Professional Documents

Culture Documents

PV Elite Result

Uploaded by

Veny MartianiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PV Elite Result

Uploaded by

Veny MartianiCopyright:

Available Formats

Table of Contents

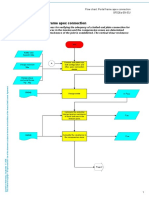

Cover Page

Title Page

Warnings and Errors :

Input Echo :

XY Coordinate Calculations :

Internal Pressure Calculations :

External Pressure Calculations :

Element and Detail Weights :

Center of Gravity Calculation :

MDMT Summary :

Vessel Design Summary :

1

2

3

4

7

8

11

13

15

16

17

Cover Page

DESIGN CALCULATION

In Accordance with ASME Section VIII Division 1

ASME Code Version

: 2013

Analysis Performed by : SPLM Licensed User

Job File

: C:\USERS\PUBLIC\DOCUMENTS\INTERGRAPH CAS\PVELITE

Date of Analysis

PV Elite 2014,

Jul 8,2015

January 2014

Title Page

Note: PV Elite performs all calculations internally in Imperial Units

to remain compliant with the ASME Code and any built in assumptions

in the ASME Code formulas. The customary Imperial database is

used for consistency. The finalized results are reflected to show

the users set of selected units.

PV Elite 2014 Licensee: SPLM Licensed User

FileName : Veny Martiani_121724030

Warnings and Errors :

Step:

9:21p

Page 3 of 17

Jul 8,2015

Class From To : Basic Element Checks.

==========================================================================

Class From To: Check of Additional Element Data

==========================================================================

There were no geometry errors or warnings.

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2014

PV Elite 2014 Licensee: SPLM Licensed User

FileName : Veny Martiani_121724030

Input Echo :

Step:

9:21p

Page 4 of 17

Jul 8,2015

PV Elite Vessel Analysis Program: Input Data

Design Internal Pressure (for Hydrotest)

Design Internal Temperature

Type of Hydrotest

Hydrotest Position

Projection of Nozzle from Vessel Top

Projection of Nozzle from Vessel Bottom

Minimum Design Metal Temperature

Type of Construction

Special Service

Degree of Radiography

Miscellaneous Weight Percent

Use Higher Longitudinal Stresses (Flag)

Select t for Internal Pressure (Flag)

Select t for External Pressure (Flag)

Select t for Axial Stress (Flag)

Select Location for Stiff. Rings (Flag)

Consider Vortex Shedding

Perform a Corroded Hydrotest

Is this a Heat Exchanger

User Defined Hydro. Press. (Used if > 0)

User defined MAWP

User defined MAPnc

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Case

Case

Case

Case

Case

Case

Case

Case

Case

Case

Case

Case

Case

Case

Case

Case

Case

Case

Case

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Wind Design Code

Basic Wind Speed

Surface Roughness Category

Importance Factor

Type of Surface

Base Elevation

Percent Wind for Hydrotest

Using User defined Wind Press.

Damping Factor (Beta) for Wind

Damping Factor (Beta) for Wind

Damping Factor (Beta) for Wind

689.46

93

not Specified

Horizontal

0.0000

0.0000

-29

Welded

None

RT 1

0.0

Y

N

N

N

N

Y

N

No

0.0000

0.0000

0.0000

KPa.

C

mm.

mm.

C

KPa.

KPa.

KPa.

NP+EW+WI+FW+BW

NP+EW+EE+FS+BS

NP+OW+WI+FW+BW

NP+OW+EQ+FS+BS

NP+HW+HI

NP+HW+HE

IP+OW+WI+FW+BW

IP+OW+EQ+FS+BS

EP+OW+WI+FW+BW

EP+OW+EQ+FS+BS

HP+HW+HI

HP+HW+HE

IP+WE+EW

IP+WF+CW

IP+VO+OW

IP+VE+EW

NP+VO+OW

FS+BS+IP+OW

FS+BS+EP+OW

[V]

Vs Elev.

(Ope)

(Empty)

(Filled)

Seismic Design Code

UBC Seismic Zone (1=1,2=2a,3=2b,4=3,5=4)

UBC Importance Factor

UBC Soil Type

ASCE-7 93

112.65

C: Open Terrain

1.0

Moderately Smooth

0.0000

33.0

N

0.0100

0.0000

0.0000

UBC 94

0.000

1.000

S1

Km/hr

mm.

PV Elite 2014 Licensee: SPLM Licensed User

FileName : Veny Martiani_121724030

Input Echo :

Step:

9:21p

UBC Horizontal Force Factor

UBC Percent Seismic for Hydrotest

3.000

0.000

Design Nozzle for Des. Press. + St. Head

Consider MAP New and Cold in Noz. Design

Consider External Loads for Nozzle Des.

