Professional Documents

Culture Documents

Waste Heat Recovery Boilers

Uploaded by

Zeeshan_Akram010 ratings0% found this document useful (0 votes)

7 views4 pagesddfc

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentddfc

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views4 pagesWaste Heat Recovery Boilers

Uploaded by

Zeeshan_Akram01ddfc

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

ISO 9001:2000 Certified ASME ‘S’ Stamp Certified

DDEC

Innovative Engineering Sok

WASTE HEAT RECOVERY BOILERS

Europes te » Maximum Heat Recovery

4

Minimum maintenance

Optimum Sizing for Engine Cluster

Quality Assured

DDFC (Pvt.) Ltd. Is amongst the leading engineering &

Fabrication companies, manufacturing Steam Boilers &

Waste Heat Recovery Boilers to British Standard BD

2790. Waste Heat Recovery Boilers (WHRBs) are used

to convert heat in exhaust gases from diesel, heavy fuel

oil and natural gas fired engines or turbines into useful

products such as steam or hot water and consequently

reduce heat emission into the atmosphere. WHRBs are

also used for process waste heat recovery generated in

refineries, fertilizer plants and sponge iron plants where

the high pressure steam produced runs steam turbines

for power generation. The steam or hot water is used in

industrial processes such as textile dyeing and

absorption chiller’s for cooling applications. DDFC

manufactures Smoke Tube type WHRBs in the following

capacities & pressure ratings:

Capacity: The capacity ofa WHRB is dependent on

the mass flow rate & temperature of exhaust gases. For

engines up to 1.5 MW capacity WHRB are offered in

Simplex, Duplex or Triplex design providing a cost

effective solution. For natural gas & HFO fired engines.

from 3 MW to 6 MW range the simplex design is

preferred.

Pressure Rating:

Capacity)

Up to 25 bars (depending upon

Design Verification & Third Party Insurance:

DDFC designs its WHRBs which are verified by a UK

based consultant. The final design is checked and

insured by Royal Sun Alliance Insurance Co. of UK.

Single and Two Pass Designs:

DDFC offers the two pass design to customers with

limited footprint requirements Space permitting, a single

pass design is preferred since it produces lesser back

pressure on the prime mover.

PRODUCT FEATURES:

‘ustom Engineered & Manufactured:

Every DDFC Waste Heat Recovery Boiler is specifically

engineered & built to the customers needs &

specifications. Special features & auxiliary equipment

are provided according to the specific customer

requirements.

Raw Material & Components:

Certified materials and components are procured from

leading international manufacturers to ensure quality,

reliability & trouble free operation

Damper for Exhaust Gas Flow Control:

‘The pressure in WHRB is controlled through a damper

which allows the exhaust gases to pass through the

boilers or vent to the atmosphere. For most application

the ON/OFF type control for damper is suitable. For Gas

Turbines or special applications requiring minimum

variation in pressure, modulating dampers are

employed

‘Actuation of dampers is through electrical units fitted with

hand wheel for damper operation in case of motor failure

Pneumatic actuators can also be

supplied on request.

Ease of Smoke Side Inspection: Hinged rear doors

provide full access to smoke side tube surfaces for

inspection and cleaning. The front smoke boxis lined with

ceramic fibre insulation and are equipped with large

bolted doors for entry purpose.

Ease of Water Side Inspection: Man holes on the top of

the shell and inspection holes on the shell sides provide

easy access for inspection of water side surfaces for

sedimentation checking.

Independent Gas Paths through WHRB: For

Duplex & Triplex WHR boilers, the exhaust from each

engine or small gas turbine does notintermix during their

passage through the boilers.

Surface Blow Down System:

Each WHRB is equipped with a connection where a manual or

automatic surface blow down system can be installed for

maintaining appropriate TDS levelin the

boiler water.

Instrumentation & Control: Each WHRB is

provided with an electric control panel which can be of

floor standing or wall mounting design and houses all

Boiler controls, starters, circuit breakers & mains

isolating switches.

The panel is steel fabricated with powder coated paint &

includes the following equipment:-

» Boiler On/Off selectors switch

» Power On indicator lamp

»Waterlow level indication lamp

» Steam pressure controller

» Feed water pump running lamp

Alarm mute & reset buttons

» Damper positi

indication amps

» Exhaust gas boiler inlet & outlet

temperatures

> Panel cooling fan & exlernally mounted

klaxon

Special intruments can be mountedin the

panel on request

Capacity Enhancement through Supplementary

Firing System: Exhaust from turbines containing

more than 10% oxygen can be utilized by means of

supplementary fired burner to heat the exhaust gasses

which increases the steam output capacity of the WHRB.

High Return on Inyestment:

Waste heat Recovery Boilers present an ideal

‘opportunity for investment since the payback period

ranges from 4 to2 years.

Hot Water Generation from Engine Cooling jackets:

Hot water in the temperature range of

70-90°C can be obtained from engine cooling jackets

through an appropriate heat exchange system.

This hot Water can be used for process applications or

operating absorption cooling system. DDFC designs &

provides such systems.

ANCILLARY EQUIPMENT: The following ancillary

equipment is offered for the complete package. The

customer has the option to fumish these items himself as.

these do not adversely effect the performance or the

warranty of the equipment.

»Feed water tank with deaerator head for non

pressurized systems, The feed water tank is equipped

with heating coils, spargers, temperature control system.

& optional level control probes.

The same system can be offered in a pressurized tank

configuration as well

»Feed Water Pumping System with one

operational & one standby pump. It is normally provided

with necessary valves & controls (optional)

>Economizers help improve efficiency by

increasing temperature of feed water by capturing

additional heat from the exhaust gasses. This increases

the output of the WHRB. Depending upon location &

application, WHRBs can be provided with combined or

independent economizers.

