Professional Documents

Culture Documents

Tds Acrylic Acid PDF

Uploaded by

semakoc624Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tds Acrylic Acid PDF

Uploaded by

semakoc624Copyright:

Available Formats

PRODUCT INFORMATION

NORSOCRYL GAA FG

GLACIAL ACRYLIC ACID FG

CAS # : 79-10-7

EINECS # : 201-177-9

CHEMICAL FORMULA

CH 2 = C C OH

=

O

Molecular weight: 72

OTHER NAMES

2-Propenoic acid

SPECIFICATIONS

Characteristic

Purity

Appearance

Color

Inhibitor Concentration

Water Content

Test Method

GC

Visual

ASTM D1209

ASTM D3125

ASTM D1364

Limit

99.8 % (min)

C.F.S.M.

10 PT-CO (max)

180 220 ppm MEHQ

1000 ppm (max)

NORSOCRYL GAA FG

MAIN PHYSICAL CHARACTERISTICS

Molecular weight .....................................................72

Boiling point, at 1013 mbar ............................ 141.3C

Freezing point .....................................................13 C

Physical Form

at > 13C ............... liquid

at < 13C ..................solid

Specific gravity

at 20C .....................1.04 9

at 25C .....................1.043

Refractive index, nD

at 20C .....................1.422

at 25C .....................1.418

Viscosity

at 20C ........................1.22 m P a.s

at 25C ........................1.15 mPa.s

Solubility

water in AA

AA in water

at 20C ........... infi nit e

at 20C ........... infinite

Specific heat in liquid state .................... 2.09 kJ/kgC

Latent heat of vaporization .......................... 621 kJ/kg

Heat of polymerization ............................... 1074 kJ/kg

Homopolymer glass transition temperature ...... 106C

Flash point

in closed cup .............48C

Lower explosion limit in volume ....................... 2.4 %

Vapor pressure

at 20C .................4 mbar

at 30C .................8 mbar

at 50C ...............24 mbar

Auto-ignition temperature ................................. 429C

CHEMICAL PROPERTIES

-

Properties of the acid function: ability to form salts,

anhydrides, acid chlorides, esters, etc.

Properties of the double bond: addition, cyclization,

polymerization and copolymerization reactions.

Some specific values for the copolymerization

reactivity ratios r1, r2 of acrylic acid (M1) with

various monomers (M2) have been calculated using

the Alfrey& Price formula:

Styrene ..................... r1 = 0.24

Methyl methacrylate ... r1 = 1.17

PACKAGING AND STORAGE

Acrylic acid is delivered:

-

in stainless steel railcars, capacity 90 tons

in 45,000 pound stainless steel tank trucks

in 450 pound polyethylene drums

The standard inhibitor level is 200 ppm Monomethyl

Ether of HydroQuinone (MEHQ). Acrylic acid should

be stored at a temperature range of 18 to 25 C

, to pr

event any crystallization (freezing point = 13 C

), and t o

ensure proper distribution of the inhibitor. It is

recommended that the product be stored indoors at a

temperature of no more than 25 C

and away from li ght.

It must also be stored under air atmosphere, as the

presence of oxygen is essential to maintain the inhibitor

effectiveness.

Under these storage conditions, the product is

commercially guaranteed for six months after

delivery.

Acrylic acid is highly corrosive, and must be stored

in glass, stainless steel or polyethylene containers.

If crystallization occurs, warm the product slowly,

while agitating it, to avoid any localized overheating,

not exceeding 25C. Too high a temperature could

cause exothermic polymerization.

Finally, acrylic acid should not be stored for excessive

periods, because of the irreversible formation of

dimers (approximately 100 ppm daily at room

temperature).

USES

Acrylic acid polymers and copolymers cover a very wide

range of applications, such as:

hydrosoluble agents for dispersing agents,

thickeners, flocculating and super absorbent agents

detergence auxiliaries

organic synthesis

copolymer emulsions for paints, varnishes and inks

dispersions for leather, textiles, non-woven fabrics,

glues and adhesives

cleaning and waxing products

plastics and synthetic resins

synthetic rubbers and latexes

r2 = 0.25

r2 = 0.75

HANDLING AND SAFETY

Carefully read the material safety data sheet.

The statements, technical information and recommendations contained herein are believed to be accurate as of the date hereof. Since the conditions and methods of use of the product

and of the information referred to herein are beyond our control, Arkema Inc. expressly disclaims any and all liability as to any results obtained or arising from any use of the product or

reliance on such information; NO WARRANTY OF FITNESS FOR ANY PARTICULAR PURPOSE, WARRANTY OF MERCHANTABILITY OR ANY OTHER WARRANTY, EXPRESS OR

IMPLIED, IS MADE CONCERNING THE GOODS DESCRIBED OR THE INFORMATION PROVIDED HEREIN. The information provided herein relates only to the specific product

designated and may not be applicable when such product is used in combination with other materials or in any process. The user should thoroughly test any application before

commercialization. Nothing contained herein constitutes a license to practice under any patent and it should not be construed as an inducement to infringe any patent and the user is

advised to take appropriate steps to be sure that any proposed use of the product will not result in patent infringement.