Use ASME VIII-1 Appendix 1-9

Material Database Year

Page 5 of 17

Jul 8,2015

Y

N

Y

N

Current w/Addenda or Code Year

Configuration Directives:

Do not use Nozzle MDMT Interpretation VIII-1 01-37

Use Table G instead of exact equation for "A"

Shell Head Joints are Tapered

Compute "K" in corroded condition

Use Code Case 2286

Use the MAWP to compute the MDMT

Using Metric Material Databases, ASME II D

No

Yes

Yes

Yes

No

Yes

No

Complete Listing of Vessel Elements and Details:

Element From Node

Element To Node

Element Type

Description

Distance "FROM" to "TO"

Element Outside Diameter

Element Thickness

Internal Corrosion Allowance

Nominal Thickness

External Corrosion Allowance

Design Internal Pressure

Design Temperature Internal Pressure

Design External Pressure

Design Temperature External Pressure

Effective Diameter Multiplier

Material Name

Allowable Stress, Ambient

Allowable Stress, Operating

Allowable Stress, Hydrotest

Material Density

P Number Thickness

Yield Stress, Operating

UCS-66 Chart Curve Designation

External Pressure Chart Name

UNS Number

Product Form

Efficiency, Longitudinal Seam

Efficiency, Circumferential Seam

10

20

Spherical

0.0000

1300.0

10.160

3.1750

45.460

0.0000

455.00

14

101.35

25

1.2

SA-516 70

137.90

137.90

179.27

0.007750

31.750

262.01

B

CS-2

K02700

Plate

1.0

1.0

Element From Node

Detail Type

Detail ID

Dist. from "FROM" Node / Offset dist

Height/Length of Liquid

Liquid Density

10

Liquid

ETHANOL

0.0000

1229.7

0.0007941

Element From Node

Detail Type

Detail ID

Dist. from "FROM" Node / Offset dist

Force in X Direction

10

For./Mom.

F/M:[1 of 1]

0.0000

0.0000

mm.

mm.

mm.

mm.

mm.

mm.

KPa.

C

KPa.

C

N./mm

N./mm

N./mm

kg./cm

mm.

N./mm

mm.

mm.

kg./cm

mm.

Kgf

PV Elite 2014 Licensee: SPLM Licensed User

FileName : Veny Martiani_121724030

Input Echo :

Step:

Force in Y Direction

Force in Z Direction

Moment about X Axis

Moment about Y Axis

Moment about Z Axis

Force/Moment Combination Method

9:21p

Page 6 of 17

Jul 8,2015

0.0000

0.0000

0.0000

0.0000

0.0000

SRSS

Kgf

Kgf

Kg-m.

Kg-m.

Kg-m.

-------------------------------------------------------------------Element From Node

Element To Node

Element Type

Description

Distance "FROM" to "TO"

Element Outside Diameter

Element Thickness

Internal Corrosion Allowance

Nominal Thickness

External Corrosion Allowance

Design Internal Pressure

Design Temperature Internal Pressure

Design External Pressure

Design Temperature External Pressure

Effective Diameter Multiplier

Material Name

Efficiency, Longitudinal Seam

Efficiency, Circumferential Seam

20

30

Cylinder

3770.0

1300.0

10.160

3.1750

45.460

0.0000

455.00

14

101.35

25

1.2

SA-516 70

1.0

1.0

mm.

mm.

mm.

mm.

mm.

mm.

KPa.

C

KPa.

C

-------------------------------------------------------------------Element From Node

Element To Node

Element Type

Description

Distance "FROM" to "TO"

Element Outside Diameter

Element Thickness

Internal Corrosion Allowance

Nominal Thickness

External Corrosion Allowance

Design Internal Pressure

Design Temperature Internal Pressure

Design External Pressure

Design Temperature External Pressure

Effective Diameter Multiplier

Material Name

Efficiency, Longitudinal Seam

Efficiency, Circumferential Seam

Element From Node

Detail Type

Detail ID

Dist. from "FROM" Node / Offset dist

Height/Length of Liquid

Liquid Density

30

40

Spherical

0.0000

1300.0

10.160

3.1750

45.460

0.0000

455.00

14

101.35

25

1.2

SA-516 70

1.0

1.0

30

Liquid

ETHANOL

0.0000

0.0000

0.0007897

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2014

mm.

mm.

mm.

mm.

mm.

mm.

KPa.

C

KPa.

C

mm.

mm.

kg./cm

PV Elite 2014 Licensee: SPLM Licensed User

FileName : Veny Martiani_121724030

XY Coordinate Calculations :

Step:

9:21p

Page 7 of 17

Jul 8,2015

XY Coordinate Calculations

|

|

|

|

|

|

From| To | X (Horiz.)| Y (Vert.) |DX (Horiz.)| DY (Vert.) |

|

|

mm.

|

mm.

|

mm.

|

mm.

|

-------------------------------------------------------------10| 20|

... |

... |

... |

... |

20| 30|

3770.00 |

... |

3770.00 |

... |

30| 40|

3770.00 |

... |

... |

... |

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2014

PV Elite 2014 Licensee: SPLM Licensed User

FileName : Veny Martiani_121724030

Internal Pressure Calculations :

Step:

9:21p

Page 8 of 17

Jul 8,2015

Element Thickness, Pressure, Diameter and Allowable Stress :

|

| Int. Press |

Nominal | Total Corr|

Element | Allowable |

From| To | + Liq. Hd | Thickness | Allowance |

Diameter | Stress(SE)|

|

|

KPa.

|

mm.

|

mm.

|

mm.

|

N./mm

|

--------------------------------------------------------------------------10| 20|

464.60 |

45.460 |

3.1750 |

1300.0 |

137.90 |

20| 30|

455.00 |

45.460 |

3.1750 |

1300.0 |

137.90 |

30| 40|

455.02 |

45.460 |

3.1750 |

1300.0 |

137.90 |

Element Required Thickness and MAWP :

|

|

Design |

M.A.W.P. |

M.A.P. |

Minimum |

Required |

From| To |

Pressure | Corroded | New & Cold | Thickness | Thickness |

|

|

KPa.

|

KPa.

|

KPa.

|

mm.

|

mm.

|

---------------------------------------------------------------------------10| 20|

455.000 |

2979.72 |

4365.30 |

10.1600 |

4.67500 |

20| 30|

455.000 |

1488.21 |

2168.92 |

10.1600 |

5.31697 |

30| 40|

455.000 |

2989.29 |

4365.30 |

10.1600 |

4.67500 |

Minimum

1488.206

2168.912

MAWP: 1488.206 KPa., limited by: Cylinder.