» Measuring Instruments for steam and water, can

be provided on request for local or remote application.

PLC based systems are also available.

i

SUT KemUMe eta

Det TU OU OCU eR eae RCC ie eae Ce ete

A ZTerctind

era ne eg ce

Oe ecu nrsu)

fora specified period.

uality Assurance

Pe Magee cd

are certified to ISO 9001-2000 by Lloyd’s

Lemon Ne eres oR ed

De enum ees

It is an assurance to our customers that

‘our quality standards are universally

acceptable and at par with the international

eet

ASME ‘S’ Stamp

With the acquisition of ASME “S” stamp,

Drees aetna

Se ne Cure ance

Per ae ON ond

DDEC GROUP OF COMPANIES:| HEAD OFFICE: 73-g/11Mode! Town, Lahore, 54700

‘Ph:92-42-5885727-32, Fax: 02-42-5885733

LUE econ een eect

Siero

(sheer aaa

After Sales Service

DDFC’s skilled personnel ensure prompt

Peete rarc

Mittin camsioasuas

DDFC offers complete turnkey services

Perot cma ey

complete steam generation system including

ESCO eee reece tLe

network.

Proven Track Record

DDFC is proud to have manufactured,

installed and commissioned Waste Heat

eee eta Toe)

Multinational companies in the following

ccs

© Textile

© Power Generation

Drs cra)

©Chemicals

@Dairy & Food

©Pulp & Paper

DINE NI UN ORKe)) or

eee pee

Te emer RSE}

BRANCH OFFICE: 12-D/1, 1st Gizti Lane, Defence | UAN:111-333-233

Fax:92-42-7541364

Re ena cena

Ph:92-21-5870289, Fax: 92-21-5836870

eens onticee et

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Advertisment ProposalDocument3 pagesAdvertisment ProposalZeeshan_Akram01No ratings yet

- Enlistment Certifcates With Different OrginizationDocument6 pagesEnlistment Certifcates With Different OrginizationZeeshan_Akram01No ratings yet

- Green CampusDocument5 pagesGreen CampusZeeshan_Akram01No ratings yet

- Vehicle Verification - Excise & TaxationDocument2 pagesVehicle Verification - Excise & TaxationZeeshan_Akram01No ratings yet

- Mein Aurat HonDocument8 pagesMein Aurat HonZeeshan_Akram01No ratings yet

- MeezanDocument6 pagesMeezanZeeshan_Akram01No ratings yet

- Advertiser Agency AgreementDocument3 pagesAdvertiser Agency AgreementZeeshan_Akram01No ratings yet

- Foodeez Inn Menu - March 2017Document4 pagesFoodeez Inn Menu - March 2017Zeeshan_Akram01No ratings yet

- Bussiness Licences & ISO CertificateDocument4 pagesBussiness Licences & ISO CertificateZeeshan_Akram01No ratings yet

- General Profile SPS PDFDocument23 pagesGeneral Profile SPS PDFZeeshan_Akram01No ratings yet

- Blank ContractDocument4 pagesBlank ContractZeeshan_Akram01No ratings yet

- SPS CertificationDocument22 pagesSPS CertificationZeeshan_Akram01No ratings yet

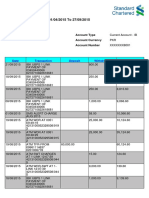

- Account Transactions FDocument7 pagesAccount Transactions FZeeshan_Akram01No ratings yet

- List of SchoolsDocument1 pageList of SchoolsZeeshan_Akram01No ratings yet

- AcsDocument16 pagesAcsZeeshan_Akram01No ratings yet

- Others Cities 18-4-16Document175 pagesOthers Cities 18-4-16Zeeshan_Akram01No ratings yet

- LCL Partnership Proposal 20151Document18 pagesLCL Partnership Proposal 20151Zeeshan_Akram01No ratings yet

- Axpert KS Inverter Selection GuideDocument1 pageAxpert KS Inverter Selection GuideZeeshan_Akram01No ratings yet

- Technoworks Engineering Services GuideDocument28 pagesTechnoworks Engineering Services GuideZeeshan_Akram01No ratings yet

- InfiniSolar DSDocument4 pagesInfiniSolar DSZeeshan_Akram010% (1)

- LED TUBES Long-Life Efficient LightingDocument2 pagesLED TUBES Long-Life Efficient LightingZeeshan_Akram01No ratings yet

- Orphan Care Program-New 2 EditedDocument5 pagesOrphan Care Program-New 2 EditedZeeshan_Akram01No ratings yet

- TWS-ST Challan-000054230334-2015-09Document3 pagesTWS-ST Challan-000054230334-2015-09Zeeshan_Akram01No ratings yet

- High Efficacy LED Fixtures for Accent LightingDocument1 pageHigh Efficacy LED Fixtures for Accent LightingZeeshan_Akram01No ratings yet

- Opti LED 88w HighBayDocument1 pageOpti LED 88w HighBayZeeshan_Akram01No ratings yet

- Opti LEDDocument1 pageOpti LEDZeeshan_Akram01No ratings yet

- Typodermic License AgreementDocument2 pagesTypodermic License AgreementWizzard GrasselliNo ratings yet

- Contraceptive Performance Report 2013-2014: Government of Pakistan Statistics Division Pakistan Bureau of StatisticsDocument31 pagesContraceptive Performance Report 2013-2014: Government of Pakistan Statistics Division Pakistan Bureau of StatisticsZeeshan_Akram01No ratings yet

- Booking Form Kisan Mela 2016 PDFDocument2 pagesBooking Form Kisan Mela 2016 PDFZeeshan_Akram01No ratings yet