See MSDS for Health & Safety Considerations

2012 Arkema Inc. All rights reserved.

Arkema Inc.

900 1st Avenue, King of Prussia, PA 19406

Tel.: (610) 205-7000

arkema-inc.com

You might also like

- Bayflex 110-50 BMSDocument2 pagesBayflex 110-50 BMSGareth Kenworthy100% (1)

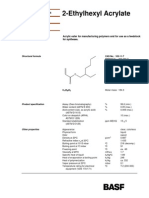

- 2-Ethylhexyl Acrylate: Technical Data SheetDocument4 pages2-Ethylhexyl Acrylate: Technical Data Sheetfake77No ratings yet

- TDS - Makonp104Document2 pagesTDS - Makonp104Alannah GuerreroNo ratings yet

- A541-Ccag Aoc Eco TekDocument2 pagesA541-Ccag Aoc Eco TekHemmingsNo ratings yet

- 105 Ta D411-350Document3 pages105 Ta D411-350isaacalvareztejanoNo ratings yet

- Technical Data Sheet: EPIKURE™ Curing Agent 3274Document4 pagesTechnical Data Sheet: EPIKURE™ Curing Agent 3274Kelvin Allan Soler LopezNo ratings yet

- Properties Data Sheet: HDPE - 5220BNDocument1 pageProperties Data Sheet: HDPE - 5220BNSergio Rubens Oliveira SantosNo ratings yet

- Epoweld 48173 58173 TDSDocument2 pagesEpoweld 48173 58173 TDSTom HookNo ratings yet

- Diethylene Glycol: Technical Data SheetDocument2 pagesDiethylene Glycol: Technical Data SheetRahman Trading CorporationNo ratings yet

- Ficha Tecnica Choline Chloride 75Document2 pagesFicha Tecnica Choline Chloride 75nicututzaNo ratings yet

- Stepan Pol Ps 2352Document2 pagesStepan Pol Ps 2352A MahmoodNo ratings yet

- Coldflow 350 Product BrochureDocument7 pagesColdflow 350 Product Brochureben7251No ratings yet

- Lupranate® T80 Toluene DiisocyanateDocument3 pagesLupranate® T80 Toluene DiisocyanateEnio Miguel Cano LimaNo ratings yet

- Derakane 411 45 TdsDocument4 pagesDerakane 411 45 TdsShankarEllampriamNo ratings yet

- P840J Feb, 09Document2 pagesP840J Feb, 09Tan Chen TatNo ratings yet

- P740JDocument2 pagesP740JTan Chen TatNo ratings yet

- Hdpe 5200B1Document1 pageHdpe 5200B1Sergio Rubens Oliveira SantosNo ratings yet

- TI - CP - 1352 - e - 2-Ethylhexyl Acrylate - 190419 - SCREEN - 02Document2 pagesTI - CP - 1352 - e - 2-Ethylhexyl Acrylate - 190419 - SCREEN - 02李承興No ratings yet

- EL-Pro P440J: Polypropylene Impact Copolymer For Injection MoldingDocument2 pagesEL-Pro P440J: Polypropylene Impact Copolymer For Injection MoldingTan Chen TatNo ratings yet

- Pds Aircol PDDocument2 pagesPds Aircol PDtribolasNo ratings yet

- GPM800 DatasheetDocument1 pageGPM800 DatasheetDitta Alfianto100% (1)

- Coldflow 402 Product BrochureDocument7 pagesColdflow 402 Product BrochureBen WigginsNo ratings yet

- Polybond 3150 TDSDocument1 pagePolybond 3150 TDSjai_dceNo ratings yet

- P640JDocument2 pagesP640JTan Chen TatNo ratings yet

- Phenoline 1205 PDS 9-06 PDFDocument2 pagesPhenoline 1205 PDS 9-06 PDFttr_1947No ratings yet

- Carpenter Co.: Carpol GSP-280Document1 pageCarpenter Co.: Carpol GSP-280A MahmoodNo ratings yet

- Caradol sc48 08Document2 pagesCaradol sc48 08GİZEM DEMİRNo ratings yet

- Datasheet SP 2000wDocument2 pagesDatasheet SP 2000wWilliam Boyle Jr.No ratings yet