Internal Pressure Calculation Results :

ASME Code, Section VIII, Division 1, 2013

Spherical Head From 10 To 20 SA-516 70 , UCS-66 Crv. B at 14 C

Material UNS Number:

K02700

Required Thickness due to Internal Pressure [tr]:

= (P*Ro)/(2*S*E+0.8*P) per Appendix 1-1(a)(2)

= (464.600*650.0000)/(2*137.90*1.00+0.8*464.600)

= 1.0935 + 3.1750 = 4.2685 mm.

Note: The thickness required was less than the Code Minimum, therefore

the Code Minimum value of 1.5000 mm. per UG-16 will be used.

Max. Allowable Working Pressure at given Thickness, corroded [MAWP]:

Less Operating Hydrostatic Head Pressure of 9.600 KPa.

= (2*S*E*t)/((Ro-0.8*t) per Appendix 1-1 (a)(2)

= (2*137.90*1.00*6.9850)/(650.0000-0.8*6.9850)

= 2989.316 - 9.600 = 2979.716 KPa.

Maximum Allowable Pressure, New and Cold [MAPNC]:

= (2*S*E*t)/((Ro-0.8*t) Appendix 1-1 (a)(2)

= (2*137.90*1.00*10.1600)/(650.0000-0.8*10.1600)

= 4365.303 KPa.

Actual stress at given pressure and thickness, corroded [Sact]:

= (P*(Ro-0.8*t))/(2*E*t)

= (464.600*(650.0000-0.8*6.9850))/(2*1.00*6.9850)

= 21.432 N./mm

Percent Elong. per UCS-79, VIII-1-01-57 (75*tnom/Rf)*(1-Rf/Ro)

Note: Please Check Requirements of UCS-79 as Elongation is > 5%.

MDMT Calculations in the Spherical Portion:

Govrn. thk, tg = 10.160 , tr = 3.515 , c = 3.1750 mm. , E* = 1.00

Stress Ratio = tr * (E*)/(tg - c) = 0.503 , Temp. Reduction = 33 C

5.435 %

PV Elite 2014 Licensee: SPLM Licensed User

FileName : Veny Martiani_121724030

Internal Pressure Calculations :

Step:

9:21p

Min Metal Temp. w/o impact per UCS-66, Curve B

Min Metal Temp. at Required thickness (UCS 66.1)

Page 9 of 17

Jul 8,2015

-28 C

-48 C

Cylindrical Shell From 20 To 30 SA-516 70 , UCS-66 Crv. B at 14 C

Material UNS Number:

K02700

Required Thickness due to Internal Pressure [tr]:

= (P*Ro) / (S*E+0.4*P) per Appendix 1-1 (a)(1)

= (455.000*650.0000)/(137.90*1.00+0.4*455.000)

= 2.1420 + 3.1750 = 5.3170 mm.

Max. Allowable Working Pressure at given Thickness, corroded [MAWP]:

= (S*E*t)/(Ro-0.4*t) per Appendix 1-1 (a)(1)

= (137.90*1.00*6.9850)/(650.0000-0.4*6.9850)

= 1488.206 KPa.

Maximum Allowable Pressure, New and Cold [MAPNC]:

= (S*E*t)/(Ro-0.4*t) per Appendix 1-1 (a)(1)

= (137.90*1.00*10.1600)/(650.0000-0.4*10.1600)

= 2168.919 KPa.

Actual stress at given pressure and thickness, corroded [Sact]:

= (P*(Ro-0.4*t))/(E*t)

= (455.000*((650.0000-0.4*6.9850))/(1.00*6.9850)

= 42.161 N./mm

Percent Elongation per UCS-79

(50*tnom/Rf)*(1-Rf/Ro)

3.624 %

Minimum Design Metal Temperature Results:

Govrn. thk, tg = 10.160 , tr = 6.985 , c = 3.1750 mm. , E* = 1.00

Stress Ratio = tr * (E*)/(tg - c) = 1.000 , Temp. Reduction = 0 C

Min Metal Temp. w/o impact per UCS-66, Curve B

Spherical Head From 30 To 40 SA-516 70 , UCS-66 Crv. B at 14 C

Material UNS Number:

K02700

Required Thickness due to Internal Pressure [tr]:

= (P*Ro)/(2*S*E+0.8*P) per Appendix 1-1(a)(2)

= (455.025*650.0000)/(2*137.90*1.00+0.8*455.025)

= 1.0710 + 3.1750 = 4.2460 mm.

Note: The thickness required was less than the Code Minimum, therefore

the Code Minimum value of 1.5000 mm. per UG-16 will be used.

Max. Allowable Working Pressure at given Thickness, corroded [MAWP]:

Less Operating Hydrostatic Head Pressure of 0.025 KPa.

