design ConsiderationsDocument42 pagesCHEVRON Shell and Tube Exchanger Component Design Considerationsbabak mir80% (5)

- Air Cooled Heat ExchangersDocument5 pagesAir Cooled Heat ExchangersRamuAlagappanNo ratings yet

- 4 Eng Induction Welded Small Diameter TubeDocument22 pages4 Eng Induction Welded Small Diameter TubeDimitri PanagiotouNo ratings yet

- Bohn Evaporator 202-3Document12 pagesBohn Evaporator 202-3Jose Arenas CañasNo ratings yet

- 450 Watt 6m Amplifier: Chris, G3WOS - July 1993Document10 pages450 Watt 6m Amplifier: Chris, G3WOS - July 1993Adrian DrakesNo ratings yet

- Question and Answers From Web Seminar: Heatsink 201: Even More About Heatsink DesignDocument10 pagesQuestion and Answers From Web Seminar: Heatsink 201: Even More About Heatsink DesignooqqNo ratings yet

- Pressure Vessel Design: 10 Key Factors to Avoid Costly MistakesDocument8 pagesPressure Vessel Design: 10 Key Factors to Avoid Costly Mistakesmarcel linaNo ratings yet

- What Is A Heat Sink and Its ImportanceDocument8 pagesWhat Is A Heat Sink and Its ImportancezulNo ratings yet

- Industrial air cooler VCI with capacities up to 149 kWDocument16 pagesIndustrial air cooler VCI with capacities up to 149 kWAleksandarAndric100% (1)

- Gas Cooling Systems For Steam Reforming PlantsDocument12 pagesGas Cooling Systems For Steam Reforming Plantsrajaramc100% (1)

- Heat Pipe Application GuidelinesDocument8 pagesHeat Pipe Application Guidelinesaliscribd46No ratings yet

- Designing Compact Heat ExchangersDocument6 pagesDesigning Compact Heat ExchangersAndrés Ramón Linares100% (1)

- Storage CalorifiersDocument5 pagesStorage CalorifiersVishnu ThampiNo ratings yet

- eBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeDocument18 pageseBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeMoly69xNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Innovation in Electric Arc Furnaces: Scientific Basis for SelectionFrom EverandInnovation in Electric Arc Furnaces: Scientific Basis for SelectionNo ratings yet

- Electroplating for Amateurs: Classic Reference for Small WorkshopsFrom EverandElectroplating for Amateurs: Classic Reference for Small WorkshopsNo ratings yet

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationFrom EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNo ratings yet

- Metal DetectorsDocument4 pagesMetal Detectorssarantapodarusa4009No ratings yet

- THD Transient Distortion Cross-Over Distortion Clipping Noise Instabilities 'Paranormal' Audio A TipDocument24 pagesTHD Transient Distortion Cross-Over Distortion Clipping Noise Instabilities 'Paranormal' Audio A Tipsarantapodarusa4009No ratings yet

- Slot Car StarterDocument4 pagesSlot Car Startersarantapodarusa4009No ratings yet

- PhotoshellsDocument5 pagesPhotoshellssarantapodarusa4009No ratings yet

- Compact Power Amplifier DesignsDocument18 pagesCompact Power Amplifier Designssarantapodarusa4009No ratings yet

- Noise MeasurementsDocument8 pagesNoise Measurementssarantapodarusa4009No ratings yet

- Pre AmpsDocument15 pagesPre Ampssarantapodarusa4009No ratings yet

- Low-Cost Radio Control SystemDocument9 pagesLow-Cost Radio Control Systemsarantapodarusa4009No ratings yet

- Light Beam CommunicationDocument3 pagesLight Beam Communicationsarantapodarusa4009No ratings yet

- Layouts and HeatDocument25 pagesLayouts and Heatsarantapodarusa4009No ratings yet

- Peter, Your Email Address Malfunctioned. Please Try Again.: Ics and ModulesDocument20 pagesPeter, Your Email Address Malfunctioned. Please Try Again.: Ics and Modulessarantapodarusa4009No ratings yet

- Amplifier Soft StartsDocument7 pagesAmplifier Soft Startssarantapodarusa4009No ratings yet

- Audio Amplifiers 17Document2 pagesAudio Amplifiers 17sarantapodarusa4009No ratings yet

- Offsetting An Audio AmplifierDocument10 pagesOffsetting An Audio Amplifiersarantapodarusa4009No ratings yet

- EqualisationDocument22 pagesEqualisationsarantapodarusa4009No ratings yet

- 100W Darlington AmplifierDocument5 pages100W Darlington Amplifiersarantapodarusa4009No ratings yet

- 200W RawDocument2 pages200W Rawsarantapodarusa4009No ratings yet

- Electronic SwitchingDocument18 pagesElectronic Switchingsarantapodarusa4009No ratings yet

- Pre AmpsDocument15 pagesPre Ampssarantapodarusa4009No ratings yet

- Noise MeasurementsDocument8 pagesNoise Measurementssarantapodarusa4009No ratings yet

- Amplifier Power SuppliesDocument33 pagesAmplifier Power Suppliessarantapodarusa4009No ratings yet

- Bessel ArraysDocument6 pagesBessel Arrayssarantapodarusa4009No ratings yet

- A Few Popular Circuits Supplied by MaplinDocument5 pagesA Few Popular Circuits Supplied by Maplinsarantapodarusa4009No ratings yet