- Baypren® 320-2 Product Data SheetDocument2 pagesBaypren® 320-2 Product Data SheetXiaofeng MengNo ratings yet

- Formulation: StartingDocument4 pagesFormulation: StartingA MahmoodNo ratings yet

- High-speed SMD adhesive for electronicsDocument2 pagesHigh-speed SMD adhesive for electronicsmatwan29No ratings yet

- Baypren® 110 M 49 Product Data Sheet_000000000002433919_REG_WORLD_EDocument2 pagesBaypren® 110 M 49 Product Data Sheet_000000000002433919_REG_WORLD_ERVNL GoaNo ratings yet

- DYMAX Ga-103Document0 pagesDYMAX Ga-103Giosue GiacoppoNo ratings yet

- Plexiglas GDocument2 pagesPlexiglas GMarco Ngawang KeelsenNo ratings yet

- DK15 0934Document1 pageDK15 0934Dileep SettyNo ratings yet

- shareCommonLEEDGBMarketingDocumentationTechnical-ManualsENGLISHCURRENT-E-MAILTM DELTACHILL DCC DCF 100-510kW 7022932 V1.17.0 11 2018Document180 pagesshareCommonLEEDGBMarketingDocumentationTechnical-ManualsENGLISHCURRENT-E-MAILTM DELTACHILL DCC DCF 100-510kW 7022932 V1.17.0 11 2018Tomasz MagieraNo ratings yet

- Lowinox CPLDocument1 pageLowinox CPLDaniel MartinsNo ratings yet

- Xiameter 65Document2 pagesXiameter 65santi2100No ratings yet

- Dispercoll C84: CharacterizationDocument3 pagesDispercoll C84: Characterizationmufid_ainunNo ratings yet

- Henk Multicore Macromelt Mm6208s TdsDocument2 pagesHenk Multicore Macromelt Mm6208s TdsAbohicham AbhNo ratings yet

- Safety Data Sheet: 1. Material and Supplier IdentificationDocument6 pagesSafety Data Sheet: 1. Material and Supplier IdentificationharshalNo ratings yet

- Syn Gear Industrial Gear Oil 220Document6 pagesSyn Gear Industrial Gear Oil 220Haider KhanNo ratings yet

- Phenoline 187 Primer PDSDocument2 pagesPhenoline 187 Primer PDSVajid MadathilNo ratings yet

- Tai County Silicones Co., Ltd. PW-240 Superwetting Agent: Description ApplicationsDocument1 pageTai County Silicones Co., Ltd. PW-240 Superwetting Agent: Description ApplicationsMark WuNo ratings yet

- Plexiglas MCDocument2 pagesPlexiglas MCMarco Ngawang KeelsenNo ratings yet

- Aircol SW RangeDocument2 pagesAircol SW RangeDouglas Neves - UnaxNo ratings yet

- PUF - Voracor CD 1786 Polyol With CD345 TDS PDFDocument2 pagesPUF - Voracor CD 1786 Polyol With CD345 TDS PDFRajendra Kumar SharmaNo ratings yet

- Skydrol 500B4Document28 pagesSkydrol 500B4Ah Huat Eugene YapNo ratings yet

- Alathon H5618Document2 pagesAlathon H5618Ing Ipn VbaNo ratings yet

- Araldite Ly564 Aradur 2954.PDF ResinDocument5 pagesAraldite Ly564 Aradur 2954.PDF ResinAbdul Hakim AbdullahNo ratings yet

- LubricantDocument2 pagesLubricantbuanaNo ratings yet

- Ps 870 Class CDocument2 pagesPs 870 Class CDaniel AndersonNo ratings yet

- Oil - Pertamina Meditran Sae40Document4 pagesOil - Pertamina Meditran Sae40dk_moehammedNo ratings yet

- 1581 enDocument2 pages1581 enyasafyNo ratings yet

- MracDocument91 pagesMracJaphet GabatanNo ratings yet

- MSDS Mesran Super SAE 20W-50 Motor OilDocument4 pagesMSDS Mesran Super SAE 20W-50 Motor OilANNaNo ratings yet

- Theory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlFrom EverandTheory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlNo ratings yet

- Flow AssuranceFrom EverandFlow AssuranceQiwei WangNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Modeling, Control, and Optimization of Natural Gas Processing PlantsFrom EverandModeling, Control, and Optimization of Natural Gas Processing PlantsRating: 5 out of 5 stars5/5 (1)

- Portable dual-input thermometer with RS232 connectivityDocument2 pagesPortable dual-input thermometer with RS232 connectivityTaha OpedNo ratings yet

- Ju Complete Face Recovery GAN Unsupervised Joint Face Rotation and De-Occlusion WACV 2022 PaperDocument11 pagesJu Complete Face Recovery GAN Unsupervised Joint Face Rotation and De-Occlusion WACV 2022 PaperBiponjot KaurNo ratings yet