= (2*S*E*t)/((Ro-0.8*t) per Appendix 1-1 (a)(2)

= (2*137.90*1.00*6.9850)/(650.0000-0.8*6.9850)

= 2989.316 - 0.025 = 2989.292 KPa.

Maximum Allowable Pressure, New and Cold [MAPNC]:

= (2*S*E*t)/((Ro-0.8*t) Appendix 1-1 (a)(2)

= (2*137.90*1.00*10.1600)/(650.0000-0.8*10.1600)

= 4365.303 KPa.

Actual stress at given pressure and thickness, corroded [Sact]:

= (P*(Ro-0.8*t))/(2*E*t)

= (455.025*(650.0000-0.8*6.9850))/(2*1.00*6.9850)

-28 C

PV Elite 2014 Licensee: SPLM Licensed User

FileName : Veny Martiani_121724030

Internal Pressure Calculations :

Step:

9:21p

Page 10 of 17

Jul 8,2015

= 20.991 N./mm

Percent Elong. per UCS-79, VIII-1-01-57 (75*tnom/Rf)*(1-Rf/Ro)

Note: Please Check Requirements of UCS-79 as Elongation is > 5%.

5.435 %

MDMT Calculations in the Spherical Portion:

Govrn. thk, tg = 10.160 , tr = 3.493 , c = 3.1750 mm. , E* = 1.00

Stress Ratio = tr * (E*)/(tg - c) = 0.500 , Temp. Reduction = 33 C

Min Metal Temp. w/o impact per UCS-66, Curve B

Min Metal Temp. at Required thickness (UCS 66.1)

Elements Suitable for Internal Pressure.

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2014

-28 C

-48 C

PV Elite 2014 Licensee: SPLM Licensed User

FileName : Veny Martiani_121724030

External Pressure Calculations :

Step:

9:21p

Page 11 of 17

Jul 8,2015

External Pressure Calculation Results :

ASME Code, Section VIII, Division 1, 2013

Spherical Head From 10 to 20 Ext. Chart: CS-2 at 25 C

Elastic Modulus from Chart: CS-2 at 25 C

: 0.200E+09 KPa.

Results for Maximum Allowable External Pressure (MAEP):

Tca Sphere OD

D/t

Factor A

B

6.985

1300.00

186.11

0.0013433

93.86

EMAP = B/((D/t)/2) = 93.8556/(186.1131/2 ) = 1008.5280 KPa.

Results for Required Thickness (Tca):

Tca Sphere OD

D/t

Factor A

B

1.851

1300.00

702.25

0.0003560

35.59

EMAP = B/((D/t)/2) = 35.5919/(702.2499/2 ) = 101.3593 KPa.

Cylindrical Shell From 20 to 30 Ext. Chart: CS-2 at 25 C

Elastic Modulus from Chart: CS-2 at 25 C

: 0.200E+09 KPa.

Results for Maximum Allowable External Pressure (MAEP):

Tca

OD

SLEN

D/t

L/D

Factor A

B

6.985

1300.00

4196.56

186.11

3.2281 0.0001555

15.55

EMAP = (4*B)/(3*(D/t)) = (4*15.5461 )/(3*186.1131 ) = 111.3672 KPa.

Results for Required Thickness (Tca):

Tca

OD

SLEN

D/t

L/D

Factor A

B

6.741

1300.00

4196.56

192.86

3.2281 0.0001466

14.66

EMAP = (4*B)/(3*(D/t)) = (4*14.6612 )/(3*192.8586 ) = 101.3546 KPa.

Results for Maximum Stiffened Length (Slen):

Tca

OD

SLEN

D/t

L/D

Factor A

B

6.985

1300.00

4589.10

186.11

3.5301 0.0001416

14.16

EMAP = (4*B)/(3*(D/t)) = (4*14.1552 )/(3*186.1131 ) = 101.4035 KPa.

Spherical Head From 30 to 40 Ext. Chart: CS-2 at 25 C

Elastic Modulus from Chart: CS-2 at 25 C

: 0.200E+09 KPa.

Results for Maximum Allowable External Pressure (MAEP):

Tca Sphere OD

D/t

Factor A

B

6.985

1300.00

186.11

0.0013433

93.86

EMAP = B/((D/t)/2) = 93.8556/(186.1131/2 ) = 1008.5280 KPa.

Results for Required Thickness (Tca):

Tca Sphere OD

D/t

Factor A

B

1.851

1300.00

702.25

0.0003560

35.59

EMAP = B/((D/t)/2) = 35.5919/(702.2499/2 ) = 101.3593 KPa.

External Pressure Calculations

|

|

Section |

Outside | Corroded |

Factor |

Factor |

From| To |

Length |

Diameter | Thickness |

A

|

B

|

|

|

mm.

|

mm.

|

mm.

|

|

N./mm

|

--------------------------------------------------------------------------10| 20|

No Calc |

1300.00 |

6.98500 | 0.0013433 |

93.8556 |

20| 30|

4196.56 |

1300.00 |

6.98500 | 0.00015550 |

15.5461 |

30| 40|

No Calc |

1300.00 |

6.98500 | 0.0013433 |

93.8556 |

External Pressure Calculations

PV Elite 2014 Licensee: SPLM Licensed User

FileName : Veny Martiani_121724030

External Pressure Calculations :

Step:

9:21p

Page 12 of 17

Jul 8,2015

|

|

External |

External | External |

External |

From| To | Actual T. | Required T.|Des. Press. |

M.A.W.P. |

|

|

mm.