- Offsetting An Audio AmplifierDocument10 pagesOffsetting An Audio Amplifiersarantapodarusa4009No ratings yet

- Layouts and HeatDocument25 pagesLayouts and Heatsarantapodarusa4009No ratings yet

- Peter, Your Email Address Malfunctioned. Please Try Again.: Ics and ModulesDocument20 pagesPeter, Your Email Address Malfunctioned. Please Try Again.: Ics and Modulessarantapodarusa4009No ratings yet

- 100W Darlington AmplifierDocument5 pages100W Darlington Amplifiersarantapodarusa4009No ratings yet

- EqualisationDocument22 pagesEqualisationsarantapodarusa4009No ratings yet

- Electronic SwitchingDocument18 pagesElectronic Switchingsarantapodarusa4009No ratings yet

- THD Transient Distortion Cross-Over Distortion Clipping Noise Instabilities 'Paranormal' Audio A TipDocument24 pagesTHD Transient Distortion Cross-Over Distortion Clipping Noise Instabilities 'Paranormal' Audio A Tipsarantapodarusa4009No ratings yet

- TEKTRONIX 576 Curve Tracer ApplicationsDocument24 pagesTEKTRONIX 576 Curve Tracer Applicationselectron1999100% (1)

- The Giant Book of Electronics ProjectsDocument496 pagesThe Giant Book of Electronics Projectsvoip54301100% (38)

- 2n3055 (NPN), Mj2955 (PNP)Document4 pages2n3055 (NPN), Mj2955 (PNP)chikulenkaNo ratings yet

- Variable Power Supply ProjectDocument33 pagesVariable Power Supply ProjectEmmanuelNo ratings yet

- JLH 2001 DesignDocument4 pagesJLH 2001 DesignDaniel ScardiniNo ratings yet

- 2N3055 Power Amplifier 60W Electronic Circuit DiagramDocument2 pages2N3055 Power Amplifier 60W Electronic Circuit DiagramClaudio FernandesNo ratings yet

- Project Report on "Name of ProjectDocument42 pagesProject Report on "Name of ProjectYash TayadeNo ratings yet

- RCA Transistor Guide for SA 5010Document3 pagesRCA Transistor Guide for SA 5010rosaire lessardNo ratings yet

- Tesla's 4-Battery CircuitDocument22 pagesTesla's 4-Battery CircuitDr_ZeusNo ratings yet

- Equivalencia de Transistor BipolarDocument35 pagesEquivalencia de Transistor Bipolarsonhador4583% (18)

- Amp ExpandibletranslatedDocument21 pagesAmp Expandibletranslatedvinxy beeNo ratings yet

- Tabela de TransistoresDocument116 pagesTabela de TransistoresNelson de CamposNo ratings yet

- Transistores PeaveyDocument27 pagesTransistores PeaveyLuis Enrique Bejarano CastilloNo ratings yet

- Invertor 12V La 240VDocument2 pagesInvertor 12V La 240Vcnx tehnicNo ratings yet

- TR 2N3055Document5 pagesTR 2N3055mi2nXtremNo ratings yet

- 2N3055 (NPN), MJ2955 (PNP) Complementary Silicon Power TransistorsDocument3 pages2N3055 (NPN), MJ2955 (PNP) Complementary Silicon Power TransistorsMichaelAngeloDelaCruzNo ratings yet

- 100 Watt Inverter Circuit: Circuit Diagram With Parts ListDocument2 pages100 Watt Inverter Circuit: Circuit Diagram With Parts ListCris DucusinNo ratings yet

- CHARLIE's Thomas Vox ReplacementsDocument7 pagesCHARLIE's Thomas Vox ReplacementsBDNo ratings yet

- ETI 466 300 WattsDocument27 pagesETI 466 300 WattsDragoş DavidNo ratings yet

- Fonte 12vDocument9 pagesFonte 12vSilvio CostaNo ratings yet

- Bipolar Transistor Equivalences PDFDocument47 pagesBipolar Transistor Equivalences PDFMarcelo LorencNo ratings yet

- Below The Circuit Diagram of Yiroshi Audio Power Amplifier DriverDocument3 pagesBelow The Circuit Diagram of Yiroshi Audio Power Amplifier Driverharry selhasNo ratings yet

- The Main Amplifier 50 Watt OCL by LF351-2N3055-MJ2955 With PCB - Electronic Circuits & Mini Projecs PDFDocument7 pagesThe Main Amplifier 50 Watt OCL by LF351-2N3055-MJ2955 With PCB - Electronic Circuits & Mini Projecs PDFPernandosNo ratings yet

- 2N3055 PDFDocument3 pages2N3055 PDFShafiqNo ratings yet

- Tabela de TransistoresDocument116 pagesTabela de Transistoresmiguel_catNo ratings yet

- About Power SupplyDocument17 pagesAbout Power SupplyAnonymous DjWqKpZ1No ratings yet

- Catu Daya 723Document6 pagesCatu Daya 723Audi MirantiNo ratings yet

- Transistores PEAVEYDocument25 pagesTransistores PEAVEYalitoparana75% (4)

- Simple and Stable 13.8V DC Regulator With LM713Document3 pagesSimple and Stable 13.8V DC Regulator With LM713rj arcinasNo ratings yet