- Entrepreneurship Style - MakerDocument1 pageEntrepreneurship Style - Makerhemanthreddy33% (3)

- Haul Cables and Care For InfrastructureDocument11 pagesHaul Cables and Care For InfrastructureSathiyaseelan VelayuthamNo ratings yet

- MsgSpec v344 PDFDocument119 pagesMsgSpec v344 PDFqweceNo ratings yet

- APM Terminals Safety Policy SummaryDocument1 pageAPM Terminals Safety Policy SummaryVaviNo ratings yet

- Department Order No 05-92Document3 pagesDepartment Order No 05-92NinaNo ratings yet

- Miniature Circuit Breaker - Acti9 Ic60 - A9F54110Document2 pagesMiniature Circuit Breaker - Acti9 Ic60 - A9F54110Gokul VenugopalNo ratings yet

- Fujitsu Spoljni Multi Inverter Aoyg45lbt8 Za 8 Unutrasnjih Jedinica KatalogDocument4 pagesFujitsu Spoljni Multi Inverter Aoyg45lbt8 Za 8 Unutrasnjih Jedinica KatalogSasa021gNo ratings yet

- Database Chapter 11 MCQs and True/FalseDocument2 pagesDatabase Chapter 11 MCQs and True/FalseGauravNo ratings yet

- Server LogDocument5 pagesServer LogVlad CiubotariuNo ratings yet

- Bob Duffy's 27 Years in Database Sector and Expertise in SQL Server, SSAS, and Data Platform ConsultingDocument26 pagesBob Duffy's 27 Years in Database Sector and Expertise in SQL Server, SSAS, and Data Platform ConsultingbrusselarNo ratings yet

- Law of TortsDocument22 pagesLaw of TortsRadha KrishanNo ratings yet

- Management Pack Guide For Print Server 2012 R2Document42 pagesManagement Pack Guide For Print Server 2012 R2Quang VoNo ratings yet

- Multiple Choice Question (MCQ) of Alternator and Synchronous Motors PageDocument29 pagesMultiple Choice Question (MCQ) of Alternator and Synchronous Motors Pagekibrom atsbha0% (1)

- PTAS-11 Stump - All About Learning CurvesDocument43 pagesPTAS-11 Stump - All About Learning CurvesinSowaeNo ratings yet

- Deed of Sale - Motor VehicleDocument4 pagesDeed of Sale - Motor Vehiclekyle domingoNo ratings yet

- BA 9000 - NIJ CTP Body Armor Quality Management System RequirementsDocument6 pagesBA 9000 - NIJ CTP Body Armor Quality Management System RequirementsAlberto GarciaNo ratings yet

- Com 0991Document362 pagesCom 0991Facer DancerNo ratings yet

- Green Management: Nestlé's Approach To Green Management 1. Research and DevelopmentDocument6 pagesGreen Management: Nestlé's Approach To Green Management 1. Research and DevelopmentAbaidullah TanveerNo ratings yet

- Flare Finance Ecosystem MapDocument1 pageFlare Finance Ecosystem MapEssence of ChaNo ratings yet

- Ebook The Managers Guide To Effective Feedback by ImpraiseDocument30 pagesEbook The Managers Guide To Effective Feedback by ImpraiseDebarkaChakrabortyNo ratings yet

- Introduction To Succession-1Document8 pagesIntroduction To Succession-1amun dinNo ratings yet

- Short Term Training Curriculum Handbook: General Duty AssistantDocument49 pagesShort Term Training Curriculum Handbook: General Duty AssistantASHISH BARAWALNo ratings yet

- Instrumentos de Medición y Herramientas de Precisión Starrett DIAl TEST INDICATOR 196 A1ZDocument24 pagesInstrumentos de Medición y Herramientas de Precisión Starrett DIAl TEST INDICATOR 196 A1Zmicmarley2012No ratings yet

- 2CG ELTT2 KS TitanMagazine Anazelle-Shan PromoDocument12 pages2CG ELTT2 KS TitanMagazine Anazelle-Shan PromoJohn SmithNo ratings yet

- Module 5Document10 pagesModule 5kero keropiNo ratings yet

- International Convention Center, BanesworDocument18 pagesInternational Convention Center, BanesworSreeniketh ChikuNo ratings yet

- SAP PS Step by Step OverviewDocument11 pagesSAP PS Step by Step Overviewanand.kumarNo ratings yet

- Jurisdiction On Criminal Cases and PrinciplesDocument6 pagesJurisdiction On Criminal Cases and PrinciplesJeffrey Garcia IlaganNo ratings yet