|

mm.

|

KPa.

|

KPa.

|

---------------------------------------------------------------10| 20|

10.1600 |

5.02619 |

101.351 |

1008.53 |

20| 30|

10.1600 |

9.91569 |

101.351 |

111.367 |

30| 40|

10.1600 |

5.02619 |

101.351 |

1008.53 |

Minimum

111.367

External Pressure Calculations

|

| Actual Len.| Allow. Len.| Ring Inertia | Ring Inertia |

From| To | Bet. Stiff.| Bet. Stiff.|

Required |

Available |

|

|

mm.

|

mm.

|

cm**4

|

cm**4

|

------------------------------------------------------------------10| 20|

No Calc |

No Calc |

No Calc |

No Calc |

20| 30|

4196.56 |

4589.10 |

No Calc |

No Calc |

30| 40|

No Calc |

No Calc |

No Calc |

No Calc |

Elements Suitable for External Pressure.

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2014

PV Elite 2014 Licensee: SPLM Licensed User

FileName : Veny Martiani_121724030

Element and Detail Weights :

Step:

9:21p

Page 13 of 17

Jul 8,2015

Element and Detail Weights

|

|

Element |

Element | Corroded |

Corroded | Extra due |

From| To | Metal Wgt. | ID Volume |Metal Wgt. | ID Volume | Misc %

|

|

|

kg.

|

cm

|

kg.

|

cm

|

kg.

|

--------------------------------------------------------------------------10| 20|

972.240 |

548720. |

908.626 |

556929. |

... |

20| 30|

5529.84 | 4.850E+06 |

5155.95 | 4.898E+06 |

... |

30| 40|

972.240 |

548720. |

908.626 |

556929. |

... |

--------------------------------------------------------------------------Total

7474

5947105.50

6973

6011773.50

0

Weight of Details

|

| Weight of | X Offset, | Y Offset, |

From|Type|

Detail | Dtl. Cent. |Dtl. Cent. | Description

|

|

kg.

|

mm.

|

mm.

|

------------------------------------------------10|Liqd|

433.689 |

-213.280 |

25.0000 |

ETHANOL

10|Forc|

... |

... |

... |

F/M:[1 of 1]

30|Liqd|

... |

213.280 |

639.840 |

ETHANOL

Total Weight of Each Detail Type

Total Weight of Liquid

433.7

--------------------------------------------------------------Sum of the Detail Weights

433.7 kg.

Weight Summation

Fabricated

Shop Test

Shipping

Erected

Empty

Operating

-----------------------------------------------------------------------------7474.3

7474.3

7474.3

7474.3

7474.3

7474.3

...

5943.5

...

...

...

433.7

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

-----------------------------------------------------------------------------7474.3

13417.8

7474.3

7474.3

7474.3

7908.0 kg.

Note: The shipping total has been modified because some items have

been specified as being installed in the shop.

Weight Summary

Fabricated Wt.

Shop Test Wt.

Shipping Wt.

Erected Wt.

Ope. Wt. no Liq

Operating Wt.

Oper. Wt. + CA

Field Test Wt.

Bare Weight W/O Removable Internals

Fabricated Weight + Water ( Full )

Fab. Wt + Rem. Intls.+ Shipping App.

Fab. Wt + Rem. Intls.+ Insul. (etc)

Fab. Wt + Intls. + Details + Wghts.

Empty Wt + Operating Liq. Uncorroded

Corr Wt. + Operating Liquid

Empty Weight + Water (Full)

Note: The Corroded Weight and thickness are used in the Horizontal

Vessel Analysis (Ope Case) and Earthquake Load Calculations.

Outside Surface Areas of Elements

Surface

7474.3

13417.8

7474.3

7474.3

7474.3

7908.0

7406.9

13417.8

kg.

kg.

kg.

kg.

kg.

kg.

kg.

kg.

PV Elite 2014 Licensee: SPLM Licensed User

FileName : Veny Martiani_121724030

Element and Detail Weights :

Step:

9:21p

Page 14 of 17

Jul 8,2015

From| To |

Area

|

|

|

cm

|

---------------------------10| 20|

29508.1 |

20| 30|

162331. |

30| 40|

29508.1 |

---------------------------Total

221347.422 cm

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2014

PV Elite 2014 Licensee: SPLM Licensed User

FileName : Veny Martiani_121724030

Center of Gravity Calculation :

Step:

9:21p

Page 15 of 17

Jul 8,2015

Shop/Field Installation Options :

Note : The CG is computed from the first Element From Node

Center of Gravity of Liquid

-213.280 mm.

Center of Gravity of Bare Shell New and Cold

Center of Gravity of Bare Shell Corroded

1884.996 mm.

1884.996 mm.

Vessel CG in the Operating Condition

Vessel CG in the Fabricated (Shop/Empty) Condition

1762.138 mm.

1884.996 mm.

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2014

PV Elite 2014 Licensee: SPLM Licensed User

FileName : Veny Martiani_121724030

MDMT Summary :

Step:

9:21p

Page 16 of 17

Jul 8,2015

Minimum Design Metal Temperature Results Summary :

Curve

Basic Reduced UG-20(f) Thickness

Gov

E*

MDMT

MDMT

MDMT

ratio

Thk

Notes

C

C

C

mm.

---------------------------------------------------------------------------[9]

B

-28

-48

0.503 10.160

1.000

[8]

B

-28

-28

1.000 10.160

1.000

[9]

B

-28

-48

0.500 10.160

1.000

---------------------------------------------------------------------------Required Minimum Design Metal Temperature

-29 C

Warmest Computed Minimum Design Metal Temperature

-28 C

Description

Warning: Computed overall MDMT was higher than the required value !

Notes:

[ ! ] - This was an impact tested material.

[ 1] - Governing Nozzle Weld.

[ 4] - ANSI Flange MDMT Calcs; Thickness ratio per UCS-66(b)(1)(c).

[ 5] - ANSI Flange MDMT Calcs; Thickness ratio per UCS-66(b)(1)(b).

[ 6] - MDMT Calculations at the Shell/Head Joint.

[ 7] - MDMT Calculations for the Straight Flange.

[ 8] - Cylinder/Cone/Flange Junction MDMT.

[ 9] - Calculations in the Spherical Portion of the Head.

[10] - Calculations in the Knuckle Portion of the Head.

[11] - Calculated (Body Flange) Flange MDMT.

[12] - Calculated Flat Head MDMT per UCS-66.3

[13] - Tubesheet MDMT, shell side, if applicable

[14] - Tubesheet MDMT, tube side, if applicable

[15] - Nozzle Material

[16] - Shell or Head Material

UG-84(b)(2) was not considered.

UCS-66(g) was not considered.

UCS-66(i) was not considered.

Notes:

Impact test temps were not entered in and not considered in the analysis.

UCS-66(i) applies to impact tested materials not by specification and

UCS-66(g) applies to materials impact tested per UG-84.1 General Note (c).

The Basic MDMT includes the (30F) PWHT credit if applicable.

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2014

PV Elite 2014 Licensee: SPLM Licensed User

FileName : Veny Martiani_121724030

Vessel Design Summary :

Step:

9:21p

Page 17 of 17

Jul 8,2015

ASME Code, Section VIII, Division 1, 2013

Diameter Spec : 1300.000 mm. OD

Vessel Design Length, Tangent to Tangent

Specified Datum Line Distance

Shell Material

3770.00

mm.

0.00

mm.

SA-516 70

Internal Design Temperature

Internal Design Pressure

93

689.460

C

KPa.

External Design Temperature

External Design Pressure

93

103.419

C

KPa.

1488.206

111.367

0.000

KPa.

KPa.

KPa.

Maximum Allowable Working Pressure

External Max. Allowable Working Pressure

Hydrostatic Test Pressure

Required Minimum Design Metal Temperature

Warmest Computed Minimum Design Metal Temperature

-29

-28

C

C

Warning: Computed overall MDMT was higher than the required value !

Wind Design Code

Earthquake Design Code

ASCE-93

UBC-94

Element Pressures and MAWP: KPa.

Element Desc

| Design Pres. | External | M.A.W.P | Corrosion

| + Stat. head | Pressure |

| Allowance

--------------------------------------------------------------------Sphere

464.600

101.351 2979.716

3.1750

Cylinder

455.000

101.351 1488.206

3.1750

Sphere

455.025

101.351 2989.292

3.1750

Element

"To" Elev Length

Element Thk

R e q d T h k

Joint Eff

Type

mm.

mm.

mm.

Int.

Ext. Long Circ

----------------------------------------------------------------------Sphere

0.0

0.0

45.5

4.7

5.0

1.00 1.00

Cylinder

3770.0

3770.0

45.5

5.3

9.9

1.00 1.00

Sphere

3770.0

0.0

45.5

4.7

5.0

1.00 1.00

Element thicknesses are shown as Nominal if specified, otherwise are Minimum

Weights:

Fabricated

Shop Test

Shipping

Erected

Empty

Operating

Field Test

Bare W/O Removable Internals

Fabricated + Water ( Full )

Fab. + Rem. Intls.+ Shipping App.

Fab. + Rem. Intls.+ Insul. (etc)

Fab. + Intls. + Details + Wghts.

Empty + Operating Liquid (No CA)

Empty Weight + Water (Full)

7474.3

13417.8

7474.3

7474.3

7474.3

7908.0

13417.8

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2014

kg.

kg.

kg.

kg.

kg.

kg.

kg.

You might also like

- Calculation ReportDocument229 pagesCalculation ReportDarioNo ratings yet

- PV EliteDocument680 pagesPV Elitengocanh_songlongNo ratings yet

- PV EliteDocument558 pagesPV EliteJavier Orna100% (1)

- Code Case 2901 - Consideration of External Loads On ASME B16.5 Standard Flanges Under ASME Code Section VIII, Division 1 & 2Document2 pagesCode Case 2901 - Consideration of External Loads On ASME B16.5 Standard Flanges Under ASME Code Section VIII, Division 1 & 2msn1981No ratings yet

- WRC Input InstructionDocument2 pagesWRC Input InstructionpandiangvNo ratings yet

- PV Elite and CodeCalcDocument102 pagesPV Elite and CodeCalcRaúl R Rojas Torres100% (1)

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionDocument3 pages"Lifting - Lug" - Lifting Lug Analysis: Program DescriptionSung Woong MoonNo ratings yet

- Eqn Reference ASME BPVC r1sDocument5 pagesEqn Reference ASME BPVC r1sagarcia654127No ratings yet

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Document32 pagesPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNo ratings yet

- Calculo Brida Ejemplo PV - EliteDocument8 pagesCalculo Brida Ejemplo PV - ElitePedro Montes MarinNo ratings yet

- Methods For WRC 107 and WRC 297 Checking in Caesar IIDocument8 pagesMethods For WRC 107 and WRC 297 Checking in Caesar IIRomner CordovaNo ratings yet

- Technical DataDocument48 pagesTechnical Datashekhar2681No ratings yet

- PV Elite WebinarDocument24 pagesPV Elite WebinarAndrea Hank LattanzioNo ratings yet

- PVElite ManualDocument691 pagesPVElite Manuals.mladin75% (4)

- Pvelite OutputDocument44 pagesPvelite OutputRam MurtyNo ratings yet

- 2400 Tema DCDocument7 pages2400 Tema DCMasoodMiyanNo ratings yet

- Earthquake load calculations as per IS1893-2002Document9 pagesEarthquake load calculations as per IS1893-2002irshad313No ratings yet

- Etab RSM Eccc Basics SCMDocument2 pagesEtab RSM Eccc Basics SCMsathiyaseelann.sNo ratings yet

- Ccopps WebinarDocument36 pagesCcopps WebinarAkenathon71No ratings yet

- BN-DS-T29 Collar Bolts For Removable Bundle Heat ExchangerDocument1 pageBN-DS-T29 Collar Bolts For Removable Bundle Heat ExchangerAlexDdd123No ratings yet

- Allowable Nozzle LoadsDocument7 pagesAllowable Nozzle LoadsZulkarnain NasrullahNo ratings yet

- PV Elite - Nozzle Interference - The SolutionDocument4 pagesPV Elite - Nozzle Interference - The Solutionayounga100% (3)

- Bursting Pressure of Mild Steel Cylindrical VesselsDocument4 pagesBursting Pressure of Mild Steel Cylindrical VesselsAris FauziNo ratings yet

- Piping Engineering - Tank Nozzle Loads 1Document1 pagePiping Engineering - Tank Nozzle Loads 1Nasrul AdliNo ratings yet

- Sec. VIII Div 1 Apen 1Document16 pagesSec. VIII Div 1 Apen 1ADRIANNo ratings yet

- Flange calculation as per ASME Section VIIIDocument9 pagesFlange calculation as per ASME Section VIIIDarshan PanchalNo ratings yet

- Ucs 66Document17 pagesUcs 66Pratik DhuriNo ratings yet

- Annex 3-F Design Fatigue Curves (Smooth Bar)Document1 pageAnnex 3-F Design Fatigue Curves (Smooth Bar)ข้าวเม่า ทอดNo ratings yet

- ASCE 7-05 Table 15-4-2Document1 pageASCE 7-05 Table 15-4-2barouniamineNo ratings yet

- Seipp 2014Document5 pagesSeipp 2014Andres VallebellaNo ratings yet

- WRC 107 and WRC 297Document2 pagesWRC 107 and WRC 297Harshal JadhavNo ratings yet

- Stainless Steel Sightglass Din 28120 28121Document4 pagesStainless Steel Sightglass Din 28120 28121Thoa Tran VanNo ratings yet

- Caesar Wrc107and297Document3 pagesCaesar Wrc107and297spiritizNo ratings yet

- PVP2016 Final ProgramDocument76 pagesPVP2016 Final Programthaivinhtuy100% (1)

- WRC107Document6 pagesWRC107Guru MoorthiNo ratings yet

- External Pressure - Pressure Vessel EngineeringDocument15 pagesExternal Pressure - Pressure Vessel Engineeringarjun100% (1)

- PV Elite Modeling Stacked Exchangers PDFDocument5 pagesPV Elite Modeling Stacked Exchangers PDFkanchanabalaji100% (1)

- Comparison ASME KTADocument7 pagesComparison ASME KTAAndres_Pastor1987No ratings yet

- PV Elite BrocDocument6 pagesPV Elite BrocprasadgssNo ratings yet

- NozzleproDocument20 pagesNozzleprossmith2007No ratings yet

- Step by Step Methods For WRC 107 (WRC 537) and WRC 297 CDocument13 pagesStep by Step Methods For WRC 107 (WRC 537) and WRC 297 C7761430No ratings yet

- CU TR 032 - 2013 EngDocument36 pagesCU TR 032 - 2013 EngLekshminarayanan Sankara100% (1)

- AutoPIPE Vessel FundamentalsDocument172 pagesAutoPIPE Vessel FundamentalsAlessio BarboneNo ratings yet

- On The Design of The Tubesheet and Tubesheet-To-Shell Junction of A Fixed Tubesheet Heat ExchangerDocument7 pagesOn The Design of The Tubesheet and Tubesheet-To-Shell Junction of A Fixed Tubesheet Heat ExchangerEdgardo Chavez BelloNo ratings yet

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionFrom EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNo ratings yet

- The Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringFrom EverandThe Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringS. S. GillRating: 3.5 out of 5 stars3.5/5 (3)

- Stress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsFrom EverandStress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsNo ratings yet

- Air Receiver Sample CalcDocument49 pagesAir Receiver Sample CalcBrian Edwin RodriguezNo ratings yet

- Vessel Design CalculationDocument54 pagesVessel Design CalculationPohn Myint Han50% (2)

- Tutorial Pressure VesselDocument19 pagesTutorial Pressure Vesseltahseenahsan100% (1)

- 003-Heat ExchangerDocument299 pages003-Heat ExchangerVijayshanker GuptaNo ratings yet

- Sample4 PVEliteDocument66 pagesSample4 PVEliteSourav Hait100% (1)

- Vessel CalculationDocument106 pagesVessel CalculationBhadresh PatelNo ratings yet

- Element Thickness 2Document20 pagesElement Thickness 2Vipul GandhiNo ratings yet

- Element Thickness 3Document24 pagesElement Thickness 3Vipul GandhiNo ratings yet

- Steam TurbineDocument11 pagesSteam TurbineVeny MartianiNo ratings yet

- Sumsel4 GRPDocument36 pagesSumsel4 GRPVeny MartianiNo ratings yet

- Boiler & AuxiliaryDocument73 pagesBoiler & AuxiliaryVeny MartianiNo ratings yet

- Ash Handling System (Standard) - Add.1Document28 pagesAsh Handling System (Standard) - Add.1Veny Martiani100% (1)

- Karakteristik Pemagnetan Generator Sinkron Tiga FasaDocument6 pagesKarakteristik Pemagnetan Generator Sinkron Tiga FasaVeny MartianiNo ratings yet

- Referensi Elektronika DayaDocument1 pageReferensi Elektronika DayaVeny MartianiNo ratings yet

- Electrical Operation Manual HandbookDocument150 pagesElectrical Operation Manual HandbookVeny Martiani100% (2)

- Composite, Nano & Bio Materials GuideDocument11 pagesComposite, Nano & Bio Materials Guidebrody100% (1)

- Brochure Steam AccumulatorDocument2 pagesBrochure Steam AccumulatorFrank HuNo ratings yet

- R1234yf 2018Document22 pagesR1234yf 2018bogdan100% (1)

- SF026a-Flow Chart Portal Frame Apex ConnectionDocument3 pagesSF026a-Flow Chart Portal Frame Apex ConnectiondvelchevNo ratings yet

- HYBACS Specific Presentation Rev26 WEBSITE1Document21 pagesHYBACS Specific Presentation Rev26 WEBSITE1Jatsika FirdhaNo ratings yet

- eCOMPRESSOR OIL PDFDocument1 pageeCOMPRESSOR OIL PDFKeshav Shrivastava KSNo ratings yet

- 3M Prestige 70 Exterior PBDocument3 pages3M Prestige 70 Exterior PBDiego Ramirez FuentesNo ratings yet

- Install and maintain Indeeco electric duct heatersDocument2 pagesInstall and maintain Indeeco electric duct heatersDoan Tien DoNo ratings yet

- Stone Cladding Fixings Technical StandardsDocument6 pagesStone Cladding Fixings Technical StandardsvtalexNo ratings yet

- Plastic and Environmental PollutionDocument13 pagesPlastic and Environmental PollutionAli KhalidNo ratings yet

- Total Water Management in Thermal Power StationsDocument8 pagesTotal Water Management in Thermal Power StationsSarah FrazierNo ratings yet

- Thermodynamics control volume analysisDocument6 pagesThermodynamics control volume analysisLUISRONo ratings yet

- Cranes, Rigging and BanksmanDocument61 pagesCranes, Rigging and BanksmanAdelCh100% (3)

- Week 1Document4 pagesWeek 1Czarina RelleveNo ratings yet

- (BROCHURE) SANACEL Experience For Extruded Products SnacksDocument23 pages(BROCHURE) SANACEL Experience For Extruded Products SnacksVincent TertiusNo ratings yet

- S275JRDocument1 pageS275JRShahzad QamarNo ratings yet

- Plastic Mixed Reinforced Concrete - BehaviourDocument4 pagesPlastic Mixed Reinforced Concrete - BehaviourThiaga RajanNo ratings yet

- D-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011Document255 pagesD-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011ganesan 00110% (1)

- Rotary Vane PumpDocument7 pagesRotary Vane PumpSanny HamdaniNo ratings yet

- Chieftain 1800 SpecsDocument16 pagesChieftain 1800 SpecsPercy Luis Nima AlvaradoNo ratings yet

- Boqcomparativechart - 2023-05-27T100002.652Document10 pagesBoqcomparativechart - 2023-05-27T100002.652Abode ArtisanNo ratings yet

- Multi-turn Actuator and Gear Reducer SpecificationsDocument10 pagesMulti-turn Actuator and Gear Reducer SpecificationspaulNo ratings yet

- Tutorial 2 Chapter 2Document2 pagesTutorial 2 Chapter 2Marko IrwinNo ratings yet

- Properties of commercial copper alloy powdersDocument2 pagesProperties of commercial copper alloy powdersLilian RoseNo ratings yet

- Operation Manual for Martin-Decker Record-O-Graph Part TW514Document32 pagesOperation Manual for Martin-Decker Record-O-Graph Part TW514Rafael Charry AndradeNo ratings yet

- Guided Wave APIDocument37 pagesGuided Wave APIAshfaq Anwer100% (3)

- XDB102 3Document3 pagesXDB102 3Young WuNo ratings yet

- Compact Variable CompressorsDocument2 pagesCompact Variable CompressorsIvan GrayNo ratings yet

- Tunnel Systems: Design & SupplyDocument8 pagesTunnel Systems: Design & SupplyJuan Luis Vilca YucraNo ratings yet

- Busines Proposal For Residential ConstructionDocument7 pagesBusines Proposal For Residential ConstructionNatsu Trojanlee QuiritNo ratings yet